AUMA SA 07.2 User manual

Control

Parallel

Profibus DP

Profinet

→Modbus RTU

Modbus TCP/IP

EtherNet/IP

Foundation Fieldbus

HART

Multi-turn actuators

SA 07.2 –SA 16.2

SAR 07.2 –SAR 16.2

Control unit - electromechanical

with actuator controls

AC 01.2 Intrusive

Assembly and commissioningOperation instructions

Read operation instructions first.

●Observe safety instructions.

●These operation instructions are part of the product.

●Store operation instructions during product life.

●Pass on instructions to any subsequent user or owner of the product.

Target group:

This document contains information for assembly, commissioning and maintenance staff.

Reference documents:

●Manual (Operation and setting) of actuator controls AC 01.2 Modbus

●Manual (Fieldbus device integration) of actuator controls AC 01.2 Modbus

Reference documents are available on the Internet at: http://www.auma.com.

Table of contents Page

51. Safety instructions................................................................................................................. 51.1. Prerequisites for the safe handling of the product 51.2. Range of application 61.3. Warnings and notes 61.4. References and symbols

72. Short description...................................................................................................................

93. Name plate..............................................................................................................................

134. Transport and storage........................................................................................................... 134.1. Transport 154.2. Storage

165. Assembly................................................................................................................................ 165.1. Mounting position 165.2. Handwheel fitting 165.3. Mount actuator to valve 175.3.1. Overview of output drive types 175.3.2. Output drive type A 185.3.2.1. Multi-turn actuator with output drive type A:mount 205.3.2.2. Stem nut for output drive type A: finish machining 215.3.3. Output drive types B/C/D and E 225.3.3.1. Multi-turn actuator with output drive type B:mount 235.4. Accessories for assembly 235.4.1. Stem protection tube for rising valve stem 245.5. Mounting positions of local controls 245.5.1. Mounting positions: modify

256. Electrical connection............................................................................................................. 256.1. Basic information 286.2. SD electrical connection (AUMA plug/socket connector) 296.2.1. Terminal compartment (for mains connection): open 306.2.2. Cable connection 316.2.3. Terminal compartment (for mains connection): close 326.2.4. Fieldbus terminal compartment: open

2

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Table of contents AC 01.2 Intrusive Modbus RTU

336.2.5. Fieldbus cables: connect 346.2.6. Fieldbus terminal compartment: close 356.3. Accessories for electrical connection 356.3.1. Actuator controls on wall bracket 366.3.2. Parking frame 366.3.3. DS intermediate frame for double sealing 376.3.4. External earth connection

387. Operation................................................................................................................................ 387.1. Manual operation 387.1.1. Manual valve operation 397.2. Motor operation 397.2.1. Operating the actuator from local controls 407.2.2. Actuator operation from remote 407.3. Menu navigation via push buttons (for settings and indications) 417.3.1. Menu layout and navigation 427.4. User level, password 437.4.1. Password entry 437.4.2. Password change 447.4.3. Timeout for incorrect password entry 447.5. Language in the display 447.5.1. Language change

468. Indications.............................................................................................................................. 468.1. Indications during commissioning 468.2. Indications in the display 478.2.1. Feedback signals from actuator and valve 498.2.2. Status indications according to AUMA classification 508.2.3. Status indications according to NAMUR recommendation 518.3. Indication lights of local controls 528.4. Optional indications 528.4.1. Mechanical position indication via indicator mark

539. Signals (output signals)......................................................................................................... 539.1. Status signals via output contacts (digital outputs) 539.1.1. Assignment of outputs 539.1.2. Coding the outputs 539.2. Analogue signals (analogue outputs)

5410. Commissioning (basic settings)........................................................................................... 5410.1. Type of seating: set 5510.2. Fieldbus address (slave address), baud rate, parity and monitoring time: set 5510.3. Open switch compartment 5610.4. Torque switching: set 5710.5. Limit switching: set 5710.5.1. End position CLOSED (black section): set 5710.5.2. End position OPEN (white section):set 5810.6. Intermediate positions: set 5810.6.1. Running direction CLOSE (black section):set 5910.6.2. Running direction OPEN (white section):set 5910.7. Test run 5910.7.1. Direction of rotation at mechanical position indicator: check 6010.7.2. Direction of rotation at hollow shaft/stem: check

