Amada GS-2 User manual

Other Amada Welding System manuals

Amada

Amada HF-2500A User manual

Amada

Amada GP-500A-P-DUAL User manual

Amada

Amada ML-3060AS User manual

Amada

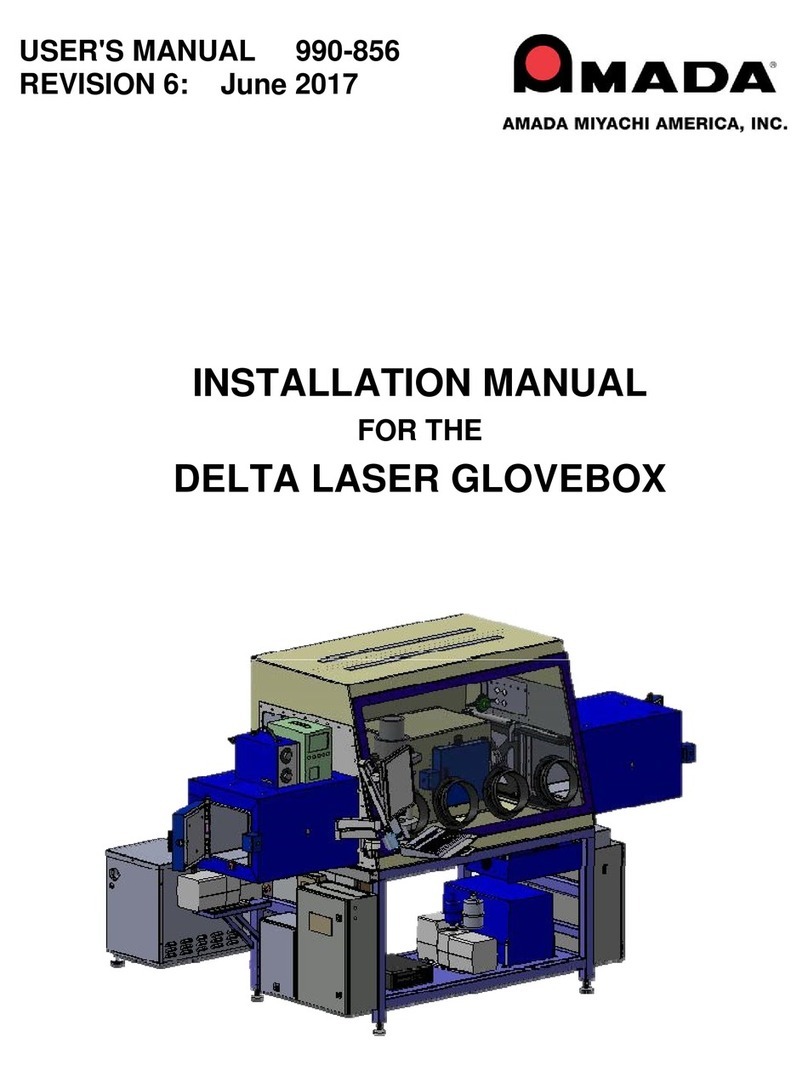

Amada Delta User manual

Amada

Amada MF-C500A-M User manual

Amada

Amada Delta User manual

Amada

Amada EZ-AIR User manual

Amada

Amada AH Series User manual

Amada

Amada CL-H601A User manual

Amada

Amada MEA-100B User manual

Amada

Amada MacGregor PA20P Series User manual

Amada

Amada ML-2650B User manual

Amada

Amada PU-G User manual

Amada

Amada ML-2350AF-CDRH User manual

Amada

Amada MM-L400A User manual

Amada

Amada Miyachi Unitek STA-200A User manual

Amada

Amada MA-650A User manual

Amada

Amada TL-180B User manual

Amada

Amada MA-520B User manual

Amada

Amada TA-150AC/300WC User manual

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual