AUMA SA 3 User manual

1

Multi-turn actuators

SA3 – SA100

SAR3 - SAR100

with epac controls in SIL version

Manual Functional Safety

2

NOTICE for use!

This document is only valid with the latest operation instructions attached to the device, the attached manual as

well as the pertaining technical and electrical data sheets respectively. They are understood as reference

documents.

Purpose of the document:

The present document informs about the actions required for using the device in safety-related systems in

accordance with IEC 61508 / IEC 61511.

Reference documents:

• Operation instructions (Assembly, operation, commissioning) for actuator.

• Manual (Operation and setting) 3.XX NI.

• Manual (Device integration Fieldbus) 3.XX NI Profibus.

• Technical data on multi-turn actuator and actuator controls.

Reference documents can be downloaded from the internet (www.auma.co.in).

Table of Content

Sl. No.

Content

Page No.

1

Terminology

4-5

1.1

Abbreviations and concepts

2

Application and validity

2.1

Range of application

2.2

Standards

2

General information about Profibus DP

6-7

2.1

Basic characteristics

2.2

Basic functions of Profibus DP

2.3

Transfer mode

2.4

BUS access

2.5

Functionality

2.6

Protective functions

2.7

Device types

3

Commissioning

8-11

3.1

Introduction

3.2

Parameter setting

3.2.1

Settings for basic functionality for Profibus DP-V1

3.2.2

Settings for Profibus DP-V1 services

3.3

BUS address (slave address)

Table of Contents

Sl. No.

Content

Page No.

1

Terminology

5-6

1.1

Abbreviations and concepts

2

Application and validity

7

2.1

Range of application

2.2

Standards

2.3

Valid device types

3

Architecture, configuration and applications

8-12

3.1

Architecture (actuator sizing)

3.2

Configuration (setting)/version

3.3

Protection against uncontrolled operation (self-locking/brake)

3.4

Operation mode (low/high demand mode)

3.5

Further notes and indications on architecture

3.6

Applications (environmental conditions)

4

Safety instrumented systems and safety functions

13-16

4.1

Safety instrumented system including an actuator

4.2

Safety functions

4.3

Safe inputs and outputs

2

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

3

4.4

Redundant system architecture

4.5

Examples of applications

4.6

System representation

5

Installation, commissioning and operation

17-19

5.1

Installation

5.2

Commissioning

5.3

Operation

5.4

Lifetime

5.5

Decommissioning

6

Indications on display

20-21

6.1

Status indications on SIL functions

6.2

SIL configuration warning

6.3

Backlight

7

Signals

22-23

7.1

Signals via SIL module

7.2

SIL fault signal via standard controls display (for troubleshooting support)

7.3

Status signals via output contacts (digital outputs) of standard controls

7.4

Signal via fieldbus of standard controls

8

Tests and maintenance

24-35

8.1

Safety equipment: check

8.2

Internal actuator monitoring with control via standard controls

8.3

Partial Valve Stroke Test (PVST): execute

8.4

Proof test (verification of safe actuator function)

8.4.1

Safe ESD safety operation “Safe OPENING/CLOSING”: check

8.4.2

SIL fault signal “Actuator monitoring”: check

8.4.3

Safe ESD reaction for “Motor protection (thermal fault)” signals: check

8.4.4

Safe ESD reaction to “Limit seating with overload protection” (limit and/or torque

evaluation): check

8.4.5

Check Safe ESD reaction to “Forced limit seating in end position” (limit evaluation) –

for actuators with electromechanical control unit

8.4.6

Safe ESD reaction to “Forced limit seating in end position” (limit evaluation) – for

actuators with electronic control unit and limit switches: check

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

4

8.4.7

Safe ESD reaction to “Forced torque seating in end position” (torque after limit

evaluation): check

8.4.8

Safe ESD reaction for “no seating” (no evaluation of limit and torque): check

8.4.9

Safe STOP function: check

8.4.10

Combination of Safe ESD and Safe STOP function: check

8.5

Maintenance

9

Safety-related figures

36-3

9.1

Determination of the safety-related figures

9.2

Specific figures for SA series with EPAC controls 3.XX/NI in SIL version with

actuators

10

SIL Certificate

38

11

Checklists

39-46

11.1

Commissioning checklist

11.2

Proof test checklists

11.2.1

Safe ESD safety operation (Safe OPENING/CLOSING)

