Parameter Groups

※Parameter setting order Parameter group 2 Parameter group 1 SV setting

The parameters are related to each other. Please set the parameters in the order above.

※When there is no key input for 60 seconds while in SV setting mode or parameter groups, the unit will return

to RUN mode automatically.

SV setting Parameter group 1 Parameter group 2

+ 3 sec

RUN mode

3 sec

3 sec

3 sec

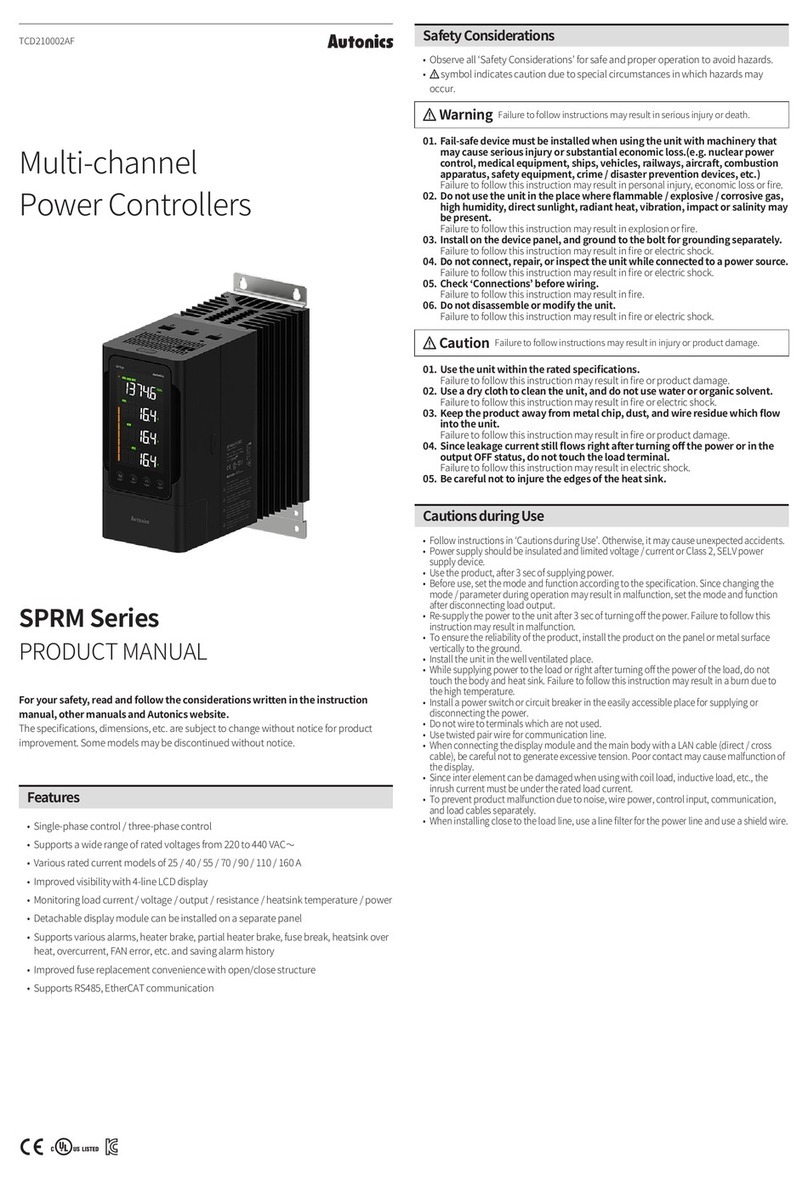

Unit Description

7. Mode key: enter parameter group, return to RUN mode, switch parameters, save setting values

8. Auto-tuning key: hold the key for 3 seconds to start auto-tuning. Hold the key for 5 seconds while auto-

tuning to stop auto-tuning.

