J-141

Dual PID Control

SENSORS

CONTROLLERS

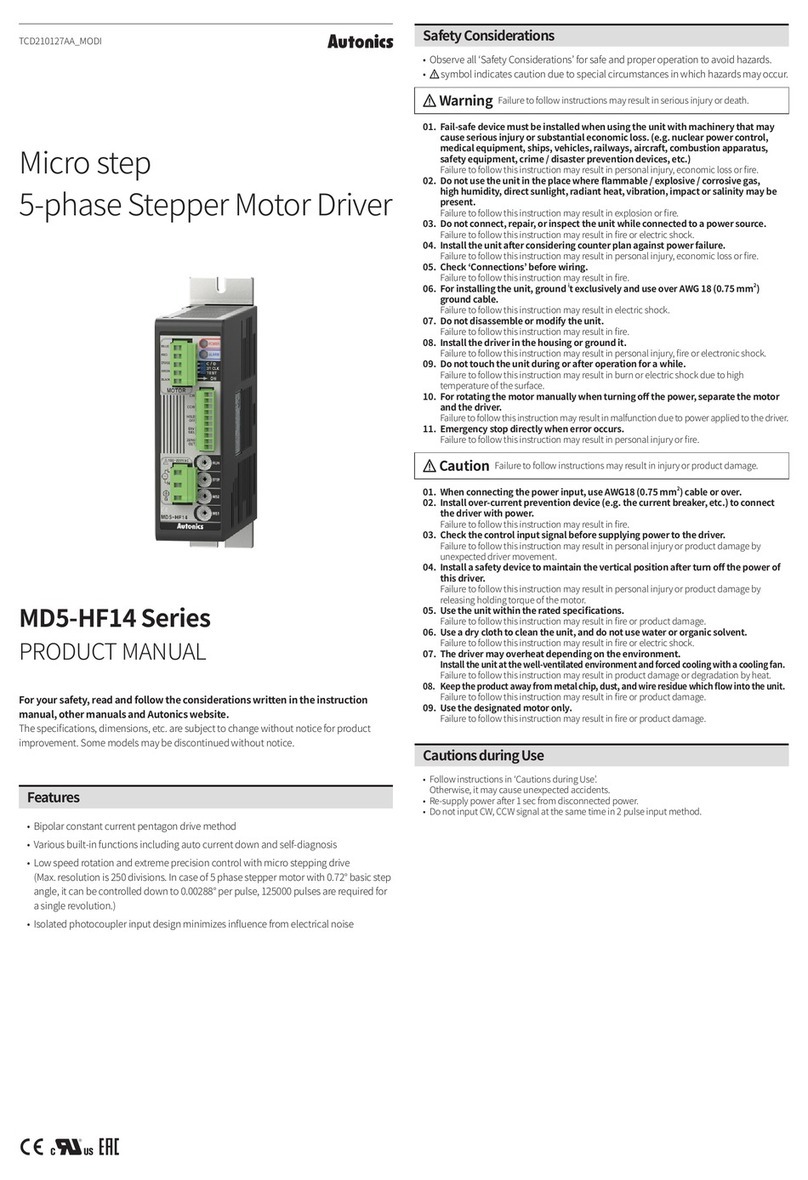

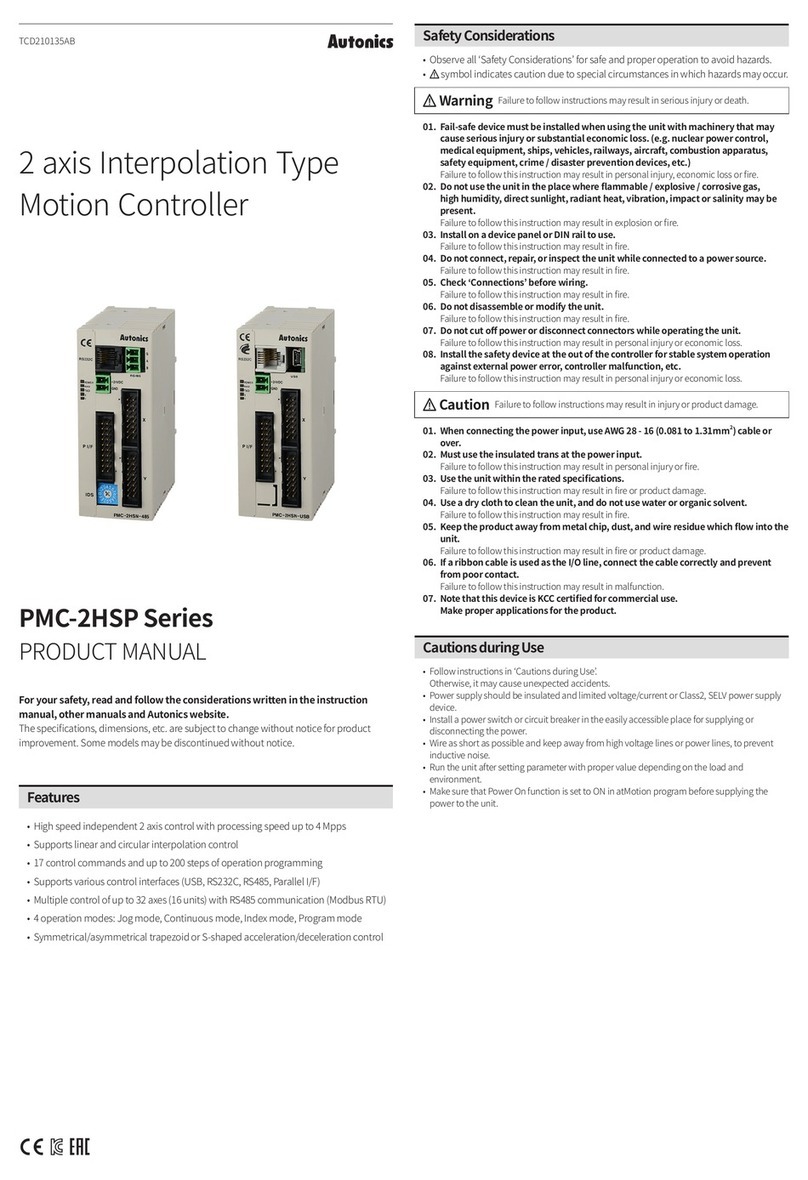

