Atmel 80C51 Installation and operating instructions

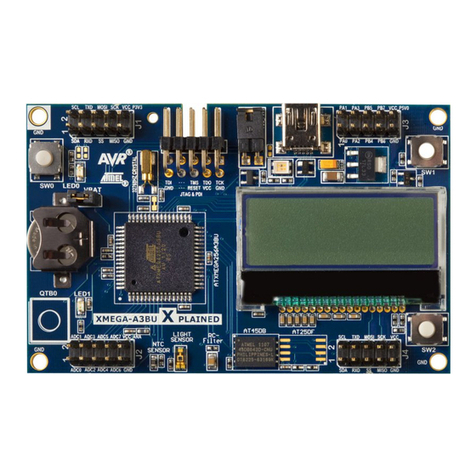

Other Atmel Microcontroller manuals

Atmel

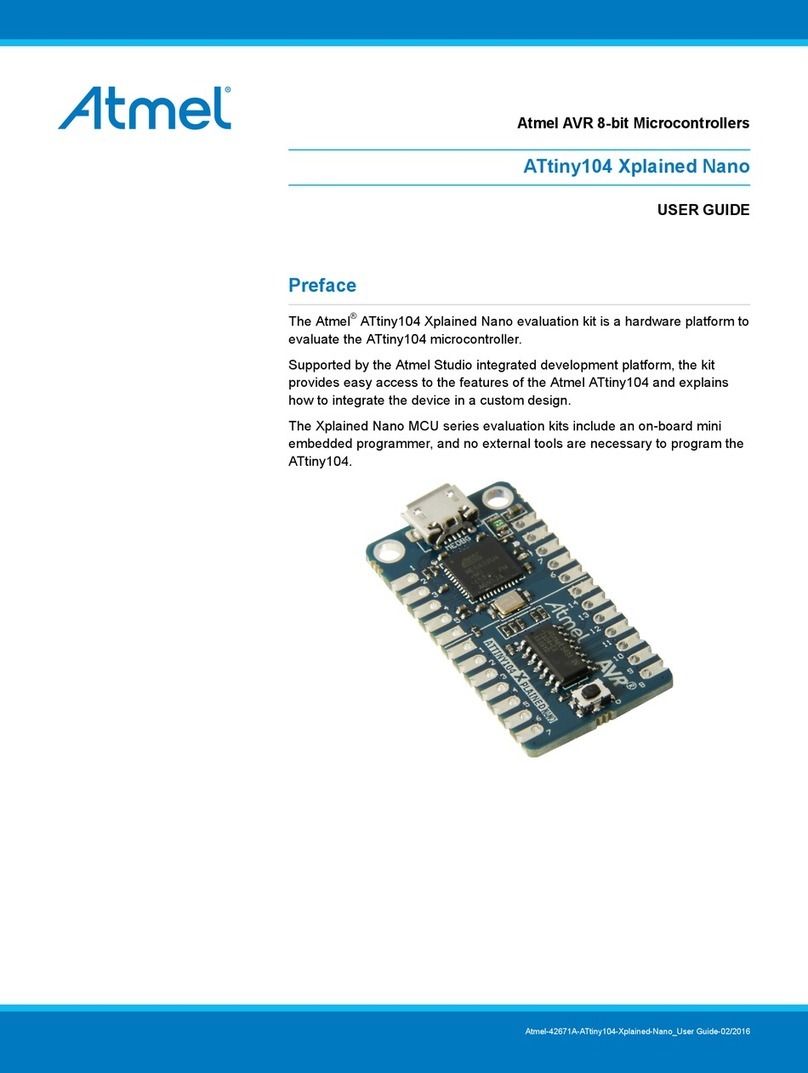

Atmel ATtiny104 Xplained Nano User manual

Atmel

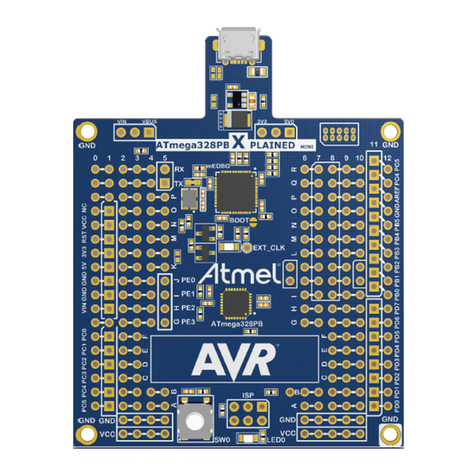

