18 19

7. Seng the operang mode via DIP switches

Located underneath the opening on the right side of the housing are

six DIP switches. Factory sengs are underlined.

S1 Test while voltage is applied (O)/ missing at T1 T2 (On)

S2 Automac reset (O) / error lock with man. reset (On)

S3 Auxiliary relay funcon: RL (On) / RLU (O)

S4 Auxiliary relay ashes on RLU (On) / does not ash (O)

S5 Auxiliary relay responds to CH1 and CH2 (On) / only to CH1 (O)

S6 Auxiliary terminal is closed in the idle state (On) / open (O)

Automac reset (factory seng of S2 = "O")

Upon reccaon of a fault in the sensor circuits or aer a power failure,

the ELMON rail 34-32 automacally closes relay contacts 13 14.

During a fault, the corresponding LEDs CH1 / CH2 illuminate constantly.

Error lock with manual reset (S2 = "On")

Upon reccaon of a fault in the sensor circuit or aer a power failure, the ELMON rail 34-32 does not

close output terminals 13 14 again unl contacts Z1 and Z2, 500 ms aer the eliminaon of the disrupon,

are bridged with a buon. An automac restart is thereby rendered impossible. Permanent bridging of

contacts Z1 Z2 is not possible and is detected by the test.

Aer the sensor is again released, the corresponding LEDs CH1 / CH2 ash unl a man. reset is performed.

During a fault, the corresponding LEDs CH1 / CH2 illuminate constantly.

Auxiliary relay undelayed RLU (factory seng S3 = "O")

In this operang mode, the auxiliary relay contact 31 32 is acvated if any error is signalled. The auxiliary relay

contact can be toggled between normally closed contact and normally open contact with S6 ("On" = normally

open contact), whereby the contacts are always open while the switching unit is in a power-free state.

Errors in channel 2 are only taken into account if S5 is in switch posion "On" (factory seng of S5 = "O").

Auxiliary relay undelayed RLU ashing (S3 "O" , S4 = "On")

With S4, ashing of the relay can be acvated in synch with the LEDs.

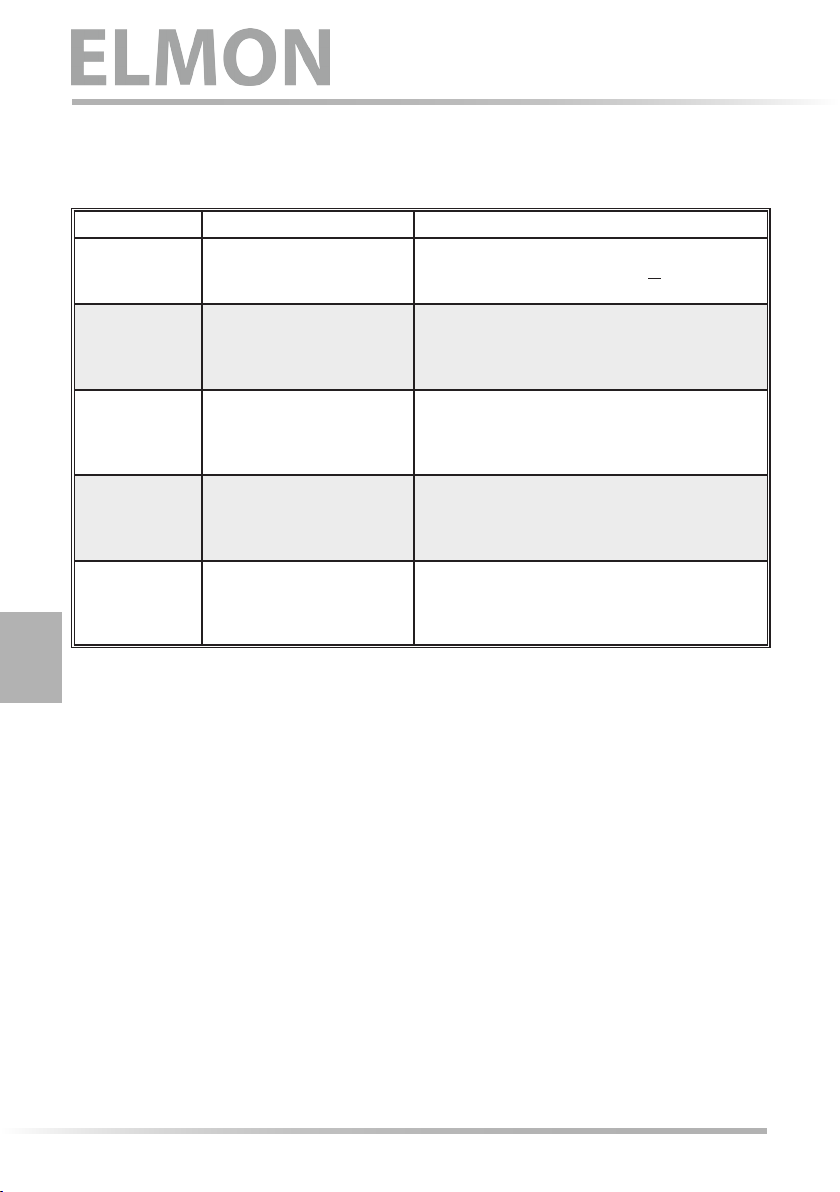

DIP switches

approx. 0.5 s approx. 3 s

Safety relay output (symbolic)

Auxiliary relay output (symbolic)

Safety relay output (symbolic)

Auxiliary relay output (symbolic)

Auxiliary relay delayed RL (S3 = "On")

In this operang mode, the auxiliary relay contact 31 32 is acvated with a delay of approx. 0.5 second and

then remains acve for max. 3 seconds if an error is signalled. The auxiliary relay contact can be toggled

between normally closed contact and normally open contact with S6, whereby the contacts are always open

while in a power-free state.

CH2 is only taken into account if S5 is in switch posion "On" (factory seng of S5 = "O"). S4 must be in the

"O" switch posion (factory seng); otherwise, the auxiliary relay is permanently inacve.

ELMON rail 34-32

Safety Relay

English