Alto-Shaam ecosmart Electronically Operated Ovens Instruction Manual

Other Alto-Shaam Oven manuals

Alto-Shaam

Alto-Shaam 6 10 User manual

Alto-Shaam

Alto-Shaam 500-TH-II SERIES User manual

Alto-Shaam

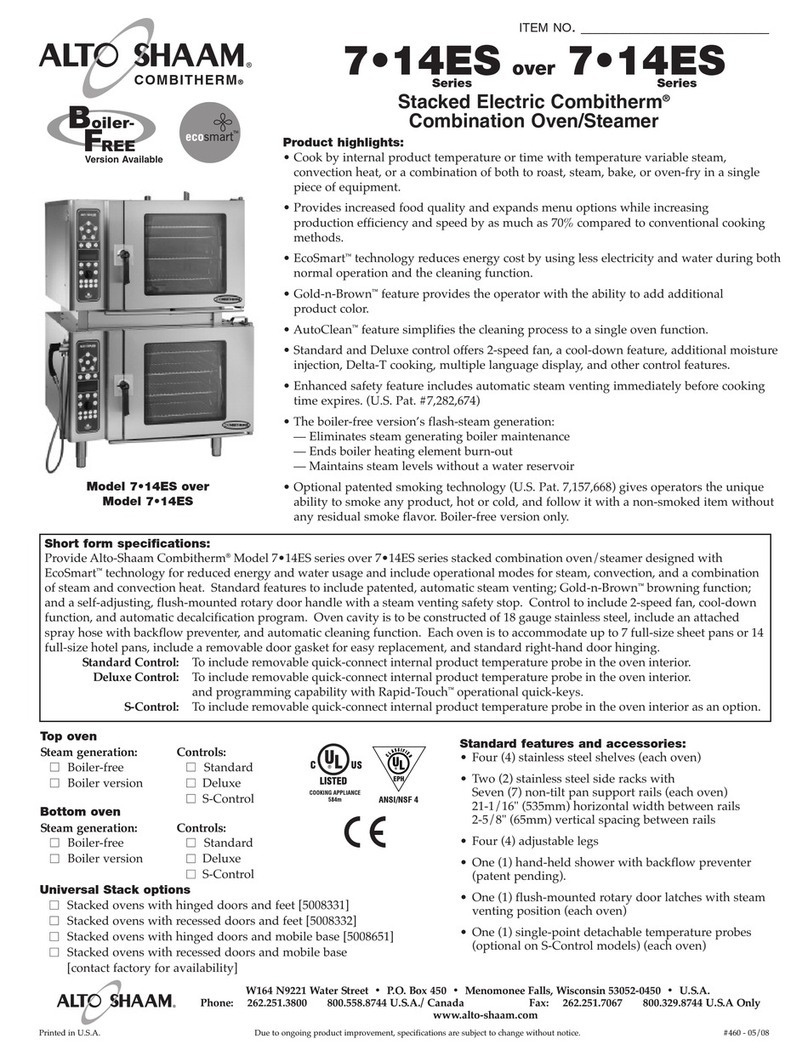

Alto-Shaam CombiTouch 7.14es User manual

Alto-Shaam

Alto-Shaam COMBITOUCH SERIES 6 10ESG User manual

Alto-Shaam

Alto-Shaam 300-TH User manual

Alto-Shaam

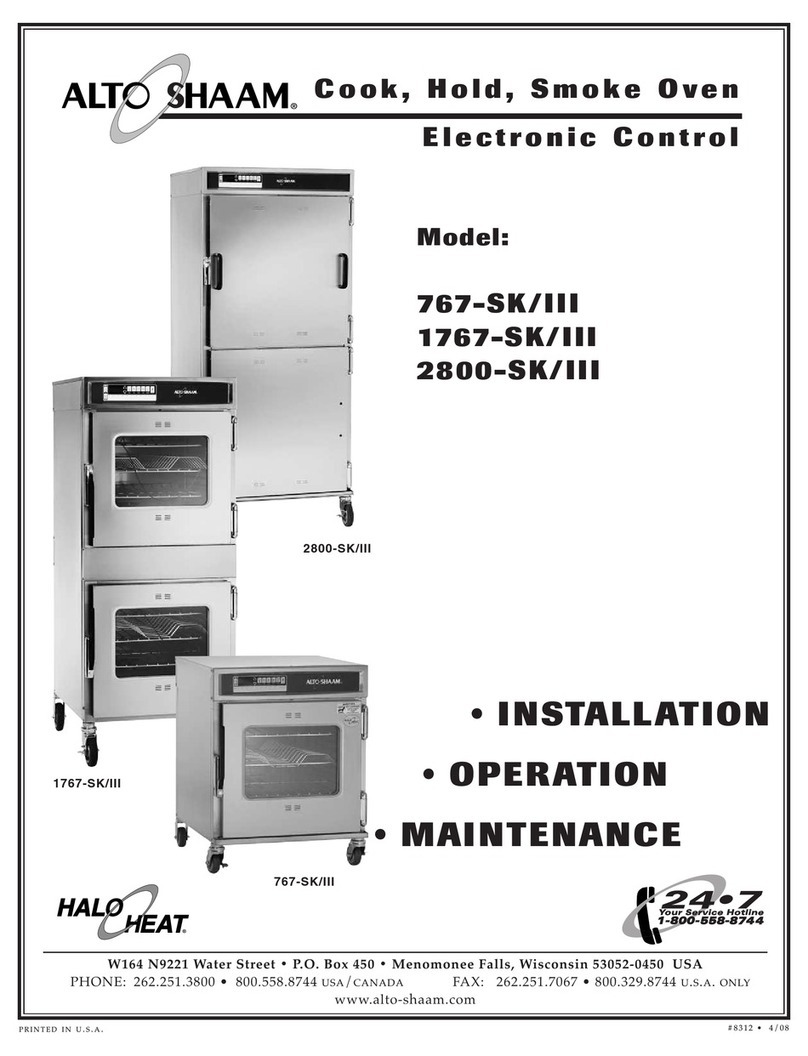

