7amiad filtrationsystems

INSTALLATION

Design recommendations

1. If flow increases and pressure drops dramatically for a long period of time during network filling-up, it is recommended

that a pressure sustaining valve is installed downstream. The pressure sustaining valve will ensure a controlled filling-up

of the line.

2. If continual water flow is essential even during maintenance period, it is recommended that a manual or automatic by-

pass is installed, and the isolating valves will be used to isolate each filter unit.

3. In places where there is an expected temporary worsening of water quality, it is possible to operate an emergency

flushing program. In order to do so, a hydraulic controlled valve has to be installed downstream. For details, please

consult the manufacturer.

Installation instructions

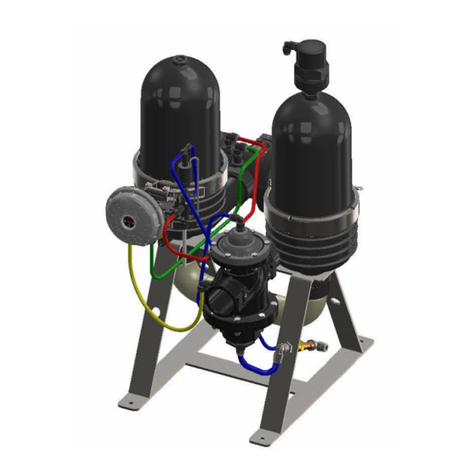

1.Install the filter horizontally in such way that allowsconvenient approach and enough space to dismantle the filter for

maintenance purposes.

2. Ensure the direction of flow according to the arrows marked on the filter housing.

3. It is recommended to install a mechanical non-return valve downstream of the filter.

4. Connect a minimum of 2"pipe to the exhaust valve. The exhaust pipe should be designed so that it creates minimal

resistance to flow of 15 m3/h (66 USgpm).

5. If the system is designed to operate with working pressure higher than 6 bar (85 psi), it is recommended that a manual

valve is installed on the exhaust pipe, in order to enable regulation of the flushing flow rate.

6. The user should arrange suitable lighting at the area of the filter to enable good visibility and safe maintenance.

7. The user should arrange suitable platforms and safety barriers to enable easy access to the filter without climbing on

pipes and other equipment.

IMPORTANT !!

•• Prevent static back pressure or reverse flow through the filter.

•• Install a manual or a hydraulic valve downstream of the filter.

Electric wiring

1. Install the control board in a dry and protected place (It is possible to order a special control board for out-door

installation).

2. Power connection to the control board:

a.Connect a three-phase voltage source through a semi-automatic switch, or 16 Amp. fuse to the L1 L2 L3 inlet

at the terminal strip in the control board.

b.b. Earth the control board.

3. Power connection to the motor:

Connect the drive unit to the control panel by means of a 4 x 2.5 mm (12 or 14 AWG) wire in flex-conduct. Use a long

enough cable to allow removal of the drive unit and placing it near the filter for maintenance, without having to disconnect

it from the cable. (It is recommended that this installation meets or exceeds local or national electrical codes, this is a

"high" voltage connection).

4. Control wiring:

Connect between the control junction box and the control board by means of 6 x 1.5 mm 2 (16 AWG) wire in flex-

conduct. The numbers on the terminals in the board and in the junction box are identical.

Start-up and first operation

1. Make sure all the electric wiring is correct, according to the enclosed drawings.

2. Switch the control & 24V circuit breakers and the motor protector to ON. The motor will start operating*.

The suction scanner shaft should turn clockwise and move towards the filter housing until it reaches limit switch "A". If

the motor rotates in the opposite direction, disconnect the electricity immediately and change the direction of the motor

rotation by changing between two phases.

The motor must stop when the magnetic disc reaches limit switch "A" and causes it to operate.

3. Operate a "dry" flushing cycle by pressing on the "TEST" push button. Make sure all flushing stages occur as described

in the filter description chapter of this manual.

4. Open the inlet valve to the filter, while the outlet valve remains closed or with an open by-pass valve (This will keep the

flow in the filter at a minimum), and operate a flushing cycle.

Make sure the exhaust valve opens and all stages of the flushing cycle are carried out. Attend to leakages, if any.

Close the 1/4" valve at the low pressure point of the pressure differential switch for 5 seconds. The PDS hand will move

to the red area and the filter will start the flushing process. Open the 1/4" valve.

5. Gradually open the outlet valve and/or close the by-pass valve. Operate the filter at the designed hydraulic conditions.

6. Set the timer for 6-8 hours.

7. Check and re-tight all bolts after the first week of operation.

•When using Control board type "C" (Relay type) it is necessary to press the "Test" push button in order to start the motor

operation for the first time.