® Copyright by ATH-Heinl GmbH & Co. KG, 2014, All rights reserved /Misprint and technical changes reserved / Issue: 08/2013

2

CONTENT

INTRODUCTION ....................................................................................................................................................................3

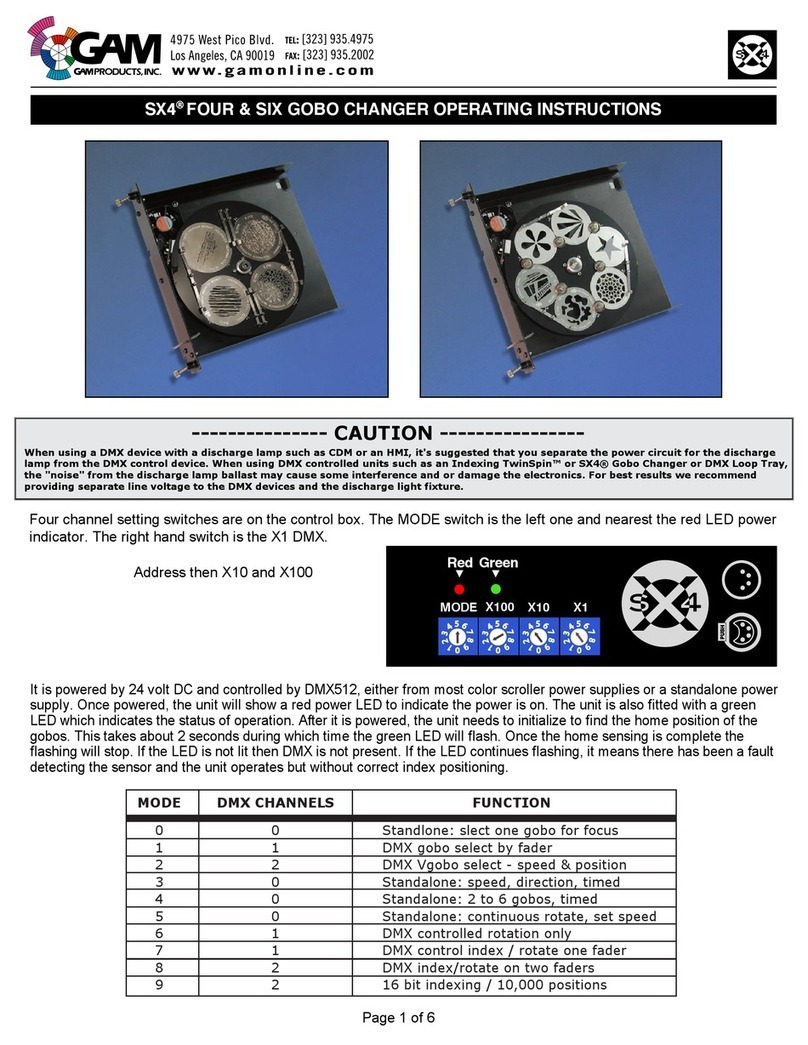