9. Setting keys:enterSVchangemode,switchelds,changevalue

( key in the dotted line is only available in TZ4M and TZ4L models)

10. Key adjustment order chart

1. Present value (PV) display (red):

RUN mode: displays the current value (PV)

Setting mode: displays parameters

2. Set value (SV) display (green):

RUN mode: displays the set value (SV)

Setting mode: displays parameter setting values

3. SV2 operation indicator: turns ON when SV2 is operating

4. Auto-tuning indicator: turns ON when auto-tuning

5. Control output operation indicator: turns ON when control

output is ON. Does not operate when the input type is current

output.

6. Event output indicator: turns ON when the according event

output is ON.

※The Event 2 output indicator does not operation in TZ4SP.

● SV setting ※When changing the previous SV of 0℃to 170℃,

( )key:Switchelds

, key: Change values

Thesettingeldwillblink.

key

key

①RUN mode

②SV setting mode ③Complete SV setting

1. SV2 temperature

You can control an additional temperature value at a desired range by using SV2. Connect a contact signal (under

5VDC, 250㎂) at the external terminal, to operate in the range where the signal turns ON.

Set the SV2 temperature in SV2 temperature [SU-2] in parameter group 1.

SV

SV 2 [SU-2]

External terminal

(SV2 IN)

ON

Temperature

Time

E.g.)The internal temperature of an electric oven may

drop rapidly if the door is opened while the oven

ismaintainingaspecictemperature.SetSV2

temperature [SU-2] to a higher value than SV, and

input a signal to the external terminal (SV2 IN), to

quickly raise the temperature.

2. Ramp

The ramp function can delay the rate of temperature rise/fall. If the SV value is changed during stabilized control,

the temperature of the controlled target will rise/fall during ramp up/down time [RAPU, RAPD] of parameter group

1. The ramp function activates when the power is reset or when the SV value is changed during stable control.

※The ramp up/down time [RAPU, RAPD] appear only when the ramp function [RAMP] of parameter group 2 is

set to ON.

●Rampuptime[RAPU]

When delaying the rise of initial control

temperature or changing the SV during

stable control, you can delay temperature

rise. Set the ramp up time [RAPU] longer

than the temperature rise time (tu) when

not using the ramp function.

: Not using ramp function

: Using ramp function

Changed SV

Initial SV

Time

tu tu

Ramp up time

[RAPU]

Ramp up time

[RAPU]

Temperature

●Rampdowntime[RAPD]

Delays declining temperature. Set the

ramp down time [RAPD] longer than the

temperature decline time (td) when not

using the ramp function.

: Not using ramp function

: Using ramp function

Changed SV

Initial SV

td Time

Ramp down time

[RAPD]

Temperature

Functions

8

7

1

2

5

6

9

10

4

3

ON ON1

OFF Unlock

ON Lock parameter 1

( key available)

ON1 Lock parameter 1

(key unavailable)

Setting range:

※1: : ( )key-Switchelds, , key-Change values

※2: Press the key after checking or changing the values in parameter

settings to save the setting value and move to the next parameter.

※Hold the key for 3 seconds anytime during parameter settings to save the

setting value and return to RUN mode.

※The dotted line parameters may not appear depending on the model or

other parameter settings.

SV 2

temperature

Event 1

alarm

temp.

Event 2

alarm

temp.

LBA

monitoring

time

Alarm

output

hysteresis

Proportional

band

Integral

time

Derivative

time

Control

period

Hysteresis

Input

correction

Manual

reset

Ramp

up time

Ramp

down time

Lock

SU-2

AL1

AL2

LBA

AHYS

P

I

D

T

HYS

IN-B

REST

RAPU

RAPD

LOC

3 sec

3 sec

RUN mode

0

10

10

600

2

#0

0

0

20

2

0

)0

10

10

OFF

● Parameter group 1

※2

Setting range: refer to " Input Type and Range".

Setting range: refer to " Input Type and Range".

※[AL1, AL2] parameters do not appear when Event 1/2 [EU-1,

EU-2] of parameter group 2 is set to AL-0, LBA, SBA.

※[AL2] parameter only appears in models that support Event 2

output.

Setting range: 0 to 999 sec

※Only appears when Event1/2 [EU-1, EU-2] of parameter

group 2 is set to LBA.