3

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

AC 01.2 Intrusive Modbus RTU Table of contents

6110.7.3. Limit switching: check 6110.7.4. Reference operation position feedback: perform 6110.8. Close switch compartment

6311. Commissioning (optional equipment settings)................................................................... 6311.1. EWG 01.1 electronic position transmitter 6411.1.1. Measuring range: set 6511.1.2. Current values : adjust 6511.1.3. LED end position signalling: switch on/off 6511.2. Potentiometer 6611.2.1. Potentiometer: set 6611.3. RWG electronic position transmitter 6711.3.1. Measuring range: set 6711.4. Mechanical position indicator: set

6912. Corrective action.................................................................................................................... 6912.1. Faults during commissioning 6912.2. Fault indications and warning indications 7412.3. Fuses 7412.3.1. Fuses within the actuator controls 7412.3.2. Fuse replacement 7412.3.2.1. Replace fuses F1/F2 7512.3.2.2. Test/replace fuses F3/F4 7512.3.3. Motor protection (thermal monitoring)

7713. Servicing and maintenance................................................................................................... 7713.1. Preventive measures for servicing and safe operation 7813.2. Maintenance 7813.3. Disposal and recycling

7914. Technical data......................................................................................................................... 7914.1. Technical data Multi-turn actuators 8114.2. Technical data Actuator controls 8714.3. Tightening torques for screws

8815. Spare parts............................................................................................................................. 8815.1. Multi-turn actuators SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 9015.2. AC 01.2 actuator controls with SD electrical connection

92Index........................................................................................................................................

4

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Table of contents AC 01.2 Intrusive Modbus RTU

1. Safety instructions

1.1. Prerequisites for the safe handling of the product

Standards/directives The end user or the contractor must ensure that all legal requirements, directives,

guidelines, national regulations and recommendations with respect to assembly,

electrical connection, commissioning and operation are met at the place of installation.

They include among others:

●Applicable configuration guidelines for fieldbus applications.

Safety instructions/

warnings All personnel working with this device must be familiar with the safety and warning

instructions in this manual and observe the instructions given. Safety instructions

and warning signs on the device must be observed to avoid personal injury or property

damage.

Qualification of staff Assembly, electrical connection, commissioning, operation, and maintenance must

be carried out by suitably qualified personnel authorised by the end user or contractor

of the plant only.

Prior to working on this product, the staff must have thoroughly read and understood

these instructions and, furthermore, know and observe officially recognised rules

regarding occupational health and safety.

Commissioning Prior to commissioning, imperatively check that all settings meet the requirements

of the application. Incorrect settings might present a danger to the application, e.g.

cause damage to the valve or the installation.The manufacturer will not be held

liable for any consequential damage. Such risk lies entirely with the user.

Operation Prerequisites for safe and smooth operation:

●Correct transport, proper storage, mounting and installation, as well as careful

commissioning.

●Only operate the device if it is in perfect condition while observing these instruc-

tions.

●Immediately report any faults and damage and allow for corrective measures.

●Observe recognised rules for occupational health and safety.

●Observe national regulations.

●During operation,thehousingwarms up and surfacetemperatures>60°Cmay

occur.To prevent possible burns, we recommend checking the surface temper-

ature prior to working on the device using an appropriate thermometer and

wearing protective gloves.

Protective measures The end user or the contractor are responsible for implementing required protective

measures on site, such as enclosures, barriers, or personal protective equipment

for the staff.

Maintenance To ensure safe device operation, the maintenance instructions included in this manual

must be observed.

Any device modification requires prior written consent of the manufacturer.

1.2. Range of application

AUMA multi-turn actuators SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 are designed

for the operation of industrial valves, e.g.globe valves, gate valves, butterfly valves,

and ball valves.

Other applications require explicit (written) confirmation by the manufacturer.

The following applications are not permitted, e.g.:

●Industrial trucks according to EN ISO 3691

●Lifting appliances according to EN 14502

●Passenger lifts according to DIN 15306 and 15309

5

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

AC 01.2 Intrusive Modbus RTU Safety instructions

●Service lifts according to EN 81-1/A1

●Escalators

●Continuous duty

●Buried service

●Continuous underwater use (observe enclosure protection)

●Potentially explosive areas

●Radiation exposed areas in nuclear power plants

No liability can be assumed for inappropriate or unintended use.

Observance of these operation instructions is considered as part of the device's

designated use.

Information These operation instructions are only valid for the "clockwise closing" standard

version, i.e. driven shaft turns clockwise to close the valve.

