Mitutoyo Corporation 20-1, Sakado 1-Chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213-8533, Japan6Date of publication: November 1, 2020

Printed in Japan

4) Switching resolution (0.001 mm models only)

The resolution setting can be changed for 0.001 mm models only.

1Entering parameter setting mode

Press and hold the [MODE] key.

⇨Shifts to parameter setting mode.

2Selecting the parameter item to set

1 Press the [MODE] key until [rES.] is displayed.

2 Press the [SET] key.

⇨Resolution can be switched.

3Setting the resolution

1 Press the [MODE] key to select the resolution.

⇨Each time the key is pressed, it will switch the value

between "0.001 mm" and "0.01 mm".

2 Press the [SET] key.

⇨Settings are confirmed; shifts to next parameter item.

(Proceed to step 2in "5) Setting the LCD Rotation

function".)

5) Setting the LCD Rotation function

The measured values displayed on the LCD can be rotated 180°.

1Entering parameter setting mode

Press and hold the [MODE] key.

⇨Shifts to parameter setting mode.

2Selecting the parameter item to set

1 Press the [MODE] key until [Lcd] is displayed.

2 Press the [SET] key.

⇨LCD Rotation function can be set.

3Setting the LCD display method

1 Select display method by pressing the [MODE] key.

⇨Each time the [MODE] key is pressed, it will switch the

display between "No rotation" and "Rotation".

2 Press the [SET] key.

⇨Settings are confirmed; shifts to next parameter item

(proceed to step 2in "2) Setting counting direction").

Tips

The LCD Rotation function is executed as soon as parameter

setting finishes and the product returns to measurement mode.

Key icon operation

=

> 2 s

=

< 1 s

1

2-1

2-2

3-2

3-1

1

3-2

2-1

2-2

3-1

9. Precautions after Use

•

Lightly wipe off dirt on this product with a lint-free soft cloth. Do not use organic solvents such as

detergents, thinner or benzine.

• If the product is to be out of use for 3 months or more, remove the battery before storage. Liquid

leakage from the battery may damage the product.

• Do not store the product in a place with a high temperature or humidity, or a lot of dust or oil mist.

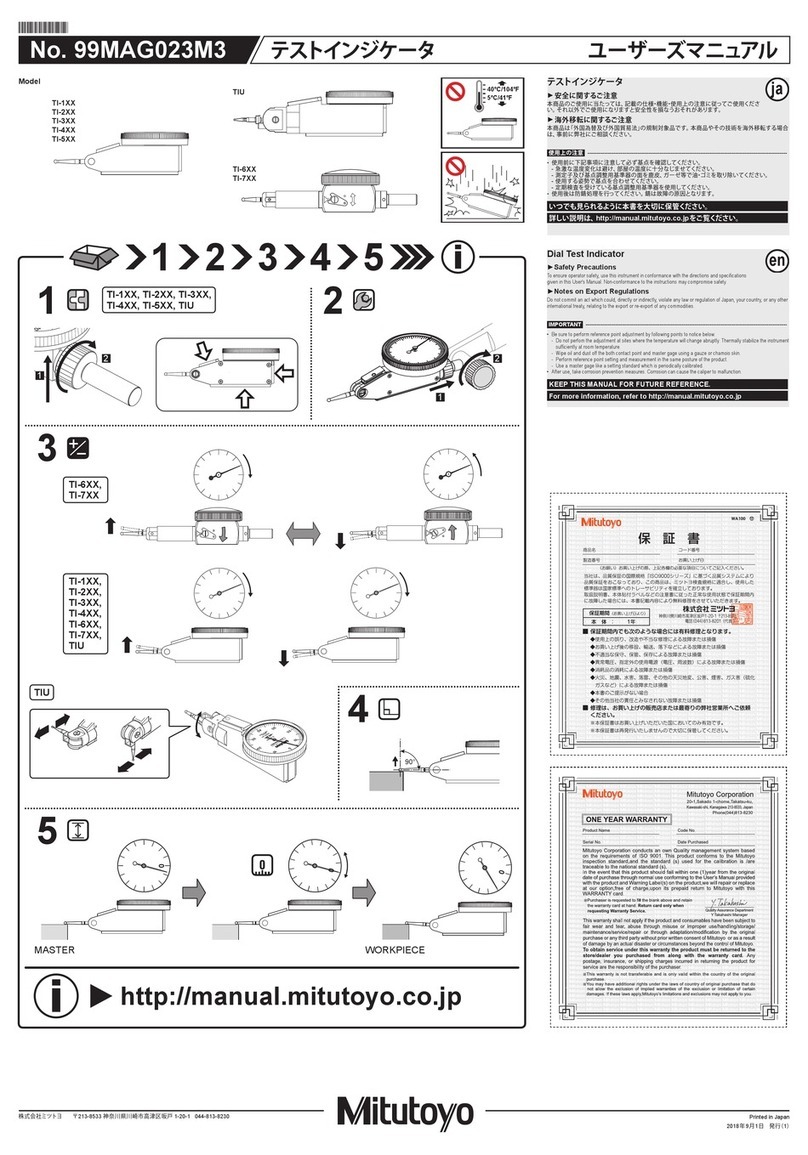

10. Replacing the Rubber Boot (Optional)

(A)

