AeroPlus Extra 330LT User manual

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

Extra 330LT

85-125CC

Item No:A-G120001

Specs:

WING SPAN: 111” (2833mm)

LENGTH: 100" (2530mm)

WING AREA: 2139sq in (138sq dm)

FLYING WEIGHT: 25.3-28lbs (11500-12800g)

ENGINE: 100cc-120cc gas

RADIO: 4CH/6-9S

Description

Covering Material Genuine Oracover

Carbon Fibre: Spinner, wing tube and sleeves, landing gear, tail gear;

Fibreglass servo arms, horn and reinforced U/C mounting

Fiberglass servo arms and horn;

Built-in tuned pipe or canister tunnel;

Removable Wings, Stabs and Rudders;

Carbon fibre rods to make the wings and fuselage light weight and strong;

Alu hub Wheels; Adjustable pushrods;

Two piece clamshell cowl, Ringed Cowl

Extra covering provided for small repairs

Pre drilled hinges

2 Colour schemes

H-G120001B

ORACOVER FERRARI RED 21-023#

ORACOVER GOLD 21-092#

ORACOVER BLACK 21-071#

ORACOVER SILVER 21-091#

H-G120001A

ORACOVER FERRARI RED 21-023#

ORACOVER WITH 21-010#

ORACOVER BLACK 21-071#

ORACOVER SILVER 21-091#

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

100-125CC Extra 330LT

Congratulations on your purchase of your new AeroPlus RC Extra 330LT. This plane

has been designed to be one of the lightest and highest performance aerobatics planes

anywhere. We hope that you will enjoy this plane and will exceed your expectations in

what a model airplane can be.

Thank you,

AeroPlus RC

Unpacking -

Carefully unpack the model, when opening the plastic bags make sure you do not to cut any covering on

the model. Inspect each item to make sure there was no damage in shipping. If for any reason you are

not happy with any part or are unsure please contact the Dealer that you purchased from.

Covering -

Because of the multiple climate zones encountered on the trip from the factory to you,

some of the covering may have wrinkles. We highly recommend that you take time to re-

seal all covering edges with an iron and to use a heat gun to remove any wrinkles and re-

tighten the covering. It is best to do this now while before the plane is assembled.

*Note: Be careful not let any heat get near parts like the canopy or cowl as this may cause

damage.

Assembly Tips

We also recommend that you go over all the accessible joints with cyano glue. Wick glue

into areas of high stress around the U/C plate and motor box.

Use a quality Thread-lock on all metal to metal joints. Even if your model is electric

powered with lower levels of vibration the thread-lock will ensure that things do not fall

off of your airplane!!

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

Landing Gear Assembly

To help prevent the fuselage from being damaged while the model is being

assembled we recommend fitting the landing gear first.

Note - Before beginning assembly be sure to determine your left and right wheels pants.

First, glue the thin wood wheel spacer to the inside of the wheel pant on what will be

the outer side of the pant. Use the bolt to help centre the spacer

Next, insert the bolt from what will be the outside of the wheel pant; put one thicker

wood spacer on to the axle bolt, followed by the wheel and one more wood spacer.

Install a lock nut onto the axle-bolt, followed by a washer.

Note- you must place the washer now as it will be impossible to place once the axle is

tightened. I use plastic servo horns drilled out in place of wood spacers for durability.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

Tighten down the bolt holding the locknut.

Note –Do not over tighten. This will prevent the wheel from turning.

Insert the protruding bolts through the landing gear hole.

Tighten up using a washer and lock nut.

Repeat for other side.

This method takes time but is worth it as the wheel pants will last many flights.

Horizontal Stab

1. Now glue the control horns into the elevators.

a. First use a sharp hobby knife to remove the covering from the slots.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

b. Before gluing the area on the horns that goes inside the elevator needs to be roughed up with

sandpaper. This allows a better glue joint.

c. Using Epoxy now glue the two control horns into their respective places.

Note: it is highly recommended to install a ball joint in between the control horns to maintain

proper spacing during gluing.

Note: also please take care to make sure the linkage whole in the control arm is on the hinge line.

2. Installing the elevator servos.

a. First test fit the servo into the servo mount. Some trimming make be required.