1.3. Warnings and notes

The following warnings draw special attention to safety-relevant procedures in these

operation instructions, each marked by the appropriate signal word (DANGER,

WARNING, CAUTION, NOTICE).

Indicates an imminently hazardous situation with a high level of risk. Failure

to observe this warning results in death or serious injury.

Indicates a potentially hazardous situation with a medium level of risk.Failure

to observe this warning could result in death or serious injury.

Indicates a potentially hazardous situation with a low level of risk. Failure to

observe this warning could result in minor or moderate injury. May also be

used with property damage.

Potentially hazardous situation. Failure to observe this warning could result

in property damage. Is not used for personal injury.

Safety alert symbol warns of a potential personal injury hazard.

The signal word (here: DANGER) indicates the level of hazard.

1.4. References and symbols

The following references and symbols are used in these instructions:

Information The term Information preceding the text indicates important notes and information.

Symbol for CLOSED (valve closed)

Symbol for OPEN (valve open)

Via the menu to parameter

Describes the menu path to the parameter.When using the push buttons of local

controls, the required parameter can be quickly found on the display. Display texts

are shaded in grey: Display.

➥Result of a process step

Describes the result of a preceding process step.

6

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Safety instructions AC 01.2 Intrusive Modbus RTU

2. Short description

Multi-turn actuator Definition in compliance with EN 15714-2/EN ISO 5210:

A multi-turn actuator is an actuator which transmits torque to a valve for at least one

full revolution.

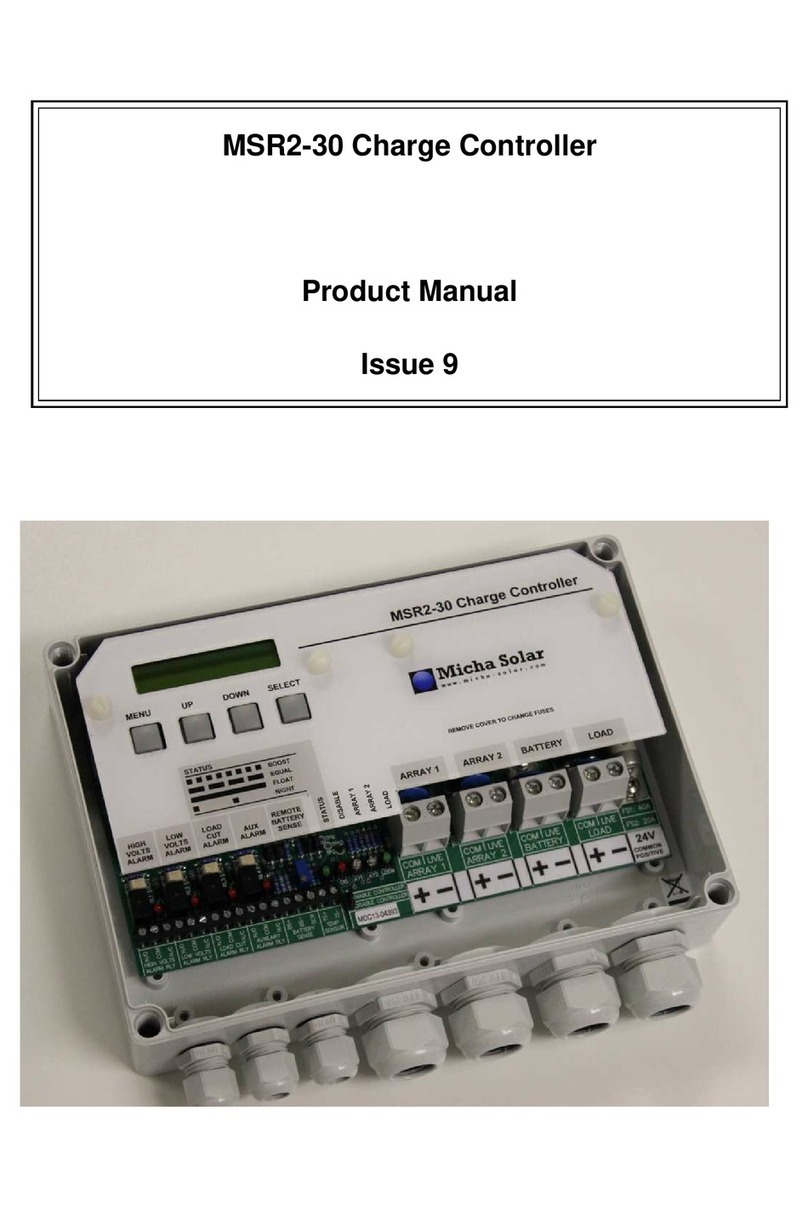

AUMA multi-turn actuat-

or Figure 1: AUMA SA 10.2 multi-turn actuator

[1] Multi-turn actuator with motor and handwheel

[2] Actuator controls

[3] Local controls with display, (a) selector switch and (b) push button

[4] Valve connection, e.g. output drive type A

AUMA multi-turn actuators SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 are driven by

