9

2. Fast gear

• Holdtheclutchbarwithlefthandtoopentheclutch.

• Pushtheshiftlevertothefrontwithrighthand,meanwhile,payattentionifitisinthefast

position,thenholdthebarwithrighthand(attention:donotholdthebackshiftbar)

• Slowly unlock the clutch bar to close the clutch. In this situation, Rotary Tiller/Power

Weeder/Cultivator can run at fast gear.

• Speedupproperlywithrighthand,thenRotaryTiller/PowerWeeder/Cultivatorcanrunat

aspeedof10km/h.

3. Back gear

• Holdtheclutchbarwithlefthandtoopentheclutch.

• Adjusttheshiftlevertotheneutralpositionwithrighthand.

• Slowlyunlocktheclutchbartoclosetheclutch,thenRotaryTiller/PowerWeeder/Cultivator

willstepback.(attention:donotunlockthebackshiftbar)

• Ifitisunnecessarytostepback,youshouldholdfastclutchbarslowlywithlefthand,then

unlocktheshiftbarwithrighthand.

4. Whenshiftingintheprocessofrunning,youshoulddecelerate(thestandard should be the

continuous work of diesel engine), then close the clutch. You should change the shift until the

machinestopworking

5. Whenchangingthedirection,youshouldrotatethebartoleftorright.(attention:donotmis-

holdthebar,soastoavoiddamagingthewheelswhendirecting)

6. Stopworking

• Holdtheclutchbarwithlefthandtoopentheclutch.

• Afteradjustingtheshiftlevertotheneutralposition,youshouldunlocktheclutchbarto

makethemachinestopworking.

• Whenitnecessarytostopworking,theprocedureshouldbedoneaccordingtothediesel

engineinstruction.(attention:thisworkisusuallydoneonthesmoothground.)

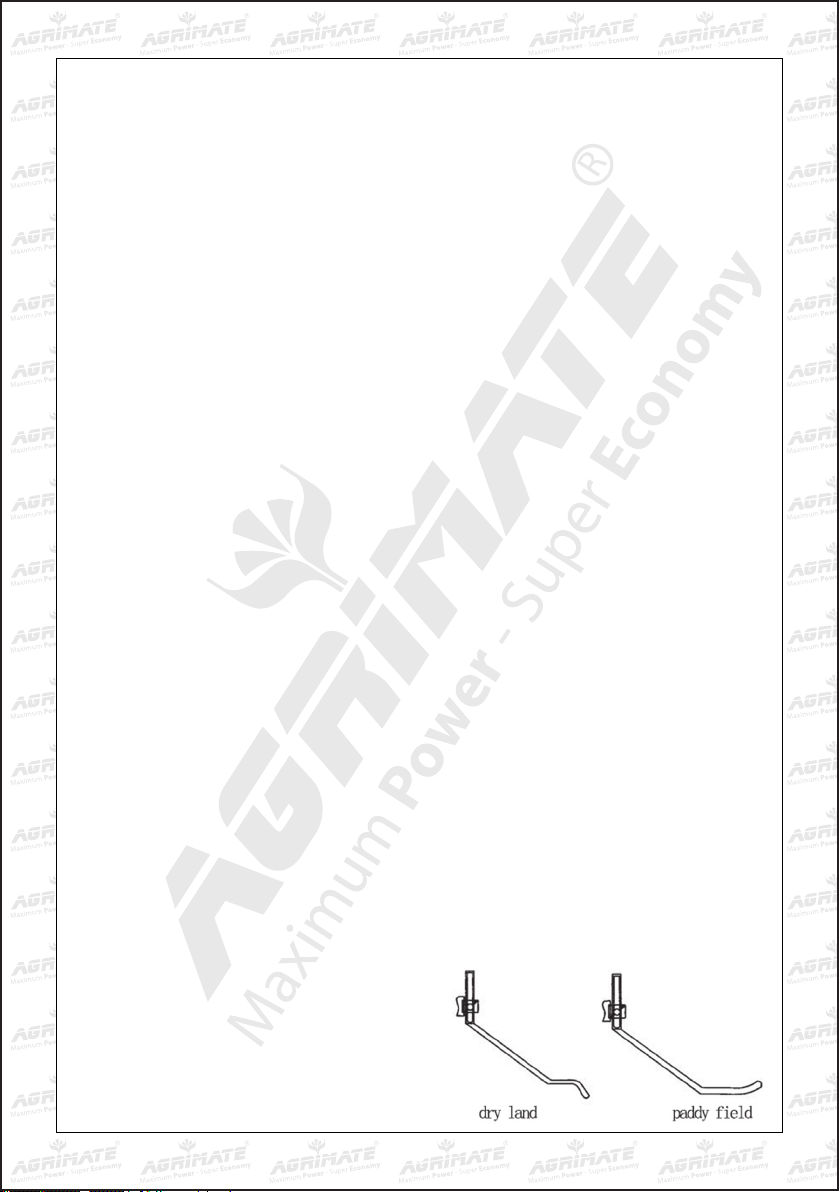

Connection of attaching tools

1. Whenrotating,youshouldtakeawaythewheels,xhexagonalsleeveofrotarydeviceonboth

sidesofthehexagonalshaftwithboltsM8×55.Attention:therearebladeunitsonbothsides;

makesurethebladecuttingedgeworksrstlywhentheRotaryTiller/PowerWeeder/Cultivator

runs.Aftertherotarybladesareinstalled,youmustinstallthesafetypaneltopreventinjures

byblades.Weedingdepthcanbeadjustedthroughadjustingshiftleveranditsincludedangle

withtheground.(refertotable4)

2. Weeding blades assy of paddy eld:

whenthedepthofpaddyeldisbelow

25cm,youcangoWeedingwithcurved

bladesofpaddyelddirectly.Whenthe

depthofpaddy eld is between25-45

cm, you can go Weeding with rotary

wheelsofpaddyeld.table4