Note. Servo fits so spline is towards the front of the plane.

b. Now pre drill the servo mounts with a 1/16 drill bit, the secure the servo into the servo mount

with servo hardware.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

c. Next remove the servo and use thin C.A. glue to reinforce the threads. After the glue is dry

reinsert the servo.

Note. Depending on servo arms used it may be necessary to install arm before reinstalling the servo.

d. Next install the servo linkages.

3. Extensions

a. Thread a 36” servo extension though the fuselage to the openings near the elevator.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

b. Connect the servo to the extension but be sure to use a servo clip or a piece of heat shrink to

ensure it does not become disconnected during flight.

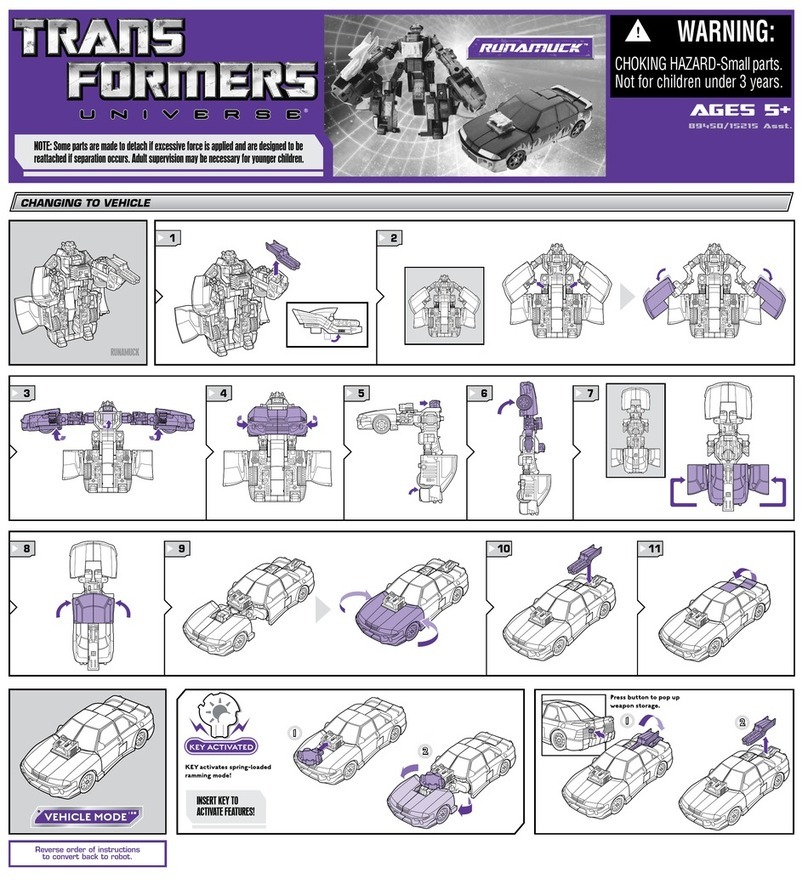

4. Installing Elevator Halfs

a. Install the small carbon tube into the fuselage.

b. Slide the Elevator Half onto the tube.

Note: make sure the servo wire goes cleanly inside the fuselage and is not pinched.

c. Attached the elevator half to the fuselage with the provided hardware.

M3×12 inner hexagon screw & M3 wrench

5. Repeat the process for the other elevator half.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

Rudder

1. Remove the covering where the rudder horns push through with either a hobby knife or soldering

iron.

2. Test fit the rudder horns

Note: Be sure the rudder horns are equal on both sides and in line with the hinge

point this is very important!

3. Sand the area on the horn that fits inside the rudder so the glue bonds better.

4. Attaching the rudder.

a. Insert the easy removal pin into the pin hinges.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

5. Glue the rudder horns in the rudder with epoxy; wipe off excess glue while it is wet.

Note: Use the ball joint and bolt while gluing to maintain alignment.

Note: While still movable measure that the same amount pushes out each side. Care needs to be taken here

otherwise your rudder geometry will be incorrect.

6. Installing the Rudder Servo

a. If using the included ruder arm assemble the rudder servo control arm as below, drill holes for

screws and use C.A. glue to stop the nuts from coming loose.

b. Fit the rudder servo and drill holes using a 1/16 drill bit for the servo screws, then drop thin C.A.

glue into the holes to strengthen the wood.

Note: besure the glue has fully cured before installing the servo again.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

c. Using servo screws fix the servo in place, note the spline is towards the front of the plane.