an electric motor. A handwheel is available for setting and emergency operation.

Switching off in end positions may be either by limit or torque seating.

Actuator controls are required to operate or process the actuator signals.

For non-intrusive version (control unit:electromechanical version), limit and torque

setting is made via switches within the actuator.

For non-intrusive version (control unit:electronic version), limit and torque setting is

made via the actuator controls, neither actuator nor the actuator controls housing

have o be opened.For this purpose, the actuator is equipped with an MWG (magnetic

limit and torque transmitter), also capable of supplying analogue torque feedback

signals/torque indication and analogue position feedback signals/position indication

at the actuator controls output.

In combination with output drive type A, the actuator is capable of withstanding thrust.

Actuator controls The actuator controls AC 01.2 may be mounted directly to the actuator or separately

on a wall bracket.

The actuator can be operated via the push buttons on the local controls of the actuator

controls or settings can be made in the actuator controls menu.The display shows

information on the actuator as well as the menu settings.

The functions of the actuator controls include standard valve control in OPEN-CLOSE

duty, positioning, process control, logging of operating data, diagnostic functions

right through control via various interfaces (e.g. fieldbus, Ethernet and HART).

App and software

Using the AUMA CDT software forWindows-based computers (notebooks or tablets)

and the AUMA Assistant App, actuator data can be uploaded and read, settings

can be modified and stored.The connection between computer and AUMA actuator

is established wireless via Bluetooth interface.With the AUMA Cloud, we provide

an interactive platform to collect and assess e.g.detailed device data of all actuators

within a plant.

7

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

AC 01.2 Intrusive Modbus RTU Short description

Figure 2: Communication via Bluetooth

AUMA CDT AUMA CDT is a user-friendly setting and operation program for AUMA actuators.

AUMA CDT software can be downloaded free of charge from our website

www.auma.com.

AUMA Cloud

The AUMA Cloud is the driving element of the digital AUMA world, acting as

interactive platform for efficient maintenance of AUMA actuators at moderate cost.

The AUMA Cloud collects all device data of all actuators within one site and provides

a clear overview at a glance. Detailed analysis provides valuable information on

potential maintenance requirements.Additional functions foster smooth asset

management.

AUMA Assistant App

The AUMA Assistant App enables remote setting and remote diagnostics of AUMA

actuators via Bluetooth using either smartphone or tablet.

The AUMA Assistant App can be downloaded free of charge from the Play Store

(Android) or App Store (iOS).

Figure 3: Link to AUMA Assistant App

8

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Short description AC 01.2 Intrusive Modbus RTU

