F

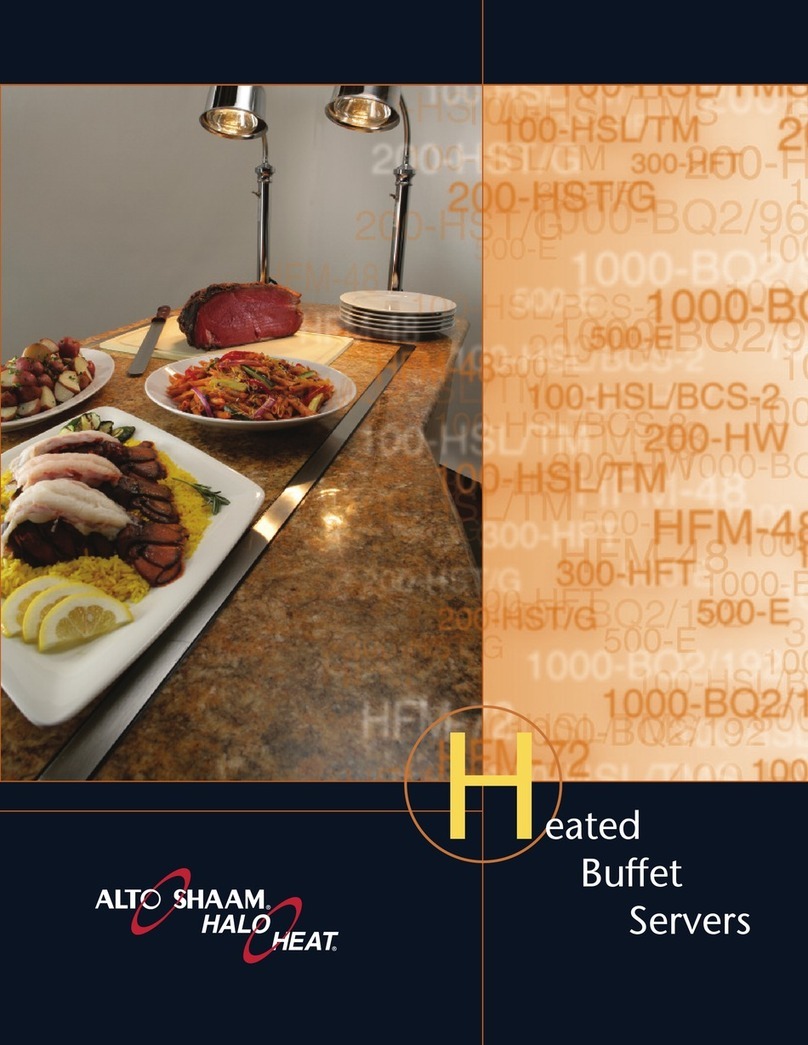

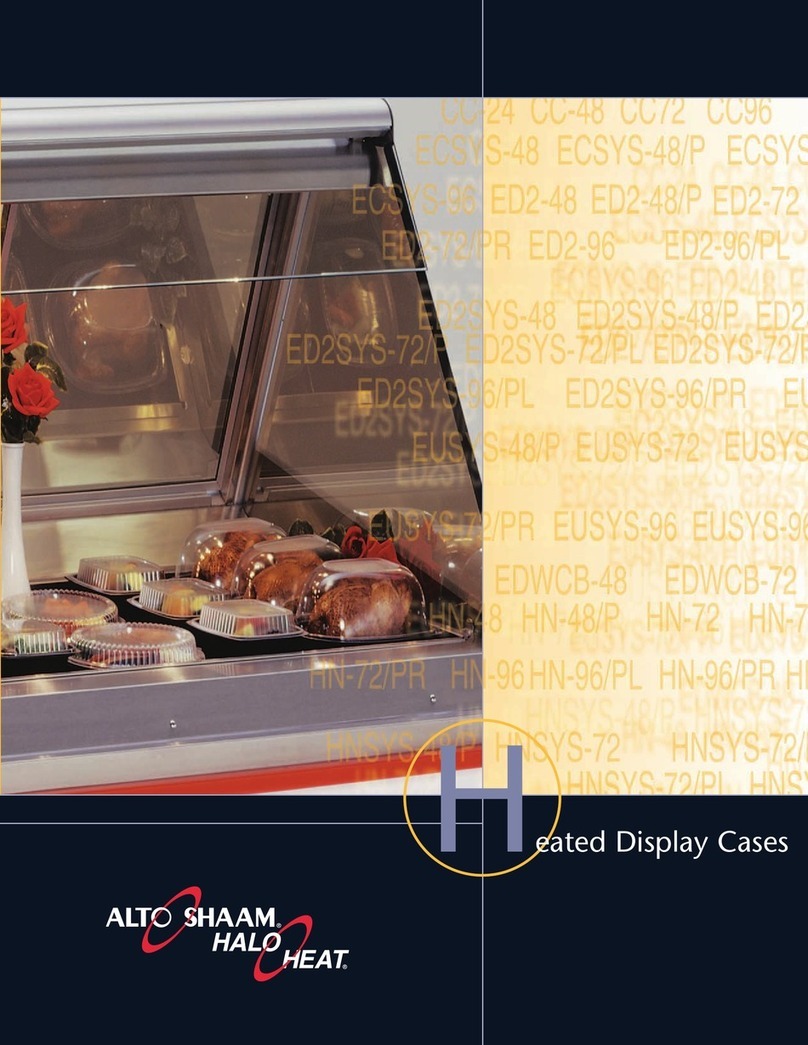

HE KEY to quality ood holding is

more than the simple application o

heat. Adding humidity or water isn't the

answer either — most o the time it just

washes out the lavor. The real key to

quality holding is to preserve as much

natural product moisture as possible and

that's exactly what the gentle holding

capability o Halo Heat is designed to

accomplish. Halo Heat keeps hot oods

at sa e, even temperatures while

retaining the maximum amount o

product moisture, the natural moisture

ound in most o the oods you need to

hold prior to service. Whether your

holding needs are large or small, Halo

Heat hot ood holding cabinets are

available in a wide variety o models and

are able to support any type o ood

preparation by extending the longest