(B)

Stem

Contact point

Rubber boot

1Remove the old rubber boot and wipe away dust or oil from the stem groove (A) and spindle

groove (B) with alcohol, etc.

2Put the rubber boot on the spindle so that the rubber boot end with the larger bore is on the

stem side, and then set the rubber boot in between the stem and the contact point.

3Lightly apply a small amount of room temperature curing silicone adhesive to grooves (A) and

(B). At this time, be careful not to apply silicone adhesive to the spindle sliding surface.

4Pinch the top end of the rubber boot with a tool such as flat tip tweezers and fit it into stem

groove (A).

5Attach the bottom end of the rubber boot to spindle groove (B) by pressing manually.

6Wipe away excess adhesive with a clean cloth.

Tips

Prompt replacement of the rubber boot is recommended if using the product in an environment

frequently exposed to water or oil (in order to prevent damage).

11. Error Displays and Countermeasures

Error Display Causes and Countermeasures

ABS Synthesis Error Although this may be momentarily displayed while the spindle is

moving, it is a normal artifact of internal processing. If it occurs while

the spindle is not moving, the internal sensor has failed.

In this case, repair is required: please contact the agent where you

purchased the product or Mitutoyo sales representative.

Low Battery Voltage

Battery is depleted.

Replace with a new battery.

Display Overflow

The measured value exceeds the number of digits that can be displayed.

• In ABS, press the [SET] key to enter the origin setting and reset the

preset value.

•

In INC, press the [SET] key at the appropriate position and set to zero.

•

Press and hold the [MODE] key to enter parameter setting mode and

change the resolution to an appropriate value. (0.001 mm models only)

Sensor Contamination

Detection Error A sudden change in temperature may create condensation on the

detector, or it may be contaminated by other sources.

• Turn the power off and allow the product to adapt to the temperature

for about 2 hours.

• If it does not recover after adapting to the temperature, repair is

required: please contact the agent where you purchased the product

or Mitutoyo sales representative.

Error Display Causes and Countermeasures

Preset Value Setting

Error (Normal Measurement)

The preset value for normal measurement exceeds the number of

digits that can be displayed.

• Press and hold the [SET] key to return to preset value settings, and

then reset to an appropriate value.

•

Press the [SET] key to return to measurement mode, and then switch to an

appropriate resolution in parameter setting mode. (0.001 mm models only)

Tolerance Limit Value

Setting Error

The upper limit is set below the lower limit.

• Press the [SET] key to return to the tolerance limit value settings,

and then reset so that the upper limit is above the lower limit.

Upper Limit Setting

Error The upper limit exceeds the number of digits that can be displayed.

• Press and hold the [SET] key to return to upper limit value settings,

and then reset to an appropriate value.

• Press the [SET] key twice to enter resolution settings, and then

switch to an appropriate resolution. (0.001 mm models only)

Lower Limit Setting

Error The lower limit exceeds the number of digits that can be displayed.

• Press and hold the [SET] key to return to lower limit value settings,

and then reset to an appropriate value.

• Press the [SET] key to enter resolution settings, and then switch to

an appropriate resolution. (0.001 mm models only)

12. Input/Output Functions

1) Externally outputting the displayed value

The displayed value can be output to a device supporting Digimatic output format by connecting

the product and the external device with a connection cable (optional). An optional external display,

external printer, PC, etc. can be connected.

1 Press the [ON/OFF] key to turn off the product.

2

Use the provided Phillips screwdriver to remove the fixing screws from the output connector cap.

3Remove the output connector cap and gasket.

4Attach the connector gasket to the connection cable and insert it.

5Tighten with the fixing screws removed in step 2.

6Connect the other end of the connection cable to the external device.

■ID-N1012, ID-N112

3

5

4

2

Output connector cap

Connection cable

■ID-B1005, ID-B105

Connection cable

54

Use the provided 0-size screwdriver (Part No. 05CZA619) when mounting/removing

the fixing screws, and tighten with a torque of 5 cN・m to 10 cN・m or so.