3. Name plate

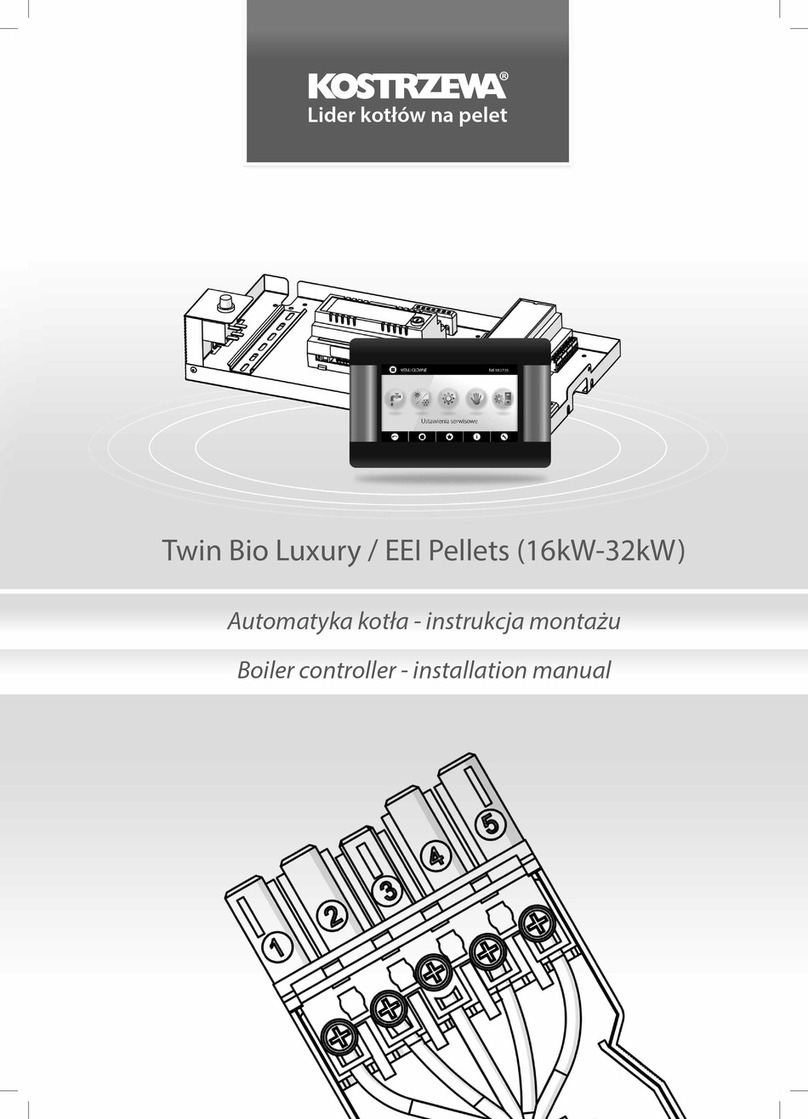

Figure 4: Arrangement of name plates

[1] Actuator name plate

[2] Actuator controls name plate

[3] Motor name plate

[4] Additional plate, e.g. KKS plate (Power Plant Classification System)

Actuator name plate

Figure 5: Actuator name plate (example)

(= manufacturer logo); (= CE mark)

[1] Name of manufacturer

[2] Address of manufacturer

[3] Type designation

[4] Order number

[5] Serial number

[6] Speed

[7] Torque range in direction CLOSE

[8] Torque range in direction OPEN

[9] Type of lubricant

[10] Permissible ambient temperature

[11] Can be assigned as an option upon customer request

[12] Enclosure protection

[13] Data Matrix code

9

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

AC 01.2 Intrusive Modbus RTU Name plate

Actuator controls name plate

Figure 6: Name plate for actuator controls (example)

[1] Type designation

[2] Order number

[3] Serial number

[4] Actuator terminal plan

[5] Actuator controls terminal plan

[6] Mains voltage

[7] AUMA power class for switchgear

[8] Permissible ambient temperature

[9] Enclosure protection

[10] Control

[11] Data Matrix code

Motor name plate

Figure 7: Motor name plate (example)

(= manufacturer logo); (= CE mark)

[1] Motor type

[2] Motor article number

[3] Serial number

[4] Current type, mains voltage

[5] Rated power

[6] Rated current

[7] Type of duty

[8] Enclosure protection

[9] Motor protection (temperature protection)

[10] Insulation class

[11] Speed

[12] Power factor cos phi

[13] Mains frequency

[14] Data Matrix code

10

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Name plate AC 01.2 Intrusive Modbus RTU

Descriptions referring to name plate indications

Type designation Table 1:

Description of type designation (with the example of SA 07.2-F07)

-F1007.2

Type SA = Multi-turn actuators for open-close duty

Type SAR = Multi-turn actuators for modulating duty

Size

These instructions apply to sizes 07.2, 07.6, 10.2, 14.2, 14.6, 16.2

07.2

Flange sizeF10

Table 2:

Description of actuator controls type designation (with the example of AC 01.2)

01.2AC

Type AC = AUMATIC actuator controlsAC

Size 01.201.2

Order number The product can be identified using this number and the technical data as well as

order-related data pertaining to the device can be requested.

Please always state this number for any product inquiries.

On the Internet at http://www.auma.com > Service & Support >myAUMA, we offer

a service allowing authorised users to download order-related documents such as

wiring diagramsand technical data (both in German andEnglish),inspection certificate

and the operation instructions when entering the order number.