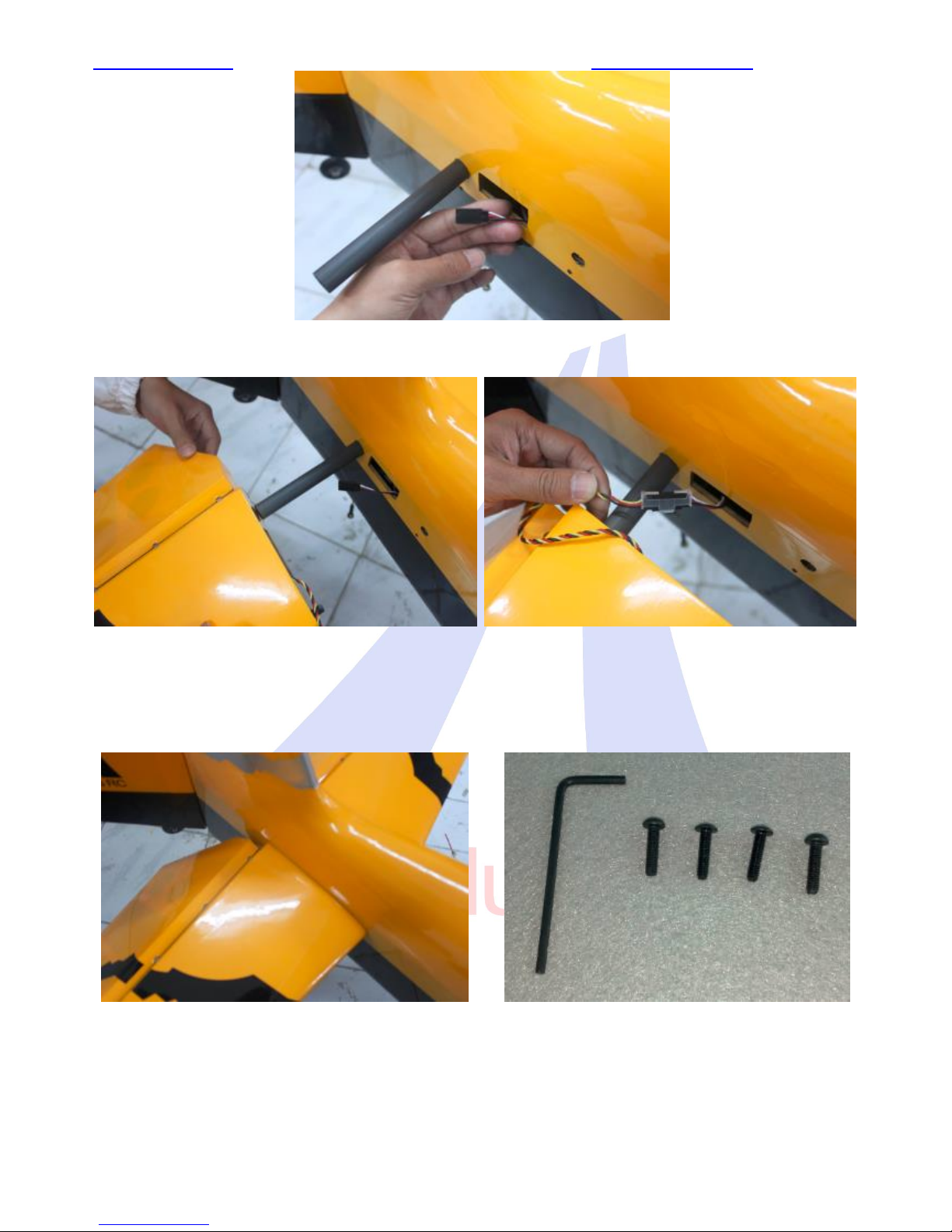

7. Installing the rudder cables

a. Thread the cables though the fuselage from the rudder to the servo tray

b. Loop the cable though the crimp and attachment point as shown below.

c. Crimp the cable using a pair of pliers then trim cable.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

d. Repeat this at the rudder end.

Note: be sure the cables are taunt but not over tight.

