Revise Date: 8/06/09 14 of 29

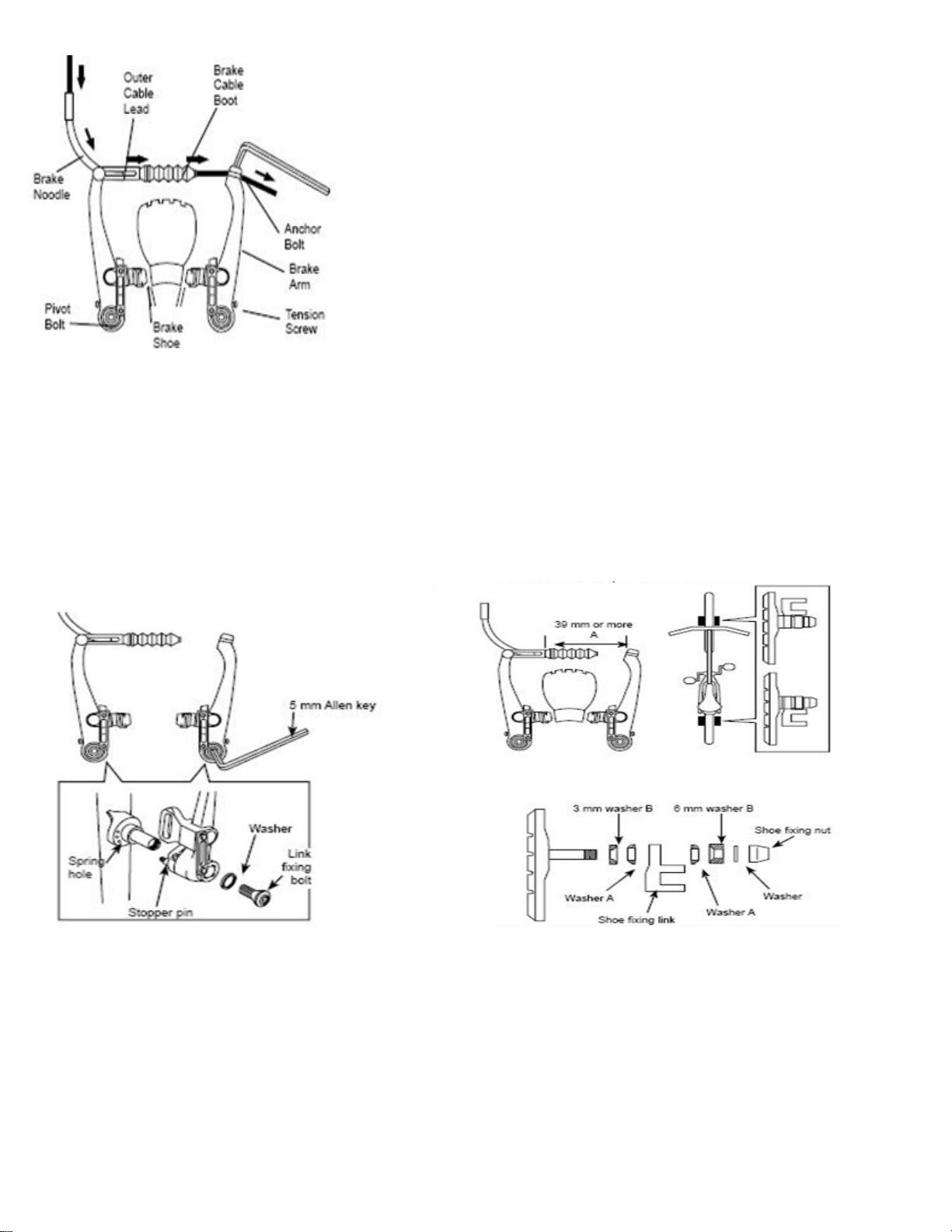

V-Style Brakes

If not already assembled, take the brake noodle from the parts box and

slide the cable through the larger opening. The cable housing will then

seat into the end of the noodle. Slide the cable through the cable lead on

the end of the left brake boot arm; this will cause the noodle to fit into the

lead. Slip the brake cable boot over the cable and position it between both

brake arms. Next loosen the 5mm anchor bolt at the end of the right

brake arm and slide the cable under the retaining washer. Pull the slack

out of the cable making sure a distance of 39mm or more remains

between the end of the lead and the start of the anchor bolt. Once the

