AUMA AC 01.2-22X User manual

This manual suits for next models

7

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA AMB 01.1 User manual

AUMA

AUMA AM 01.1 User manual

AUMA

AUMA Profibus PBD 100 User manual

AUMA

AUMA SA 25.1 User manual

AUMA

AUMA Aumatic ACExC 01.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SVCR 05.1 User manual

AUMA

AUMA SAExC 07.1 User manual

AUMA

AUMA SAEx 25.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SA 07.1 User manual

AUMA

AUMA SAV 07.2 User manual

AUMA

AUMA SQEx 05.2 User manual

AUMA

AUMA SQ 05.2 User manual

AUMA

AUMA SQEx 05.2 User manual

AUMA

AUMA SBA 12 User manual

AUMA

AUMA SAE 07.2 Series Training manual

AUMA

AUMA SQEx 05.2 User manual

AUMA

AUMA SA 07.1 - SA 30.1 User manual

AUMA

AUMA SQEx 05.2 User manual

Popular Controllers manuals by other brands

Mitsubishi Electric

Mitsubishi Electric L26CPU-BT user manual

Mitsubishi Programmable Controllers

Mitsubishi Programmable Controllers ENHANCED F2 Series instruction manual

Phasetronics

Phasetronics EP1 Series Operation and service manual

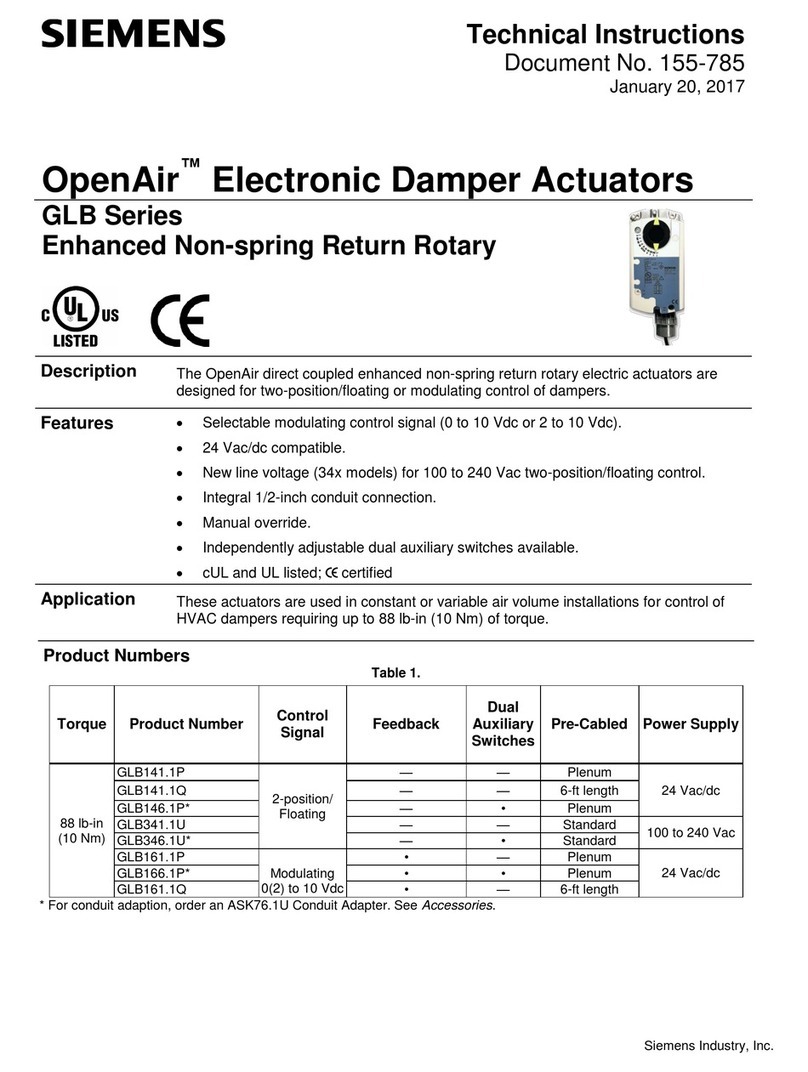

Siemens

Siemens OpenAir GLB141.1P Technical instructions

Beckhoff

Beckhoff CU8880-0010 Installation and operating instructions

Fisher

Fisher ED Safety manual

Ingenium

Ingenium SR Technical installation manual

sauter

sauter TSHK 68. F Series operating instructions

giulio lighting

giulio lighting LC-001 user manual

Xycom

Xycom XVME-202 manual

Siemens

Siemens Simatic S7 Series manual

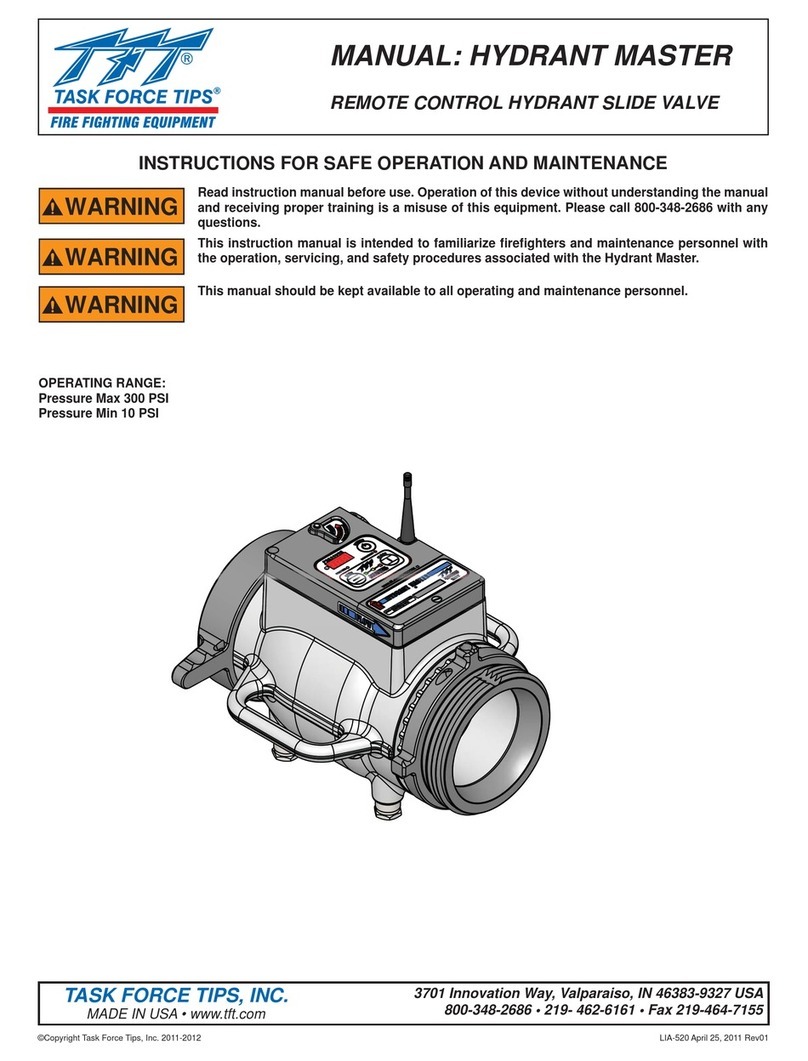

Task Force Tips

Task Force Tips HYDRANT MASTER INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE

Honeywell

Honeywell 10260A Series Replacement instructions

Delta Electronics

Delta Electronics Programmable Logic Controller DVP-PLC instruction sheet

Heatcraft

Heatcraft intelligen Webserver Card Installation & operation manual

dji

dji T1d user manual

Parker

Parker COMPAX-M /-S (L) user guide

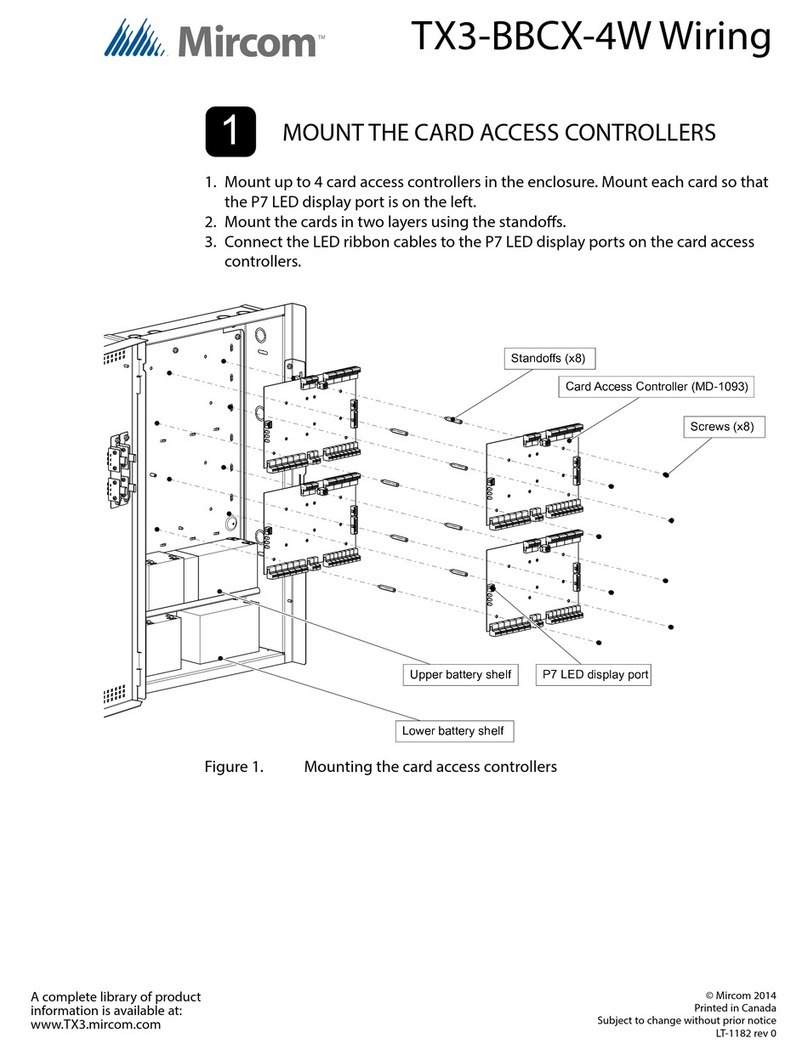

Mircom

Mircom TX3-BBCX-4W Wiring