Service Support Spirit

Unique Solution WWW.ARCBRO.COM

Contents

Technical Support ...................................................................................................................... 2

Technical Parameters................................................................................................................. 5

Notes ......................................................................................................................................... 6

Safety......................................................................................................................................... 7

1.Information for your safety............................................................................................... 7

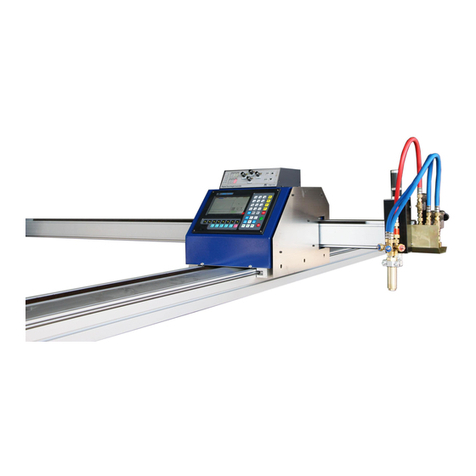

1. Stinger Description.............................................................................................................. 9

1.1. What is Stinger?........................................................................................................... 9

1.2. Application................................................................................................................... 9

1.3. Programming and Nesting .......................................................................................... 9

2. Packing List...........................................................................................................................10

2.1. Introduction.................................................................................................................10

2.2. Packing List ................................................................................................................10

3. Installation.............................................................................................................................12

3.1 Mechanical Assemble Steps .......................................................................................12

3.2 Basic assemble steps: ................................................................................................13

Step: Unpack the equipment box and remove all items....................................................14

Step 1: Assemble the legs of the Gantry Frame................................................................15

Step 2: Assemble the legs of the Water Table. ..................................................................16

Step 3: Assemble each Side Board onto the frame leg ....................................................18

Step 4: Install longitudinal drag chain trough. ...................................................................18

Step 5: Connect the machine Base to the Ground............................................................19

Step 6: Air pressure gauge part assemble........................................................................20

Step 7: Plasma cutting part assemble...............................................................................21

Step 8: Pneumatic cutting part installation. .......................................................................22

Step 9: Flame cutting part installation. ..............................................................................27