Page 1

create a higher vacuum by using the outlet to draw

more air thru the inlet and creating an open head to

prevent vacuum lock. The high vacuum is electrically

tied to the compressor thru the relay. If the system is

pressurized and the high vacuum hose is removed from

the holder and the toggle on the holder is in the ON

position, the compressor will turn on and air from the

pressure side will vent to the atmosphere. The saliva

ejector works from the pressure side of the compressor

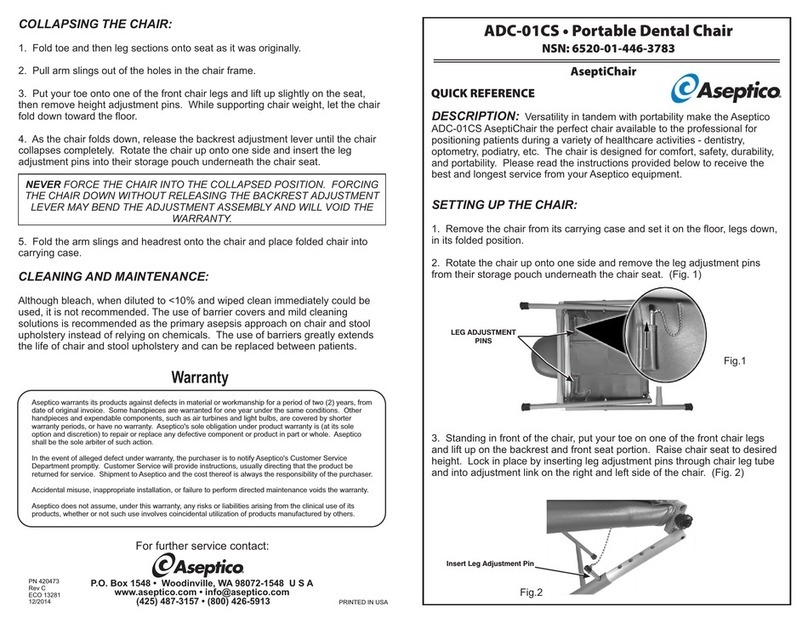

thru an air toggle switch with the red dot (Fig. 1) and an

air pilot and vacuum pump. When the saliva ejector is

removed from it’s holder with the toggle on the holder

in the ON position, the air pilot is activated allowing air

to flow to the vacuum pump. When the saliva ejector is

on, the pressure gauge will cycle as the air pressure

drops until the pressure sensor turns the compressor on

and reaches a pressure of 50 PSI. If the high vacuum is

on at the same time, the compressor motor will run

continuously and the cycling of the pressure side will

not be as audible.

To check the system, verify that unit holds pressure on

the pressure gauge and that the pressure toggle switch

is in the ON position. Note that when the unit is first

turned on, the unit will charge two to three times before

pressure is stabilized. If the unit fails to stabilize, or

turns on within a few seconds, then an air or water leak

is present. Inspect the unit for air or water leaks. It is

best to detect air leaks with a tube or a stethoscope. To

check the three way syringe, depress the air and water

buttons individually and the buttons together for spray.

Spray may be adjusted with the syringe water and air

adjustment screws in the underside of the plumbing

chassis on the left side of the unit (Fig. 2).