possible holding li e.

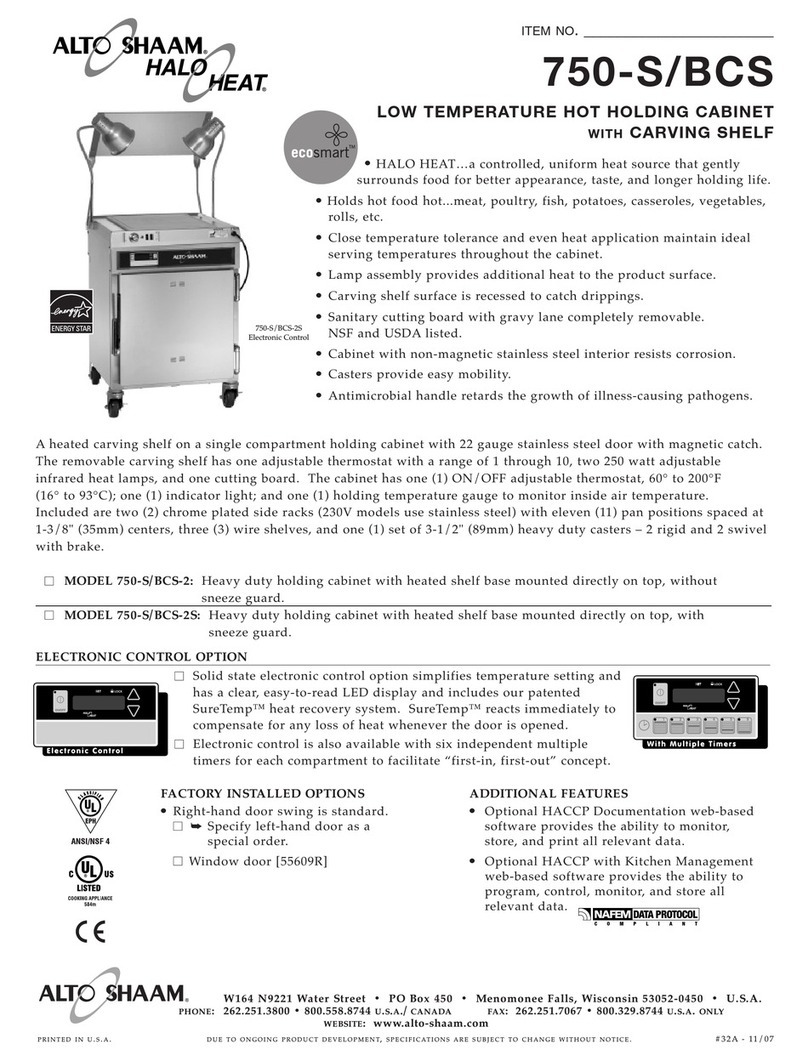

HE SECRET is in the unique

electric thermal cable, wrapped on three

sides o the cabinet between the exterior

casing and the stainless steel inside

walls. This gentle, radiant heat source

provides gentle, even heat distribution

without cold spots, hot spots, or hot air

movement to dry the product. Halo

Heat is speci ically designed to provide

signi icantly longer holding li e, resulting

in less product waste and greater

product acceptability in prolonged

holding situations. When properly

planned, Halo Heat holding equipment

can be a time management aid, support

the ood service operation by extending

preparation times outside o peak

preparation hours, and provide a quality

product — even when it becomes

necessary to delay service.