※Does not appears in current output models.

Setting range: 1 to 100℃/℉(0.1 to 100.0℃/℉)

※Does not appears when Event 1/2 [EU-1, EU-2] of parameter

group 2 is set to AL-0, LBA, SBA.

Setting range: 0.0 to 100.0%

※ON/OFF control: Set to )0, PID control: Set to over )0

※Only appears during PID

control (proportional band

[P] set to over )0).

Setting range: 1 to 100℃/℉(0.1 to 100.0℃/℉)

※Only appears during ON/OFF control (proportional band

[P] set to )0).

Setting range: -49 to 50℃/℉(-50.0 to 50.0℃/℉)

Setting range: 0.0 to 100%

※Only appears when P control (proportional band [P] set to over

)0, integral time [I], and derivative time [D] are set to 0)

Setting range: 1 to 99 min

※Only appears when ramp function [RAMP] of parameter group

2 is set to ON.

Setting range: 0 to 3,600 sec

※Integral operation is turned OFF

when set to 0.

Setting range: 0 to 3,600 sec

※Derivative operation is turned

OFF when set to 0.

Setting range: 1 to 120 sec

※Set to a small value in SSR drive

output models. (i.e. 2 sec)

PV display SV display

※1

Cautions during Use

Major Products

RS485 Communication

Applicable for models that support RS485 communication. Please refer to ' Ordering Information'.

It is used to transmit PV or SV, and/or set the SV.

Protocol BCC Communication speed 2400, 4800, 9600bps

Applied standard EIA RS485 Start bit 1-bitxed

Max. connections 31 units (address: 1 to 99) Data bit 8-bitxed

Communication method 2-wire half duplex Parity bit None

Synchronization method Asynchronous Stop bit 1-bitxed

Communication distance Within 1.2km

Error Dispaly

Display Description Troubleshooting

OPEN Blinks when input is disconnected. Check input status.

HHHH Blinks when the measured input value is higher than the temperature range. Adjust the value to within

the temperature range.

LLLL Blinks when the measured input value is lower than the temperature range.

Symptoms Troubleshooting

OPEN is displayed on the PV

display during operation

Disconnect the power and check the input connection.

If the input is connected, disconnect the input wiring from the temperature

controller and short the + and - terminals. Power the temperature controller

and check if it displays the room temperature. If it does not display the room

temperature and continues to display OPEN, the controller is broken. Please

contact our technical support. (Input type is thermocouple)

Load (heater, etc.) does not

operate during operation

Check the state of the control output indicator on the front panel.

If the indicator is not working, check parameter settings. If the indicator is

working, disconnect the wiring from the output terminal of the temperature

controller and check the output (replay contact, SSR drive, current)

ERR0 (error) is displayed on

the PV display during operation

Indicates damage to internal chip by strong noise (2kVAC).

Please contact our technical support. Locate the source of the noise and

devise countermeasures.

