3

11. Keep ngers away from a running unit; fast

moving and hot parts will cause injury and/or

burns.

12. If the equipment starts to vibrate abnormally,

STOP the motor and check immediately for

the cause. Vibration is generally an indication

of trouble.

General safety

Since the mobile ORSM uses high-speed

components to atomize liquids, the following safety

precautions must be observed at all times:

1. Read all manuals included

with this product. Be familiar

with the product and controls.

2. The ORSM is intended to be

used on level ground. Test for stability before

operation.

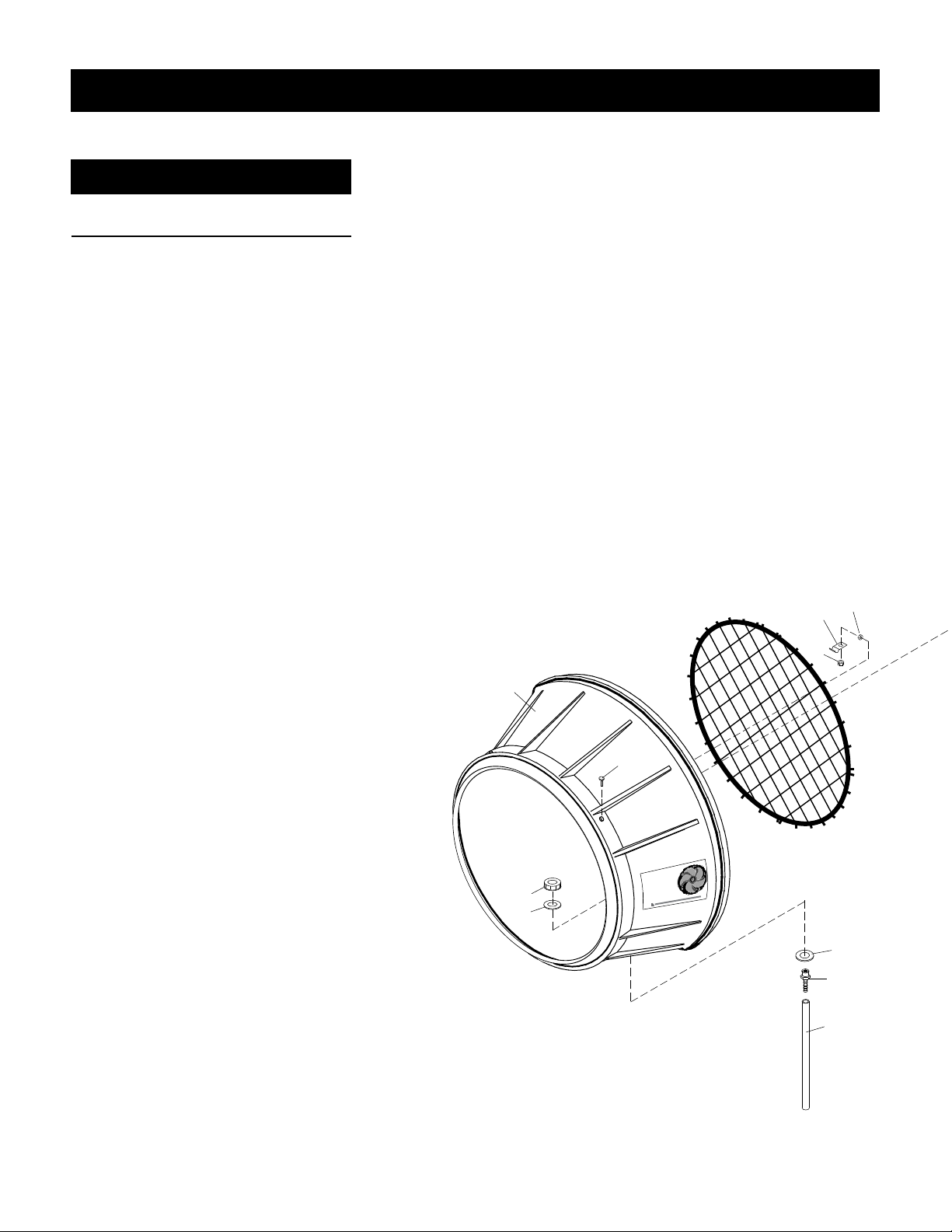

3. Always operate ORSM with it's safety guards

and housing securely attached.

4. Follow United States Environmental Protection

Agency (EPA) guidelines and regulations when

fogging pesticide or chemical solutions.

