2

AKO Electromecànica thanks you and congratulates you on the purchase of our product, the development and manufacture of which

involved the most innovative technologies, as well as rigorous production and quality control processes.

Our commitment to achieving customer satisfaction and our continuous efforts to improve day by day are confirmed by the various

quality certificates obtained.

This is a high performance, technologically advanced product. Its operation and the final performance achieved will depend, to a great

extent, on correct planning, installation, configuration and commissioning. Please read this manual carefully before proceeding to install

it and respect the instructions in the manual at all times.

Only qualified personnel may install the product or carry out technical support.

This product has been developed for use in the applications described in the manual. AKO Electromecànica does not guarantee its

operation in any use not foreseen in this document and accepts no liability in the case of damage of any type which may result from

incorrect use, configuration, installation or commissioning.

Complying with and enforcing the regulations applying to installations where our products are destined to be used is the responsibility of

the installer and the customer. AKO Electromecànica accepts no liability for damage which may occur due to failure to comply with these

regulations. Rigorously follow the instructions described in this manual.

In order to extend the lifetime of our products to the maximum, the following points must be observed:

Do not expose electronic equipment to dust, dirt, water, rain, moisture, high temperatures, chemical agents or corrosive

substances of any type.

Do not subject equipment to knocks or vibrations or attempt to handle them in any way differently to that indicated in

the manual.

Do not under any circumstances exceed the specifications and limitations indicated in the manual.

Respect the indicated environmental conditions for operation and storage at all times.

During installation and on completion of this, avoid the presence of loose, broken or unprotected cables or cables in poor

condition. These may constitute a risk for the equipment and its users.

AKO Electromecànica reserves the right to make any modification to the documentation and the product without prior notification.

