1. Safety instructions

1.1. Basic information on safety

Standards/directives AUMA products are designed and manufactured in compliance with recognised

standards and directives.This is certified in a Declaration of Incorporation and an

EC Declaration of Conformity.

The end user or the contractor must ensure that all legal requirements, directives,

guidelines, national regulations and recommendations with respect to assembly,

electrical connection, commissioning and operation are met at the place of installation.

Theyinclude among others standards and directivessuch as IEC/EN 60079“Electrical

apparatus for explosive atmospheres" –

●Part 14: Electrical installations in hazardous areas (other than mines).

●Part 17: Inspection and maintenance of electrical installations in hazardous

areas (other than mines).

Safetyinstructions/warn-

ings All personnel working with this device must be familiar with the safety and warning

instructions in this manual and observe the instructions given. Safety instructions

and warning signs on the device must be observed to avoid personal injury or property

damage.

Qualification of staff Assembly, electrical connection, commissioning, operation, and maintenance must

be carried out exclusively by suitably qualified personnel having been authorised by

the end user or contractor of the plant only.

Prior to working on this product, the staff must have thoroughly read and understood

these instructions and, furthermore, know and observe officially recognised rules

regarding occupational health and safety.

Work performed in potentially explosive atmospheres is subject to special regulations

which have to be observed.The end user or contractor of the plant are responsible

for respect and control of these regulations, standards, and laws.

Commissioning Prior to commissioning, it is important to check that all settings meet the requirements

of the application. Incorrect settings might present a danger to the application, e.g.

cause damage to the valve or the installation.The manufacturer will not be held

liable for any consequential damage.Such risk lies entirely with the user.

Operation Prerequisites for safe and smooth operation:

●Correct transport, proper storage, mounting and installation, as well as careful

commissioning.

●Only operate the device if it is in perfect condition while observing these instruc-

tions.

●Immediately report any faults and damage and allow for corrective measures.

●Observe recognised rules for occupational health and safety.

●Observe the national regulations.

●During operation,thehousing warmsupand surfacetemperatures>60°C may

occur.To prevent possible burns, we recommend checking the surface temper-

ature using an appropriate thermometer and wearing protective gloves, if re-

quired, prior to working on the device.

Protective measures The end user or the contractor are responsible for implementing required protective

measures on site, such as enclosures, barriers, or personal protective equipment

for the staff.

Maintenance To ensure safe device operation, the maintenance instructions included in this manual

must be observed.

Any device modification requires prior consent of the manufacturer.

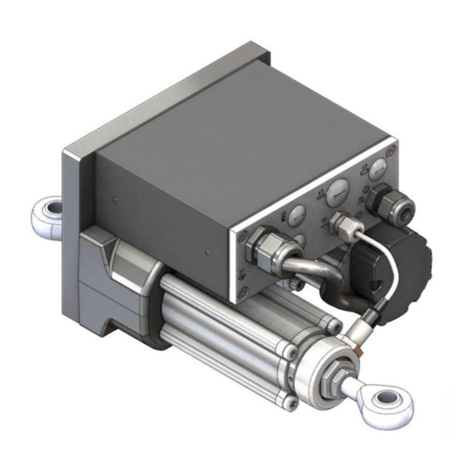

1.2. Range of application

AUMA part-turn actuators are designed for the operation of industrial valves, e.g.

butterfly valves and ball valves.

5

SQEx 05.2 –SQEx 14.2 / SQREx 05.2 –SQREx 14.2

AMExC 01.1 Safety instructions