Troubleshooting

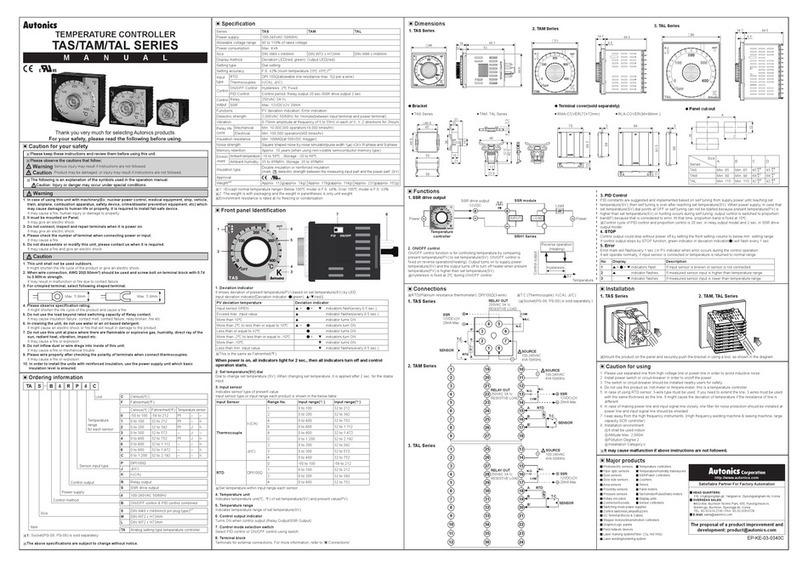

Parameter group 2

Parameter Default Parameter Default Parameter Default

SU-2 0 P #0 IN-B 0

AL1 10 I 0 REST )0

AL2 10 D 0 RAPU 10

LBA 600 T 20 RAPD 10

AHYS 2 HYS 2 LOC OFF

Parameter Default Parameter Default Parameter Default

IN-T KCaH O-FT HEAT FS-L `00

EU-1 AL-1 UNIT ?C RAMP OFF

EU-2 AL-2 H-SC 1300 BPS 2400

AL-T AL-A L-SC `00 ADRS 01

AtT TVN1 DOT 0 LOC OFF

PIDT PIdS FS-H 1300

Parameter group 1

Factory Default

4. Auto-tuning

Auto-tuning allows the temperature controller to detect the thermal characteristics and response rates of the

control target. It then calculates the PID time constant and sets the value to allow fast response rates and high

accuracy. Hold the key for 3 seconds during RUN mode to start auto-tuning. The auto-tuning indicator will

blink. When auto-tuning is completed, the auto-tuning indicator will durn off and the PID time constant will be

saved to each parameter of parameter group 1. The saved parameters can be adjusted as desired.

To manually stop auto-tuning, hold the key for 5

seconds. When auto-tuning is stopped, the controller

maintains the PID value before auto-tuning.

TZ Series supports 2 auto-tuning modes.

Select TUN1 mode or TUN2 mode [TUN1, TUN2]

from auto-tuning mode [AtT] of parameter group 2.

※

Run auto-tuning during initial setup of the

temperature controller.

※

If the thermal characteristics of the control target

device has changed after extended usage, re-run

auto-tuning.

3. Alarm (Event)

Alarmoutputcanbeconguredbycombiningalarmoperationandalarmoptions.Setthealarmoperationin

event 1/2 [EU1, EU2] of parameter group 2, and set the alarm options in alarm option[AL-T].

1)Alarm operation

Mode Name Alarm operation Description

ㅁAL-0 - - Alarm output not used.

AL-1

Deviation

high-limit

alarm SV

100℃

PV

110℃

OFF ONHIf the deviation of PV and SV are

higher than the high-limit deviation,

the alarm output turns ON.

High-limit deviation: 10℃

AL-2

Deviation

low-limit

alarm PV

90℃

SV

100℃

OFFON HIf the deviation of PV and SV are

higher than the low-limit deviation,

the alarm output turns ON.

Low-limit deviation: 10℃

AL-3

Deviation

high-limit

/low-limit

alarm

PV

90℃

PV

110℃

SV

100℃

OFFON ONH H If the deviation of PV and SV are

higher than the high-limit deviation

or low-limit deviation, the alarm

output turns ON.

High-limit/low-limit deviation: 10℃

AL-4

Deviation

high-limit

/low-limit

reverse

alarm

PV

90℃

PV

110℃

SV

100℃

OFF OFFONH H If the deviation of PV and SV are

higher than the high-limit deviation

or low-limit deviation, the alarm

output turns OFF.

High-limit/low-limit deviation: 10℃

AL-5

Absolute

value

high-limit

alarm

PV

90℃

SV

100℃

OFF ONH

SV

100℃

PV

110℃

OFF ONH

Alarm output turns ON when PV is

higher than the absolute value.

Absolute value alarm:

90℃

Absolute value alarm:

110℃

AL-6

Absolute

value

low-limit

alarm

PV

90℃

SV

100℃

OFFON H

SV

100℃

PV

110℃

OFFON H

Alarm output turns ON when PV is

lower than the absolute value.