MOTION DEVICES

SOFTWARE

(J)

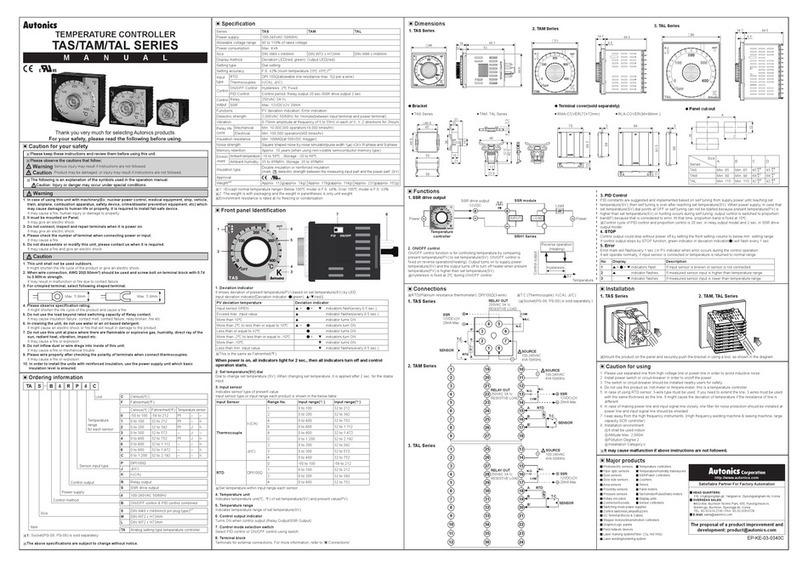

Temperature

Controllers

(K)

SSRs

(L)