cable is secured to the brake arms, engage the brake lever several times,

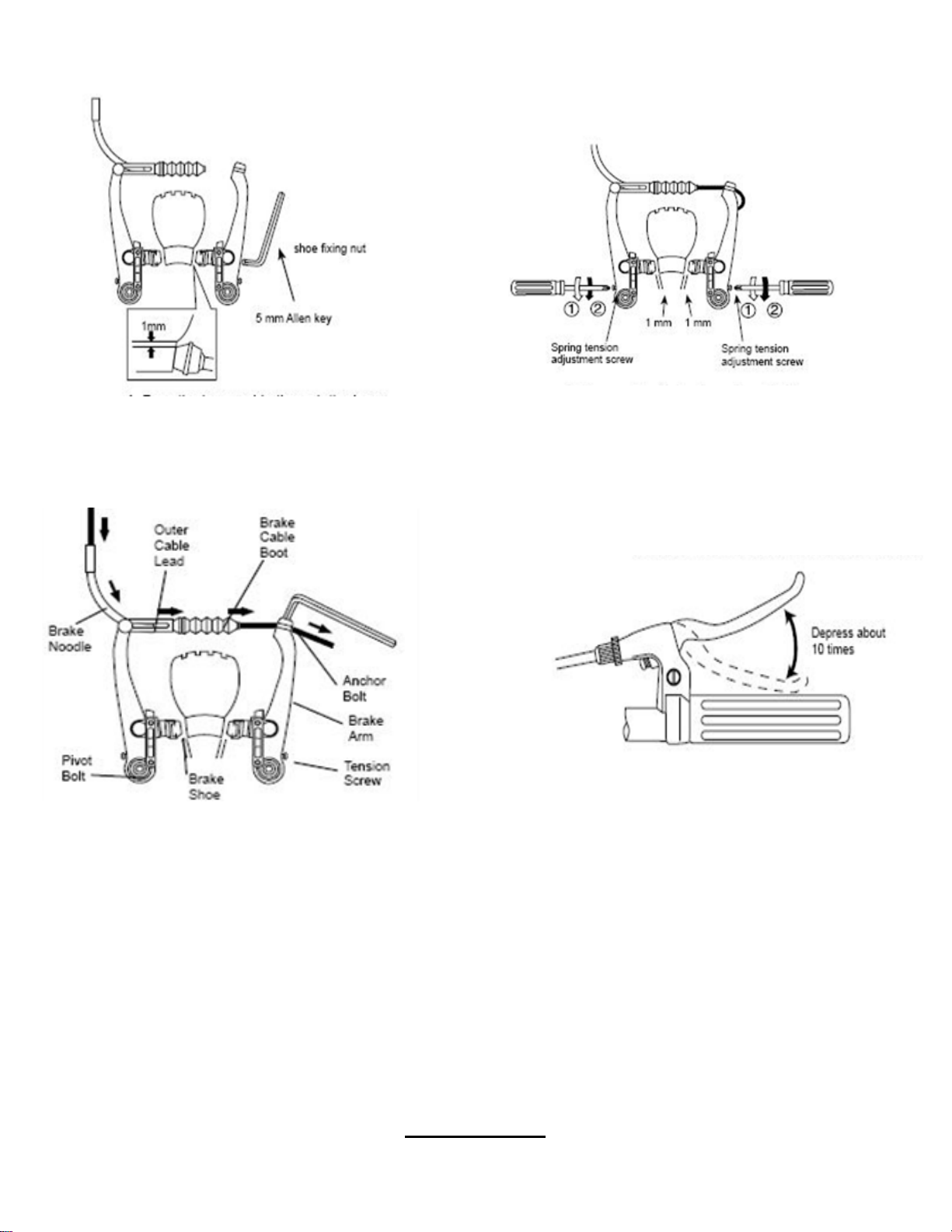

checking the position of the brake shoes at the rim. The brake shoes

should be 1mm away from the rim when in a relaxed position. When the

brake lever is engaged, the brake shoe should hit the rim flush (never the

tire) with the front brake pad touching the rim slightly before the rear.

This is called “toeing-in” your brake shoe. If this position is not achieved,

adjustments to the brake shoe are required. Loosen the brake shoe

hardware and reposition the brake shoe. It may take several shoe and

cable adjustments before the required position is accomplished.