Atmel ATmega328PB Xplained Mini Installation and operating instructions

Atmel

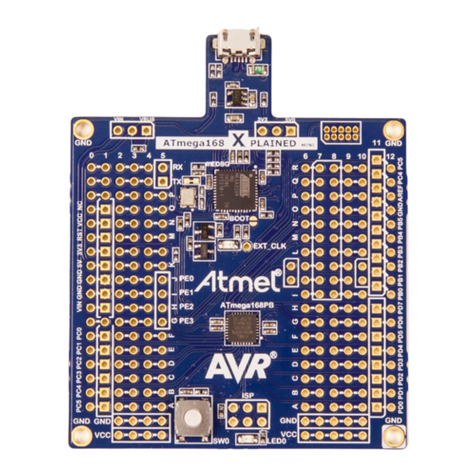

Atmel ATmega168PB Xplained Mini User manual

Atmel

Atmel 8051 User manual

Atmel

Atmel AVR ATtiny15L User manual

Atmel

Atmel AT91 Series User manual

Atmel

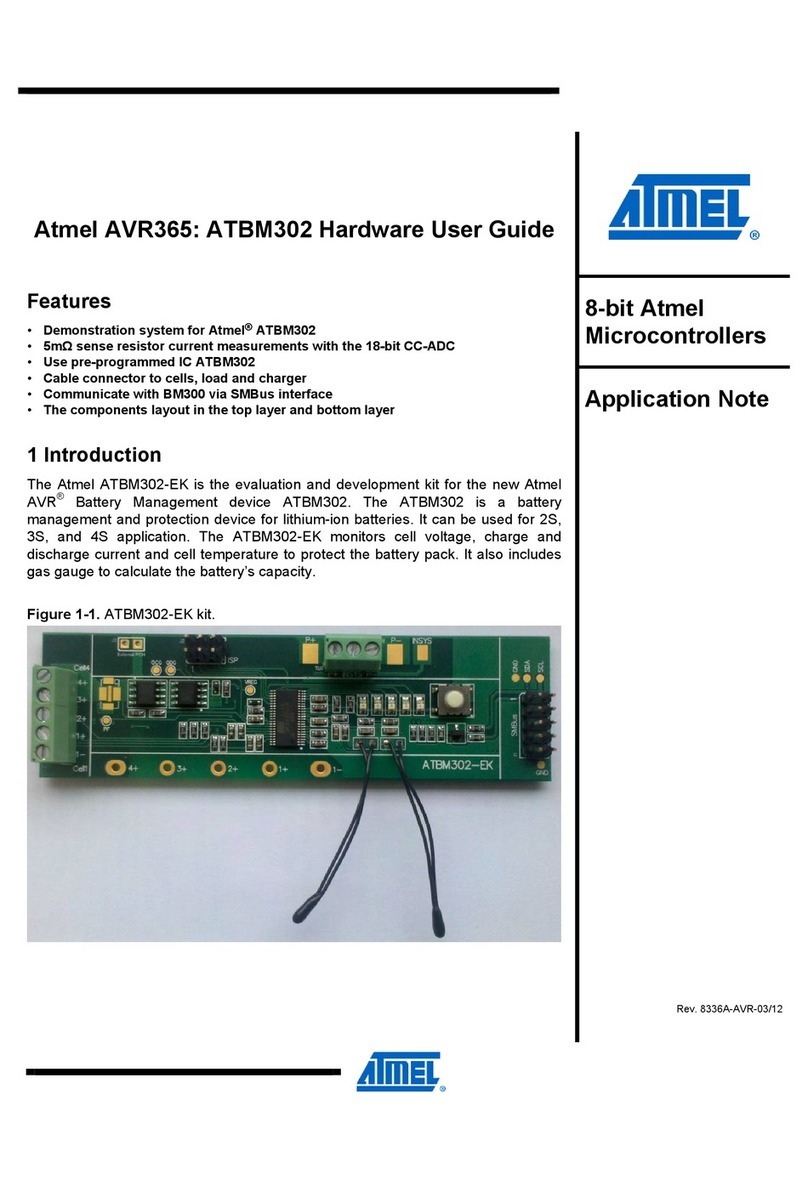

