Page 1 of 2

50-60 Hanover Road, Florham Park, New Jersey 07 32

ASCO Valves

MCMXCIII All Rights Reserved. Printed in U.S.A.

Installation & Maintenance Instructions SERIES

Form No.V6860R1

-WAY DIRECT-ACTING QUICK EXHAUST SOLENOID VALVES 8 17

UNIVERSAL OPERATION - BRASS OR STAINLESS STEEL CONSTRUCTION

1/4 NPT - AIR OR INERT GAS SERVICE

IMPORTANT: See separate solenoid installation and maintenance

instructions for information on: Wiring, Solenoid Temperature,

Causes of Improper Operation, Coil, or Solenoid Replacement.

ESCRIPTION

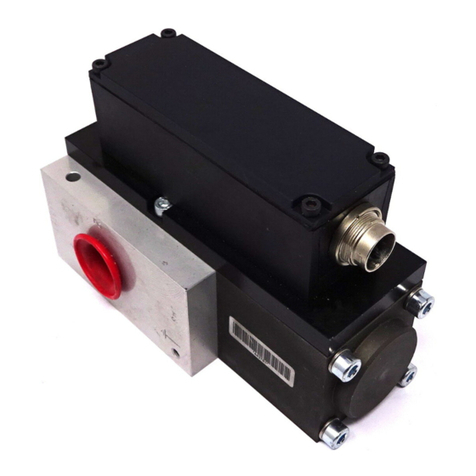

Series 8317 valves are 3-way direct-acting with quick exhaust

solenoid valves designed for air or inert gas service. Valve bodies are

ade of rugged brass or stainless steel. The valves ay be provided

with a low power or intrinsically safe solenoid.

OPERATION

Universal Pressure at 2 (Normally Closed Operation)

Solenoid e-energized: Pressure at 2 is closed, flow is fro cylinder

1 to ain exhaust 4. Pilot exhaust 3 is open.

Solenoid Energized: Flow is fro pressure 2 to cylinder 1. Main

exhaust 4 and pilot exhaust 3 are closed.

Universal Pressure at 3 (Normally Open Operation)

Solenoid e-energized: Flow is is fro pressure 3 cylinder 1. Main

exhaust 4 and pilot exhaust 2 are closed.

Solenoid Energized: Pressure at 3 is closed, flow is fro cylinder 1 to

ain exhaust 4. Pilot exhaust 2 is open.

Note: This construction is interchangeable fro Pressure at 2 to

Pressure at 3 (or vice versa) by changing the piping.

IMPORTANT: Minimum operating pressure differential 5 psi.