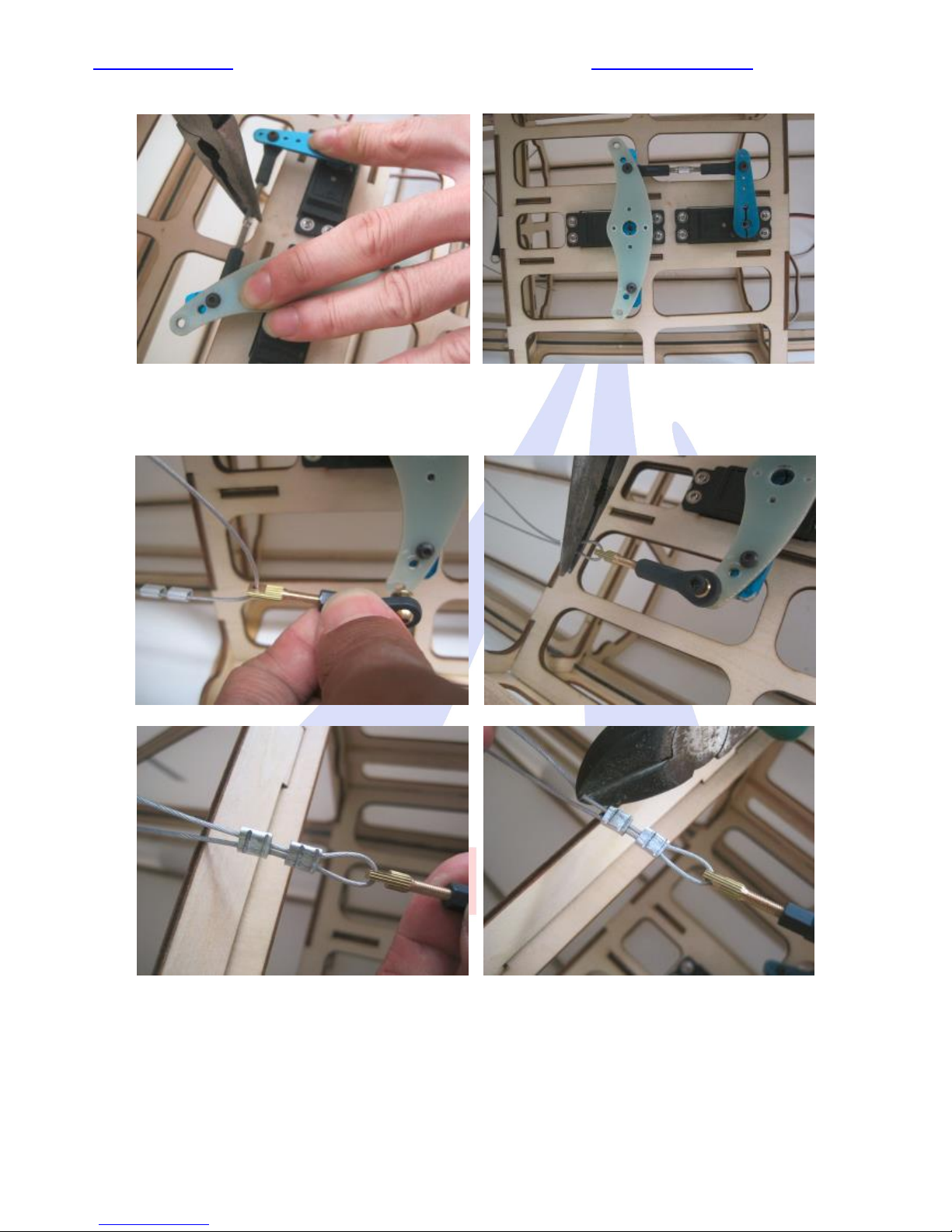

Tail Gear

1. Locate all parts in picture below, when assembling remember to use thread-lock on all parts

2. Assemble gear according to photograph.

3. Before glueing in till mount be sure to slip tiller mount over tiller rod.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

4. Screw the tail gear to the fuselage with the three supplied bolts

Wings and Ailerons

1. The ailerons on the wings are pre-glued. Check each one by gently pulling to make sure that

they are secure

2. Installing aileron control horns

a. Remove the covering where the aileron horns are glued in place. Use either a soldering

iron or a sharp knife

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

b. Using sand paper rough the area that will be glued into the aileron.

c. Glue both horns in with epoxy glue.

Note: be sure to install a ball link to insure correct alignment when glueing

d. Repeat for all 4 aileron control horns.

