24

We stronglyadvise the use of a class B autoclave.

All other methods of sterilisation must be avoided.

Read the instructions for use provided by the autoclave manufac-

turer.

Maintain the space between the bags and do not overload the

autoclave.

Only sterilise instruments that have been predisinfected, cleaned,

lubricated and tested.

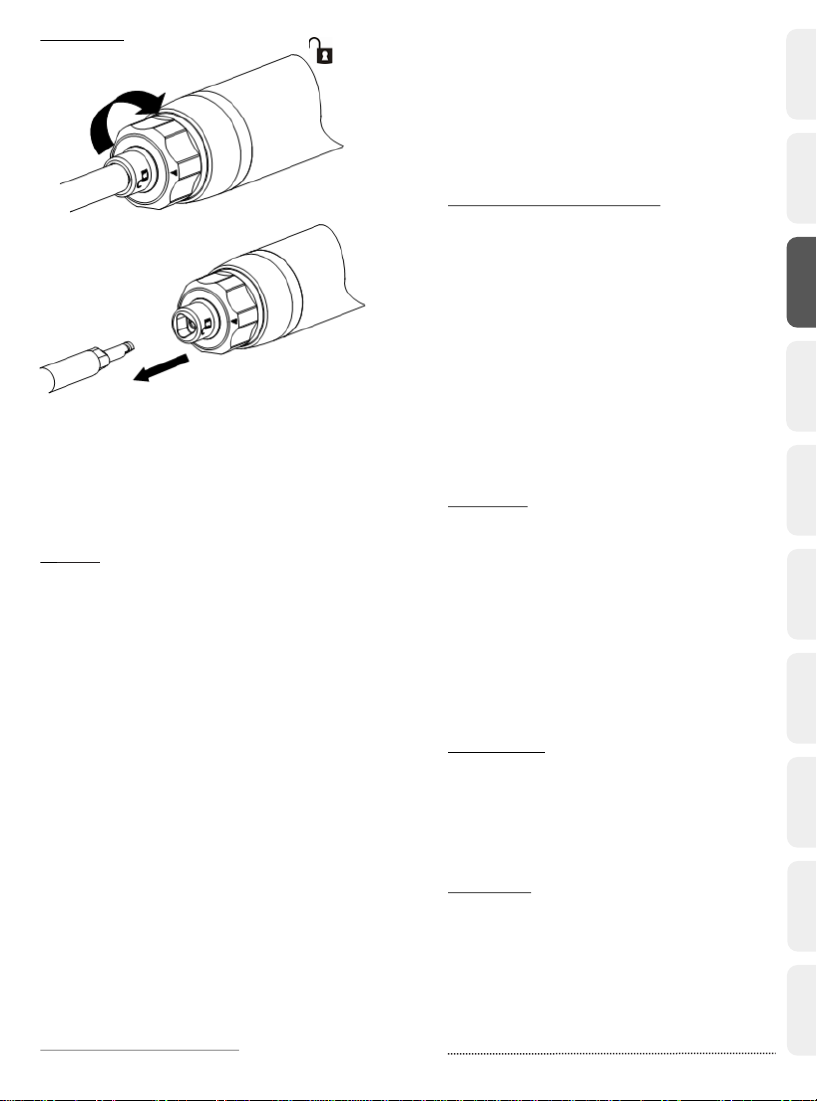

Remove the instruments from the MD Impactor before sterilisa-

tion (See Section 5.5).

Make sure that the MD (Impactor + Instruments) do not have any

areas of corrosion or cracks, and checkthat it is working properly.

Ensure that the MD (Impactor + Instruments) are dry; if necessary,

dry any residual waterusing medical quality pressurised air.

Use the sterilisation bags that are designed for the MD (Impactor+

Instruments) and for the autoclave, or use a sterilisation cassette.

Each bag should always only contain one MD or sterilisation tray.

In order to avoid any retention of water, place the bag in the

autoclave in such a way that any hollow parts are face

down.