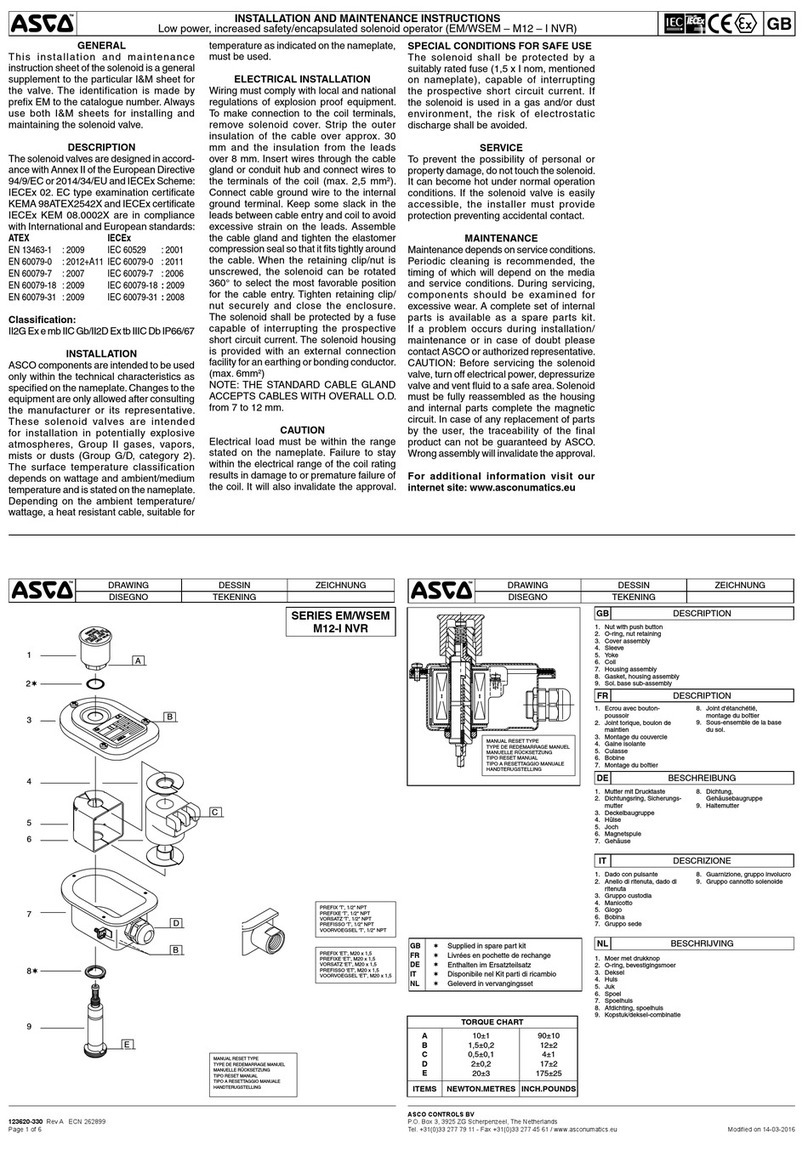

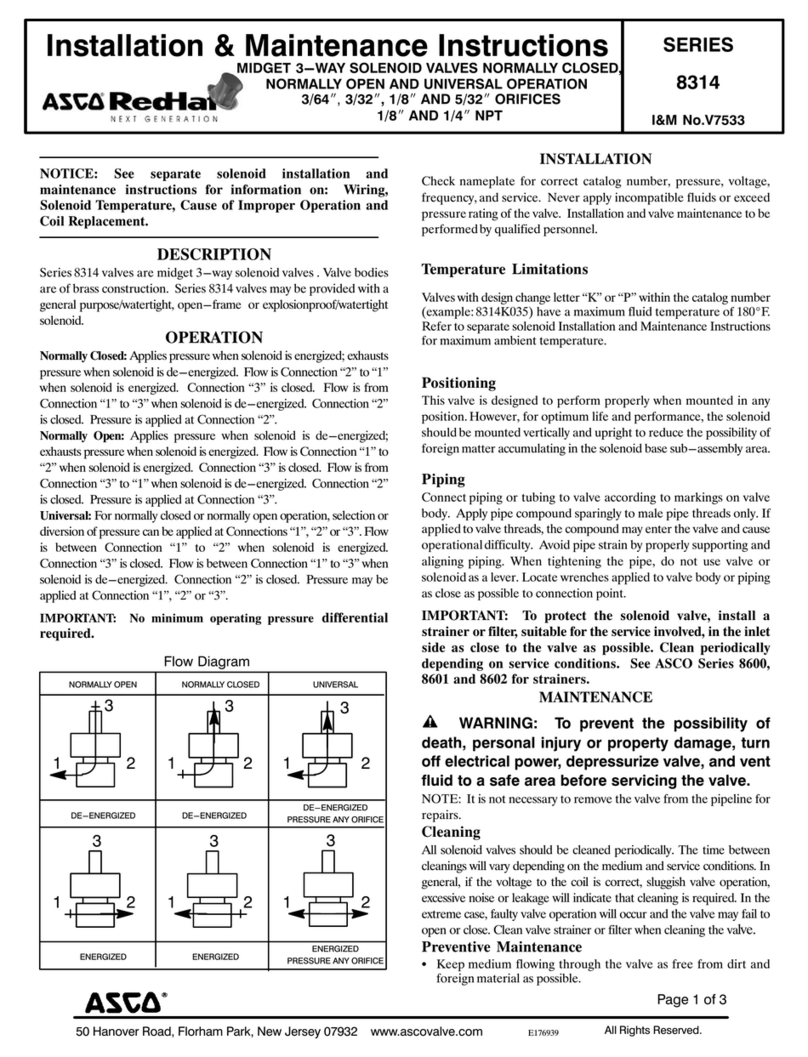

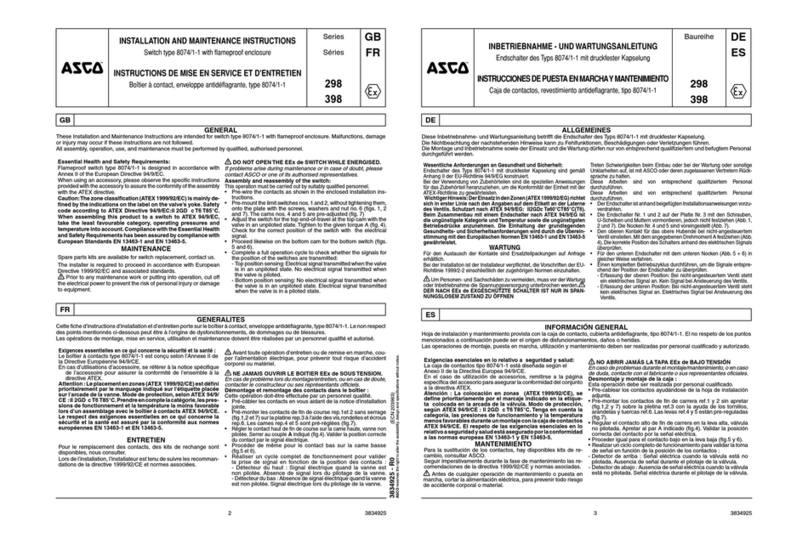

Flow iagrams

Universal - Pressure at 2

De-energized

Universal - Pressure at 3

Energized

De-energized

Energized

12

3

4

3

33

1

11

2

22

4

44

Main

Exh. Pilot

Exh.

