Operating Instructions PA-xxP

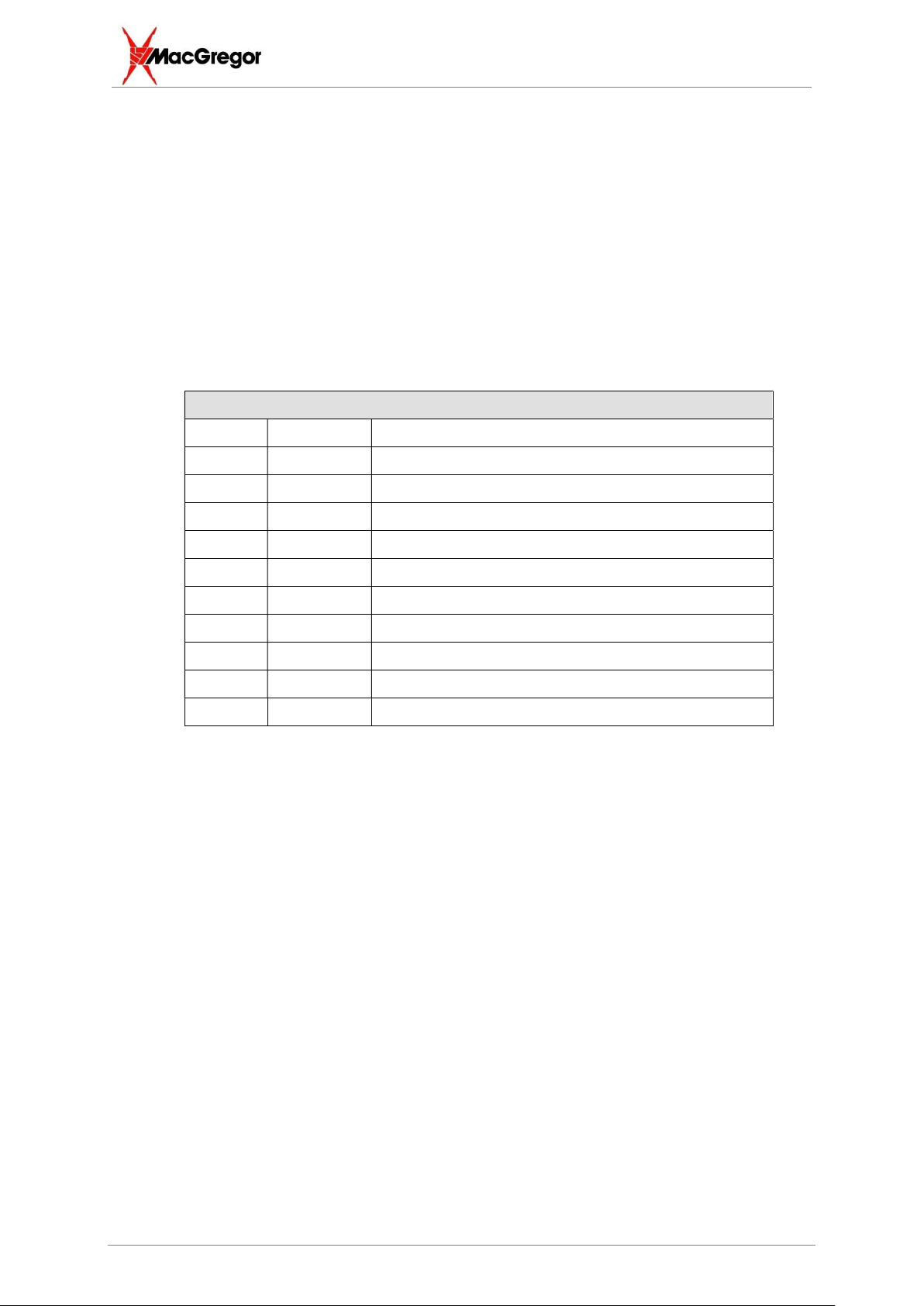

Table of Contents

961-00035 rev11 3/42

Table of Contents

1 General Information ...........................................................................................................5

2 Technical Description ........................................................................................................6

2.1 Technical Specification .....................................................................................................6

2.2 Introduction ........................................................................................................................7

3 Commissioning ..................................................................................................................8

3.1 Electrical Connections ......................................................................................................8

3.2 Shield Gas Connections ....................................................................................................9

3.3 Rear Panel Layout ........................................................................................................... 10

3.4 Getting Started ................................................................................................................ 12

3.4.1 Power on .......................................................................................................................... 12

3.4.2 The Default Menu Screen ............................................................................................... 12

3.4.3 Information Colour Coding Key ..................................................................................... 13

3.4.4 Memory Organisation ..................................................................................................... 14

3.4.4.1 Memory Locations (Profiles) ............................................................................................. 14

3.4.4.2 Scratchpad Memory .......................................................................................................... 14

3.5 Limit Functions ............................................................................................................... 15

3.5.1 Monitored Limit Parameters .......................................................................................... 15

3.5.2 High Voltage Limit .......................................................................................................... 15

3.5.3 Low Voltage Limit ........................................................................................................... 15

3.5.4 High Energy Limit ........................................................................................................... 15

3.5.5 Low Energy Limit ............................................................................................................ 15

3.6 Password Entry Screen (Log in/out) ............................................................................. 16

4 Setup (Man mode) ........................................................................................................... 17

4.1 Setup screen .................................................................................................................... 17

4.2 Setup (Man mode) Graph Screen .................................................................................. 19

4.3 Setup (Man mode) Load Screen .................................................................................... 20

4.4 Setup (Man mode) Save Screen .................................................................................... 21

5 Profile Editor .................................................................................................................... 22

5.1 Profile Editor screen ....................................................................................................... 22

5.2 Profile Editor Load Screen ............................................................................................. 24

5.3 Profile Editor Save Screen ............................................................................................. 25

6 Run (Auto Mode) ............................................................................................................. 26

6.1 Run (Auto Mode) Main Monitor Screen ........................................................................ 26

6.2 Run (Auto mode) Monitor Screen .................................................................................. 27

6.3 Run (Auto mode) Load Screen ...................................................................................... 30

7 Configuration Screen ..................................................................................................... 31

8 Gas Control Screen ........................................................................................................ 32

9 IO Monitor Screen ........................................................................................................... 33

10 Control Connections ...................................................................................................... 34