Absolute value alarm:

90℃

Absolute value alarm:

110℃

SBA Sensor

break

-

Alarm output turns ON when sensor

disconnection is detected.

LBA Loop

break

-

Alarm output turns ON when loop

break is detected.

※H: Alarm output hysteresis [AHYS]

2)Alarm options

Mode Name Description

AL-A Standard

alarm

Alarm output turns ON upon alarm condition, and alarm output turns OFF when

condition is cleared.

AL-B Alarm latch Alarm output turns ON and maintains ON upon alarm condition.

AL-C Standby

sequence

Therstalarmconditionisignored.Itwilloperateasstandardalarmfromthesecond

alarm condition. If it is under alarm condition when power is supplied, it will ignore the

condition and operate as standard alarm from the next alarm condition.

AL-D

Alarm latch

and standby

sequence

It will operate as both alarm latch and standby sequence upon alarm condition. If it is

under alarm condition when power is supplied, it will ignore the condition and operate

as alarm latch from the next alarm condition.

3) Sensor break alarm

Alarm output turns ON when sensor is not connected or loses its connection during temperature control. Sensor

disconnection can be tested by connecting buzzers or other devices to the alarm output contact. Sensor break

alarm output operates through EV1 OUT or EV2 OUT contacts. Alarm output is disengaged after resetting the

power.

4) Loop break Alarm (LBA)

Diagnose control loop and transmit alarm output through temperature change of control target. During

heating(cooling)control,thealarmoutputturnsONifthePVdoesnotrise/dropbyaspecicamount(approx.2℃)

during LBA monitoring period [LBA] while control output amount is at 100%(0%).

※

If the thermal response of the control target is slow, the LBA monitoring period [LBA] of parameter group 1

should be set longer.

※

LBA only operates when the control output amount is 100%(0%) so it cannot be used in current output models.

※

If the alarm output turns ON after the sensor has been disconnected, the alarm output will not turn OFF even

after reconnecting the sensor. To disengage the alarm output, the temperature controller power must be reset.

TUN1

mode

[TUN1]

Temperature

Time

SV

Auto-tuning

TUN2

mode

[TUN2]

Temperature

Time

70%

SV

Auto-tuning

6. Input correction [IN-B]

Used to correct deviation from external devices such as temperature controllers.

E.g.)If the actual temperature is 80℃but the display value is 78℃, set the input correction [IN-B] value to 2

and it will display 80℃as the display value.

High-

speed

response

mode

[PIdF]

Temperature

Time

SV

S

t

PV Used to minimize the time (t) required to reach the SV.

Overshoot (S) occurs.

Used in machinery that may require warming up.

(injection molding machine, electric furnace, etc.)

Low-

speed

response

[PIdS]

Temperature

Time

t

SV PV Used to minimize overshoot (S). Time (t) required to

reach SV may be slower.

Used for machinery or environments where overshoot

maycauseexplosionorre.(oiltemperaturecontrol,

metal plating machinery, etc.)

5. Dual PID control

The response rate of the PID control can be selected depending on the characteristics of the control target.

Select high-speed response mode or low-speed response mode [PIdF, PIdS] from PID method [PIDT] of

parameter group 2.

● Parameter group 2

+

3 sec

Setting range: refer to " Input Type and Range".

OFF Unlock

ON Lock parameter 2

Setting range:

Input type

Event 1

Event 2

Alarm

option

Auto-tuning

mode

PID method

Heating/

Cooling

Temperature

unit

SV

high-limit

SV

low-limit

Decimal

point

Trans. output

high-limit

Trans. output

low-limit

Ramp

function

3 sec

RUN mode

※2

Setting range: refer to " Input Type and Range".

Setting range: refer to '3. Alarm'.

※Event 2 [EU-2] only appears in models that support Event

2 output.

Setting range: refer to '3. Alarm'.

※Does not appear when Event 1/2 [EU-1, EU-2] is set to

AL-0, LBA, SBA.

Setting range: 0, )0, )00, )000

※Only appears with analog input.