Alto-Shaam 767-SK Series User manual

Alto-Shaam

Alto-Shaam 300-TH/III Touch User manual

Alto-Shaam

Alto-Shaam xcelerate XL-300 Manual

Alto-Shaam

Alto-Shaam CT EXPRESS 4 10ESi User manual

Alto-Shaam

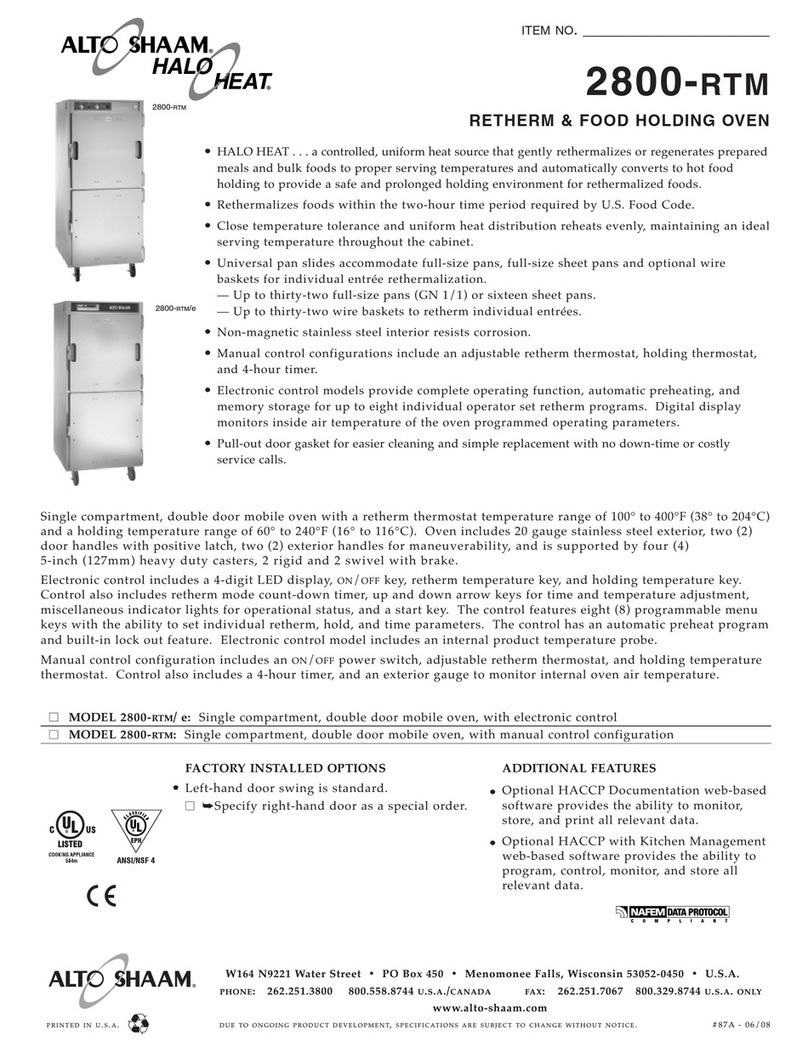

Alto-Shaam 2800-RTM User manual

Alto-Shaam

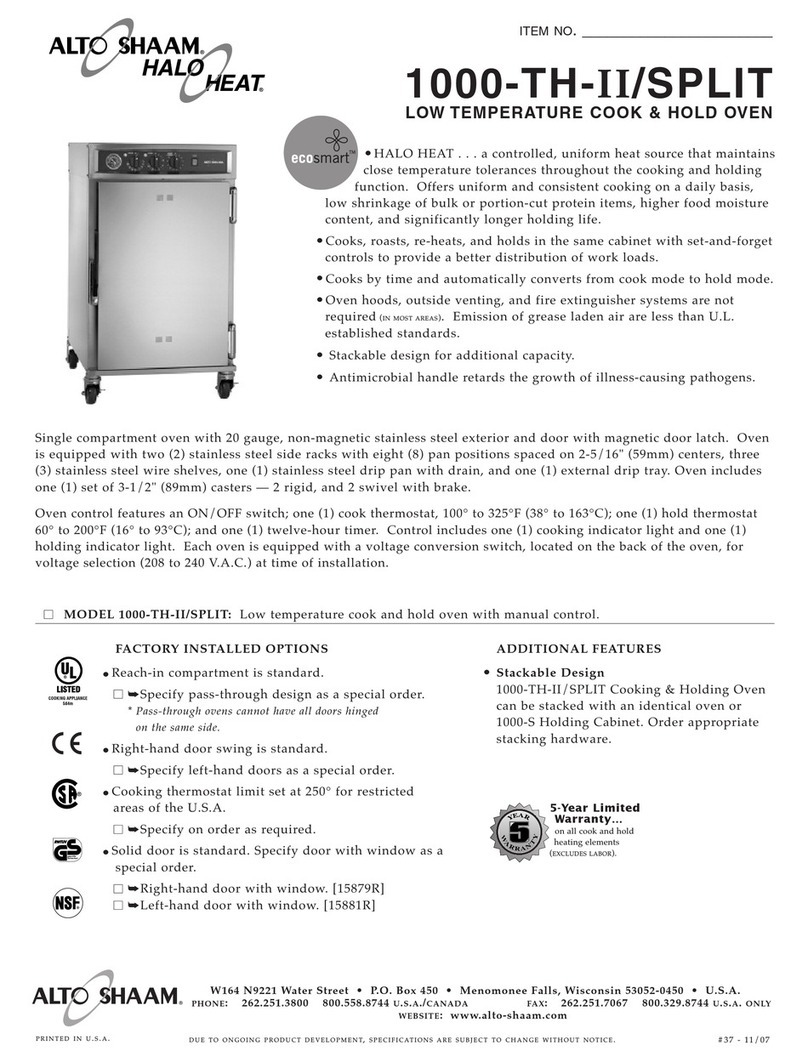

Alto-Shaam 1000-TH-II/Spilt User manual

Alto-Shaam

Alto-Shaam Vector VMC-H2 User manual

