8

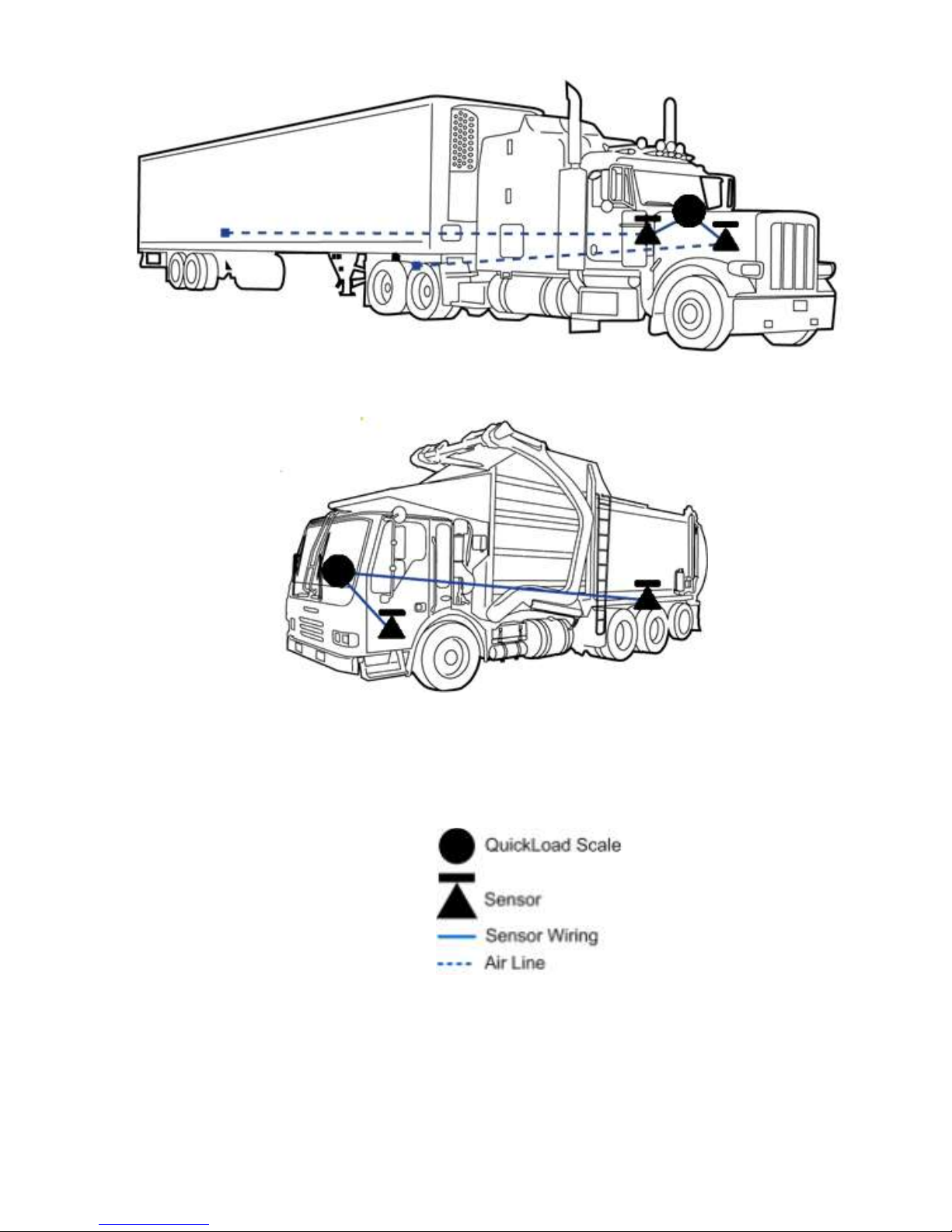

For scales where the steer axle weight is intentionally

not displayed (configurations 5803, 5809, 5810, 5816,

5840, 5844, 5850, 5854), no steer axle sensor is

needed.

For scales with a steer axle with air suspension

(configurations 5805, 5806, 5815, 5821, 5826, 5827,

5838, 5842, 5847, 5852, 5856), route air line(s) from

steer axle suspension to sensor(s) installed under dash.

For scales which determine the weight at the lift axle

(configurations 5833 –5836, 5838, 5839 and 5864),

refer to p/n 901-0117-000, Application Note,

LoadMaxx, Installing and Calibrating the Lift Axle, for

lift axle sensor installation instructions.

For Dedicated Tractor/Trailer Scales (configurations

5840 –5857 except 5849), route trailer suspension air

line(s) to sensor(s) installed under dash.

C. Overview for Deflection Sensor(s) Installation

For scales that include steer axle deflection sensors

(configurations 5807, 5808, 5814, 5817, 5820, 5822,

5823, 5825, 5828, 5829, 5831, 5833, 5834, 5835, 5836,

5839, 5843, 5846, 5853, 5857 and 5864), refer to p/n

901-0059-000, Steer Axle Deflection Sensor Kit

Installation Guide, for installation instructions.

For scales that include dual drive axle deflection sensors

on Hendrickson™ HaulMaxx or HN 462/463

suspensions (configurations 5810, 5814, 5818, 5824,

5829 or 5833), refer to p/n 901-0092-000, Drive Axle

Dual Deflection Sensor Installation Guide.

For scales that include a single drive axle deflection

sensor (configurations 5807, 5708, 5817, 5833 –5836,

5839, 5843, 5853), contact Air-Weigh.