Actuator serial number Table 3:

Description of serial number (example of 0520MD12345)

MD123452005

Positions 1+2: Assembly in week = week 0505

Positions 3+4:Year of manufacture = 202020

Internal number for unambiguous product identificationMD12345

Actuator terminal plan Position 9 after TPA: Position transmitter version

0= without position transmitter

A, B, J, K, L, N, R,T = potentiometer

C, D, E, G, H, M, P, S, U = Electronic position transmitter

AUMA power class for

switchgear The switchgear used in the actuator controls (reversing contactors/thyristors) are

classified according to AUMA power classes (e.g.A1, B1, ....).The power class

defines the max. permissible rated power (of the motor) the switchgear has been

designed for.The rated power (nominal power) of the actuator motor is indicated in

kW on the motor name plate.For the assignment of the AUMA power classes to the

nominal power of the motor types, refer to the separate electrical data sheets.

For switchgear without assignment to any power classes, the actuator controls name

plate does not indicate the power class but the max. rated power in kW.

Control Table 4:

Control examples (indications on actuator controls name plate)

DescriptionInput signal

Control vie Modbus RTU interfaceModbus RTU

Control via Modbus RTU interface and control voltage for OPEN-CLOSE

control via digital inputs (OPEN, STOP, CLOSE)

Modbus RTU/24 V DC

11

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

AC 01.2 Intrusive Modbus RTU Name plate

Data Matrix code Whenregistered as authoriseduser,youmayuseour AUMA Assistant App to scan

the Data Matrix code and directly access the order-related product documents without

having to enter order number or serial number.

Figure 8: Link to AUMA Assistant App:

For further Service & Support, Software/Apps/...refer to www.auma.com

12

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Name plate AC 01.2 Intrusive Modbus RTU

4. Transport and storage

4.1. Transport

Actuator For transport to place of installation, use sturdy packaging.

Suspended load!

Death or serious injury.

→Do NOT stand below suspended load.

→Attach ropes or hooks for the purpose of lifting by hoist only to housing and NOT

to handwheel.

→Actuators mounted on valves: Attach ropes or hooks for the purpose of lifting

by hoist to valve and NOT to actuator.

→Actuatorsmountedtogearboxes:Attach ropes or hooks forthepurpose of lifting

by hoist only to the gearbox using eyebolts and NOT to the actuator.

→Actuators mounted to controls: Attach ropes or hooks for the purpose of lifting

by hoist only to the actuator and NOT to the controls.

→Respect total weight of combination (actuator, actuator controls, gearbox, valve)

→Secure load against falling down, sliding or tilting.

→Perform lift trial at low height to eliminate any potential danger e.g. by tilting.

Figure 9: Example: Lifting the actuator

Weights Table 5:

Weight for AC 01.2 actuator controls

Weight approx.[kg]with electrical connection type:

7AUMA plug/socket connector with screw-type connection

13

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

AC 01.2 Intrusive Modbus RTU Transport and storage

Table 6:

Weights for multi-turn actuators SA 07.2 –SA 16.2 / SAR 07.2 –SAR 16.2

with 3-phase AC motors

Weight2)

Motor type1)

Type designation

Actuator approx. [kg]

19VD...SA 07.2/

SAR 07.2 20AD...

20VD...SA 07.6/

SAR 07.6 21AD...

22VD...SA 10.2/

SAR 10.2 25AD...

44VD...SA 14.2/

SAR 14.2 48AD...

46VD...SA 14.6/

SAR 14.6 53AD...

67VD...SA 16.2/

SAR 16.2 83AD...

Refer to motor name plate1) Indicated weight includes AUMA NORM multi-turn actuator with 3-phase AC motor, electrical con-

nection in standard version, output drive type B1 and handwheel.For other output drive types, heed

additional weights.

2)

Table 7:

Weights for multi-turn actuators SA 07.2 –SA 16.2 / SAR 07.2 –SAR 16.2

With 1-phase AC motors

Weight2)

Motor type1)

Type designation

Actuator approx. [kg]

21VB...SA 07.2/

SAR 07.2 21VE...

28AE...

21VB...SA 07.6/

SAR 07.6 25VE...

28AE...

37AC...

28VE...48-4...SA 10.2/

SAR 10.2 31VE...48-2...

40AC... 56-4...

43AC... 56-2...

59VE...SA 14.2/

SAR 14.2 61VC...

63AC...

63VE...SA 14.6/

SAR 14.6 66VC...

