1 General information .............................................................................................................5

1.1 Introduction to the monitoring theory....................................................................................... 5

1.2 Characteristics of the device..................................................................................................... 5

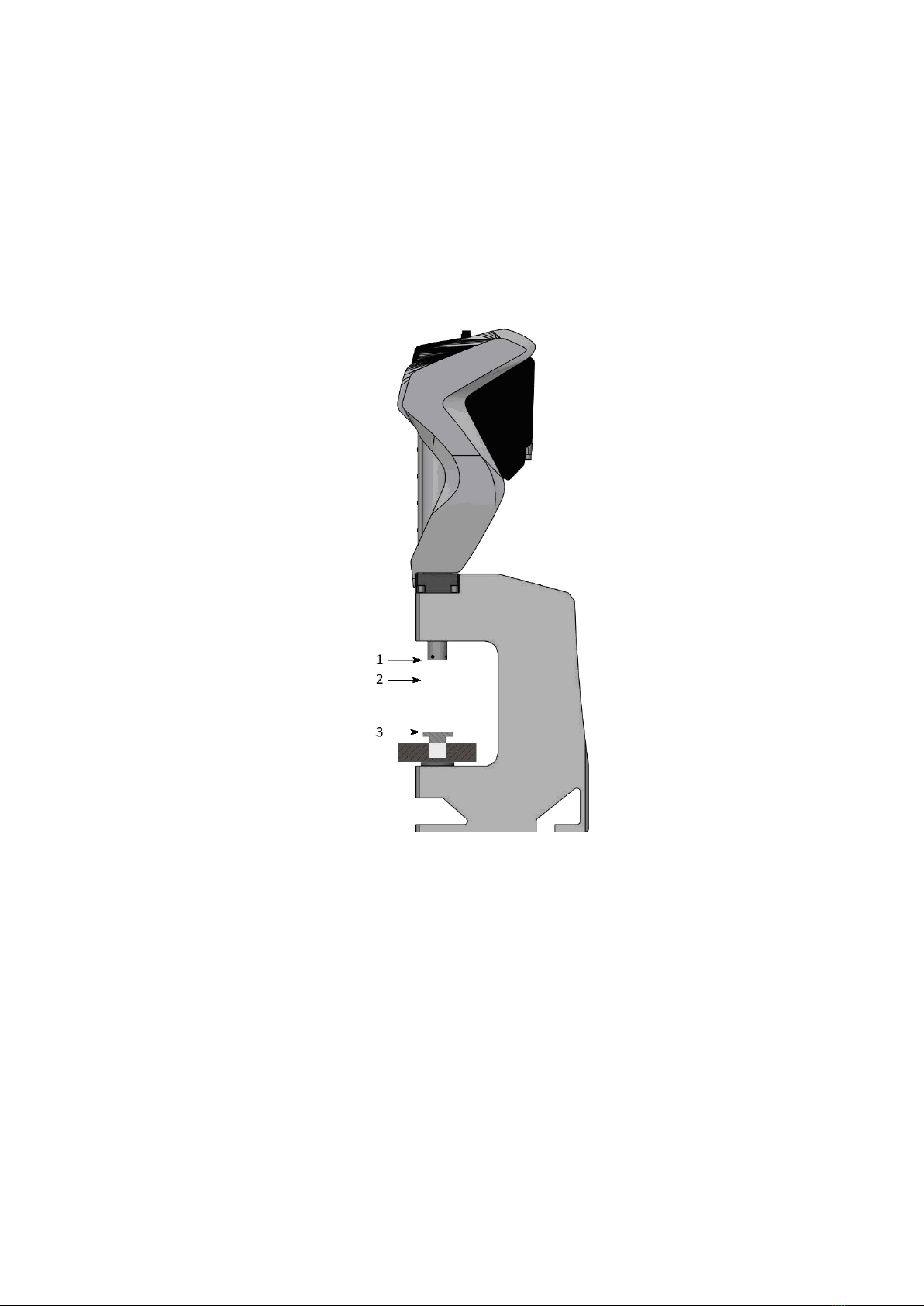

1.3 Device operating principle........................................................................................................ 5

2 Installation of Press-Right....................................................................................................8

3 Getting started ......................................................................................................................9

3.1 The keyboard of Press-Right..................................................................................................... 9

3.2 First approach ........................................................................................................................ 10

3.3 Set visualization ...................................................................................................................... 11

3.4 Using the menus...................................................................................................................... 11

3.5 The main menu........................................................................................................................ 11

4 The JOB..............................................................................................................................13

4.1 Create a new job ..................................................................................................................... 13

4.2 Select a job.............................................................................................................................. 13

4.3 Edit the job name .................................................................................................................... 14

4.4 Copy a job............................................................................................................................... 14

4.5 Delete a job............................................................................................................................. 14

4.6 Edit a job................................................................................................................................. 14

4.7 Job counters............................................................................................................................ 14

4.8 Managing the automatic selection of jobs as an external user............................................... 14

4.9 The graph................................................................................................................................ 15

4.10 Scraps options and management............................................................................................. 16

4.11 Managing the phases .............................................................................................................. 16

4.12 Channel management.............................................................................................................. 17

4.13 Self-verification....................................................................................................................... 17

4.14 Managing further monitoring ................................................................................................. 17

5 Parameters ..........................................................................................................................19

5.1 Motion management................................................................................................................ 19

5.2 Limits and thresholds.............................................................................................................. 19

5.3 Check points............................................................................................................................ 20

5.4 Job options.............................................................................................................................. 20

6 The tolerance range ............................................................................................................22

6.1 Create the range...................................................................................................................... 22

6.2 Change the range.................................................................................................................... 22

6.3 Delete the range...................................................................................................................... 24

7 Scrap piece .........................................................................................................................25

7.1 The discard causes.................................................................................................................. 25

7.2 Scrap management.................................................................................................................. 26

8 Measured values .................................................................................................................27

8.1 The window of measured values ............................................................................................. 27

8.2 Analysis cursor........................................................................................................................ 28

9 The Tools menu..................................................................................................................29

9.1 Display management............................................................................................................... 29

9.2 Counters and self-verification................................................................................................. 30

9.3 Manual cylinder movement..................................................................................................... 30

9.4 Advanced options.................................................................................................................... 30

10 Device configuration ..........................................................................................................31

10.1 General options....................................................................................................................... 31

10.2 Job, phase and channel configuration .................................................................................... 32

10.3 Diagnosis ................................................................................................................................ 33