Index Page

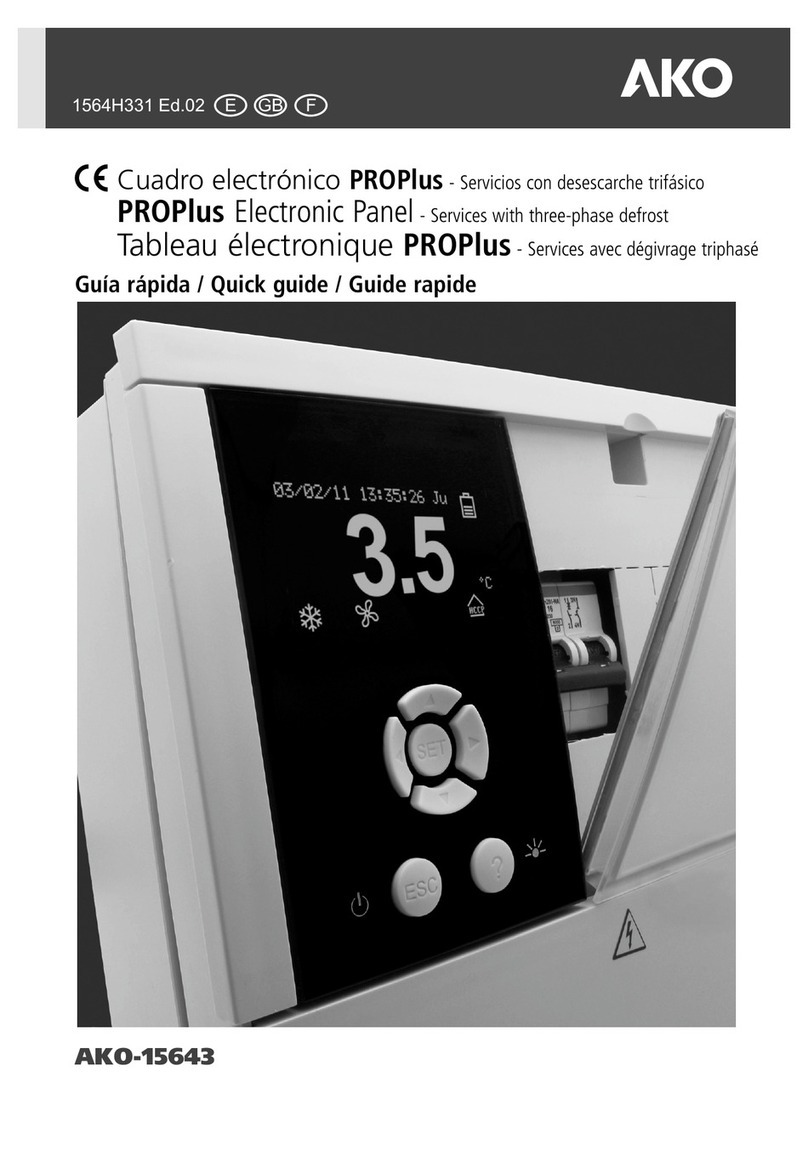

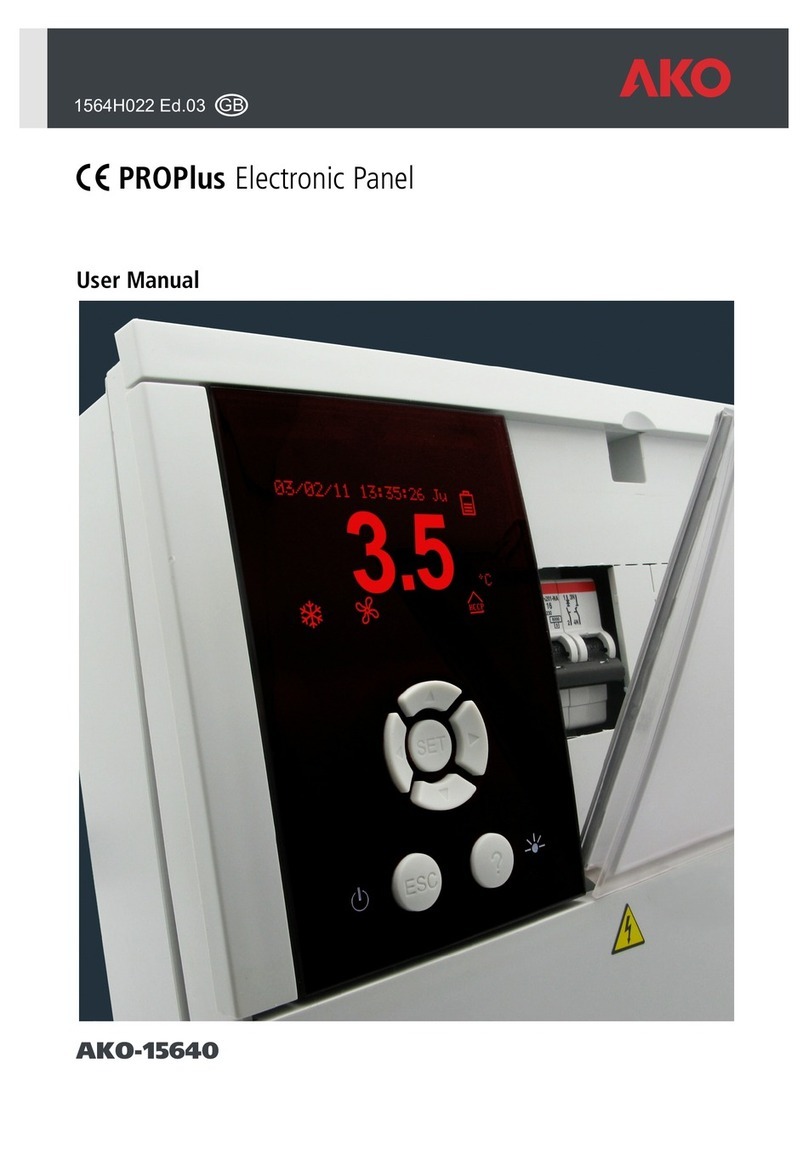

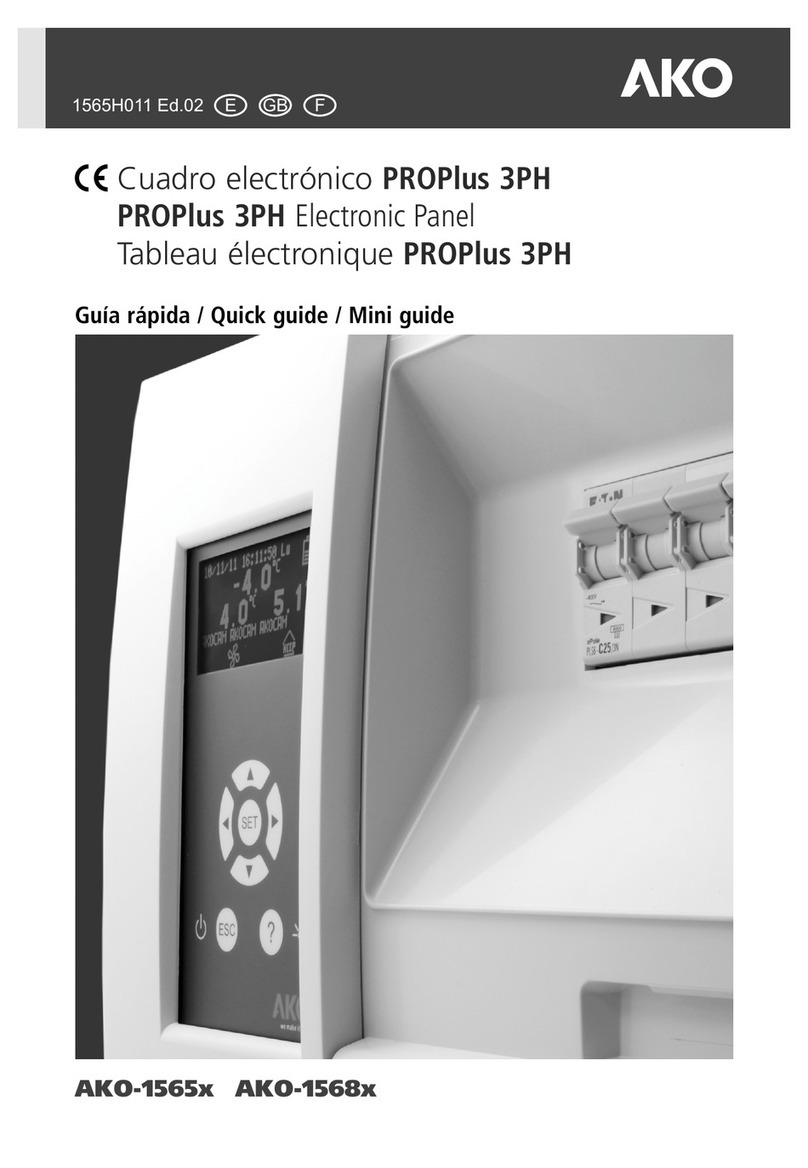

1.- Presentation ..............................................................................................................................3

1.1.- Maintenance...................................................................................................................3

1.2.- Precauciones...................................................................................................................3

2.- Versions and references..............................................................................................................3

3.- Installation ...............................................................................................................................4

4.- Recommendations .....................................................................................................................7

5.- Description ...............................................................................................................................8

5.1.- Quick access to functions ................................................................................................8

5.2.- Messages........................................................................................................................9

6.- Component location ................................................................................................................10

7.- Pressure switch wiring options ................................................................................................11

8.- Basic configuration ..................................................................................................................12

9.- Operation................................................................................................................................13

9.1.- Compressor control .......................................................................................................13

9.2.- Defrost control ..............................................................................................................15

9.3.- Fan control....................................................................................................................16

9.4.- Light control..................................................................................................................16

9.5.- Pump down function .....................................................................................................17

9.6.- Alarms ..........................................................................................................................18

9.7.- Access code (password) .................................................................................................19

10.- Parameter transfer .................................................................................................................20

11.- Connectivity ..........................................................................................................................21

12.- Advanced configuration .........................................................................................................22

12.1.- Return to initial parameters .........................................................................................22

12.2.- Program version ..........................................................................................................22

12.3.- Parameters..................................................................................................................23

13.- Technical specifications ..........................................................................................................27

1569H042 Ed.03