9

HEALTH & SAFETY GUIDANCE

Electrical Safety

Installation of the stairlift is mainly a manual process. Although you do need to plug the stairlift

into a mains power supply socket, this socket MUST already have been installed by a qualified

electrician.

:eephkdhgma^FZbgllrlm^ffnlm[^]hg^[rZjnZebÛ^]^e^\mkb\bZg'

Safe Working Practices

When installing the stairlift, follow safe working practices in these areas:

• Working at heights or on the stairs

• Working with power tools or equipment which generate noise

• All loading, transport, unloading, unpacking, lifting and carrying of the equipment

should be done in line with current HSE guidelines

Be aware of the risks of equipment falling from a height. For example, tools falling through

open-treaded staircases or through banister rails, or equipment falling or sliding down stairs.

Always use lifting points supplied in equipment packaging.

Please observe warnings and guidelines printed on equipment packaging.

Important – Intruder Alarms

Intruder alarms often have sensor pads at the top or bottom of staircases or on one or more steps.

There may also be alarm wires hidden under a carpet or tucked under a skirting board. Check

whether any such sensors or cables need to be moved before drilling into a staircase or floor.

Provide guidance to the home owner about what safety risks they and any other people might be

exposed to during the installation. For example

• Movement of equipment and tools posing a risk to the buildings or things in it

(such as pictures, paintings or ornaments)

• Cables and other equipment posing a trip hazard - especially on or near stairs

• Live electrical equipment (such as electric drills) posing a hazard

(for example, if used inappropriately by children)

• Potentially sharp equipment (such as saws, drills bits, knives or chisels)

• Potential noise due to the use of power tools

• Potential creation of airborne dust

• Remember to let the resident know you will take them through how to use the stairlift,

so they can let some-one else know what time a demonstration might take place

• Resident must keep boarding/exit areas of the stairlift clear and well lit to a level of 50 lux.

Preparing The Workplace

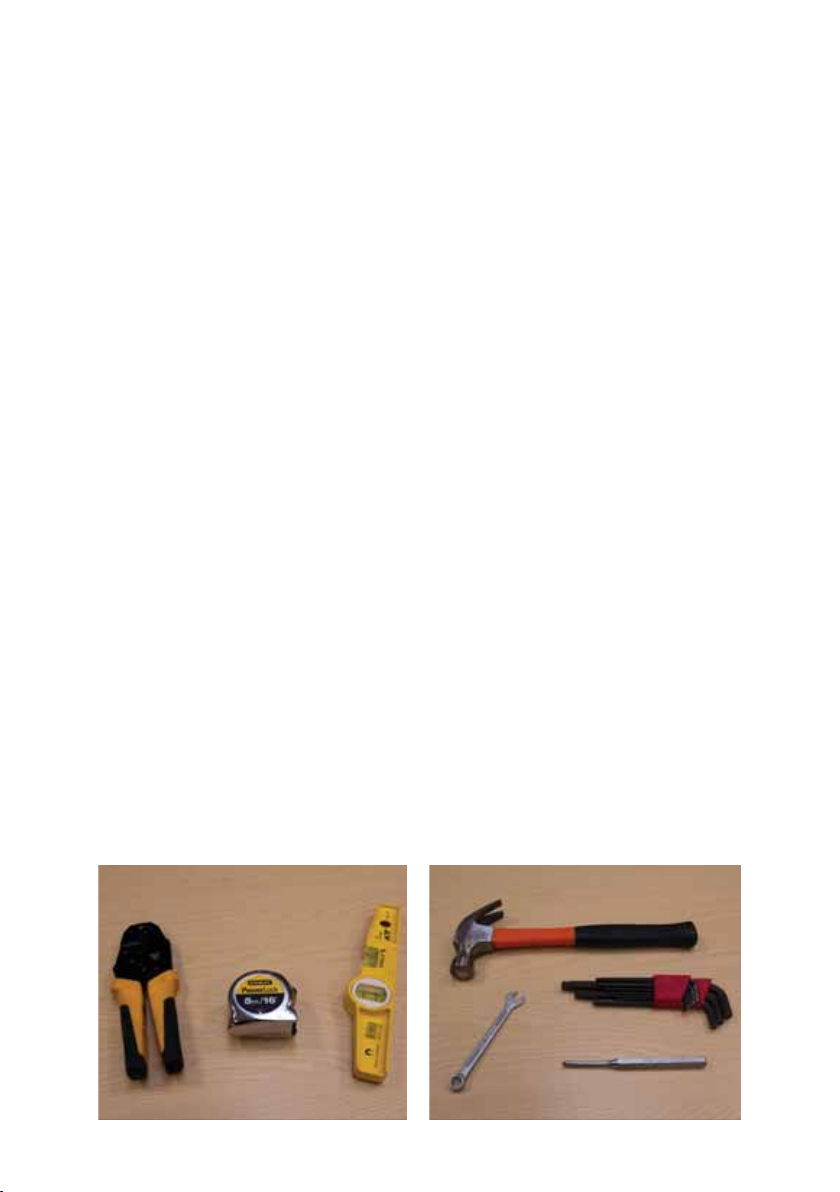

Before you start the installation, make sure of a Safe Working Environment, with enough space to

assemble the stairlift assembly and for you to work around it.

Make sure any loose or fragile property (such as pictures or ornaments) are located in a safe

place away from the potential working area. Inspect the area for potential obstructions such as

central heating pipes, hidden cables, underfloor heating, etc. The work area should be well lit. If

sufficient lighting is not available, temporary lighting should be used. The stair treads should be

inspected for their suitability of supporting the installed machinery.

If in doubt, a qualified person should be engaged to check suitability.