11.2.2

SIL fault signal “Actuator monitoring”

11.2.3

Safe ESD reaction for “Motor protection (thermal fault)” signal

11.2.4

Safe ESD reaction to “Limit seating with overload protection” (limit and/or torque

evaluation)

11.2.5

Safe ESD reaction to “Forced limit seating in end position” (limit evaluation) – for

actuators with electromechanical control unit

11.2.6

Safe ESD reaction to “Forced limit seating in end position” (limit evaluation) – for

actuators with electronic control unit and limit switches

11.2.7

Safe ESD reaction to "Forced torque seating in end position" (torque after limit

evaluation)

11.2.8

Safe ESD reaction to “no seating”

11.2.9

Safe STOP function

11.2.10

Combination of Safe ESD and Safe STOP

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

5

1 Terminology

Information sources

• IEC 61508-4, Functional safety of electrical/electronic/programmable electronic safety

related systems – Part 4: Definitions and abbreviations.

• IEC 61511-1, Functional safety - Safety instrumented systems for the process industry

sector – Part 1: Framework, definitions, system, hardware and software requirements.

1.1 Abbreviations and concepts

To evaluate safety functions, the lambda values or the PFD value (Probability of Dangerous

Failure on Demand) and the SFF value (Safe Failure Fraction) are the main requirements.

Further figures are required to assess the individual components. These figures are

explained in the table below:

SIL

Safety Integrity Level

The international standard IEC 61508 defines 4 levels (SIL1 through SIL 4).

Safety function

Function to be implemented by a safety-related system for risk reduction with the objective to

achieve or maintain a safe state for the plant/equipment with respect to a specific dangerous

event.

Safety instrumented

function (SIF)

Function with specified safety integrity level (SIL) to achieve functional safety.

Safety instrumented

system (SIS)

Safety instrumented system for executing a single or several safety instrumented functions.

A SIS consists of sensor(s), logic system and actuator(s).

Safety-related system

A safety-related system includes all factors (hardware, software, human factors) necessary

to implement one or several safety functions. Consequently, failures of safety function would

result in a significant increase in safety risks for people and/or the environment.

Abbreviation

Full expression

Description

λS Lambda Safe Number of safe failures

λD Lambda Dangerous Number of dangerous failures

λDU Lambda Dangerous Undetected Number of undetected dangerous failures

λDD Lambda Dangerous Detected Number of detected dangerous failures

DC Diagnostic Coverage Diagnostic Coverage - ratio between the failure

rate of dangerous failures detected by diagnostic

tests and total rate of dangerous failures of the

component or subsystem. The diagnostic

coverage does not include any failures detected

during proof tests.

MTBF Mean Time Between Failures Mean time between the occurrence of two

subsequent failures

SFF Safe Failure Fraction Fraction of safe failures as well as of detectable

dangerous failures

PFDavg Average Probability of dangerous

Failure on Demand

Average probability of dangerous failures on

demand of a safety function.

HFT Hardware Failure Tolerance Ability of a functional unit to execute a required

function while faults or deviations are present.

HFT = n means that the function can still be safely

executed for up to n faults occurring at the same

time.

Tproof Proof test interval Interval for proof test

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

6

A safety-related system can comprise stand-alone systems dedicated to perform a

particular safety function or can be integrated into a plant.

Proof test

Periodic test is performed to detect dangerous hidden failures in a safety-related system so

that, if necessary, a repair can restore the system to an "as new" condition or as close as

practical to this condition.

MTTR (Mean Time To

Restoration)

Mean time to restoration once a failure has occurred, indicates the expected mean time to

achieve restoration of the system. It is therefore an important parameter for system

availability for the safety function. The time for detecting the failure, planning tasks, as well

as operating resources is also included. This should be reduced to a minimum.