If the pre-vacuum autoclave offers a number of different cycles,

choose a cycle for MD (at least 135°C at 2.13 bar (275°F at 30.88

psi) for 3 minutes with a drying timeof 16 minutes).

After every sterilisation cycle, check that there is no water re-

maining on the inside and outside of the packaging.

Check that the change in colour of the flow indicator is correct.

7.6. Storage:

Keep the MD (Impactor + Instruments) in the sterilisation

bags away from light, moisture and contamination of any

kind. Follow the recommendations of the packaging manufacturer.

The duration for which the MD (Impactor + Instruments) may be

kept after sterilisation may not exceed 1 month.

Label the MD (Impactor + Instruments), specifying the expiration

date. After the expiration date, repeat the cleaning and sterilisa-

tion cycle.

VIII. REPAIRS

In the case of device failure, please contact your authorised

distributor, or contact our after-sales service department directly.

Repairs may only be carriedout by an authorised repair service or

by the Anthogyr after-sales service department, and only using

original Anthogyr replacement parts.

For any servicing or repair work, the MD must be returned com-

plete and sterile with proof of sterility. It must be accompanied by

a document that describes the problem in question and also

includes the complete contact details of the practitioner who used

the device.

Exchange of replacement parts is possible for 7 years after sales

discontinuation.

CONTACT DETAILS: AFTER-SALES SERVICE

AFTER-SALES SERVICE DEPARTMENT

Anthogyr

2237 Avenue André Lasquin -74700 Sallanches - FRANCE

Direct line: +33 (0)4 50 58 50 53

Mail: sav@anthogyr.com

IX. GUARANTEE

These MD (Impactor + Instruments) are guaranteed for parts and

labour against any defect in manufacture for a period of 12

months from the date of invoicing. This guarantee does not apply

to wear parts and does not cover transport costs. For claims to be

considered under the guarantee, please enclose a copy of the

invoice or the delivery note with the MD (Impactor + Instruments) .

Any modification of or addition to the product without the express

consent of Anthogyr will nullify this guarantee.

The guarantee shall become null and void if the technical instruc-

tions supplied with all of our equipment are not observed.

Anthogyr cannot be held responsible for damage and ensuing

damage resulting or possibly resulting from normal wear and

tear, incorrect use, cleaning or maintenance, non-compliance

with the provisions regarding use or connection, scaling or corro-

sion, impurities in the water supply system or abnormal chemical

or electrical effects, or non-compliance with the instructions for

use, maintenance or installation provided by Anthogyr, and other

manufacturer instructions.

E

D

Français

English (UK)

Deutsch

Español

Italiano

Português

Nederlands

中国的

25

English (US)

