Operating manual

AQUA S.p.A. ENGLISH Page 2

SUMMARY

INTRODUCTION......................................................................................................................................................................................3

RESPONSABILITY LIMITATIONS.......................................................................................................................................................3

VALIDITY.............................................................................................................................................................................................3

ENVIRONMENT AND SAFETY REQUESTS...........................................................................................................................................5

ICONS AND SUGGESTIONS IN THE FOLLOWING INSTRUCTIONS ................................................................................................5

POTENTALLY EXPLOSIVE AREA USE..............................................................................................................................................5

SAFETY VALVE ..................................................................................................................................................................................5

SUITABILITY AND CHEMICAL COMPATIBILITY CHECK...................................................................................................................5

ELECTROMAGNETIC COMPATIBILITY NOTE:..................................................................................................................................5

NOISE LEVELS...................................................................................................................................................................................6

VIBRATIONS.......................................................................................................................................................................................6

HOT SURFACE...................................................................................................................................................................................6

TRANSPORT, MOVEMENT AND STORAGE..........................................................................................................................................6

RECEIVEMENT CHECK......................................................................................................................................................................6

STORAGE...........................................................................................................................................................................................6

TRANSPORTATION AND RAISING ....................................................................................................................................................7

STANDARD PACKAGE.......................................................................................................................................................................7

DESCRIPTION.........................................................................................................................................................................................7

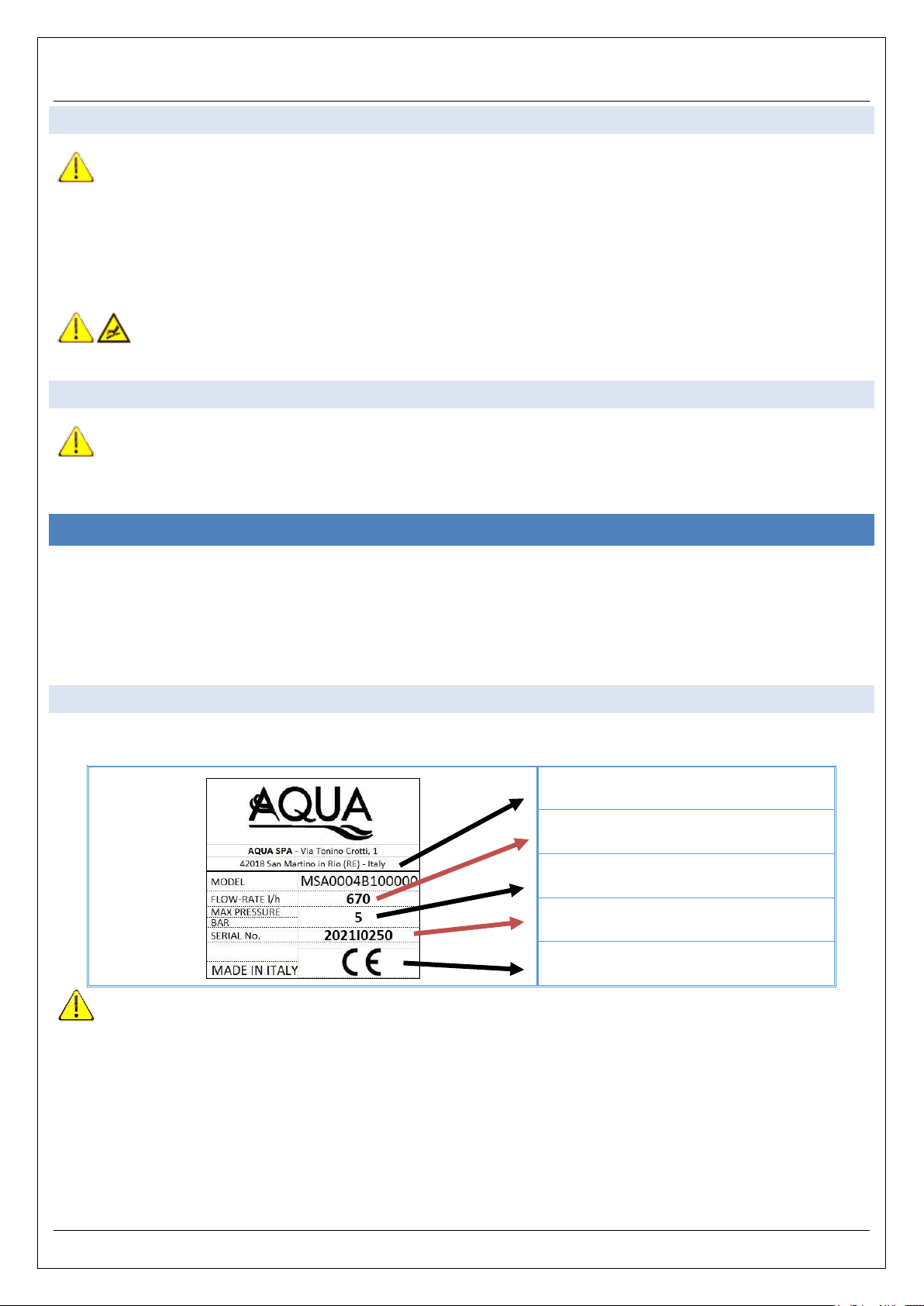

DATA STICKER...................................................................................................................................................................................7