Atmel AVR365 User manual

Atmel

Atmel AT89STK-03 Installation manual

Atmel

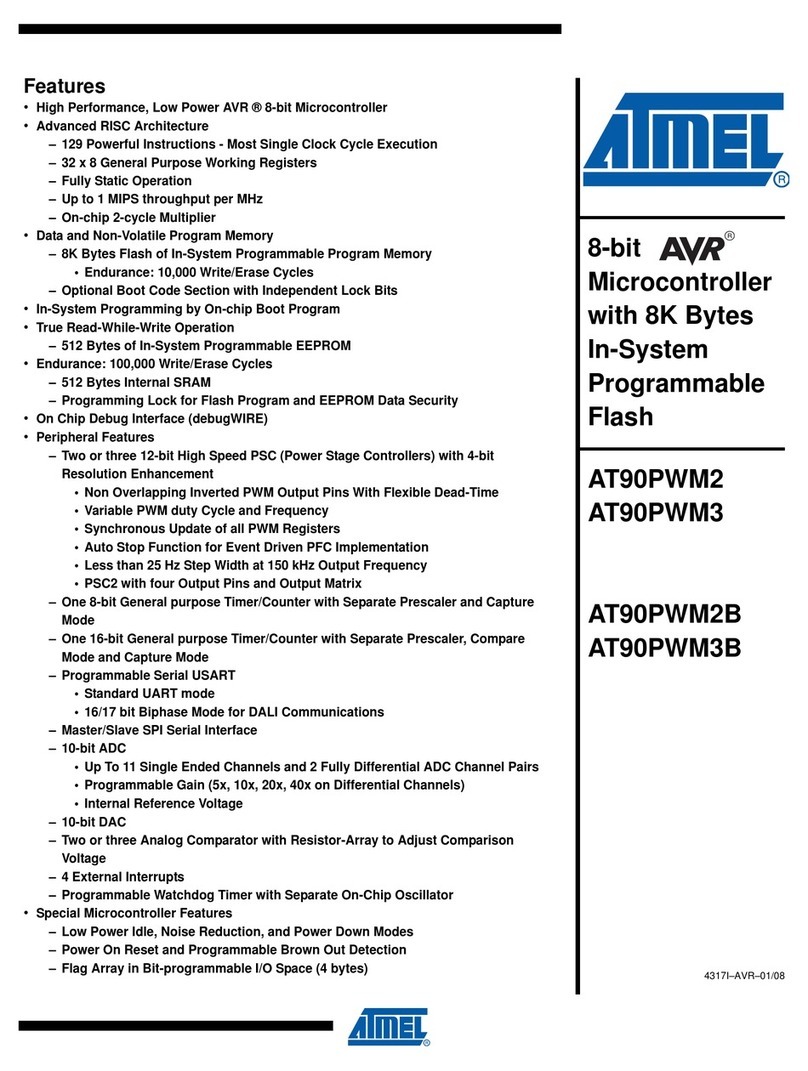

Atmel AT90PWM2 User manual

Atmel

Atmel AVR ATtiny22 Instruction Manual

Atmel

Atmel AT43DK325 User manual

Atmel

Atmel AT89RFD-10/EVLB002 User manual

Atmel

Atmel AT18F-DK3 User manual

Atmel

