WARRANTY CERTIFICATE

AFBM 160

WARRANTY DECLARATION

That the product will perform seamlessly during the warranty period if the obstructions are observed.

That the service and necessary spare parts for the products will be provided within the warranty period as well as 5 years

after its expiry.

That during the warranty period, we will repair the product within 45 days at the latest at our own expense, which also

includes transport costs for the products that is the subject of the complaint.

If the mixer is not repaired in the aforementioned deadline, it will be replaced by a new one at your request. Transport costs

cannot exceed the valid costs of rail transport or mailing via postal services. The warranty becomes valid on th

which is verified with a confirmed warranty certificate and a confirmed receipt. If the product is repaired, the warranty per

iod is

extended by the duration of the repair. Please provide the following information when notifying us of a malfunction: product

designation and type, date of purchase, description of the malfunction, and the exact address.

THE WARRANTY PERIOD is 12 months.

The warranty will be void:

If the usage of the mixer is incorrect or non

approved, or if the mixer is

If the manufacturer’s written instructions are not observed.

If repairs are completed by an unauthorized person without the manufacturer’s consent.

The warranty for products is valid in the geographical area of the country in which the product

WARRANTY PROVIDER PRODUCT SELLER

Altrad Fort BV ______________________

SimonStevinstraat 6 ______________________

4004 JV Tiel ______________________

Nederland ______________________

DATE OF HANDOVER PRODUCT

IDENTIFICATION

____________________

4

Altrad Fort BV.

Simon Stevinstraat 6, 4004 JV Tiel

The Netherlands

www.altradfort.nl

DECLARATION OF CONFORMITY

Based on the European Community Machinery Directive 2006/42/EC, on

the Electromagnetic Compatibility Directive 2006/108/EC, on the Low

Voltage Directive 2006/95/EC, and the Noise Directive 2000/14/EC.

Simon Stevinstraat 6

4004 JV Tiel

The Netherlands

declares under its sole responsibility that during the development,

construction and production of

the AFBM 160 concrete mixer

the following standards were met:

2006/42/EC

EN 12151:2007, EN 60204-1:2006+2009+AC:2010 EN

60335-1:2012+AC:2014+A11:2014

EN 62233:2008+AC:2008

Director: H. Lindemann

DEAR CUSTOMER!

You have purchased a new concrete mixer. Our many years of experience

are an assurance that you have made the right choice. We have ensured a

high-quality production meeting strict European regulations, which ensure a

safe operation if these instructions are observed.

The mixer is intended for mixing construction materials.

