SECTION

1

SERVICE

MANUAL

TABLE

OF

CONTENTS

E..

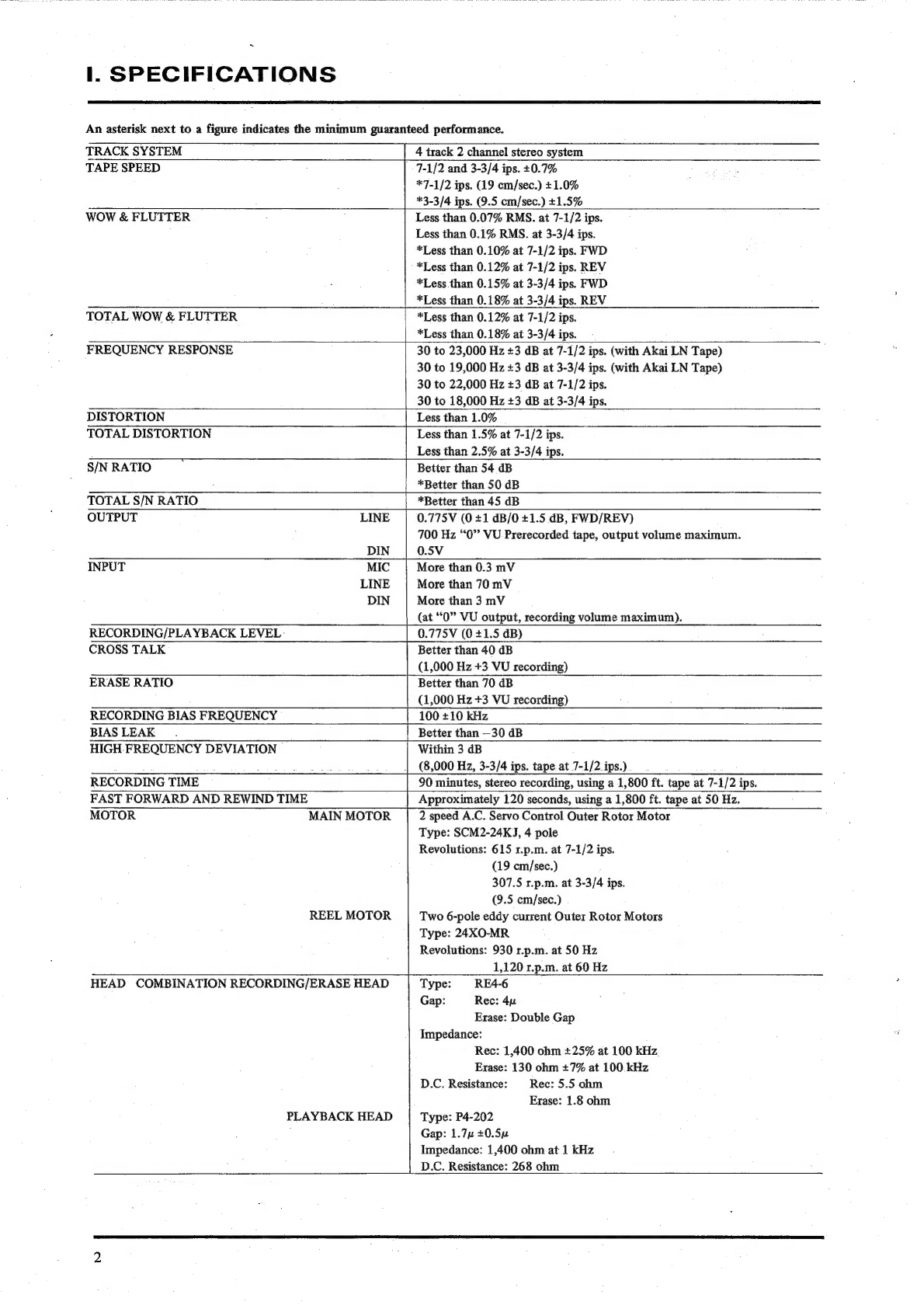

GSPECIFICATIONS

ceva

eScssGac

ts

edudoe

Ue

bak

bo

eed

ea

tau

des

tn

te

2

Il.

DISMANTLING

OF

UNIT

............

0.00

c

ccc

e

cence

cece

eee

eeeeeeeeees

4

Il.

ARRANGEMENT

OF

MAIN

PARTS

.............

0.00

cceececceceeeseeeeeeees

6

IV.

MECHANISM

ADJUSTMENT

.......0.000000

00.

ccceeecccceeeeeseeeeeeeees

7

1.

ADJUSTMENT

OF

PINCH

WHEEL

PRESSURE

............00

ccc

eeeeeceueee

7

2.

BRAKE

TENSION

ADJUSTMENT

...........0.

0.0.0

cceceeceeeeeeeeeeeues

8

3.

ADJUSTMENT

OF

REEL

TABLE

HEIGHT

................000ceeeceeseeeee

9

4,

ADJUSTMENT

OF

CAPSTAN

MOTOR

SHAFT

LOOSE

PLAY

............00000

9

5,

ADJUSTMENT

OF

IMPEDANCE

ROLLER

SHAFT

LOOSE

PLAY................

10

6.

HEIGHT

ADJUSTMENT

OF

TAPE

GUIDE

ON

TENSION

ARM

.................

10

7,

ADJUSTMENT

OF

TENSION

ARM

MICROSWITCH

SW-9

POSITION..............

11

8.

ADJUSTMENT

OF

RECORDING

SLIDE

SWITCH

(SW-10)

TIMING

...............

7

9,

ADJUSTMENT

OF

FF

MICROSWITCH

(SW-5)

ACTUATOR

POSITION

............

12

10,

ADJUSTMENT

OF

PLAY

MICROSWITCH

(SW-7

and

SW-11)

ACTIVATOR

POSITION

......

sido

eh

tene

bole

ieueaas,

ath

ee

rm

ya

NV,

“HEAD

ADIUSTMENT

95050000

92

oo

dee

dev

ose

G

ha

W

ES

Eciads

Aaa

Gemee

gloes

13

VI.

AMPLIFIER

SYSTEM

ADJUSTMENT

.

0.00000...

00.00

ccc

cece

cee

eee

cece

eeeees

15

1.

POWER

SUPPLY

VOLTAGE

ADJUSTMENT

...........

ccc

ceccececucceeeee

15

Bs

TAPE’

SPEED

ADJUSTMENT

scious

tac

sire

is.

2

dealqa

cel

Wed

cr

heed

eared

15

3.

RECORDING,

PLAYBACK

AMPLIFIER

ADJUSTMENT

.................-000-.

16

VII.

D.C.

RESISTANCE

OF

VARIOUS

COILS

........0.

0000

c

cece

cee

cece

ee

eeeees

17

VII.

CLASSIFICATION

OF

VARIOUS

P.C.

BOARDS

............

00000

cece

eeeeueeeee

17

1,

P.C.

BOARD

INTERCHANGEABILITY

CHART

..

0.0...

0.00

cee

cee

cece

eeeeee

V7

2.

COMPOSITE

VIEWS

OF

COMPONENTS

.........0..

0.000

cece

ceeeeuuceeees

18

For

basic

adjustments,

measuring

methods,

and

operating

principles,

refer

to

GENERAL

OPERATING

PRINCIPLES

AND

ADJUSTMENTS.