Atmel AVR042 Installation and operating instructions

Atmel

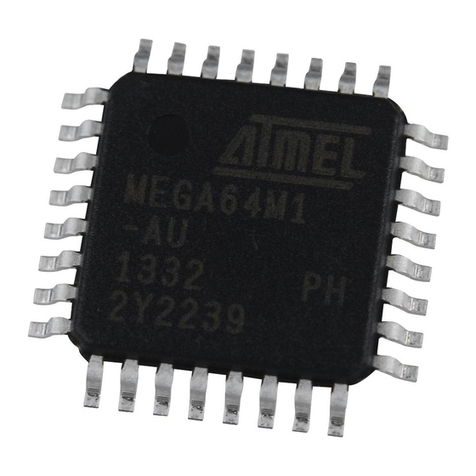

Atmel ATmega32M1 User manual

Atmel

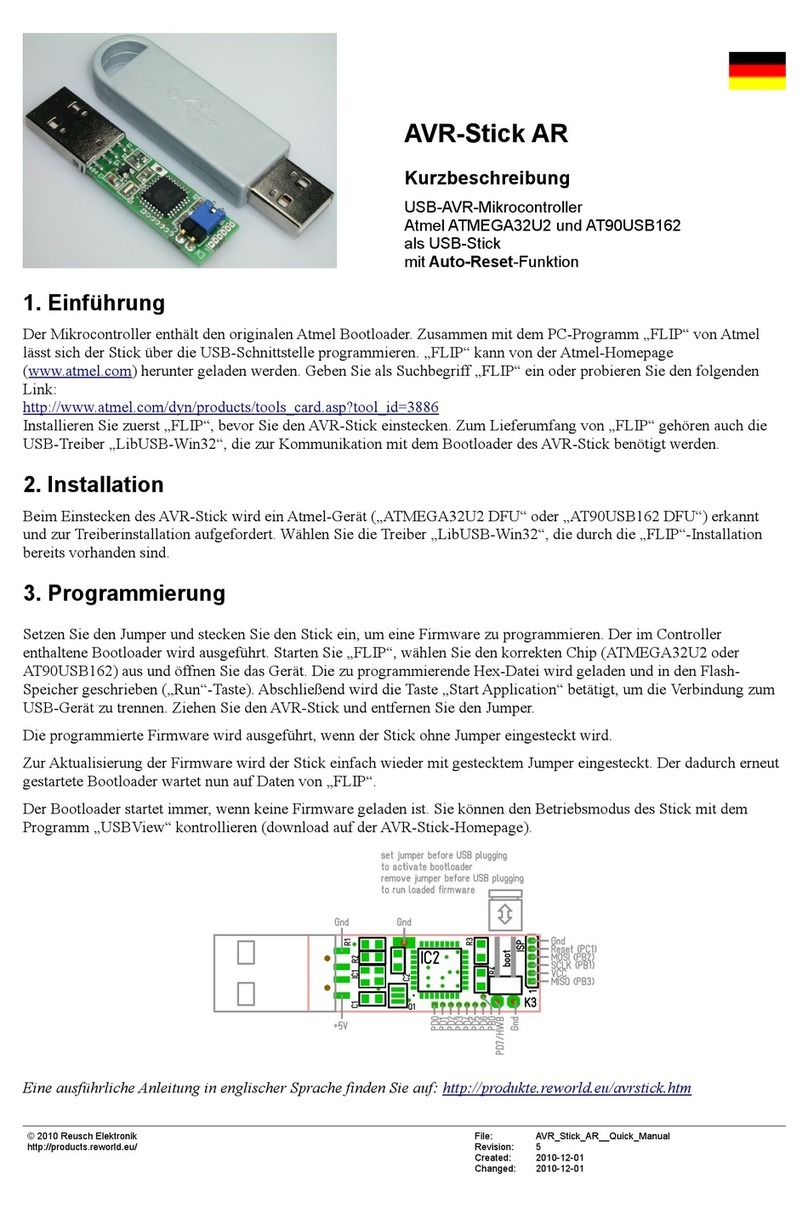

Atmel AT90USB162 User manual

Atmel

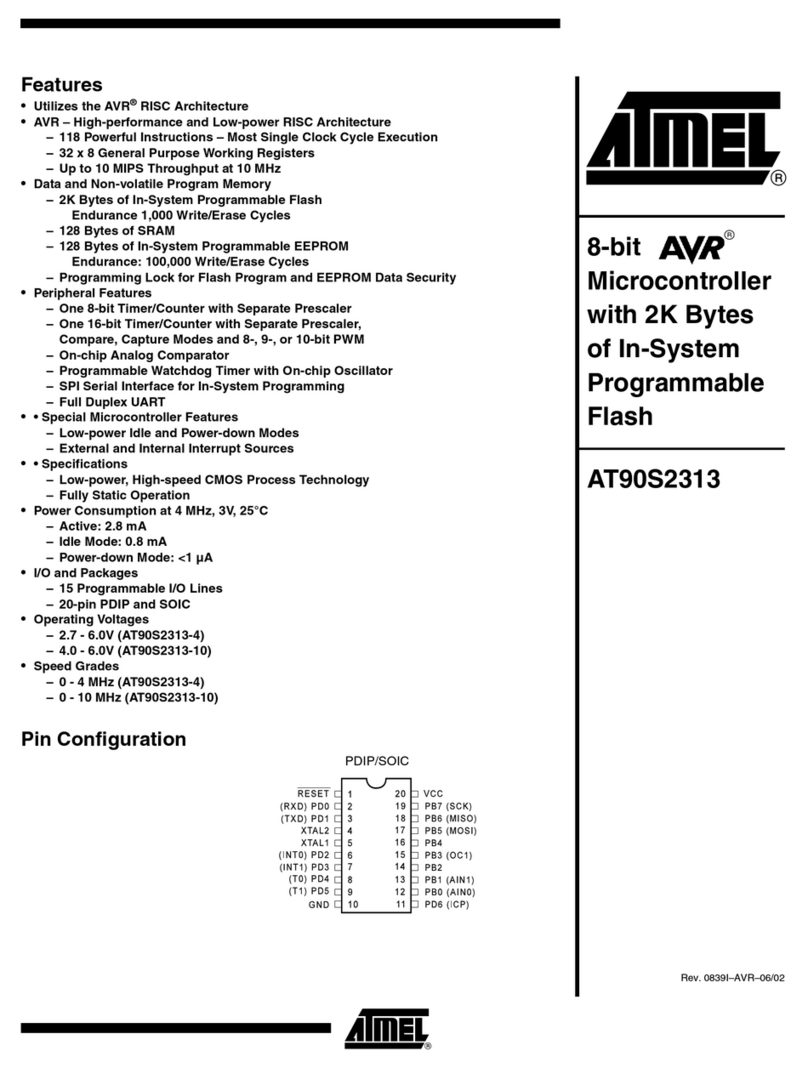

Atmel AT90S4433-8AC User manual

Atmel