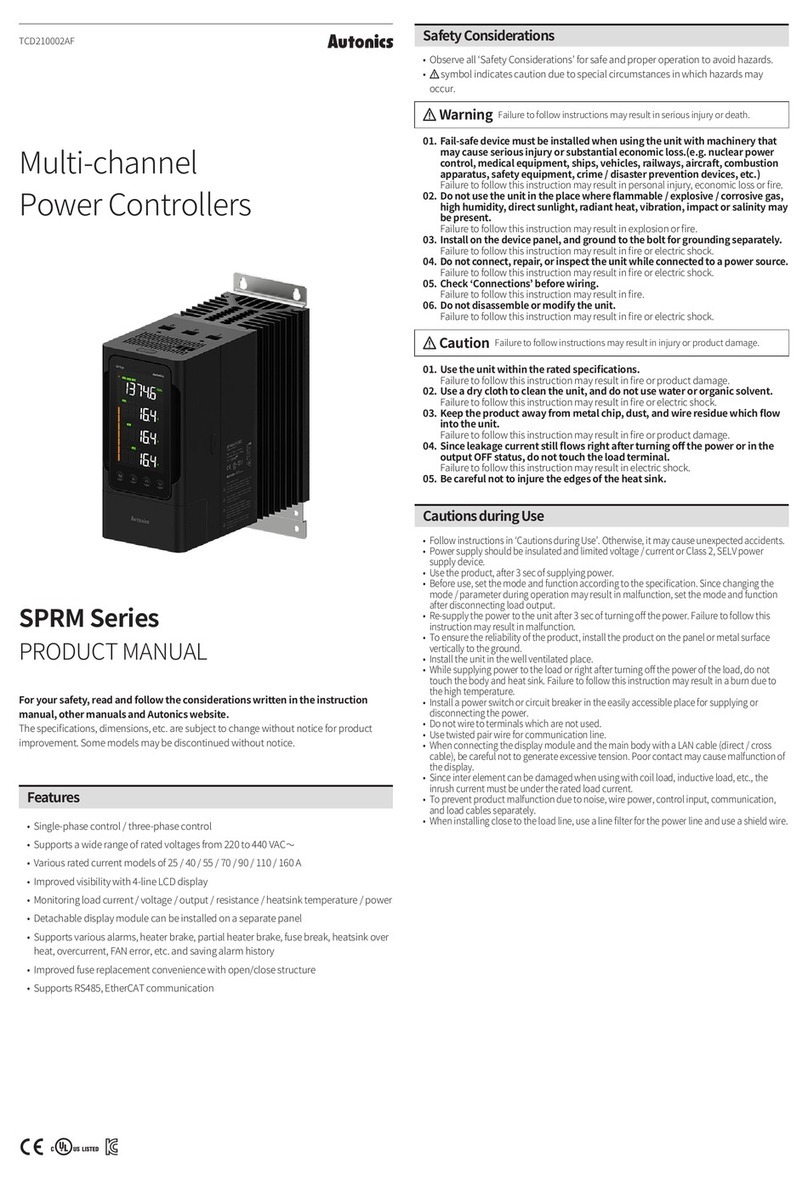

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

Specifications

Series TZ4SP

TZN4S TZ4ST TZ4M

TZN4M

TZ4W

TZN4W

TZ4H

TZN4H

TZ4L

TZN4L

Power supply 100-240VACᜠ50/60Hz

Allowable voltage range 90 to 110% of rated power voltage

Power consumption Max. 5VA (100-240VACᜠ50/60Hz) Max. 6VA (100-240VACᜠ50/60Hz)

Display method 7-segment LED (PV: red, SV: green)

Character size

(W×H)

PV

TZ4SP:

4.8×7.8mm

TZN4S:

7.8×11.0mm 4.8×7.8mm

TZ4M:

9.8×14.2mm

TZN4M:

8.0×13.0mm 8.0×10.0mm

TZ4H:

3.8×7.6mm

TZN4H:

7.8×11.0mm

9.8×14.2mm

SV

TZ4SP:

4.8×7.8mm

TZN4S:

5.8×8.0mm

TZ4M:

8.0×10.0mm

TZN4M:

5.0×9.0mm

TZ4H:

3.8×7.6mm

TZN4H:

5.8×8.0mm

8.0×10.0mm

Input

type

RTD DPt100Ω, JPt100Ω, 3-wire (allowed resistance: max. 5Ω per line)

TC K(CA), J(IC), R(PR), E(CR), T(CC), S(PR), N(NN), W(TT) (allowed resistance: max. 100Ω per line)

Analog 1-5VDCᜡ, 0-10VDCᜡ, DC4-20mA

Display accuracy F.S. ±0.3% or 3℃, greater value

Control

output

Relay 250VACᜠ 3A, 30VDCᜡ 3A, 1c

SSR Max. 12VDCᜡ ±3V 30mA

Current DC4-20mA (load resistance max. 600Ω)

Option

output

EVENT1 250VACᜠ1A 1a

EVENT2

-

250VACᜠ1A 1a

PV transmission

-

DC4-20mA (load resistance max. 600Ω)

Communication

-

RS485 communication

Control method ON/OFF, P, PI, PD, PIDF, PIDS control

Alarm output hysteresis 1 to 100℃(0.1 to 100.0℃) variable

Proportional band (P) 0.0 to 100.0%

Integral time (I) 0 to 3,600 sec

Derivative time (D) 0 to 3,600 sec

Control period (T) 1 to 120 sec

Sampling period 0.5 sec

LBA setting 1 to 999 sec

Ramp setting Ramp Up, Ramp Down: 1 to 99 min each

Dielectric strength 2,000VAC 50/60Hz for 1 min (between input and power terminals)

Vibration Mechanical 0.75mm amplitude at frequency 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Electrical 0.5mm amplitude at frequency 10 to 55Hz (for 1 min) in each X, Y, Z direction for 10 min

Relay

life cycle

Control output Mechanical: min. 10,000,000 operations,

Electrical: min. 100,000 operations (250VAC 3A resistance load)

Option output Mechanical: min. 20,000,000 operations,

Electrical: min. 500,000 operations (250VAC 1A resistance load)

Insulation resistance Over 100MΩ (at 500VDC megger)

Noise immunity Square shaped noise by noise simulator (pulse width 1㎲) ±2kV R-phase, S-phase

Memory retention Approx. 10 years (non-volatile semiconductor memory type)

Environ-

ment

Ambient temp. -10 to 50℃, storage: -20 to 60℃

Ambient humi. 35 to 85%RH, storage: 35 to 85%RH

Approval

Weight※1

TZ4SP:

approx. 205g

(approx. 144g)

TZN4S:

approx. 226g

(approx. 164g)

Approx. 218g

(approx. 162g)

TZ4M:

approx. 360g

(approx. 228g)

TZN4M:

approx.355g

(approx. 246g)

TZ4W:

approx. 365g

(approx. 246g)

TZN4W:

approx. 351g

(approx. 232g)

TZ4H:

approx. 365g

(approx. 246g)

TZN4H:

approx. 351g

(approx. 232g)

TZ4L:

approx. 474g

(approx. 304g)

TZN4L:

approx. 474g

(approx. 303g)

※1: The weight includes packaging. The weight in parenthesis is for unit only.

※Environment resistance is rated at no freezing or condensation.