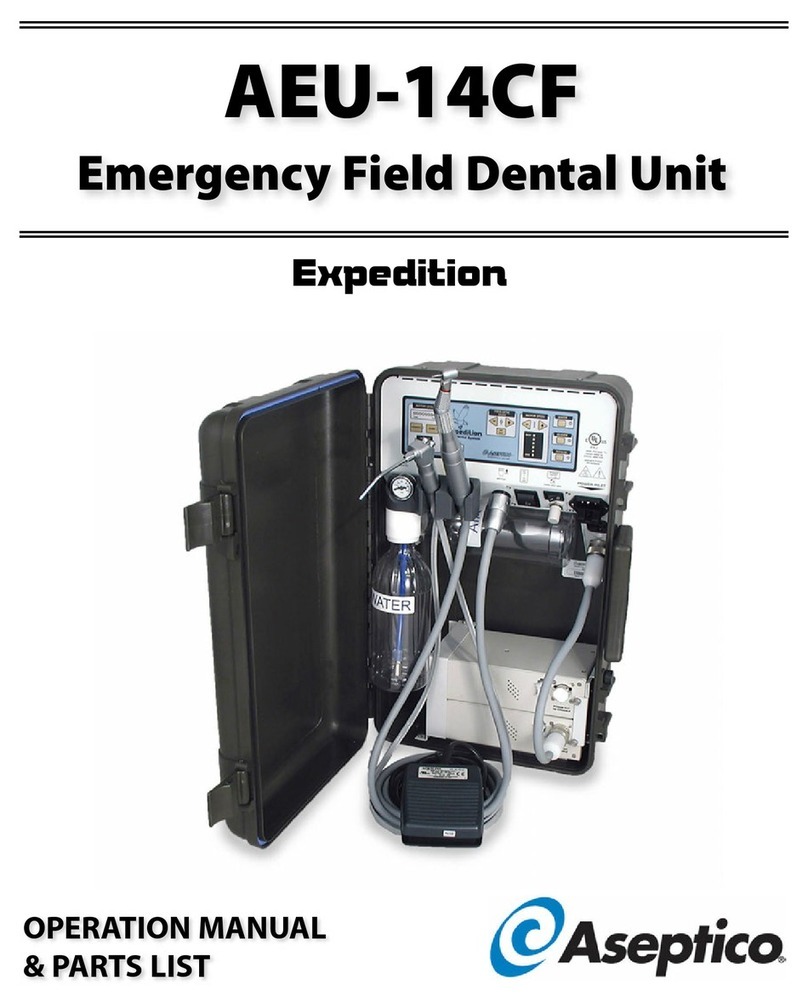

Inspect the water filter on the water

pick-up tube (Fig. 3). Water filter

requires replacement if it becomes

clogged and restricts water flow.

GENERAL SERVICE INFORMATION

This service and parts manual offers information and

parts lists not available in the AEU-425CF/CF

Operation and Maintenance Instruction Manual. It will

help you better understand how the AEU-425CF/CF

Transport II MDS portable dental system works,

thereby reducing service time. Parts drawings, parts

photographs, and schematic diagrams show compo-

nents in their actual places in the unit relative to one

another. A plumbing schematic is provided with water

lines indicated in blue. Plumbing parts are called out by

Aseptico part number in the assembly drawings. An

electrical schematic is provided with wires color coded.

Electrical parts are called out by Aseptico part number

in the assembly drawings. Parts, with photo callouts, are

listed in the Parts List. Parts marked “commercially

available” are those items that can be purchased at

retail hardware stores, and minimize service delays

when obtained locally. Use the information in the Parts

List when ordering replacement parts.

Insp ction & Op ration V rification

To verify that the AEU-425CF/CF unit is functioning

properly, first follow the set-up procedure in the

Operation & Maintenance manual. Note that connectors

from the waste tank must be connected to the underside

of the plumbing chassis in order for the compressor

motor to turn on. The high vacuum hose is placed in the

toggle holder with the yellow dot and the saliva ejector

vacuum hose is placed in the toggle holder with the red

dot (see Fig. 1). The reason for this is that the unit is

operated by a single dual headed compressor.

The compressor is set up to work one head as a

pressure side and the other head as the high vacuum

side. This is accomplished by using a three way solenoid

on the pressure side in conjunction with a pressure

switch and relay. The three way solenoid allows for air

from the pressure side to be distributed to the air

canister or to the atmosphere. When the power switch

is turned on, the pressure switch will activate the relay

and start the compressor motor. The compressor motor

will turn on and the pressure gauge will start to climb to

50 PSI in a few seconds. The delay prevents stalling of

the compressor and is shorter once the unit is pressur-

ized. When ever the compressor motor is on, the high

vacuum tube will be on. Stalling of the compressor on

the vacuum side is prevented by using a vacuum pump

plumbed to the input and the output of the head to

Figure 1

Yellow

Dot

Red Dot

Figure 2

Adjustment Screws

Water

Filter

Figure 3