LIQUID END MATERIALS ...................................................................................................................................................................8

FUNCTION PRINCIPLES ....................................................................................................................................................................8

USE RESTRICTIONS..........................................................................................................................................................................9

PREDICTED USE................................................................................................................................................................................9

RATIONALLY PREDICTED WRONG USE ..........................................................................................................................................9

FORBIDDEN USE..............................................................................................................................................................................10

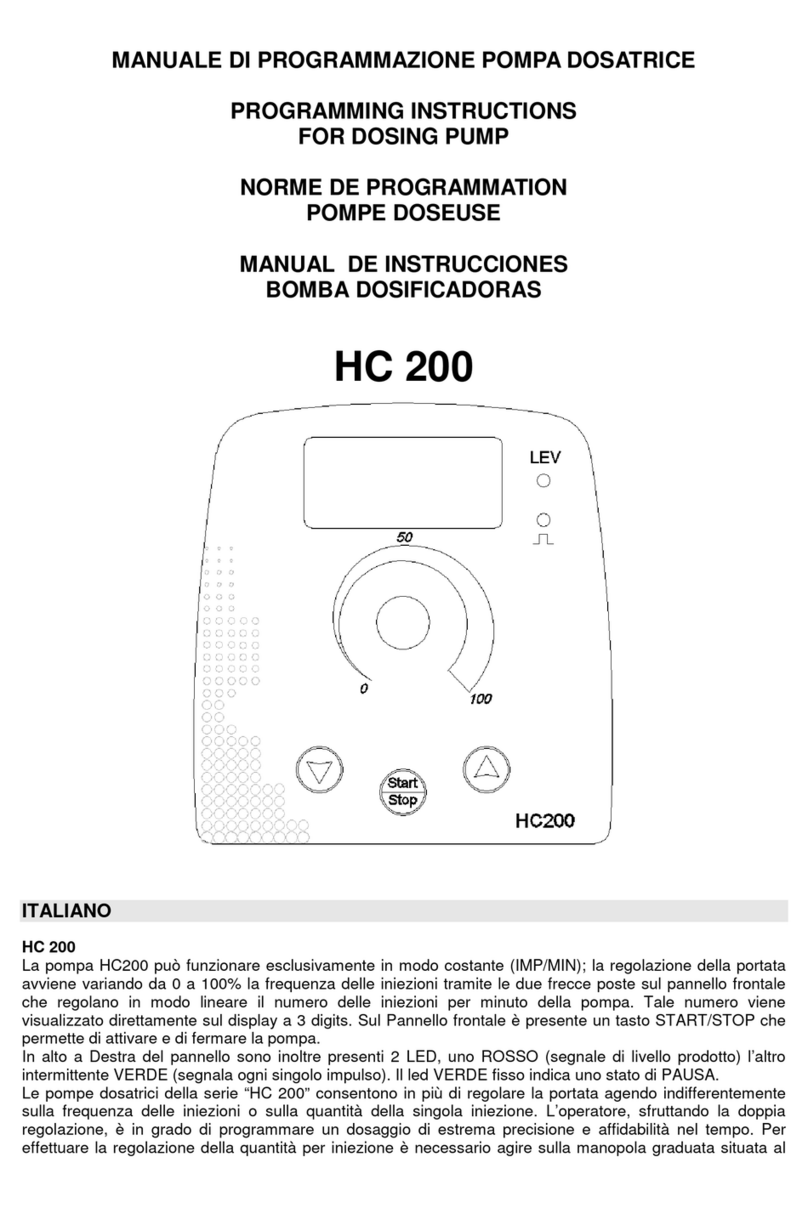

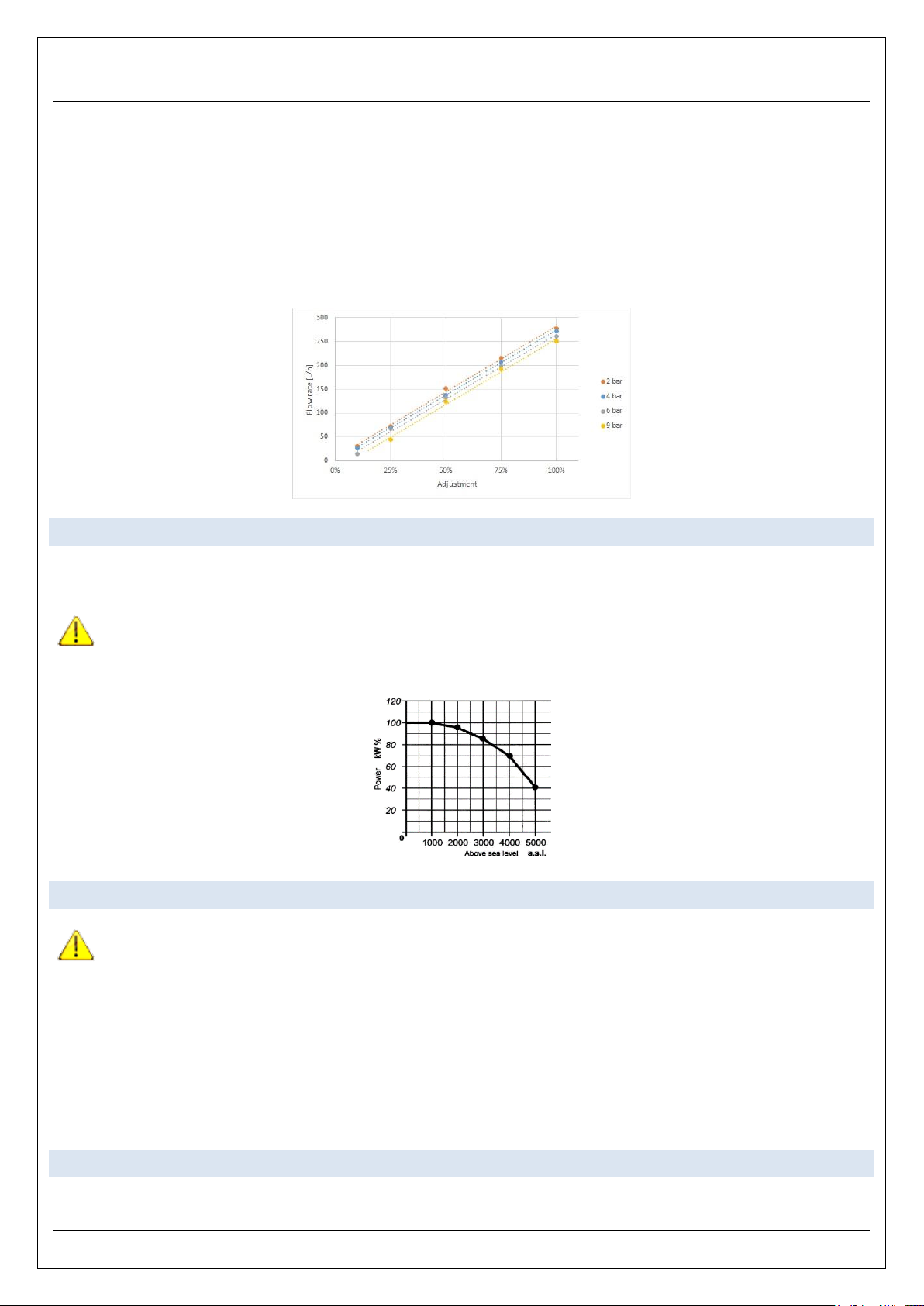

FLOWRATE ADJUSTMENT SYSTEM...............................................................................................................................................10

MANUAL ADJUSTMENT WITH KNOB AND LINEAR VERNIER........................................................................................................10