Refer to motor name plate1) Indicated weight includes AUMA NORM multi-turn actuator with 1-phase AC motor, electrical con-

nection in standard version, output drive type B1 and handwheel.For other output drive types, heed

additional weights.

2)

14

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Transport and storage AC 01.2 Intrusive Modbus RTU

Table 8:

Weights for multi-turn actuators SA 07.2 –SA 16.2 / SAR 07.2 –SAR 16.2

With DC motors

Weight2)

Motor type1)

Type designation

Actuator approx. [kg]

29FN... 63-...SA 07.2/

SAR 07.2 32FN... 71-...

30FN... 63-...SA 07.6/

SAR 07.6 44FN... 80-...

33FN... 63-...SA 10.2/

SAR 10.2 36FN... 71-...

56FN... 90-...

68FN... 71-... / FN... 80-...SA 14.2/

SAR 14.2 100FN... 90-...

76FN... 80-... / FN... 90-...SA 14.6/

SAR 14.6 122FN... 112-...

123FN... 100-...SA 16.2/

SAR 16.2

Refer to motor name plate1) Indicated weight includes AUMA NORM multi-turn actuator with DC motor, electrical connection in

standard version, output drive type B1 and handwheel.For other output drive types, heed additional

weights.

2)

Table 9:

Weights for output drive type

[kg]Flange sizeType designation

1.1F07A 07.2

1.3F10

2.8F10A 10.2

6.8F14A 14.2

11.7F16A 16.2

4.2. Storage

Danger of corrosion due to inappropriate storage!

→Store in a well-ventilated, dry room.

→Protect against floor dampness by storage on a shelf or on a wooden pallet.

→Cover to protect against dust and dirt.

→Apply suitable corrosion protection agent to uncoated surfaces.

Risk of damage due to excessively low temperatures!

→Actuator controls may only be stored permanently down to –30 °C.

→On request, actuators controls may be transported in specific cases and for

short duration at temperatures down to –60 °C.

Long-term storage For long-term storage (more than 6 months), observe the following points:

1. Prior to storage:

Protect uncoated surfaces, in particular the output drive parts and mounting

surface, with long-term corrosion protection agent.

2. At an interval of approx.6 months:

Check for corrosion.If first signs of corrosion show, apply new corrosion protec-

tion.

15

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

AC 01.2 Intrusive Modbus RTU Transport and storage

5. Assembly

5.1. Mounting position

When using grease as lubricant, the product described herein can be operated in

any mounting position.

When using oil instead of grease within the actuator gear housing, perpendicular

mounting position is specified whereby the flange is pointing downward.The type of

lubricant used is indicated on the actuator name plate (short designation F...= grease;

O...= oil).

5.2. Handwheel fitting

To avoid transport damage, handwheels are supplied separately as appropriate.In

this instance, the handwheel must be mounted prior to commissioning.

Figure 10: Handwheel

[1] Spacer

[2] Input shaft

[3] Handwheel

[4] Retaining ring

How to proceed 1. If required, fit spacer [1] on input shaft [2].

2. Slip handwheel [3] onto input shaft.

3. Secure handwheel [3] with retaining ring [4].

Information: The retaining ring [4] (together with these operation instructions)

is stored in a weatherproof bag, which is attached to the device prior to delivery.

5.3. Mount actuator to valve

Corrosion due to damage to paint finish and condensation!

→Touch up damage to paint finish after work on the device.

→After mounting, connect the device immediately to electrical mains to ensure

that heater minimises condensation.

16

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Assembly AC 01.2 Intrusive Modbus RTU

5.3.1. Overview of output drive types

Table 10: Overview on output drive types AssemblyDescriptionApplicationValve attachment

➭page 18, Multi-turn actuator with

output drive type A: mount

➭page 17, Output drive type A

●for rising, non-rotating valve stem

●capable of withstanding thrust

●not appropriate for radial forces

A

➭page 22, Multi-turn actuator with

output drive type B: mount

➭page 21, Output drive types B/C/D

and E

●for rotating, non-rising valve stem

●not capable of withstanding thrust

B, B1 –B4

C

D

E

5.3.2. Output drive type A

Figure 11: Output drive type A

[1] Output mounting flange

[2] Stem nut

[3] Valve stem

Short description Output drive type A consisting of output mounting flange [1] with axial bearing stem

nut [2].The stem nut transmits the torque from the actuator hollow shaft to the valve

stem [3]. Output drive type A can withstand thrusts.