Alto-Shaam

Alto-Shaam CombiTouch 7.14es User manual

Alto-Shaam

Alto-Shaam Combitherm 6.10ESiN User manual

Alto-Shaam

Alto-Shaam Low Temperature Cook & Hold Oven 750-TH-II User manual

Alto-Shaam

Alto-Shaam Combitherm CT PROFORMANCE Series User manual

Alto-Shaam

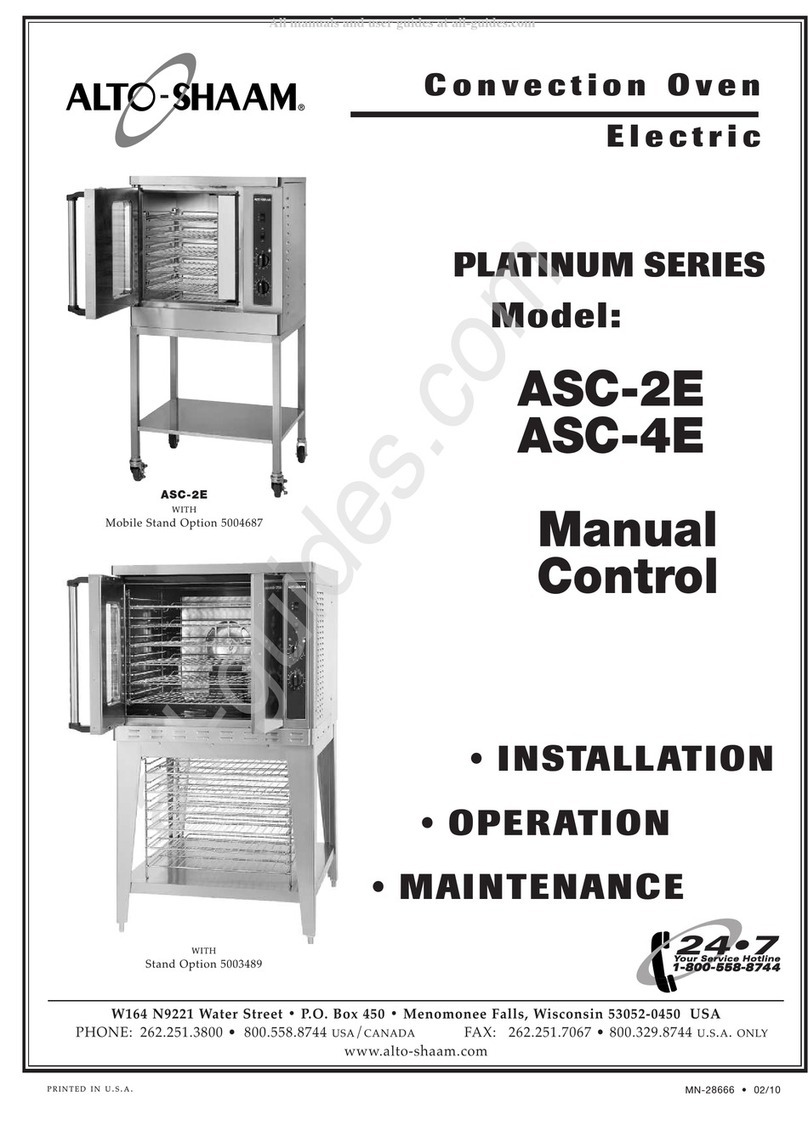

Alto-Shaam PLATINUM Series General instructions

Alto-Shaam

Alto-Shaam CombiTouch 7.14es User manual

Alto-Shaam

Alto-Shaam 767-SK Installation instructions

Alto-Shaam

Alto-Shaam 1000-TH-II-SPLIT User manual

Popular Oven manuals by other brands

Brandt

Brandt FC 222 user manual

aumate

aumate TOA20M04N-1E instruction manual

Maytag

Maytag CWE4100AC - 24" Single Electric Wall Oven Dimension Guide

Kernau

Kernau KBO 1076 S PT B instruction manual

Bosch

Bosch HB 37 N Series User manual and installation instructions

Electrolux

Electrolux EOD5420AA user manual