INITIAL START-UP

1. Fan Blade Does Not Spin

2. No Fog but Blade Spins

3. Hard To See Fog Output

NO FOG

1. Stiff/Locked Motor Shaft

2. Bad Motor

3. Clogged Flowmeter Panel

4. Clogged In-Line Strainer

5. Clogged Water Solenoid

6. Clogged SST Feed Tube

POOR QUALITY FOG

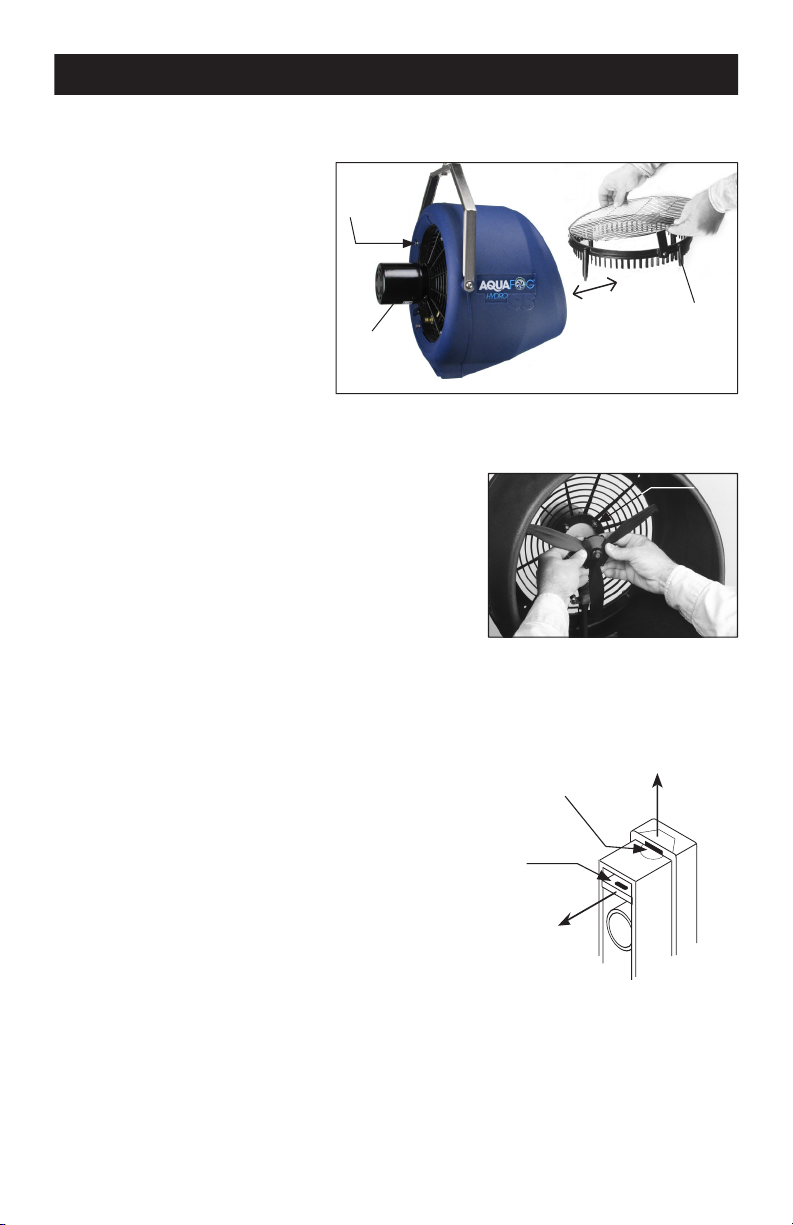

1. Clogged Blade Assembly

2. Misaligned Feed Tube

3. Stiff Motor Shaft

4. Loose Blade Assembly

FAN DOES NOT SPIN

1. Stiff/Locked Motor Shaft

2. Bad Motor

3. Bad Controller

MOTOR OVERHEATING

1. Stiff/Locked Motor Shaft

Issue

Corrective Action

TROUBLESHOOTING

1. Check power supply. If using a controller, try bypassing it and plug unit

directly into a power outlet. Check for a faulty power cord.

2. Open Flowmeter’s needle valve [counterclockwise]. Check for water

pressure starting at the source and temporarily disconnect water line

ttings to locate the issue. If using a controller and the water solenoid is

not opening, check the power from controller to solenoid.

3. As fog evaporates, it becomes transparent. Dry air and propulsion

evaporates fog quickly. As humidity increases, evaporation slows and fog

becomes more apparent. A dark background helps to see the output.

1. Remove blue plugs and lubricate motor bearings while manually rotating

shaft back and forth until loose.

2. If motor smells, doesn’t start (with a direct power supply) or shaft will not

loosen up, replace motor.

3. Remove valve and clean. If problem reoccurs, perform a thorough

cleaning inside the owmeter body.

4. Remove strainer cap, screen, and O-ring. Flush clean with water.

5. Remove the top clip and disassemble the valve’s brass body for cleaning.

6. Remove Feed Tube and ream with a small wire. Clean and reinstall.

1. Remove and clean out the rear reservoir and the blades’ passageways.

2. Adjust feed tube so its water stream ows into the blades rear reservoir.

3. Remove blue plugs and lubricate motor bearings while manually rotating

shaft back and forth until loose.

4. If the blade can spin without motor shaft, reposition the blade and tighten

the setscrew on the at of the shaft, replace assembly if necessary.

1. Remove blue plugs and lubricate motor bearings while manually rotating

shaft back and forth until loose.

2. If motor smells, doesn’t start (with a direct power supply) or shaft will not

loosen up, replace motor.

3. Check controller for loose connections, test unit’s motor and controller

independently with a direct power supply for process of elimination.

1. Remove blue plugs and lubricate motor bearings while manually rotating

shaft back and forth until loose.