3

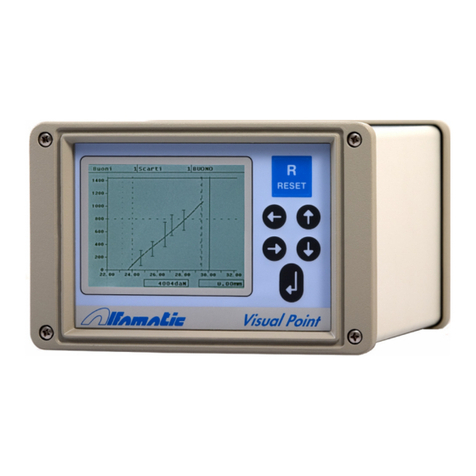

1 Installing CSQ-Visual

This paragraph describes the operations necessary to fit and connect the CSQ-Visual to the machine

and make it operative.

The CSQ-Visual has been designed to be independent: all you have to do is connect the valves and

sensors that will be powered by the instrument. Naturally there’s nothing to stop you from

combined use with a PLC.

To operate, the CSQ-Visual requires different input and output signals. As regards the inputs, a

force transducer (load cell), a position transducer (incremental encoder, potentiometer or 0-10 V

transducer) and various sensors are required. The outputs are connected to the unit descent

enabling valve, the protection closure valve (where installed) and the warning lights.

1.1 Important notes for installation

This manual refers only to the instrument with expansion card CSQVIO8.

The CSQ-Visual has to be powered at 24VDC. An optional internal power feeder is

available, enabling direct connection to the mains power.

This instrument is not (and could not be) a safety device: the descent of the press must be

entrusted to elements outside the instrument. The instrument synchronises the descent of

the press in order for it to work.

It is very important for the load cell wire terminal, which is not sheathed, to be as short as

possible.

When the machine has electric motors, these must be equipped with an anti-interference

filter and be controlled using semiconductor devices.

Always connect the container of the instrument to the earth conductor.

1.2 Operating of the instrument

Attention: the CSQ-Visual is not (and could not be) a safety device: the descent of the press must

be entrusted to external elements. The CSQ-Visual synchronises the descent for its operation.

The GO Output is usually connected serially to the chain of the cylinder descent. In short, if the

CSQ-Visual activates the GO enabling output, the cylinder must not descend if it is not safe.

Operation takes place as follows: when the START input is activated by an external command, the

CSQ–Visual, if ready, activates the protection descent output (PROTECTION) where present and

enables the cylinder descent (GO). When the protection is closed, a safety device must activate the

cylinder until the CSQ-Visual removes the cylinder descent enabling signal (GO). The CSQ-Visual

then commands the arrest of the press, removing the GO signal, controls the curve until the force

begins to diminish or is activated by way of the T.D.C. input (withdraw cylinder signal). Only then

does it indicate whether or not the piece is good or a reject.

If the piece is good, the GOOD output is activated and the PROTECTION output, where present, is

deactivated. If the piece is a reject, the REJECTED output is activated intermittently and the

PROTECTION output, where present, is left active. When the operator presses the reset button,

which can be external or always active, the instrument maintains the REJECTED output as fixed

and removes the PROTECTION output.