5. Follow all local electrical and safety codes

as well as the United States National

Electrical Codes (NEC) and Occupational Safety

and Health Act (OSHA).

6. Only persons well acquainted with these rules

of safe operation should be allowed to use the

atomizer.

7. Keep visitors away and NEVER allow children in

the work area.

8. Use of an extension cord for the ORSM

is not recommended. If necessary, refer

to the A.W.G chart in the following section or

consult a certied electrician.

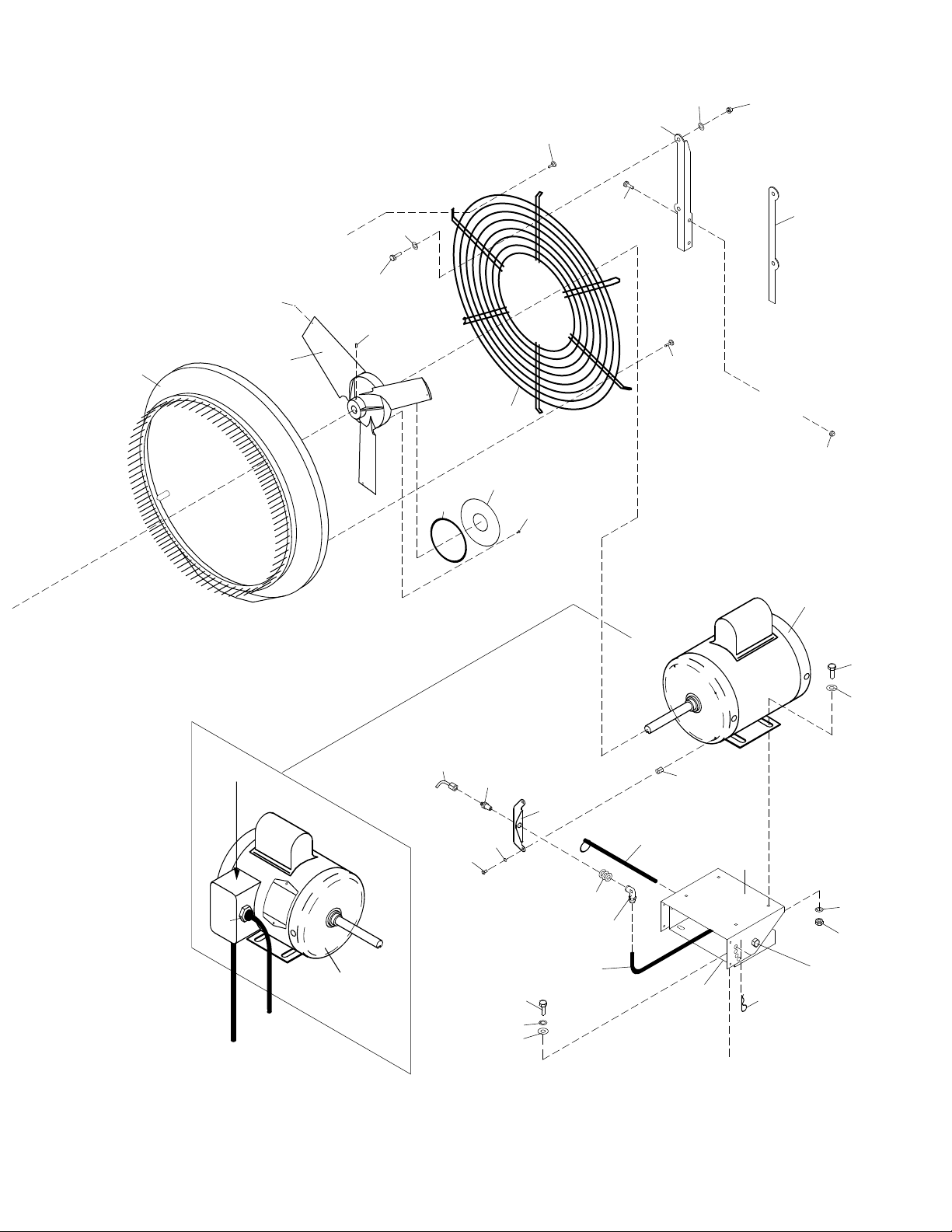

9. Before each use, inspect blade assembly

and electrical components for signs of damage,

deterioration, weakness or leakage. Repair or

replace defective items before using.

10. Check all fasteners at frequent intervals for

proper tightness.