MRT (Mean Repair Time)

Mean repair time indicates the mean time required to repair a system. The MRT is crucial

when defining the reliability and availability of a system for safety operation. The MRT should

preferably be small.

Device type (type A and

type B)

Actuator controls version can be regarded as type A devices if all of the following conditions

are met for all components required to achieve the safety instrumented function:

• The failure modes for all constituent components involved are well defined.

• The behavior under fault conditions can be completely determined.

• There is sufficient dependable failure data from the field to show that the claimed rates of

failure are met (confidence level min. 70%).

Actuator controls shall be regarded as type B devices if one or several of the following

conditions are met:

• The failure of at least one constituent component is not well defined.

• The fault behavior is not completely known.

• There is insufficient dependable failure data to support claims for rates of failure for

detected and undetected dangerous failures.

PTC (Proof Test Cover-

age)

Proof test coverage describes the fraction of failures which can be detected by means of a

proof test.

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

7

2 Application and validity

2.1 Range of application

AUMA actuators and actuator controls in SIL version are intended for operation of industrial

valves and are suitable for use in safety instrumented systems in accordance with IEC 61508

/ IEC 61511.

2.2 Standards

Actuators and actuator controls meet the following requirements:

• IEC 61508 ED.2: Functional safety of electrical/electronic/programmable electronic

safety-related systems

2.3 Valid device types

The data on functional safety contained in this manual applies to the device types indicated

hereafter.

Table 2: Overview on suitable device types

Hardware, software and configuration of actuator and actuator controls must not be modified

without prior written consent by AUMA. Unauthorized modification may have a negative

impact on both safety figures and SIL capability of the products.

Information

In applications with requirements on functional safety, only AUMA actuator controls and

actuators in SFC or SIL version may be used.

AUMA actuator controls and actuators in SIL version can be identified by the letters “SIL” on

the nameplate.

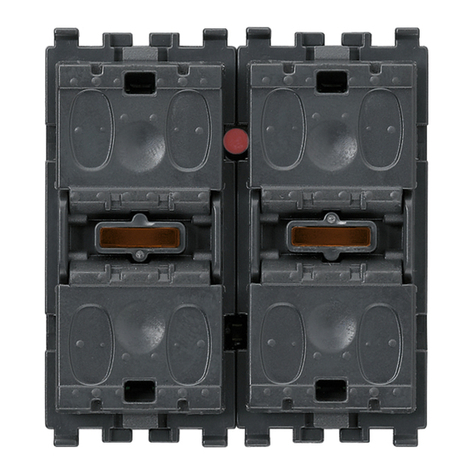

Figure 1: Example of name plate with “SIL” marking on EPAC.

Type

Power supply

Actuator

Controls

Motor

SA3 – SA100 EPAC controls in SIL version 3-phase AC current

SAR3 – SAR100 EPAC controls in SIL version 3-phase AC current

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

8

3 Architecture, configuration and applications

3.1 Architecture (actuator sizing)

For actuator architecture (actuator sizing) the maximum torques, run torques and operating

times are taken into consideration.

Incorrect actuator architecture can lead to device damage within the safety- related

system!

Possible consequences can be valve damage, motor overheating, contactor jamming,

defective thyristors, heating up of cables or damage to cables.

→ The actuator technical data must imperatively be observed when selecting the

actuator.

→ Sufficient reserves have to be provided to ensure that actuators are capable of reliably

opening or closing the valve even in the event of an accident or under- voltage.

Architecture when using the Safe STOP function

Information

For the Safe STOP function, the motor is switched off, overrun may possibly occur!

Valve damage due to overrun!

→ For the Safe STOP function (SS), the overrun of the arrangement (actuator, gearbox,

valve) and the reaction time have to be observed.

→ If the application requires self-locking of the actuator, please consult AUMA.