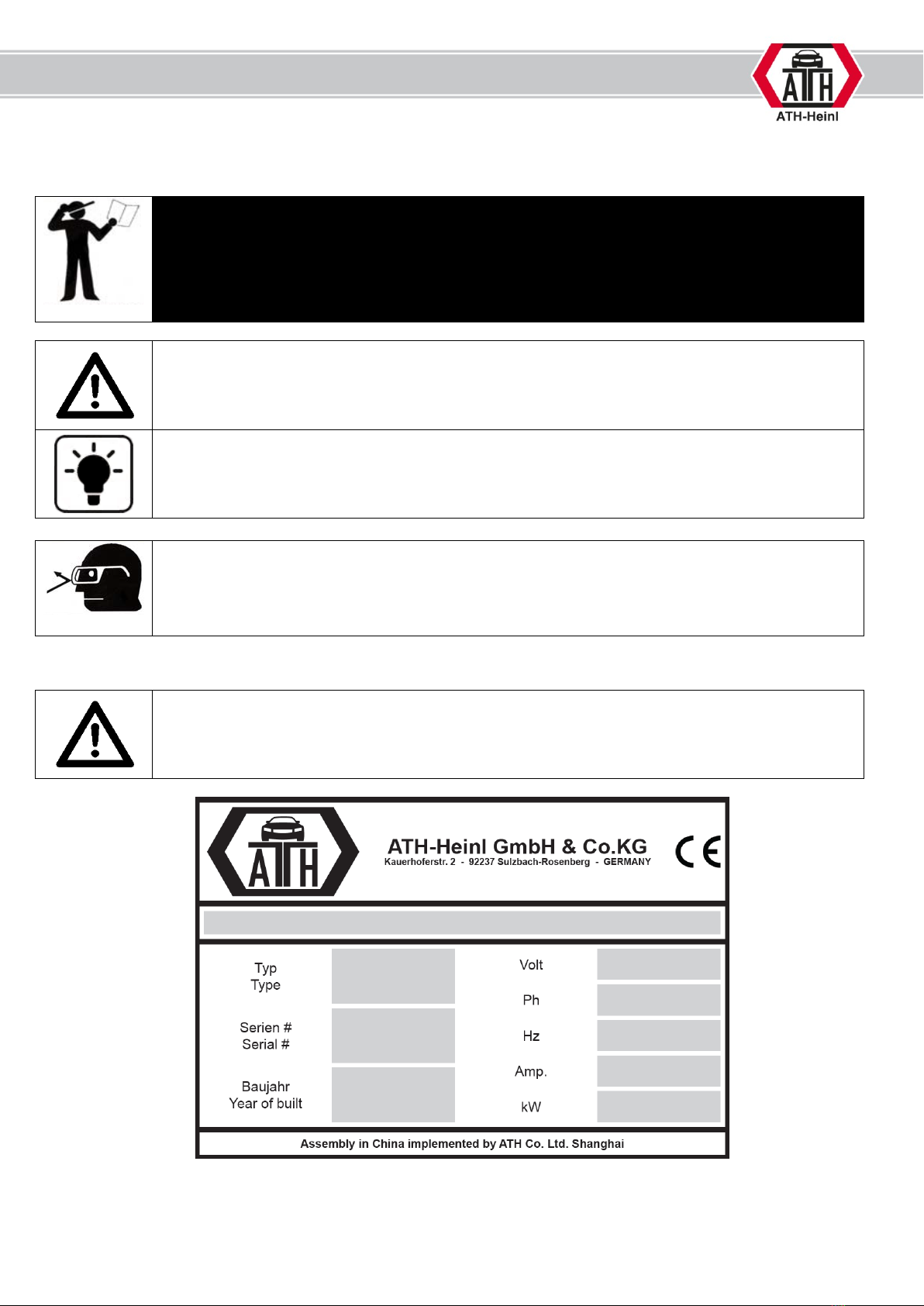

Description of assist arm ....................................................................................................................................................4

Technical data ....................................................................................................................................................................4