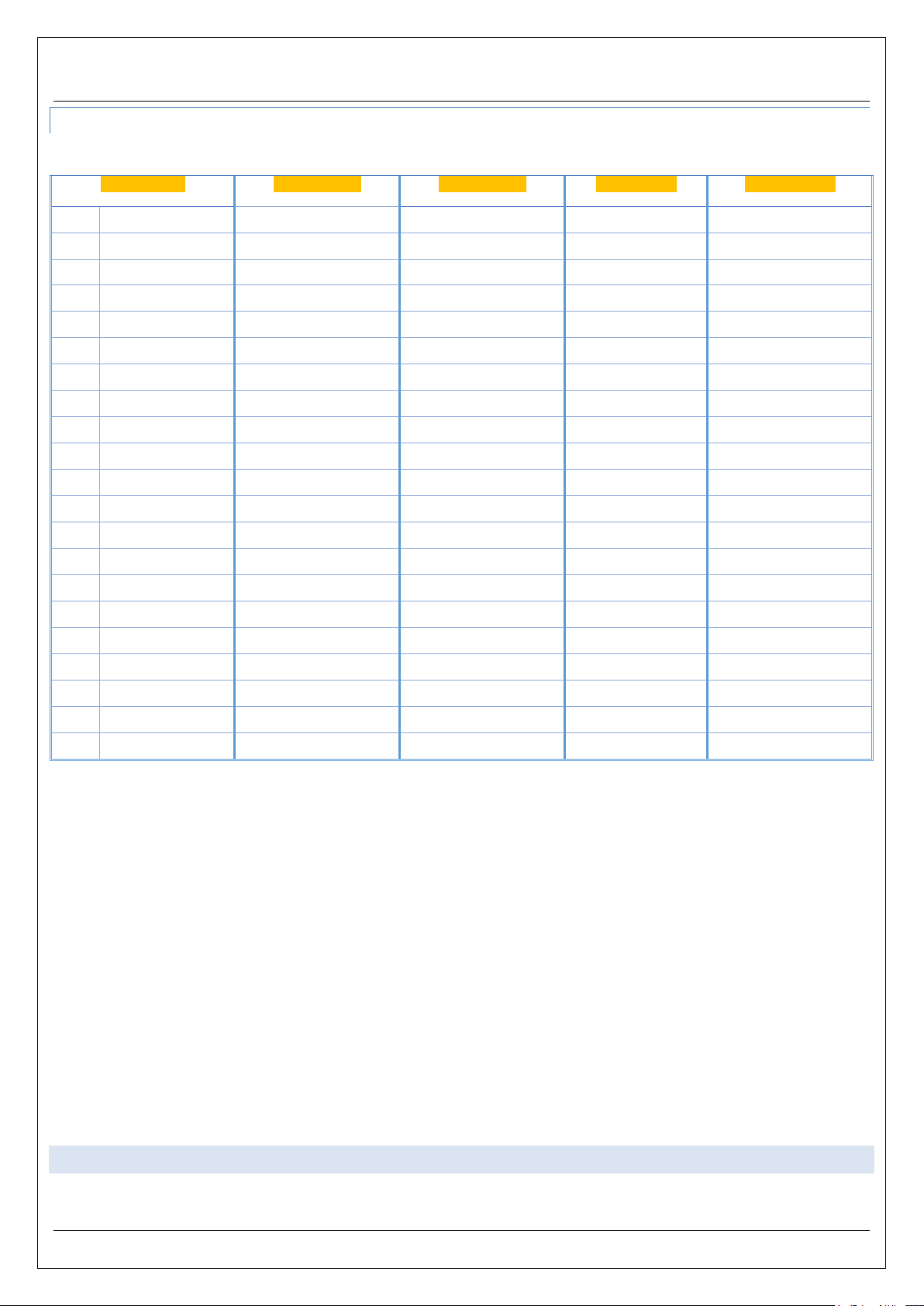

TECHNICAL DATA............................................................................................................................................................................10

INSTALLATION.....................................................................................................................................................................................11

GENERAL INDICATIONS:.................................................................................................................................................................12

CONNECTION TO PLANT PIPES .....................................................................................................................................................12

ELECTRIC MOTOR CONNECTION ..................................................................................................................................................12

HYDRAULIC PART INSTALLATION..................................................................................................................................................13

SUCTION PIPE..................................................................................................................................................................................14

PROTECTION BY IMPURITIES:........................................................................................................................................................16

LIQUIDS WHIT GAS EMISSIONS:.....................................................................................................................................................16

CALIBRATION POT...........................................................................................................................................................................16

DISCHARGE PIPE.............................................................................................................................................................................16

SAFETY VALVE ................................................................................................................................................................................17

PULSATION DAMPENER..................................................................................................................................................................18

MANOMETER....................................................................................................................................................................................18

START 18

PRELIMINARY CHECKS...................................................................................................................................................................18

STARTING SEQUENCE....................................................................................................................................................................18

MAINTENANCE PROGRAM..............................................................................................................................................................18

PERIODICAL VISUAL CHECK ..........................................................................................................................................................19

PRECAUTIONS BEFORE MAINTENANCE.......................................................................................................................................19

VALVE GROUP REPLACEMENT......................................................................................................................................................19

DIAPHRAGM REPLACEMENT..........................................................................................................................................................20

PUSHING ROD SEAL REPLACEMENT ............................................................................................................................................20

GEARBOX OIL CHECK AND REPLACEMENT. ................................................................................................................................21

MALFUNCTIONS AND possible SOLUTIONS .....................................................................................................................................21

DECOMMITIONING, Disposal and demolition.....................................................................................................................................22

DECOMMITIONING...........................................................................................................................................................................22

DISPOSAL AND DEMOLITION..........................................................................................................................................................22

WARRANTY ..........................................................................................................................................................................................24

REPAIRS TO AQUA ASSISTANCE CENTER....................................................................................................................................24