Architecture when using the Safe STOP function

Actuators with electromechanical control unit:

For end position signaling (limit switching) and torque signaling via the electromechanical

control unit are safe signals which may be integrated into a safety-related system. However,

this signal is not part of the certification by TÜV Nord. Please refer to the specific safety

manual for details regarding this signal.

For “SIL seating” = “no seating” (without end position protection), we recommend:

• To prevent valve damage during safety operation, we recommend, depending on the

stiffness, sizing the valve to 3 – 5 times the maximum actuator torque.

• To avoid thermal damage due to excessive currents, we recommend monitoring

(assessing) the motor protection.

Actuators with electronic control unit MWG:

Information

For end position signaling (limit switching) and torque signaling via the electronic control unit

MWG are not considered as safe signals.

• In case safe signals are required, they have to be implemented differently, e.g. using

switches on the valve.

• To prevent valve damage during safety operation, we recommend, depending on the

stiffness, sizing the valve to 3 – 5 times the maximum actuator torque.

• To avoid thermal damage due to excessive currents, we recommend monitoring

(assessing) the motor protection.

NOTICE

NOTICE

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

9

Actuators with electronic control unit MWG including limit switches:

Information

In this version, safe signaling can exclusively be ensured via limit switches. However, this

signal is not part of the certification by TÜV Nord. Please refer to the specific safety manual

for details regarding this signal.

For “SIL seating” = “no seating” (without end position protection), we recommend:

• To prevent valve damage during safety operation, we recommend, depending on the

stiffness, sizing the valve to 3 – 5 times the maximum actuator torque.

• To avoid thermal damage due to excessive currents, we recommend monitoring

(assessing) the motor protection.

Information

For “SIL seating” = “Forced limit seating in end position”, the seating is performed via limit

switches in the end position. Since, each switch has a hysteresis, the actuator leaves the end

position prior to limit switch release. Consequently, there is a marginal range of actuator

positions to the safety position, for which the limit switch is still operated when leaving the

safety position, while the Safe ESD function is NOT available. In this case, safety function

triggering leads to actuator standstill. If the range in question is approached from the opposite

direction, this limitation does not apply. In general this range is relatively small. However, for

unfavorable configurations (low number of turns per stroke), this range can amount to more

than 10 % of the total stroke.

Should within the framework of unfavorable conditions the effect described above represent

an unacceptable limitation for the safety function, we recommend applying the configuration

“Forced torque seating in end position” or “no seating” for safety operation.

Power Supply

Information

The plant operator is responsible for power supply.

3.2 Configuration (setting)/version

Configuration (setting) of safety-related functions is defined in the factory during actuator

controls assembly and validated during final inspection. Subsequent modification of the

configuration by the plant operator is not permissible.

General functions are set as described in the Operation instructions or the Manual (Operation

and setting) 3.XX EPAC actuator.

Configuration of safety-related functions is listed in the order-related technical data sheet.

Configuration options for safety function

Table 3:

When configuring a Safe ESD function and a Safe STOP function, the Safe ESD function is

always prioritized compared to the Safe STOP function when requested simultaneously.

Configuration options for safety function

Configuration

SIL function

Short description

Safe ESD CLOSE/CLOSE

Safe CLOSING

Safe ESD OPEN/OPEN

Safe OPENING

Safe STOP CLOSE/OPEN

Safe STOP in direction CLOSE and direction OPEN

Safe ESD CLOSE/CLOSE + Safe STOP

CLOSE/OPEN

Safe CLOSING and Safe STOP in direction CLOSE and direc-

tion OPEN

Safe ESD OPEN/OPEN + Safe STOP

CLOSE/OPEN

Safe OPENING and Safe STOP in direction CLOSE and direc-

tion OPEN

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

10

Seating configuration options

Information

Seating of standard actuator controls should be configured as set forth in the tables below.

Table 4:

Table 5:

Table 6:

Configuration options for motor protection assessment

Table 7:

Information

“SIL motor protection” = “inactive” configuration is only set if explicitly required. The version

does not meet the Ex approval requirements.

3.3 Protection against uncontrolled operation (self-locking/brake)

For self-locking AUMA actuators, it can be assumed that a load up to nominal torque will not

result in uncontrolled valve operation from standstill due to valve torque load. Consequently,

in these cases, further protection against uncontrolled operation is not imperatively required.

However, certain applications may require active position locking, for example by using a

brake. There are user-specific standards demanding this type of protection. Therefore, each

project must be subject to individual verification if any further protection is required. In any

case this protection is required for actuators without self-locking.

For actuators with electromechanical control unit:

Configuration

SIL seating type

Short description

Configuration

Type of seating

Standard controls

1: No seating

No seating by limit or torque switches during

safety operation

Freely selectable

2: Forced torque seating

in end position

Safety operation is stopped if both limit and

torque switches trip simultaneously

Torque seating

3: Forced limit seating in

end position

Safety operation is stopped by limit switch trip-

ping

Limit seating

4: Limit seating with

overload protection

Safety operation is stopped by tripping the limit

switches and/or the torque switches (overload

protection).

Limit seating

For actuators with electronic control unit MWG

Configuration

SIL seating type

Short description

Configuration

Type of seating

Standard controls

1: No seating

No seating by limit or torque switches during

safety operation

Freely selectable

For actuators with electronic control unit MWG including limit switches

Configuration

SIL seating type

Short description

Configuration

Type of seating

Standard controls

3: Forced limit seating in

end position

Safety operation is stopped by limit switch trip-

ping

Limit seating

Configuration options for motor protection assessment

Configuration

SIL motor protection

Short description

Active

Tripping of the motor protection (thermal fault) stops or prevents safety oper-

ation

Inactive

Motor protection has no impact on the safety operation

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

11

Table 8: Overview self-locking for AUMA actuators (at the time of printing of this document)

If actuators with insufficient self-locking function paired with “Forced torque seating in end

position” SIL seating type are used for the safety function, the following effect might occur:

During ESD, the actuator operates to the end position and switches off due to reaching

the travel position and the tripping torque. Thereafter, the gear train is relieved and the

torque falls below the preset limit value. As a matter of fact, the actuator controls detect

this incident and switch the actuator on again since the behavior is correctly considered

as termination of the ESD condition. The latter generates additional torque until the

switching off condition is reached again, and so on. The “pumping effect” of the actuator is

the consequence.

To successfully avoid this incident, we recommend either selecting actuator or other

elements with sufficient self-locking within the gear train or – if acceptable from a process and

safety point of view – selecting “Forced limit seating in end position” as safety function.

3.4 Operation mode (low/high demand mode)

The safety functions of the actuators supplied by AUMA are suitable for the low demand

mode and may only be used in this operation mode. If a non-safety instrumented function of

basic process control system is executed via the same actuator in addition to the safety

function, note that while considering the sum of non-safety instrumented function, required

1)

tests and safety function, the defined number of maximum permissible cycles for the

2)

respective actuator as well as the maximum number of starts may not be exceeded during

deployment of the actuator within a safety instrumented system.

3.5 Further notes and indications on architecture

HFT is 0.

The systematic capability is 3 (SC=3)

Only flanges of sizes or larger may be used for valve attachment.F07 or FA07

If the actuator is equipped with a position transmitter like MWG, RWG or EWG, they may not

be integrated within the safety instrumented system.

The actuator safety functions can be considered as type A device.

The operating time for a complete stroke must exceed 4 seconds. Attention: Any modification

of the nominal stroke results in operating time change.

Safety function(s) and their feedback signals may only be issued via the digital inputs and

outputs of the SIL module.

The signal issued via SIL fault output must be permanently evaluated. If the output

signals a fault, assumption can be made that the safety function is not available. The safety

function must be checked without delay. Possibly further safety measures are to be taken

until the safety function is restored without fault.

3.6 Applications (environmental conditions)

When specifying and using the actuators within safety instrumented systems, make sure that

the permissible service conditions and the EMC requirements by the peripheral devices are

met. Service conditions are indicated in the technical data sheets:

Type

Output speed

Self-locking

50 Hz

60 Hz

SA 3 – SA 100

90 rpm or below

108 rpm or below

Self-locking

SAR 3 – SAR 100

125 rpm or above

150 rpm or above

NOT self-locking

1) Definition of “cycles” according to EN 15714-2:2010

2) Definition of “starts” according to DIN EN 15714-2:2010

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

12

• Enclosure protection test

• Corrosion protection test

• Ambient temperature

• Definition of “cycles” test

• Definition of “starts” test

• Vibration resistance

If the actual ambient temperatures exceed an average of +40 °C, the lambda values have to

be incremented by a safety factor. For an average temperature of +60 °C, this factor is

specified to 2.5.

For environmental test, actuator and actuator controls will be subjected to the following tests:

• Dry heat test

• Damp heat test

• Vibration test

• Induced seismic vibration (earthquake)

• Enclosure protection IP68 test

• Salt spray test

• Immunity requirements test

• Emission test

All SIL actuators will be with below caution label for identification.

NOTICE

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

13

4 Safety instrumented systems and safety functions

4.1 Safety instrumented system including an actuator

Typically, a safety instrumented system including an actuator is composed of the

components as shown in the figure.

Figure 2: Typical safety instrumented system

[1] Sensors

[2] Controls (safety PLC)

[3] Actuator with actuator controls

[4] Valve

[5] Process control system

The safety integrity level is always assigned to an overall safety instrumented system and not

to an individual component.

For an individual component (e.g. an actuator), safety figures are determined. These figures

are used to assign the devices to a potential safety integrity level (SIL). The final classification

of the safety instrumented system can only be made after assessing and calculating all

subsystems.

4.2 Safety functions

In calculating the safety figures of actuators, the following safety functions are taken into

account:

• Safe ESD function (Emergency Shut Down): Safe OPENING/CLOSING

- Redundant Safe ESDa and Safe ESDb signals (standard: low active) make the

actuator travel to the configured direction (OPEN/CLOSE).

• Safe STOP function: Safe STOP

- An operation command of standard controls (in directions OPEN or CLOSE) will only

be executed if an additional enable signal for the operation command is applied.

- If this is not the case, operation in directions OPEN or CLOSE is stopped or even

suspended (motor is switched off).

• Safe ESD function combined with Safe STOP function.

- Safe ESD function has a higher priority i.e. if both functions are activated, the

actuator is operated into the configured direction (OPEN/CLOSE).

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

14

“Safe end position feedback” is not part of the certification by TÜV Nord and neither part of

this safety manual. Please refer to the specific safety manual for details regarding this

function.

The different configuration options of the safety functions are described in the <Configuration

(setting)/version> chapter.

4.3 Safe inputs and outputs

Safe inputs for Safe OPENING/CLOSING (Safe ESD function):

• Safe ESDa

• Safe ESDb

Safe inputs for safe stop (Safe STOP function):

• Safe STOP OPEN

• Safe STOP CLOSE

Safe outputs (indication that it might not be possible to perform the safety function:

• SIL fault

• SIL ready

For detailed information on safe inputs and outputs, refer to <Configuration (setting)/version>

chapter and <Installation> chapter.

4.4 Redundant system architecture

Besides the already described typical safety instrumented system including an actuator,

safety can be increased by integrating a second, redundant valve and actuator with actuator

controls in SIL version into the safety instrumented system. The decision on the correct

version depends on the entire system. With the redundant system architecture shown below,

actuator with actuator controls achieve SIL 3 in accordance with IEC 61508.

Figure 3: Redundant system with Safe ESD for Safe CLOSING

Figure 4: Redundant system with Safe ESD for Safe OPENING

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

15

4.5 Examples of applications

Safe OPENING of a pressure vessel using the Safe ESD function

The standard PLC controls the entire system. A system fault occurs if excessive pressure is

generated within the system. In this case, the safety PLC immediately opens the valve for

safe pressure relief.

Figure 5: Application example: Pressure vessel

Safe stop of locks to prevent destruction using the Safe STOP function.

Operation safety (preventing hazards to persons and systems) is of utmost importance for

locks. Once the lock closes, no boats must be between the gates. Otherwise, the Safe STOP

function (e.g. via EMERGENCY Stop button) is executed.

Figure 6: Application example: Lock

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

16

4.6 System representation

The representation below shows the simplified design of an epac in SIL version.

Figure 7: Simplified system representation

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

17

5 Installation, commissioning and operation

Information

Installation and commissioning have to be documented by means of an assembly report and

an inspection certificate. Installation and commissioning may only be performed by

authorised personnel who have been trained on functional safety.

The plant operator is responsible for ensuring power supply protection against over-voltage

and under-voltage during execution of a safety function.

5.1 Installation

Information

The PIN assignments (XK ...) mentioned in this chapter (and also in other chapters) are

considered as standard assignments of SA series with controls 3.XX /NI/SIL. In certain

configurations, this PIN assignment could be different and for the typical assignment refer to

wiring diagram as applicable.

General installation tasks (assembly, electrical connection) have to be performed according

to the operation instructions pertaining to the device and the enclosed order-specific wiring

diagram.

Safety functions are connected via the SIL module integrated in the SA series with 3.XX

/NI/SIL actuator controls.

SIL fault must be connected to a SIL2 compatible input of a safety PLC and subsequently

analyzed.

Figure 8: Connections for safety functions via SIL module

[1] Typical connection assignment for parallel control

[2] Typical connection assignment for fieldbus control

Input switching behavior of Safe ESDa/ESDb and Safe STOP OPEN/CLOSE:

•Input level = high level (standard: +24 V DC)

= No safety operation for Safe ESD function or

= No safe stop for Safe STOP function

•Input signal = low level (0 V DC or input open)

= Failure operation for Safe ESD function or

= Safe stop for Safe STOP function

Permissible input voltage range:

• High level: 15 – 30 V DC

• Low level: max. 5 V DC

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

18

Signal behavior of SIL ready and SIL failure outputs:

•SIL ready/ Absence of fault to be detected by diagnostics:

NO (NO contact) output = closed

NC (NC contact) output = open

SIL fault displayed via SIL failure output

For further information on SIL faults and in particular to assist in troubleshooting, refer to

chapter <Indications>.

Information

In case of mains failure, the SIL module would no longer be operable.

5.2 Commissioning

The operation instructions pertaining to the device must be observed for general

commissioning.

Information

For the Safe ESD function, operation into the safe position can be performed irrespective of

the selector switch position (LOCAL - OFF - REMOTE) or the operating status. Even in

positions LOCAL and OFF or at system start, the actuator can start by triggering the safety

function.

Risk of immediate actuator start when switching on

Risk of personal injuries or damage to the valve

→ Ensure that high level is present at the Safe ESDa/ESDb inputs when switching

on (standard: +24 V DC).

Designation

Wiring diagram

Signal

Customer connections for

control (typical assignment)

[1] Parallel

[2] Fieldbus

Safe ESDa Digital input for Safe ESD function XK 31 XK 3

Safe ESDb Redundant input for Safe ESD function XK 32 XK 5

0 V Reference potential for Safe ESDa and Safe ESDb XK 33 XK 7

Safe STOP CLOSE Digital input for Safe STOP function in direction CLOSE XK 35 XK 8

0 V Reference potential for Safe STOP CLOSE XK 37 XK 9

Safe STOP OPEN Digital input for Safe STOP function in direction OPEN XK 36 XK 10

0 V Reference potential for Safe STOP OPEN XK 38 XK 11

SIL ready NO contact of SIL fault signal XK 40 XK 15

SIL failure NC contact of SIL fault signal XK 39 XK 14

Com. Reference potential for SIL fault signal XK 42 XK 16

Fault causes

SIL

Description

Thermal fault Motor protection tripped

Torque fault Torque fault in directions OPEN and/or CLOSE

Fault position feed-

back

Current position feedback is outside permissible range.

Phase failure One phase of power supply is missing.

Controls are not supplied with mains voltage

Power supply failure The safety-related part of controls is without power supply.