INSTALLATION

Check na eplate for correct catalog nu ber, pressure, voltage,

frequency, and service. Never apply inco patible fluids or exceed

pressure rating of the valve. Installation and valve aintenance to be

perfor ed by qualified personnel.

Temperature Limitations

Fluid and a bient te perature range: -4 F to +140F.

Future Service Considerations

Provision should be ade for perfor ing seat leakage, external

leakage, and operational tests on the valve with a nonhazardous,

nonco bustible fluid after disasse bly and reasse bly.

Positioning Valve ay be ounted in any position.

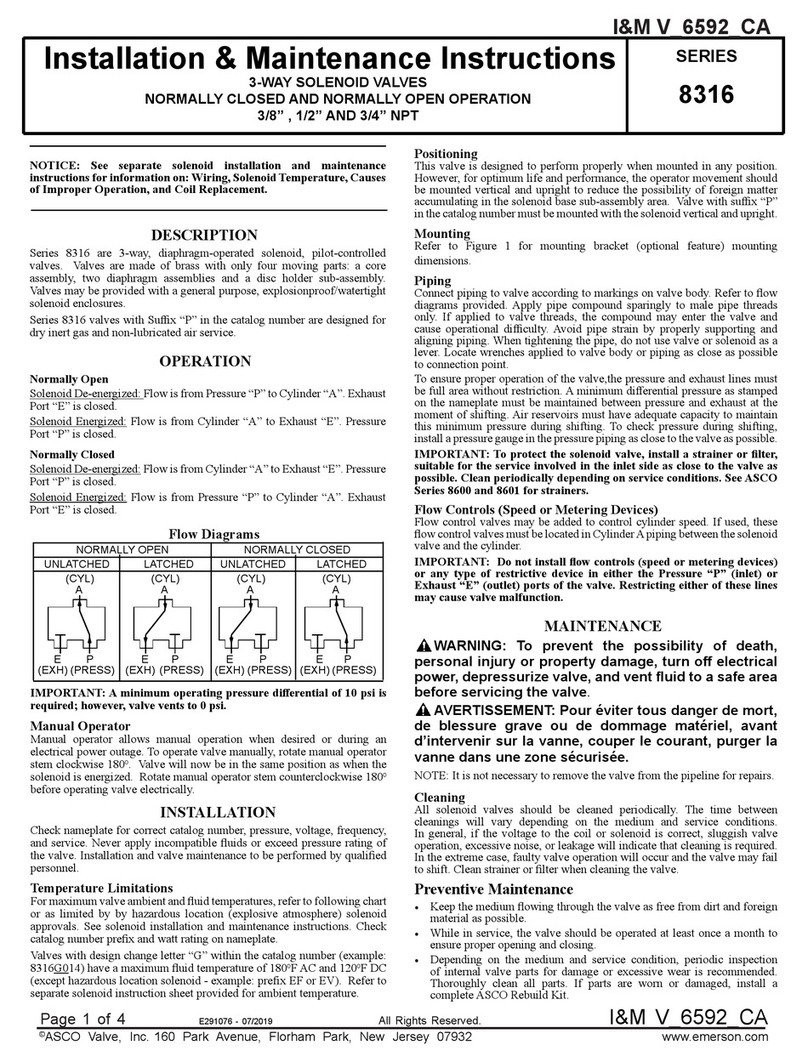

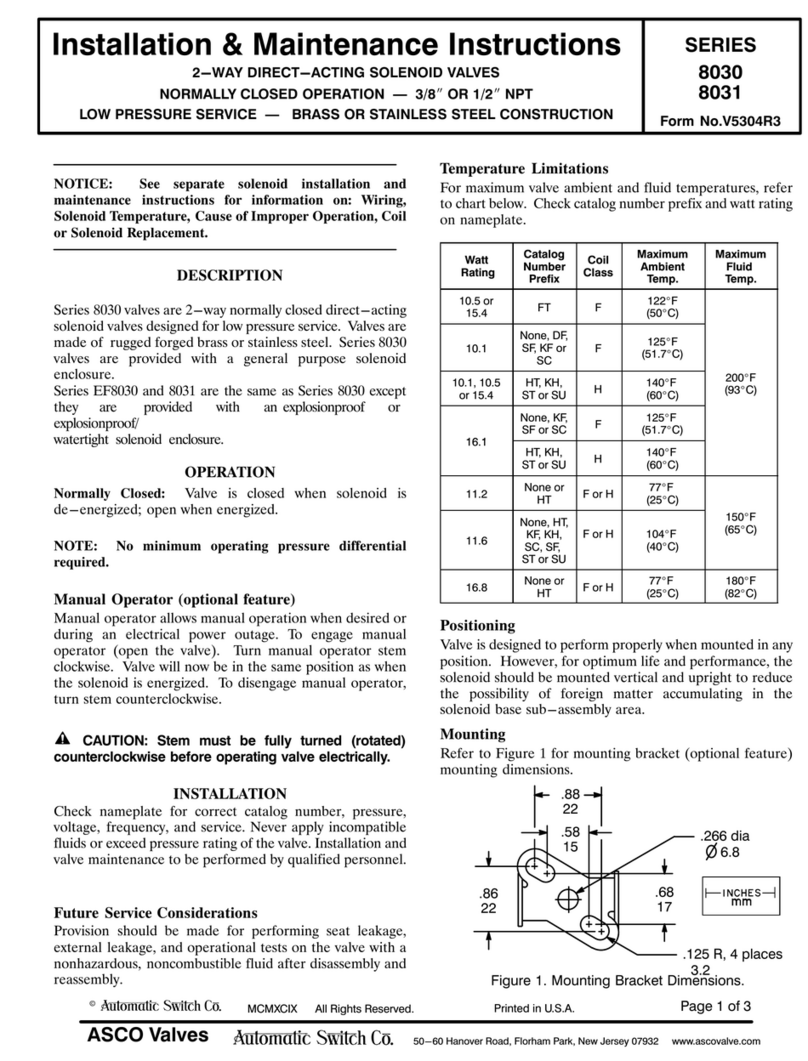

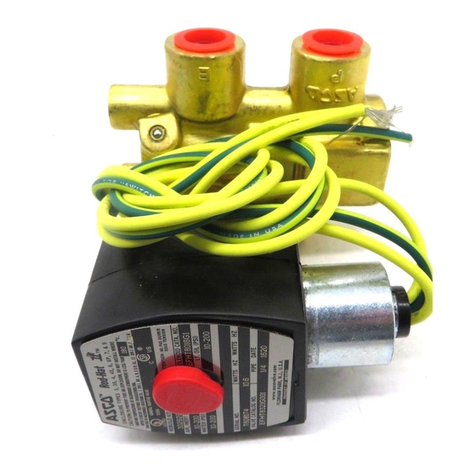

Mounting For ounting valve body refer to Figure 1.

.750

1

1.500

38

.200

5

Figure 1. Dimensions for mounting valve body.

Piping

There are two exhaust flows in the exhaust ode. The pilot exhaust

ay be connected to the ain exhaust if the air or inert gas cannot be

exhausted directly to the at osphere. For universal valves with

pressure at 2 (nor ally closed operation) the pilot exhaust is at 3 and

ay be connected to ain exhaust 4. For universal valves with

pressure at 3 (nor ally open operation) the pilot exhaust is at 2 and

ay be connected to ain exhaust 4. Connect piping or tubing to

valve according to arkings on valve body. Refer to flow diagra s in

OPERATION section.

CAUTION: To avoid damage or accidental disengagement of

cartridge assembly from valve body, hold cartridge assembly

