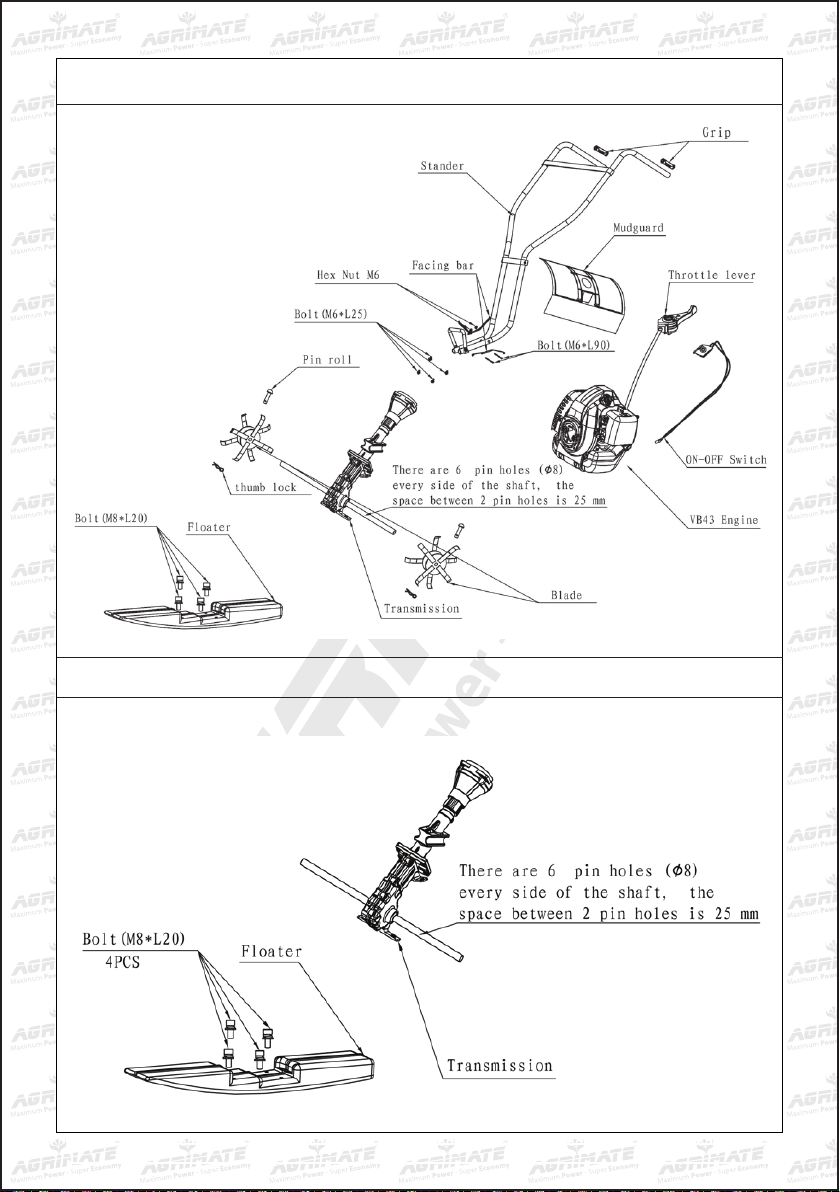

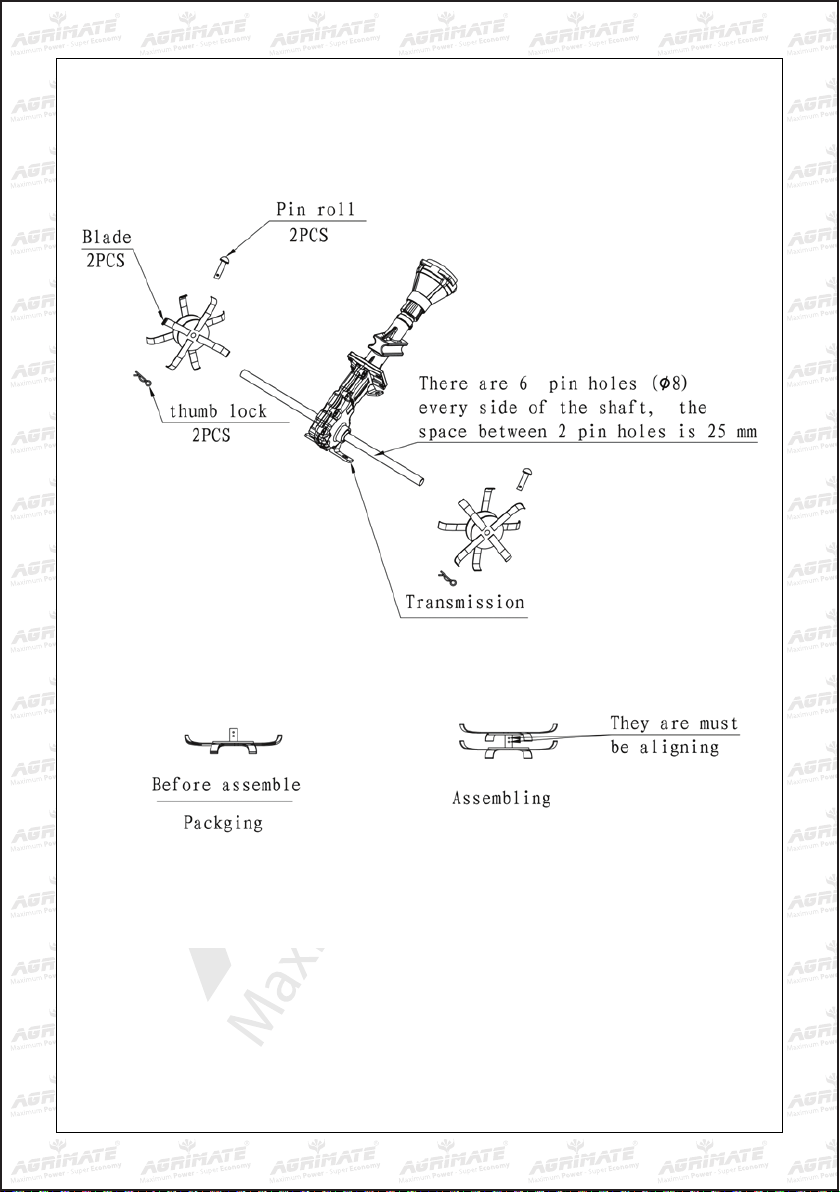

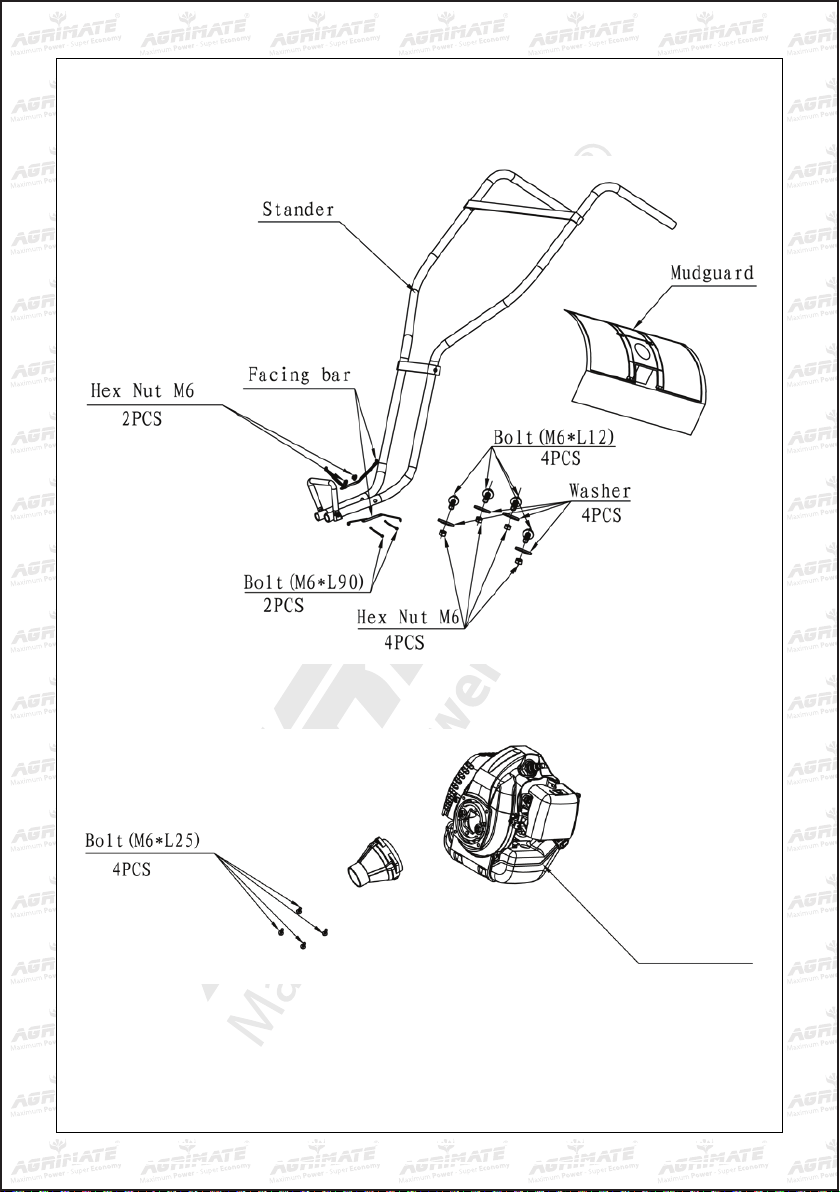

Agrimate AMWL-432 User manual

Other Agrimate Lawn And Garden Equipment manuals

Agrimate

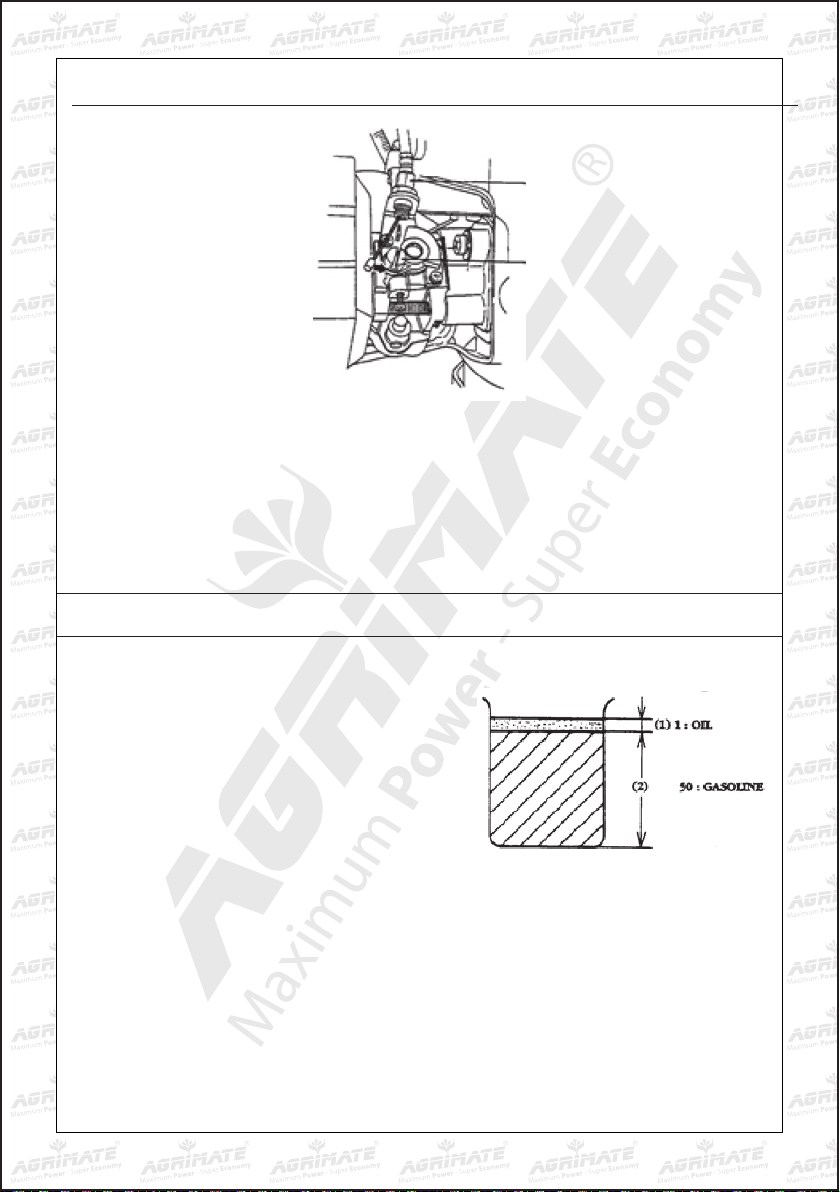