MOTORS, ELECTRICAL EQUIPMENT, AND

CONTROLS CAN CAUSE ELECTRICAL

ARCS THAT WILL IGNITE FLAMMABLE

LIQUID OR GAS. NEVER OPERATE

OR REPAIR IN OR NEAR FLAMMABLE LIQUID OR GAS.

NEVER STORE FLAMMABLE LIQUIDS OR GASES IN THE

VICINITY OF THE ATOMIZER.

POTENTIALLY HAZARDOUS

CHEMICAL VAPORS

1. Avoid exposure to

hazardous chemicals. Wear a

respirator and protective

clothing: goggles, gloves, long

sleeves and pants, etc.

2. Read and understand all directions and safety

precautions before operating CRSM. Follow all

E.P.A. guidelines for chemical/pesticide use.

3. NO humans or animals should be in the area

during chemical/pesticide application.

SERIOUS INJURY OR DEATH COULD OCCUR!

4. Follow chemical manufacturer's

instructions regarding length of restricted

entry interval (REI).

WARNING

DANGER

DANGER

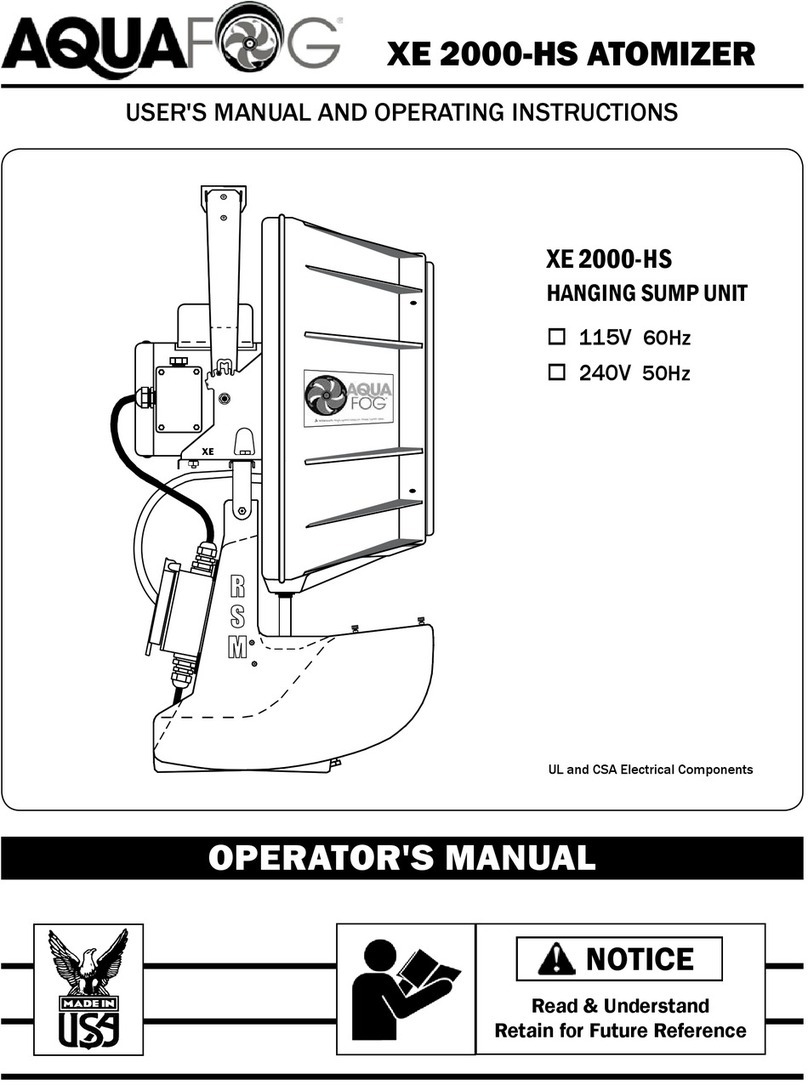

A motionless atomizer may

appear safe, but its blade

could suddenly begin high-

speed rotation without

warning as a result of

control programming.

When the ORSM is automated by controls,

warning signs should be posted near the high-

speed equipment.

Disconnect and lock out power source to inspect

or service the unit.

NEVER OPERATE UNIT WITHOUT

THE HOUSING INSTALLED.

WARNING

HIGH-SPEED ROTATION

DANGER

KEEP SAFETY GUARDS ATTACHED

AND IN GOOD WORKING CONDITION

Fogging Precautions