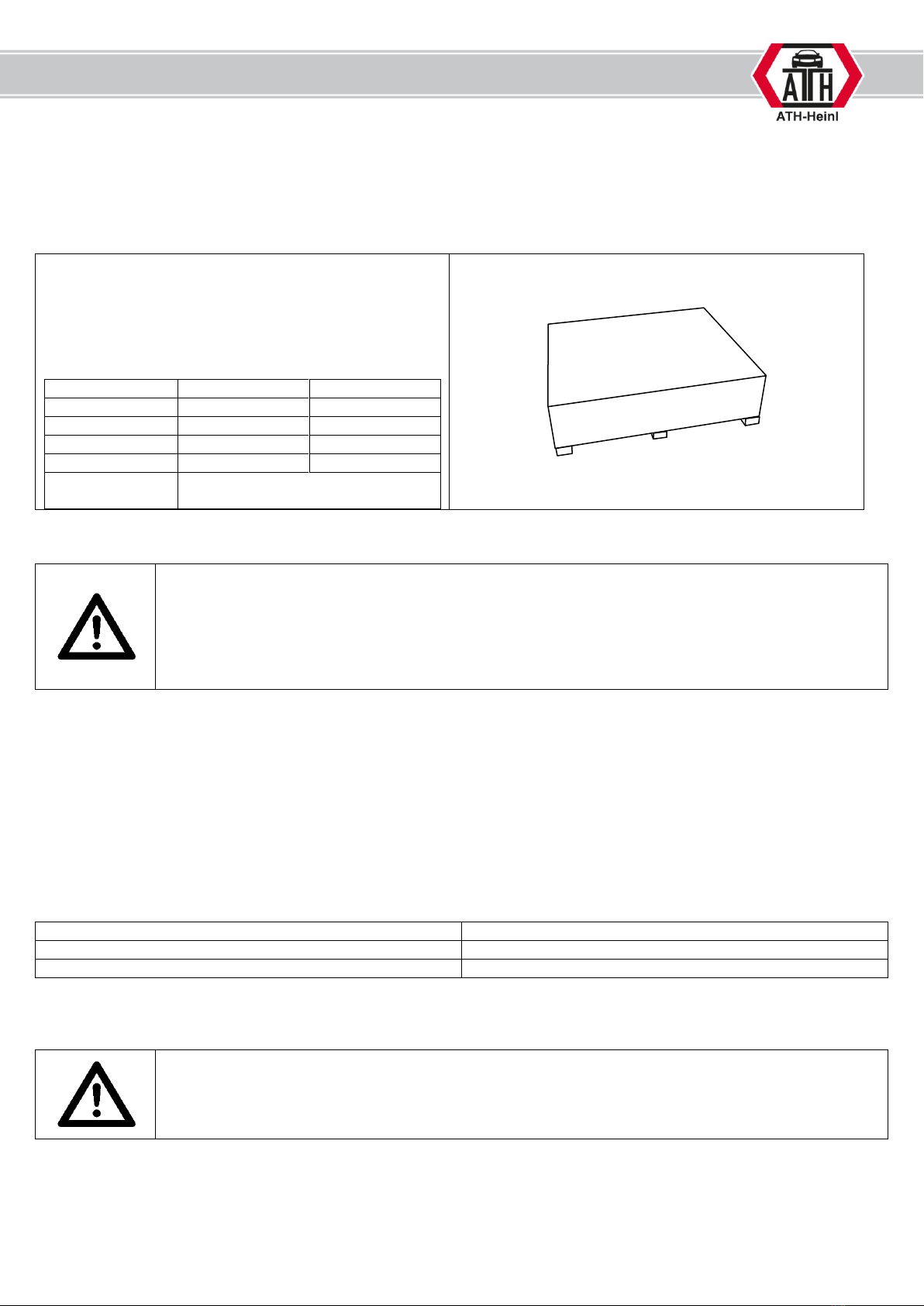

Transport and storage ........................................................................................................................................................5

Unpacking of machine ........................................................................................................................................................5

Standort ..............................................................................................................................................................................5

Fixing ..................................................................................................................................................................................5

