Table of contents

2

Target group:

This document contains information for assembly, commissioning and maintenance staff.

Read operation instructions first.

• Heed safety instructions.

• These operation instructions are part of the product.

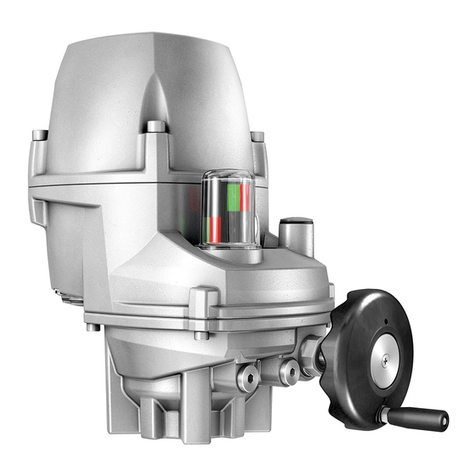

• Store operation instructions during product life.

• Pass on instructions to any subsequent user or owner of the product.

Table of contents

1 Safety instructions ........................................................................................................................................... 4

1.1 Prerequisites for the safe handling of the product...................................................................................... 4

1.2 Range of application .................................................................................................................................. 4

1.3 Warnings and notes ................................................................................................................................... 5

1.4 References and symbols............................................................................................................................ 5

2 Short description.............................................................................................................................................. 7

3 Name plate ........................................................................................................................................................ 8

4 Transport and storage ..................................................................................................................................... 11

4.1 Transport.................................................................................................................................................... 11

4.2 Storage....................................................................................................................................................... 12

5 Assembly .......................................................................................................................................................... 13

5.1 Mounting position ....................................................................................................................................... 13

5.2 Fit handwheel............................................................................................................................................. 13

5.3 Mount actuator to valve.............................................................................................................................. 13

5.3.1 Overview on coupling variants ........................................................................................................ 14

6 Electrical connection ....................................................................................................................................... 17

6.1 Basic information........................................................................................................................................ 17

6.2 S/SH electrical connection (AUMA plug/socket connector) ....................................................................... 18

6.2.1 Open terminal compartment ........................................................................................................... 19

6.2.2 Cable connection ............................................................................................................................ 19

6.2.3 Close terminal compartment ........................................................................................................... 21

6.3 Accessories for electrical connection (option)............................................................................................ 22

6.3.1 Parking frame.................................................................................................................................. 22

6.3.2 DS intermediate frame for double sealing....................................................................................... 22

6.3.3 External earth connection ............................................................................................................... 23

7 Operation .......................................................................................................................................................... 24

7.1 Manual operation ....................................................................................................................................... 24

7.1.1 Manual valve operation................................................................................................................... 24

7.2 Motor operation .......................................................................................................................................... 24

8 Indications (option) .......................................................................................................................................... 25

8.1 Mechanical position indication via indicator mark ...................................................................................... 25

9 Signals (output signals)................................................................................................................................... 26

9.1 Feedback signals from actuator ................................................................................................................. 26

10 Commissioning (basic settings) ..................................................................................................................... 27

10.1 End stops in part-turn actuator................................................................................................................... 27

10.1.1 Set end stop CLOSED .................................................................................................................... 28