securely by wrenching flats when installing or removing piping at

Port 3.

Apply pipe co pound sparingly to ale pipe threads only. If applied

to valve threads, the co pound ay enter the valve and cause

operational difficulty. Avoid pipe strain by properly supporting and

aligning piping. When tightening the pipe, do not use valve or

solenoid as a lever. Locate wrenches applied to valve body or piping

as close as possible to connection point.

To insure proper operation of the valve, the pressure and exhaust lines

ust be full area without restriction. A ini u differential

pressure (5 psi), as sta ped on the na eplate, ust be aintained

between pressure and exhaust at the o ent of shifting. Air

reservoirs ust have adequate capacity to aintain this ini u

pressure during shifting. To check pressure during shifting, install a

pressure gauge in the pressure piping as close to the valve as possible.

IMPORTANT: These solenoid valves are intended for use on clean

dry air or inert gas, filtered to 50 micrometres or better. The dew

point of the media should be at least 10 C (18 F) below the

minimum temperature to which any portion of the clean air/inert

gas system could be exposed to prevent freezing. If lubricated air is

used, the lubricants must be compatible with Buna N elastomers.

iester oils may cause operational problems. Instrument air in

compliance with ANSI/ISA Standard S7.3-1975 (R1981) exceeds

the above requirements and is, therefore, an acceptable media for

these valves.