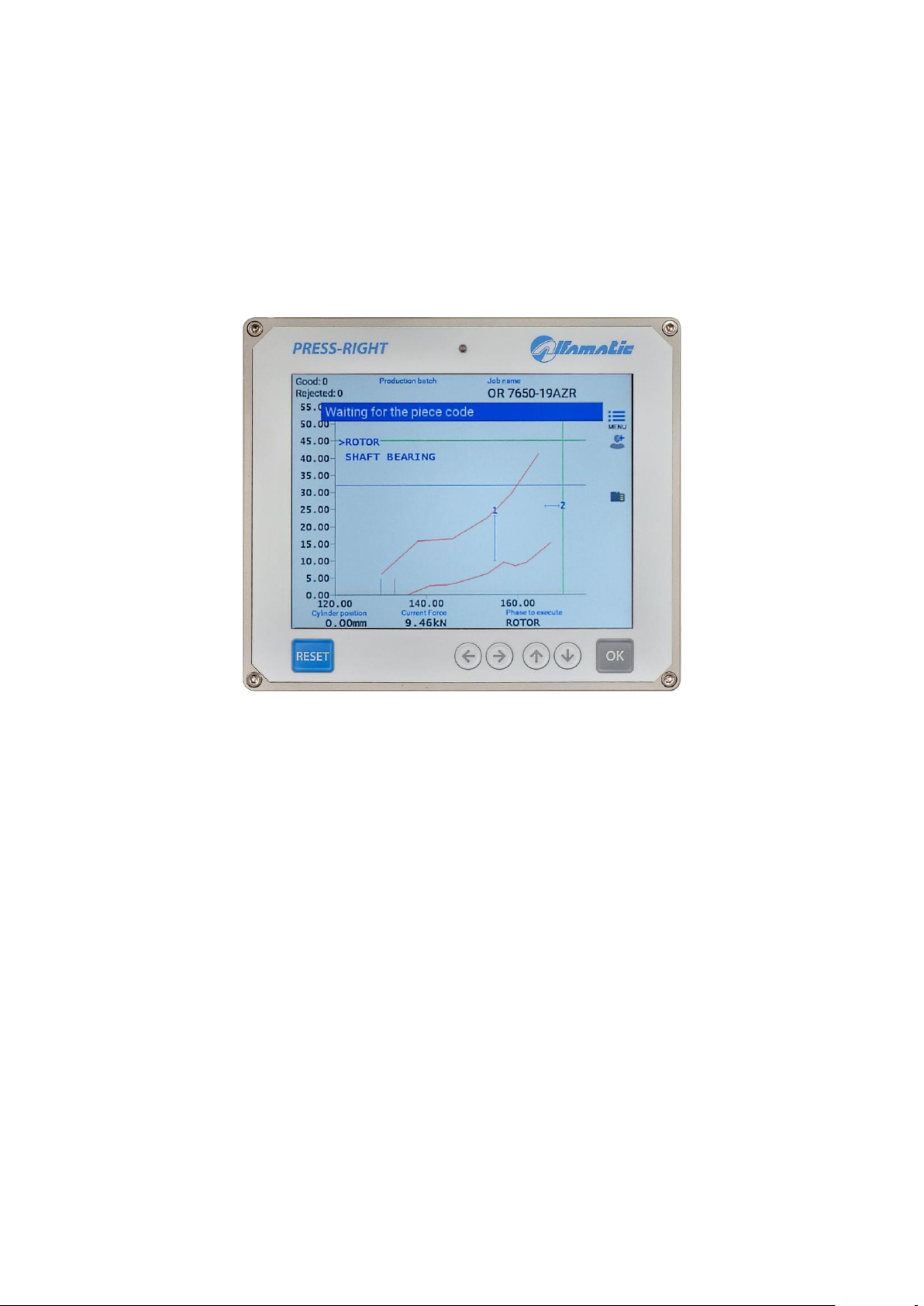

PRESS-RIGHT 3

1General information .............................................................................................. 5

1.1 Notes on control theory.............................................................................................5

1.2 Control of position-force curve...................................................................................5

1.3 Absolute and relative positions..................................................................................6

2Installation of Press-Right..................................................................................... 8

3Getting started...................................................................................................... 9

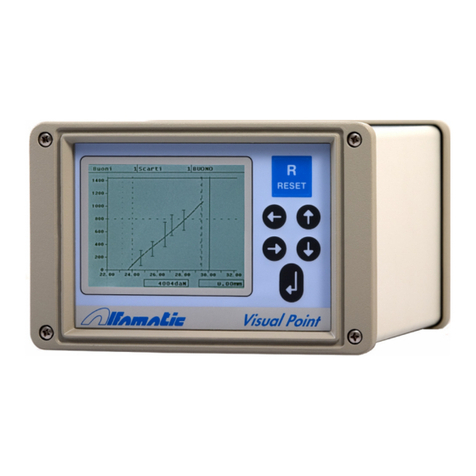

3.1 The keyboard of Press-Right.....................................................................................9

3.2 First approach...........................................................................................................9

3.3 Setting the display...................................................................................................10

3.4 The main menu.......................................................................................................10

4The jobs.............................................................................................................. 12

4.1 Creating a new job..................................................................................................12

4.2 Select a job.............................................................................................................12

4.3 Modifying the Job Name..........................................................................................12

4.4 Selecting a job using a bar code .............................................................................12

4.5 Job selection via tools recognition...........................................................................13

4.6 Selecting a Job via Fieldbus....................................................................................13

4.7 Changing Job Codes...............................................................................................14

4.8 Copy a job...............................................................................................................14

4.9 Deleting a job..........................................................................................................14

4.10 Modify a job.............................................................................................................14

4.11 Job counters ...........................................................................................................14

4.12 The graph ...............................................................................................................15

4.13 Options and rejected management .........................................................................15

4.14 Phase management................................................................................................16

4.15 Channel management.............................................................................................16

4.16 Functionality verification procedure.........................................................................16

4.17 Management of supplementary control signals .......................................................17

5Parameters......................................................................................................... 19

5.1 Stop values.............................................................................................................19

5.2 Control limits...........................................................................................................21

5.3 How to setup job.....................................................................................................22

5.4 Check points...........................................................................................................23

5.5 Job Options.............................................................................................................23

5.6 Job accessories......................................................................................................24

6The tolerance range............................................................................................ 25

6.1 Create the tolerance range......................................................................................25

6.2 Modify the tolerance range......................................................................................25

6.3 Detete the tolerance range......................................................................................26

7Rejected parts..................................................................................................... 27

7.1 The causes of the rejected......................................................................................27

7.2 Management of reject .............................................................................................28

8Measured values ................................................................................................ 30

8.1 The window of measured values.............................................................................30

8.2 Analysis cursor........................................................................................................30

9The tools menu................................................................................................... 31

9.1 Display options........................................................................................................31

10 Special configurations......................................................................................... 32

10.1 Transducer of additional force.................................................................................32

10.2 Tool recognition ......................................................................................................32