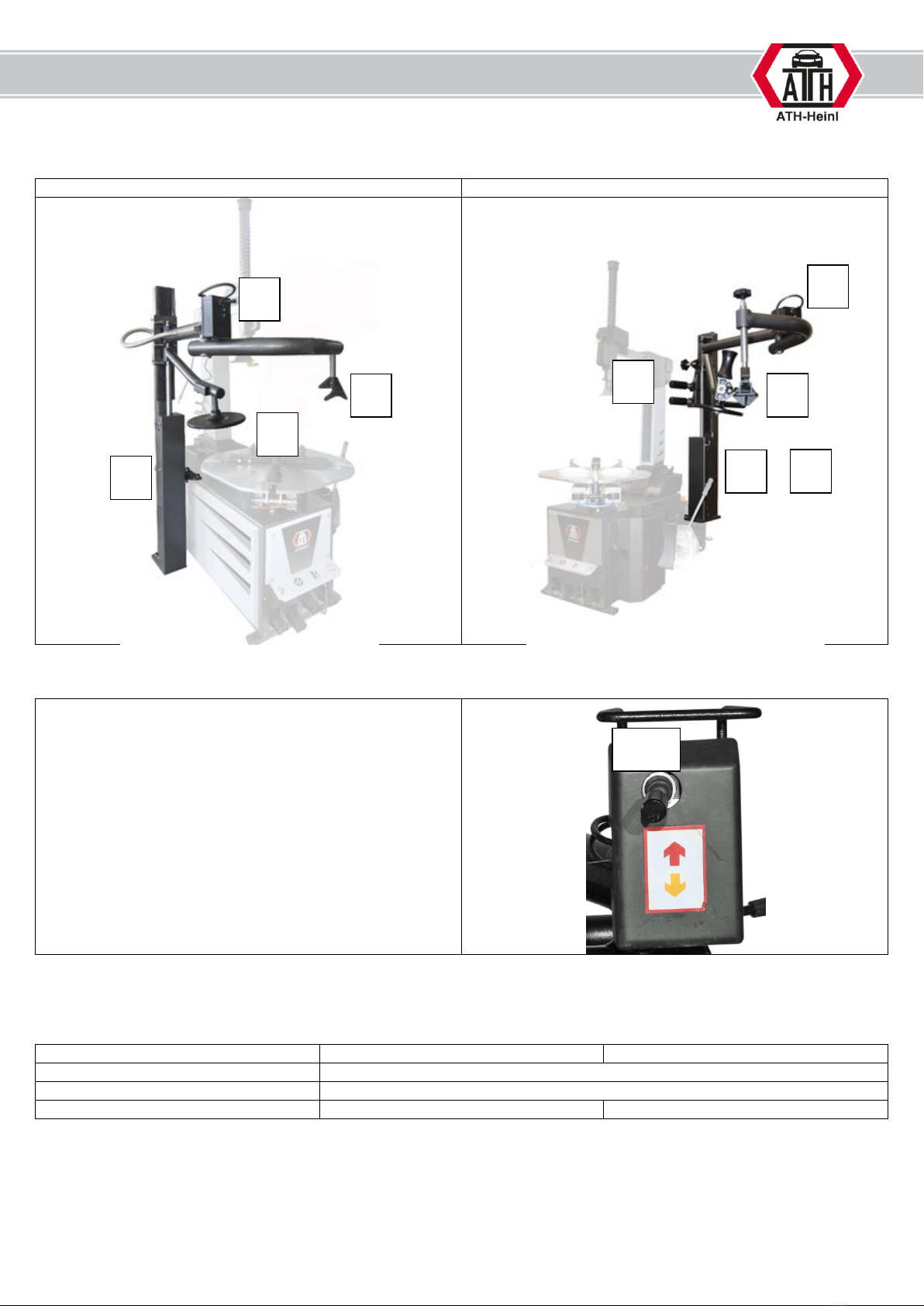

OPERATION.........................................................................................................................................................................11

Safty instructions ..............................................................................................................................................................11

Use ...................................................................................................................................................................................13

MAINTENANCE ...................................................................................................................................................................16

Troubleshooting ................................................................................................................................................................16

Maintenance instruction....................................................................................................................................................16

KONFIRMITÄTSERKLÄRUNG............................................................................................................................................17

SPARE PARTS ....................................................................................................................................................................18

Spare part list A31 ............................................................................................................................................................20

Exploded drawing A34......................................................................................................................................................22

Spare part list A34 ............................................................................................................................................................23

ATTACHEMENT...................................................................................................................................................................26