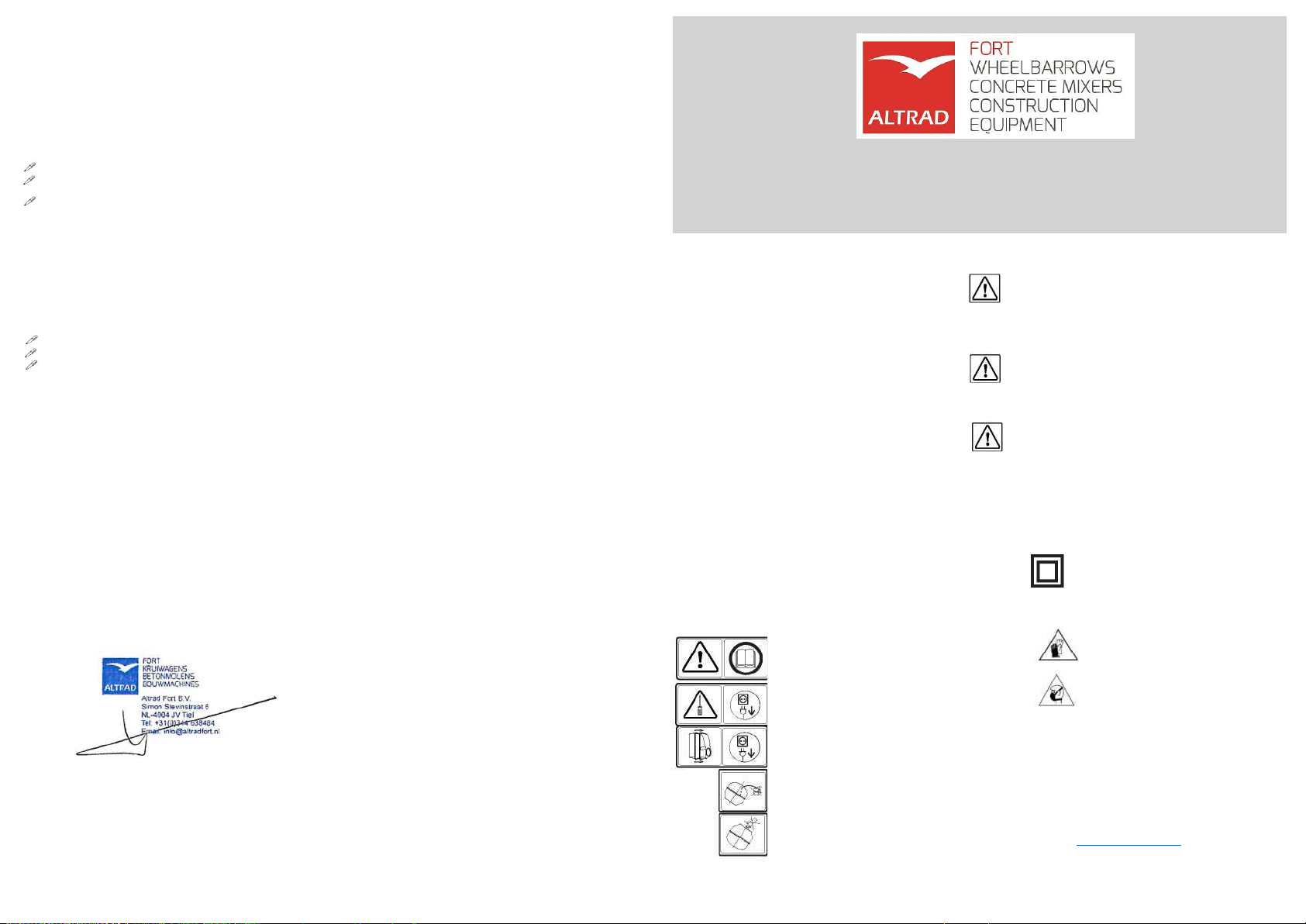

EXPLANATION OF SYMBOLS ON THE MIXER

Before use, please read the operating

instructions for the mixer.

Before every repair, do not forget to unplug

the mixer from the electrical grid.

Before removing the cabinet cover, do not

forget to unplug the mixer from the electrical

grid.

The lubrication of drive gears is prohibited

at all times.

Reaching into a rotating drum is

dangerous and therefore prohibited.

The observance of instructions and recommendations for the operation

and maintenance ensures safe operation and a long service life of the

mixer.

Electrical Safety

The mixer is manufactured according to the applicable regulations.

Double insulation ensures complete protection against electrical shock

therefore the product can be connected to the electrical grid without extra

protection. This applies only to the single-phase motor.

Mechanical Safety

During the construction of the mixer, we have ensured complete safety of

the operator. All the dangerous spots are protected or constructed in order

to prevent injury.

Safety Warnings

Do not remove any protection ele

ments from the mixer because they ensure a safe

operation.

The cabinet of the electrical motor shall be closed during operation. Reaching

into a rotating drum is prohibited. The power cable must not be

damaged. Lay the cable so that any damage will be prevented

during operation. Make sure not to place the mixer on the cable. The drum

can only be filled and emptied when it is rotating. The mixer can

only be started if the drum is empty. Do not use the mixer in an

explosive atmosphere. During operation (rotating of the drum), the mixer must not

move.

CAUTION! Double insulation machine

(applies only to the single-phase

motor)

During all repairs, original parts must be used in order to provide a

double insulation also after the repair!

CAUTION!

inhalation hazard

CAUTION! Mandatory use of

personal protective equipment

The mixer is stored in rooms with minimal risks for damage. Longer storage

periods require an enclosed and dry room. For shorter storage periods, no

special room is required. The storage temperature can be in the range

between -30°C and +50°C.

INSTRUCTIONS FOR DISPOSAL OF PRODUCT AND ITS

PACKAGING AFTER SERVICE LIFE

We recommend that you submit the product after the expiry of its service life

to authorized organizations for the collection of secondary metals.

Website: http://www.altradfort.nl/

EN