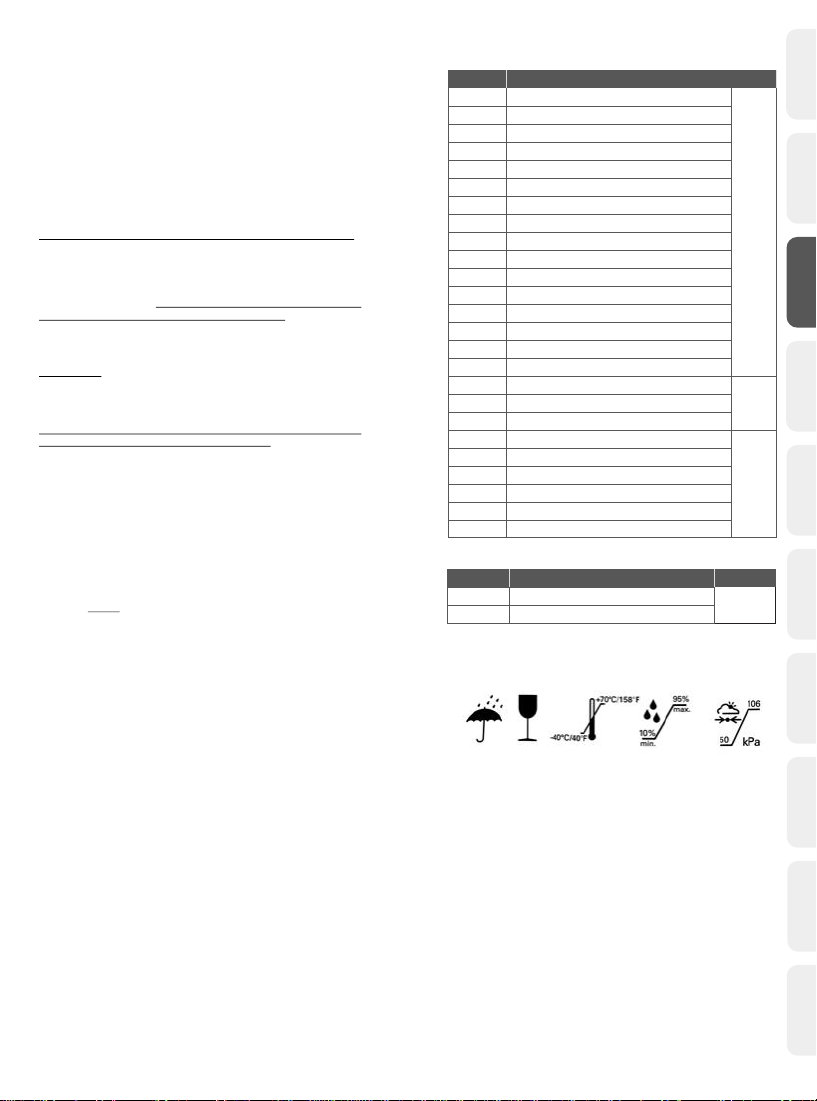

X. ACCESSORIES - INSTRUMENTS

Instruments

Accessories

XI. CONDITIONS OF STORAGE & TRANSPORT

XII. DISPOSAL OF THE PRODUCT

The MD (Impactor + Instruments) must be sterilised before dispos-

al in order to prevent the risk of third-party contamination.

On the basis of current knowledge, the product does not contain

any substances that are harmful to the environment. Observe

national legislation, standards and provisions with regard to

disposal.

References Designation

OSTSCC34 OsteotomeØ3.4 concavestraight

OSTEOSAFE Solution

OSTSCC40 OsteotomeØ4.0 concavestraight

OSTSCC46 OsteotomeØ4.6 concavestraight

OSTSCC52 OsteotomeØ5.2 concavestraight

OSTSCX34 OsteotomeØ5.2 convex straight

OSTSCX40 OsteotomeØ4.6 convex straight

OSTSCX46 OsteotomeØ4.0 convex straight

OSTSCX52 OsteotomeØ3.4 convex straight

OSTECC34 Osteotome Ø3.4 concave bayonet

OSTECC40 Osteotome Ø4.0 concave bayonet

OSTECC46 Osteotome Ø4.6 concave bayonet

OSTECC52 Osteotome Ø5.2 concave bayonet

OSTECX34 Osteotome Ø3.4 convex bayonet

OSTECX40 Osteotome Ø4.0 convex bayonet

OSTECX46 Osteotome Ø4.6 convex bayonet

OSTECX52 Osteotome Ø5.2 convex bayonet

OPIP100 Tip for abutment 0°/7°

SAFELOCK®

Solution

OPIP200 Tip for abutment 15°/23°

OPIP400 Tip for extra-orally cemented prosthesis

PERIO01 Cx right Fine Periotome

EXO SAFE Solution

PERIO02 Cx rightWide Periotome

PERIO03 Cx Ang. Vertical Periotome

PERIO04 Cx Ang. Horizontal Periotome

PERIO05 Cc right Fine Periotome

PERIO06 Cc right Medium Periotome

References Designation

1930X Lubricating spray All

solutions

1932X ISO type E connection tip