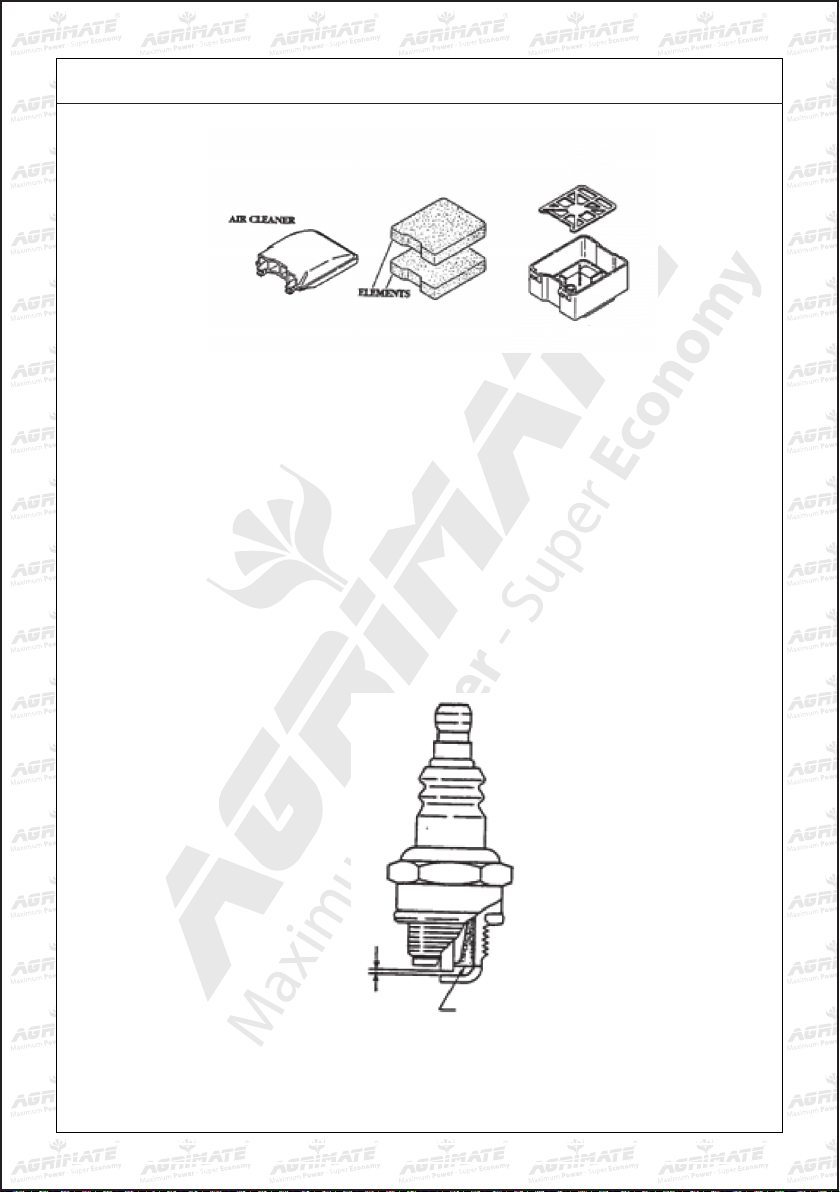

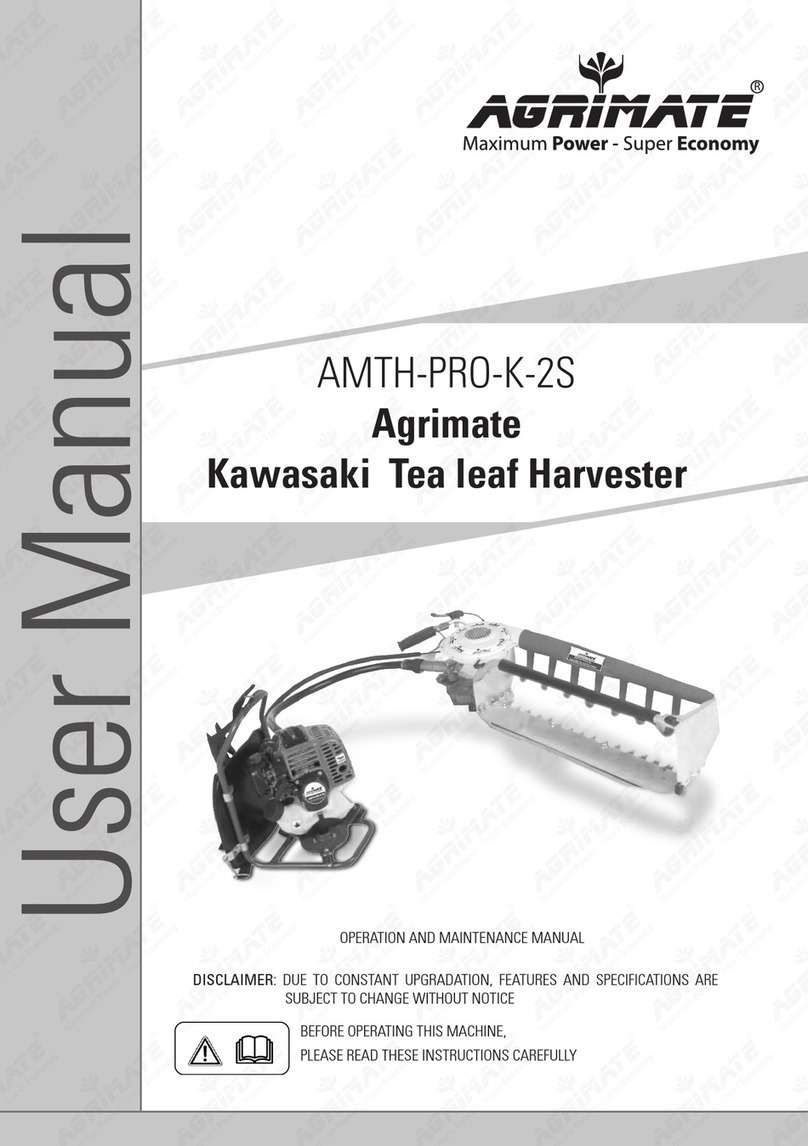

Agrimate AMTH-PRO-K-2S User manual

Agrimate

Agrimate AM-MPT-1100-9D/6D-CHAMPION NEW User manual

Agrimate

Agrimate AM-RTP-7P CHAMPION User manual

Agrimate

Agrimate AM-MPT-1100-6D User manual

Agrimate

Agrimate AM-RT-212-7P User manual

Agrimate

Agrimate AM-MPT-9D User manual

Agrimate

Agrimate AMH 200 User manual

Agrimate

Agrimate AMH-P888-WITH GX-35-FF User manual

Popular Lawn And Garden Equipment manuals by other brands

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Millcreek

Millcreek 406 Operator's manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

AQUA FLOW

AQUA FLOW PNRAD instructions

Tru-Turf

Tru-Turf RB48-11A Golf Green Roller Original instruction manual

BIOGROD

BIOGROD 730710 user manual

Land Pride

Land Pride RCF2784 Operator's manual

Makita

Makita UM110D instruction manual

BOERBOEL

BOERBOEL Standard Floating Bar Gravity Latch installation instructions