To adapt the actuators to available output drive types A with flanges F10 and F14

(year of manufacture 2009 and earlier), an adapter is required.The adapter can be

ordered from AUMA.

17

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

AC 01.2 Intrusive Modbus RTU Assembly

5.3.2.1. Multi-turn actuator with output drive type A: mount

1. If output drive type A is already mounted to the multi-turn actuator: Loosen

screws [3] and remove output drive type A [2].

Figure 12: Multi-turn actuator with output drive type A

[1] Multi-turn actuator

[2] Output drive type A, from left to right:

with finish-machined, unbored and pilot bore stem nut

[3] Screws to multi-turn actuator

Information For an unbored or pilot bore stem nut, the stem nut must be finish machined prior

to mounting valve stem and prior to performing the following steps.➭page 20, Stem

nut for output drive type A: finish machining

2. Apply a small quantity of grease to the valve stem.

3. Place output drive type A [2] on valve stem and turn until it is [4] flush on the

valve flange.

4. Turn output drive type A [2] until alignment of the fixing holes.

5. Fasten screws [5] between valve and output drive type A [2] without completely

tightening them.

Figure 13:

18

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Assembly AC 01.2 Intrusive Modbus RTU

6. Fit multi-turn actuator on the valve stem so that the stem nut dogs engage into

the output drive sleeve.

Figure 14:

➥The flanges are flush with each other if properly engaged.

7. Adjust multi-turn actuator until alignment of the fixing holes.

8. Fasten multi-turn actuator with screws [3].

9. Fasten screws [3] crosswise with a torque according to table.

Table 11:

Tightening torques for screws

Tightening torque [Nm]Threads

Strength class A2-80/A4–80

24M8

48M10

200M16

392M20

10. Turn multi-turn actuator with handwheel in direction OPEN until valve flange

[4] and output drive type A [2] are firmly placed together.

Figure 15:

11. Tighten screws [5] between valve and output drive type A crosswise applying

a torque according to table.

19

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

AC 01.2 Intrusive Modbus RTU Assembly

5.3.2.2. Stem nut for output drive type A: finish machining

This working step is only required if stem nut is supplied unbored or with pilot bore.

Information For exact product version, please refer to the order-related technical data sheet or

the AUMA Assistant App.

Figure 16: Output drive type A

[1] Stem nut

[2] Axial needle roller bearing

[2.1] Axial bearing washer

[2.2] Axial needle roller and cage assembly

[3] Spigot ring

Procedure 1. Remove spigot ring [3] from output drive.

2. Remove stem nut [1] together with axial needle roller bearings [2].

3. Remove axial bearing washers [2.1] and axial needle roller and cage assemblies

[2.2] from stem nut [1].

4. Drill and bore stem nut [1] and cut thread.

5. Clean the machined stem nut [1].

6. Apply sufficient Lithium soap EP multi-purpose grease to axial needle roller and

cage assemblies [2.2] and axial bearing washers [2.1], ensuring that all hollow

spaces are filled with grease.

7. Place greased axial needle roller and cage assemblies [2.2] and axial bearing

washers [2.1] onto stem nut [1].

8. Re-insert stem nut [1] with axial needle roller bearings [2] into output drive.

9. Screw in spigot ring [3] until it is firm against the shoulder.

20

SA 07.2 –SA 16.2/SAR 07.2 –SAR 16.2 Control unit - electromechanical

Assembly AC 01.2 Intrusive Modbus RTU

Other manuals for SA 07.2

5

This manual suits for next models

12

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA PROFOX PF-M25 Manual

AUMA

AUMA SAExC 07.1 User manual

AUMA

AUMA SQEx 05.2 User manual

AUMA

AUMA SAEx 25.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SAV 07.2 User manual

AUMA

AUMA SA 25.1 User manual

AUMA

AUMA EQ 40 Assembly instructions

AUMA

AUMA Aumatic AC 01.1 User manual

AUMA

AUMA SAEx Series User manual

AUMA

AUMA SAM Ex 07.1 User manual

AUMA

AUMA SA 16.1 User manual

AUMA

AUMA AUMATIC ACExC User manual

AUMA

AUMA AMB 01.1 User manual

AUMA

AUMA SA 25.1 User manual

AUMA

AUMA SQVEx 05.2 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA GST 10.1 Administrator Guide

AUMA

AUMA SAI 07.2 User manual