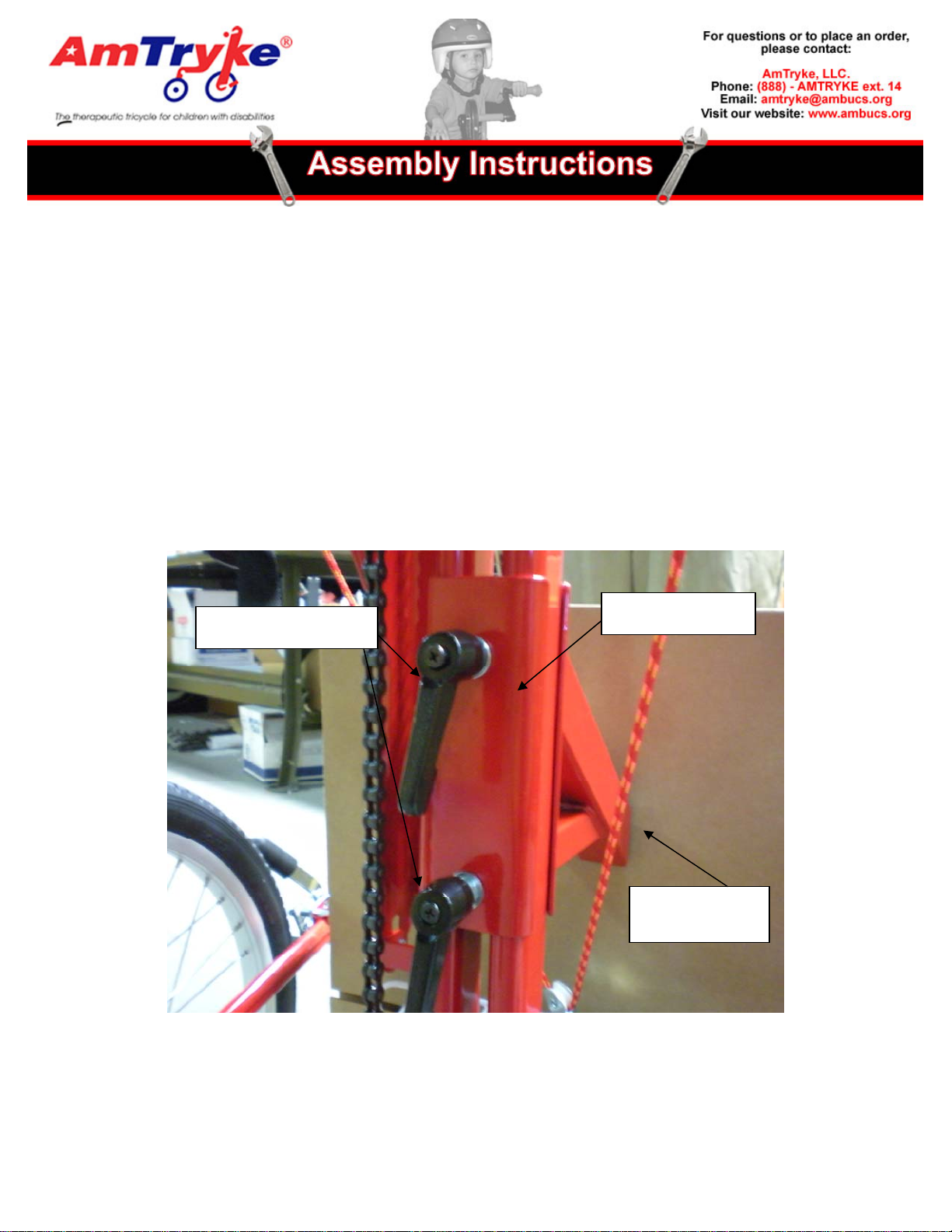

V-Brake

1. If fitted with V-Brakes, insert the brake body

into the center spring hole in the frame mounting

boss, and then secure the brake body to the frame

with the link fixing bolt.

2. While holding the shoe against the rim, adjust the amount

of shoe protrusion by interchanging the position of the B

washers (i.e. 6 mm and 3 mm) so that dimension A is kept at

39 mm or more.

3. While holding the shoe against the rim,

tighten the shoe fixing nut. 5. Adjust the balance with the spring tension adjustment

screws.