3. Install Aileron Servos

a. First test fit the servo into the servo mount. Some trimming make be required.

Note. Servo fits so spline is towards the front of the plane.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

b. Now pre drill the servo mounts with a 1/16 drill bit, then secure the servo into the

servo mount with servo hardware.

c. Next remove the servo and use thin C.A. glue to reinforce the threads. After the glue is

dry reinsert the servo.

d. If required install a servo extension lead onto the servo, remember to use a servo plug

clip or heat shrink

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

e. Fit the servo.

f. Using the supplied pushrod screw a ball-link onto each end.

g. Using the supplied bolts attach the pushrod at both ends. Check to see you have

sufficient movement of the aileron. If not adjust.

h. Repeat on other wing

Note: On wings using two servos be sure the servos are not binding. If the are you make have to

adjust linkages or use a product such as a match box

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

Gas Engine installation

1. Using the template that came with your chosen engine, check the diameter of the required bolts

and drill accordingly.

2. mount the engine with the stand offs to the bulkhead. Remember to use large washers on the

inside to spread the load and use plenty of thread-lock.

Note: Depending on what engine is used you will need different length standoffs to get correct space in the

cowl

Note: To determine the standoff length needed measure the distance from the bulk head to the cowl ring

plus a little clearance. Then subtract the distance from the front up the engine hub to the back plate of the

engine. The difference will be the standoff length needed.

3. Exhaust options. The plane is equipped with a pipe tunnel so it will accommodate many kinds of

exhaust including stock, cans, and pipes.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

4. Cutting cowl for exhaust and airflow. Mark the area needed to be removed and cut out using a

rotary cutting tool.

a. You will need to cut the cowl accordingly to clear your chosen exhaust. Remember to start

wholes small and work them until it fits.

b. To make sure the engine stays cool. Ensure that enough air can get out of the cowl. The ration

is usually 3 to 1. With the exit being 3 times larger then the intake.

5. Attach gas proof tube such as Tygon according to the labelling on tank

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

6. Use the supplied pushrod with a ball joint to connect to the throttle arm on the engine. Then find a

convenient place to locate the throttle servo using the supplied mount.

7. Install the engine box cover plate once all connections have been made for the engine.

8. Mount the engines ignition to the motor box on radio foam to reduce vibrations.

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

9.

Radio Gear

1. On each side of the fuselage near the canopy bolts are areas for switches to be mounted.

2. A convenient place to mount the RX is just in front of the rudder servo. Ensure that it is

mounted on Velcro or radio foam and securely strapped down.

Canopy Attachment

3. The canopy is held in place with the 4 screws, ensure these are tight before flying

www.aeroplusrc.com [email protected]om

AeroPlus RC Copyright 2014 © All Rights Reserved

Before you fly!

We highly recommend the use of both dual rates and exponential. This will allow the model to fly both

precision and 3D at the flick of a switch.

Suggested Set up

Low Rates Exponential High Rate Exponential

Elevator 15-20 deg 15-20 % 35-45 deg 30-60 %

Ailerons 15-20 deg 15-20 % 35-45 deg 30-60 %

Rudder 25-30 deg 15-20 % 35-45 deg 30-60 %

For your maiden flights always use low rates, Also please remember that + and –exponential is different

per manufacturer, check your TX manual.

Always range check your model before the maiden flight. Carry out a short flight then go over everything

to make sure nothing has come loose.

CG Location

We suggest for initial test flights set the CG 172mm or 6 3/4 inches from the leading edge of the wing.

Adjust after first flights to personal preference.

Enjoy flying!

Table of contents

Other AeroPlus Toy manuals

AeroPlus

AeroPlus Edge 540 V3 20CC User manual

AeroPlus

AeroPlus A?G030010A User manual

AeroPlus

AeroPlus Corvus Racer 540 59 User manual

AeroPlus

AeroPlus Corvus Racer 540 User manual

AeroPlus

AeroPlus Corvus Racer 540 35CC User manual

AeroPlus

AeroPlus Sbach 342 User manual

AeroPlus

AeroPlus MXS-R 30CC User manual

AeroPlus

AeroPlus Sbach 342 20CC User manual

AeroPlus

AeroPlus YAK 55M User manual

AeroPlus

AeroPlus EXTRA 330SC 60CC User manual