3

■

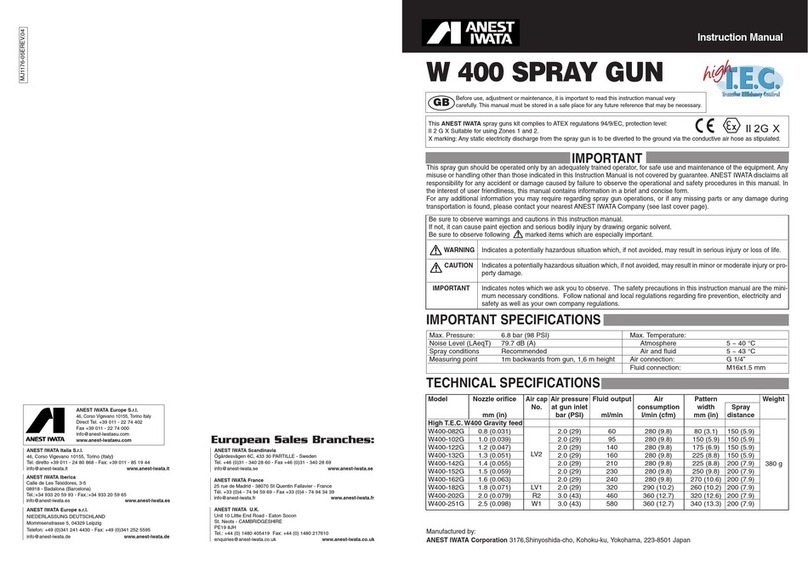

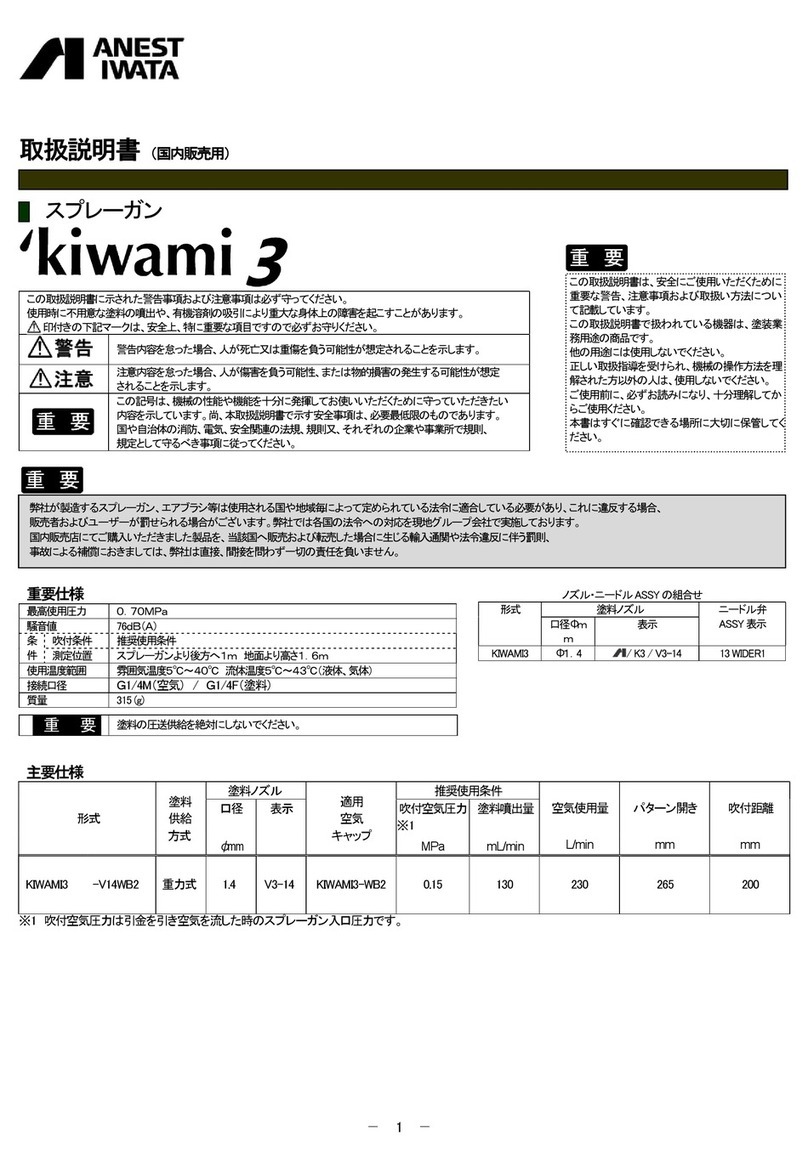

How to connect

・

Use clean airfiltered through air dryer and air filter.

If not,dirty air can cause paintingfailure.

・

Before using the spray gun for the first time, clean fluid passages with thinner to remove rust preventive oil.

If not cleaned, the rust preventive oil can cause paint failure,such as fish eyes.

・

Firmly connect hose or cup to spray gun.

If not, disconnection of hose or drop of cupcan cause bodily injury

.

Step1.Connect an air hoseto airnipple tightly.

Step2.Connect a containertofluid nipple tightly.

Step3.Flush the spray gun fluid passage with a compatiblesolvent.

Step4.Pour paint into container, testspray and adjust fluidoutputas wellas pattern width.

■

Maintenance and inspection

・

First releaseair and pressure fully according to item No. 3 of“Improper useof equipment” of WARNING on page 2.

・

Only an experienced person who is fullyknowledgeable of the equipment should perform maintenance and inspection.

・

pH value shall be 6 to 8, otherwise could cause corrosion.

・

Only use genuine ANEST IWATAparts for any maintenance or repairs.

Step-by-step procedure

Pour remaining paint to anothercontainer. Clean fluid passages and

Spray asmall amount of thinner into fluidpassages to clean them.

Incomplete cleaning canresultin poor spray pattern andcontaminatedpaint.

It is especially importantclean the gun fully and promptly after using two-component paint.

Clean each section withbrush soaked with thinner and wipe out with waste cloth.

Soaking whole spray gun in solvent may cause spray gun malfunction.

cap assy. itself forextended period may cause a defective spray pattern.

When cleaning, never scratchtheaircapassy., fluid nozzle, or fluid needle.

Avoid touching or damagingthetip of the fluid nozzle or needle.

3. Before disassembly, fully clean fluid passages.

Removefluidnozzle,usingaringspanner,boxwrenchoroptionalaccessoryspanner(code

93538601)

3. During disassembly,avoidscratchingtheneedleseatingsurface.

Either first remove thefluidneedle or holdthe triggerback while removing the fluid nozzle,

to protecttheseatingsurface.