TT

ECO SMART™ is technology that's good

or the environment and great or your

bottom line

EcoSmart is proo o our commitment to help

our customers drive down ownership costs

and protect the environment with energy-

e icient, eco- riendly products. So now you

can be con ident that the company you turn

to or unsurpassed quality is also leading the

way in veri iable solutions that help you keep

rising energy costs under control while

minimizing environmental impact.

Look or the EcoSmart™ logo on equipment

selections that have been engineered to save

operational costs in electrical power

consumption to help add to your bottom line.

On select models

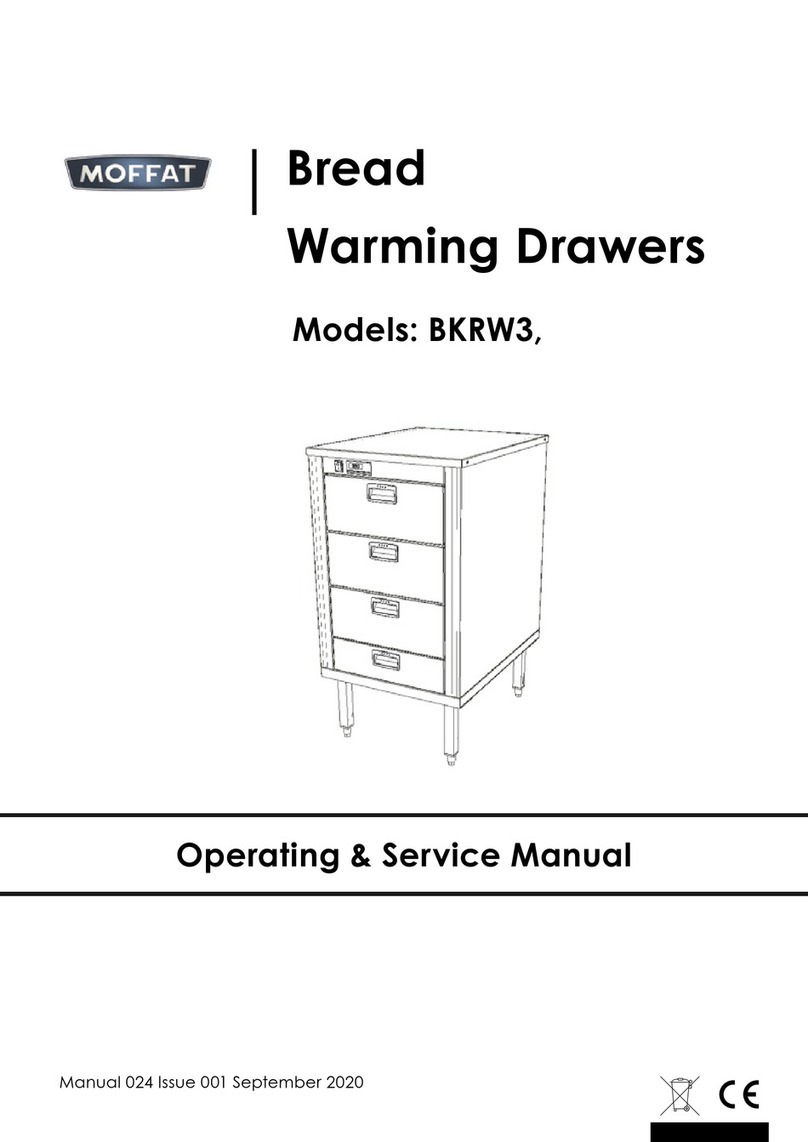

OOD PRODUCTION in most operations

is accomplished in a variety o di erent types o

cooking equipment. Food quality can be easily

lost between the time a product is removed rom

an oven and the time o direct service. Regardless

o the method o preparation, proper handling o

ood within this time period is o critical

importance to the operator.