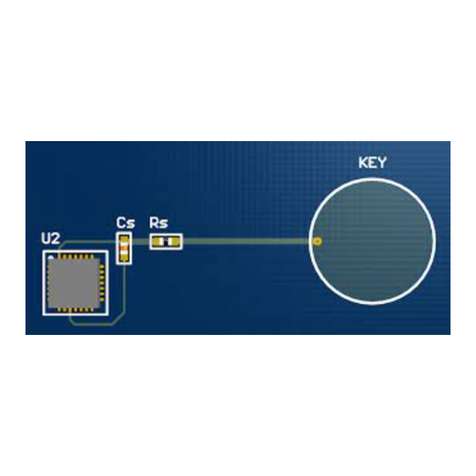

Atmel QTouch Installation and operating instructions

Atmel

Atmel ATF15 DK2 Series User manual

Atmel

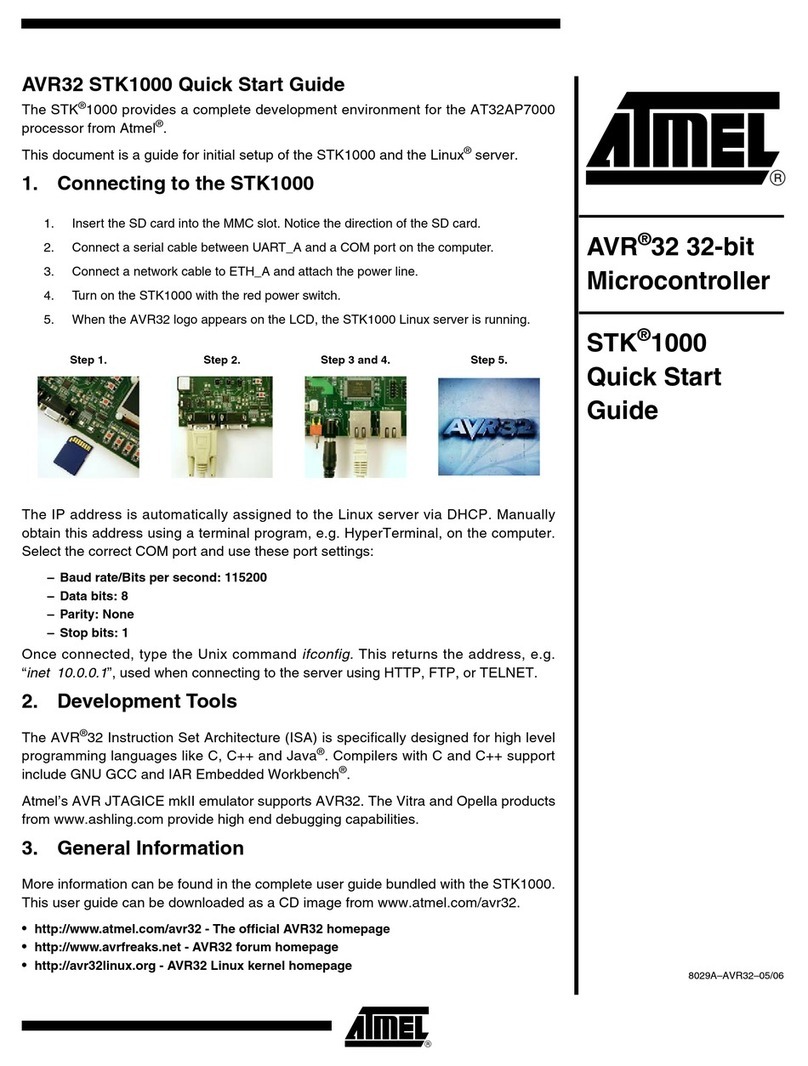

Atmel AVR32 STK1000 User manual

Popular Microcontroller manuals by other brands

DIGITAL-LOGIC

DIGITAL-LOGIC MICROSPACE manual

Texas Instruments

Texas Instruments TMS320F2837 D Series Workshop Guide and Lab Manual

CYPRES

CYPRES CY14NVSRAMKIT-001 user guide

Espressif Systems

Espressif Systems ESP8266EX Programming guide

Abov

Abov AC33M8128L user manual

Silicon Laboratories

Silicon Laboratories C8051F800 user guide