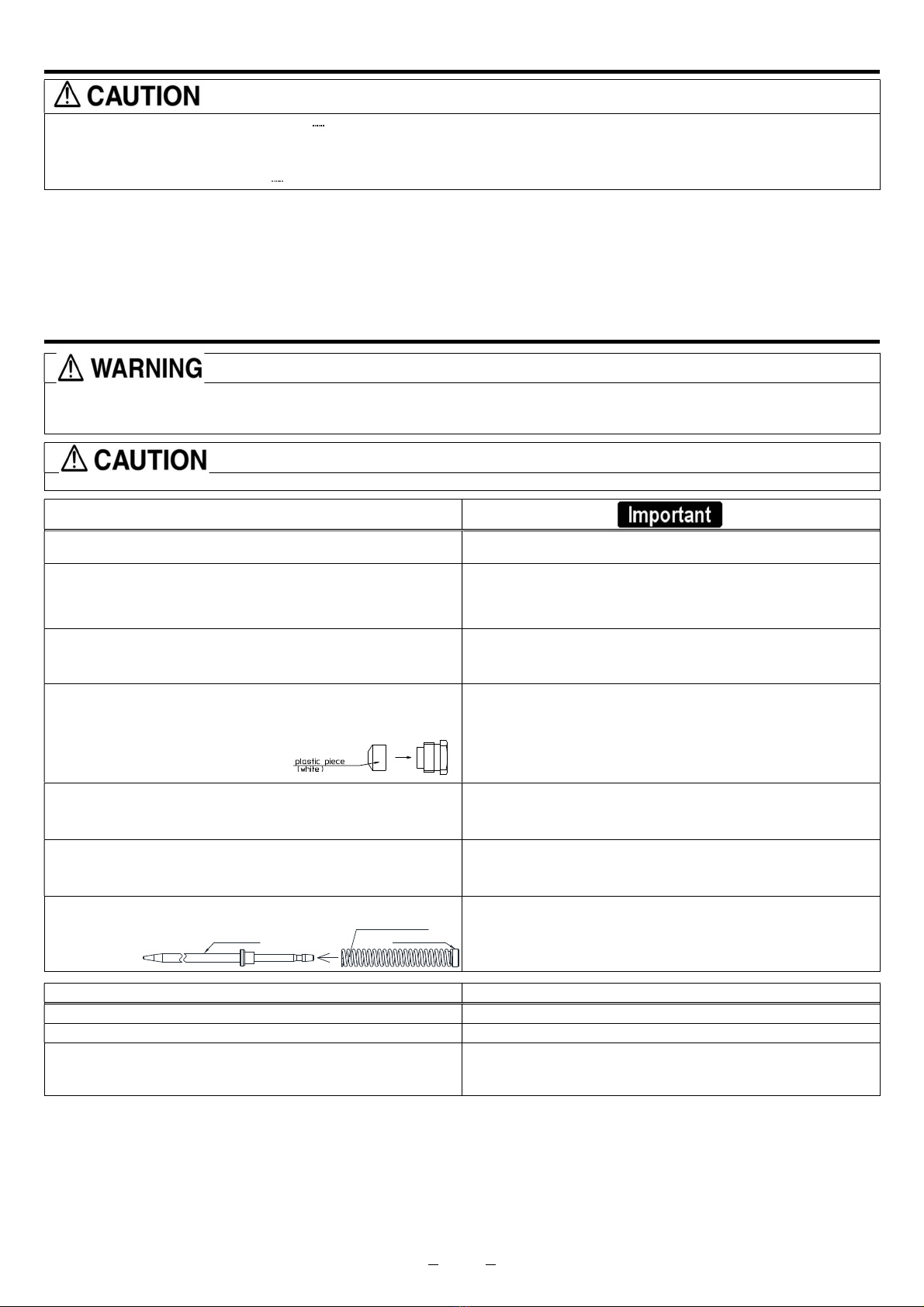

Ifyouneedtoadjustfluidneedlepackingset,firsttightenitbyhand(withfluidneedleinplace).

Then tighten it further about 1/6 turn (60-degree) by spanner.

Whenyouremoveneedlepackingset,donotleave the plastictipofthepackinginthespray

gun body.

If you tighten the fluid needle packing set too much, fluid needle will not move smoothly,

resultinginpaintleakage fromtip of the fluidnozzle. Trytoadjust it carefully whilepulling the

trigger and confirming smooth movement of the fluid needle.

If you tighten it toomuch, first fully loosen it and then retighten again carefully.

5. To assemble the air valve,first assemble the air valve, air valvespring, and fluid adj. guide

assy. together.Next, insertfluid needleinto fluid adj. guide assy., then fititto spray gun body

and screw fluid adj. guide assy. in.

Ifyou trytofit airvalvespring andairvalve tothespray gunbodywithoutthefluidneedle,

the air valve may not be fitted correctly and the packing inside fluid adj. guide assy. can

be damaged.

6. Before assembling the pattern adj. assy. or air adj. assy. back on to the gun body, fully turn

the adjustment knobs counterclockwiseto open.Onceinthegun body thepatternadj. knob

and air adj.knob can be tightened.