Failure of actuator

monitoring

Actuator not operated on Safe ESDa and ESDb command.

Fault in redundant

wiring Safe ESD

Both signals Safe ESDa and Safe ESDb are not simultaneously on the same

level.

Internal error Internal error of the SIL module

! CAUTION

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

19

After commissioning, the safe actuator function must be verified. Refer to <Proof test>

chapter.

5.3 Operation

Regular maintenance and device checks in determined T intervals are the basis for safe

proof

operation. The figures indicated in the <Safety figures> chapter are valid for T = 1 year.

proof

For operation, both the pertaining operation instructions and the manual (Operation and

setting) SA series with epac 3.XX /NI/SIL have to be observed.

In case of possible failures or defects of the safety system, safe function must be guaranteed

by introducing alternative actions. Furthermore, a detected fault including fault description

has to be sent to AUMA. Autonomous repair work by the plant operator is not permitted.

5.4 Lifetime

Lifetime of actuators is described in the technical data sheets or the operation instructions.

Safety-related figures are valid for the cycles or modulating steps defined in the technical

data specifications for typical periods of up to 10 years (the criterion achieved first is valid).

After this period, the probability of failure increases.

Extending this period is basically feasible in many cases provided both manufacturer and

operator introduce respective actions in compliance with footnote N3 of IEC 61508-2:2010

7.4.9.5 b). This is the responsibility of the operator who will have to take appropriate and

suitable measures. Please contact us if you need support in identifying suitable measures.

5.5 Decommissioning

When decommissioning an actuator with safety functions, the following must be observed:

• Impact of decommissioning on relevant devices, equipment on other work must be

evaluated.

• Safety and warning instructions contained in the actuator operation instructions must be

met.

• Decommissioning must be carried out exclusively by suitably qualified personnel.

• Decommissioning must be recorded in compliance with regular requirements.

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

20

6 Indications on display

This section contains indications of standard controls only available in SIL version. General

indications as well as settings and operation are described in the pertaining operation

instructions and in the manual (operation and setting) SA series with epac 3.XX /NI/SIL.

Information

Indications on the display are not part of a safety function! They must not be integrated in a

safety-related system!

The indications support the user on site at the device, to understand the safety function status

easily.

6.1 Status indications on SIL functions

Actuator controls may indicate status information on safety-related functions on the display.

SIL status (S001)

Indication Signals the safety function and the SIL fault indication status. S001

If the SIL symbol is shown in the header of the display, one of the following three

indications is active: , or .Safe ESD Safe STOP SIL fault

Figure 9: Safety function and SIL fault indication status

Warnings (S003)

Indication shows the numbers of warnings having occurred.S003

In case a occurs, the message is listed in indication . Refer to SIL fault SIL fault Details > S003

Status for further details.

Figure 10: Warning: SIL fault

Status indications on

display

Status

Safe ESD Safe ESD function (Safe OPENING/CLOSING) is active: Actuator

is operated in the configured direction (CLOSE/OPEN) (inputs

Safe ESDa/Safe ESDb = 0 V or open)

Safe STOP Safe STOP function is active, actuator stops (Safe STOP

OPEN or Safe STOP CLOSE = 0 V or open inputs)

SIL fault SIL fault signal active, i.e. possible problems when executing a

safety function (Safe ESD or Safe STOP).

Multi-turn actuators

SA series with Control 3.XX /NI/SIL

Other manuals for SA 3

1

This manual suits for next models

3

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SA 07.1 User manual

AUMA

AUMA SAVEx 07.2 User manual

AUMA

AUMA SA 07.2 User manual

AUMA

AUMA SA 07.2 User manual

AUMA

AUMA SA-UW User manual

AUMA

AUMA SA 48.1 SAR 25.1 User manual

AUMA

AUMA VARIOMATIC SARV 10.1 User manual

AUMA

AUMA SA 25.1 User manual

AUMA

AUMA PROFOX PF-M25 User manual

AUMA

AUMA SAExC 07.1 User manual