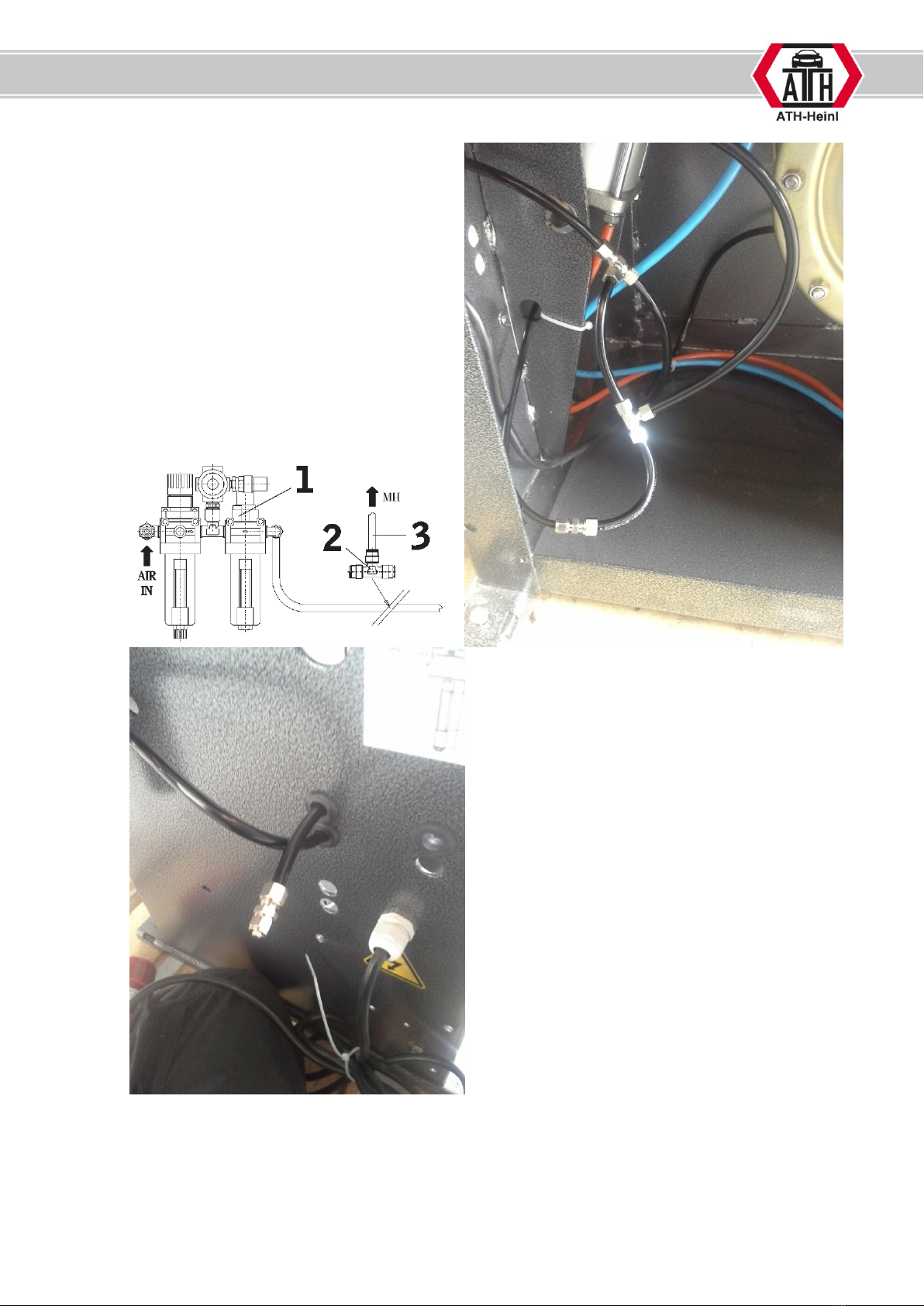

Pneumatic sceme .............................................................................................................................................................26

GARANTYKARD..................................................................................................................................................................27

NOTES..................................................................................................................................................................................29