6. If pattern adj. knob or air adj. knob is not fullyopened when tightening into gunbody,thetip

of it can contact anddamage the seating surface.

7. When you assemble the needle spring on the fluid needle, the plastic tip should be on the

opposite sideasthefluidneedletip.

7. If plastic tip is on the wrong side, it may not operate normally.Incorrectinstallation ofthe

needle spring may cause a heavy triggerpull.

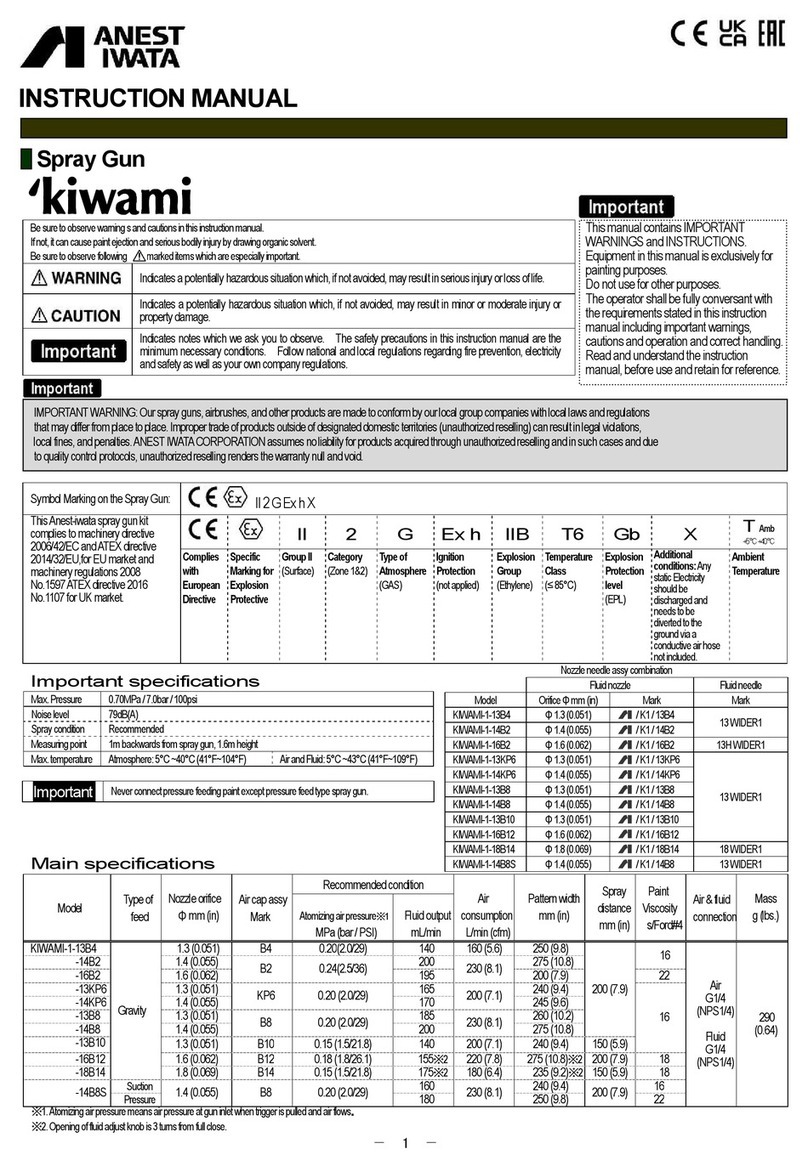

1. Eachhole passage of air cap assy and fluid nozzle Replace if it iscrushed or deformed.

2. Packing andO ring Replace if it isdeformed or worn out.

3. Leakage from seatingsurfacebetween fluid nozzle and fluid needle Replace them ifleakage does not stop after fully cleaning the fluid nozzle and needle.

If you replace the fluid nozzle or fluid needle only, ensure they fully match and confirm that

thereisnoleakage.

Fluidneedle

Needlespringassy

Plastictip