Setting range: refer to " Input Type and Range".

※Only appears in models that support PV transmission.

※1

Com.

address

Lock

※Only appears in models

that support RS485

communication

Setting range: 1 to 99 (address)

※1: : ( )key-Switchelds, , key-Change values

※2: Press the key after checking or changing the values in parameter

settings to save the setting value and move to the next parameter.

※Hold the key for 3 seconds anytime during parameter settings to save the

setting value and return to RUN mode.

※The dotted line parameters may not appear depending on the model or

other parameter settings.

※Please set according to control application.

Do not change the settings during operation.

Itmayresultinreoraccidents.

PV display SV display

IN-T

EU-1

EU-2

AL-T

AtT

PIDT

O-FT

UNIT

H-SC

L-SC

DOT

FS-H

FS-L

RAMP

KCaH

AL-1

AL-2

AL-A

1300

`00

0

1300

`00

※2

※1

ON

ON

4800 9600

BPS

ㅁㅁ ADRS

LOC

01

OFF

OFF

2400

TVN2

PIdF

COOL

?F

TVN1

PIdS

HEAT

?C

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse (Rate) Meters

Rotary Encoders Display Units

Connector/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (Fiber, CO₂, Nd: YAG)

Laser Welding/Cutting System

Com.

speed

http://www.autonics.com

HEADQUARTERS:

18, Bansong-ro 513beon-gil, Haeundae-gu, Busan,

South Korea, 48002

TEL: 82-51-519-3232

DRW170713AA

7. Manual reset [REST]

When using proportional control (P control), the time of temperature

rising time and falling time may differ depending on factors such as

the heat capacity of the control device or the heater. A certain amount

of deviation occurs even under stable conditions.

Thisdeviationisreferredtoasoffset,andcanbecongured/corrected

using manual reset [REST].

When PV and SV are equal, the reset value is 50.0%. If the PV is

lower than the SV during stable control, set the value to over 50.0%,

and if the PV is higher than the SV, set the value to under 50.0%

Conguringmanualreset[REST]

according to control results.

Reset value set at under 50.0%

Reset value set at over 50.0%

Offset

Offset

SV

1. Follow instructions in 'Cautions during Use'. Otherwise, It may cause unexpected accidents.

2. Check the polarity of the terminals before wiring the temperature sensor.

For RTD temperature sensor, wire it as 3-wire type, using cables in same thickness and length.

For thermocouple (CT) temperature sensor, use the designated compensation wire for extending wire.

3. Keep away from high voltage lines or power lines to prevent inductive noise.

Incaseinstallingpowerlineandinputsignallineclosely,uselinelterorvaristoratpowerlineandshielded

wire at input signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

4. Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting the

power.

5. Do not use the unit for other purpose (e.g. voltmeter, ammeter), but temperature controller.

6.Whenchangingtheinputsensor,turnoffthepowerrstbeforechanging.

After changing the input sensor, specify internal switch and modify the value of the corresponding parameter.

7. Do not overlapping communication line and power line.

Use twisted pair wire for communication line and connect ferrite bead at each end of line to reduce the effect

of external noise.

8. Make a required space around the unit for radiation of heat.

For accurate temperature measurement, warm up the unit over 20 min after turning on the power.

9. Make sure that power supply voltage reaches to the rated voltage within 2 sec after supplying power.

10. Do not wire to terminals which are not used.

11. This unit may be used in the following environments.

①Indoors(intheenvironmentconditionratedin'Specications') ②Altitude max. 2,000m

③Pollution degree 2 ④Installation category II

Comprehensive Device Management Program[DAQMaster]

DAQMaster is a comprehensive device management software for setting parameters and monitoring

processes. DAQMaster can be downloaded from our website at www.autonics.com.

Item Minimumspecications

System IBM PC compatible computer with Pentium Ⅲor above

Operations Windows 98/NT/XP/Vista/7/8/10

Memory 256MB+

Hard disk 1GB+ of available hard disk space

VGA Resolution: 1024×768 or higher

Others RS232C serial port (9-pin), USB port