Avdel eRiv User manual

D

GB

F

I

E

PT

NL

DK

SE

FI

NO

Originalbedienungsanleitung (S.3+4 / 5-10)

Original instructions (3+4 / 11-14 )

Notice originale (3+4 / 15-18 )

Istruzioni originali (3+4 / 19-22)

Manual original (3+4 / 23-26)

Manual original (3+4 / 27-30)

Oorspronkelijke gebruiksaan ijzing

(3+4 / 31-34)

Original brugsanvisning (3+4 / 35-38)

Bruksanvisning i original (3+4 / 39-42)

Alkuperäiset ohjeet (3+4 / 43-46)

Original driftsinstruks (3+4 / 47-50)

GR

HU

TR

RO

BG

SI

HR

BA

SK

Πρωτότυπο οδηγιών χρήσης

(3+4 / 51-55)

Uutasítás (3+4 / 56-59)

Orijinal işletme talimat (3+4/ 60-63)

Instrucţiuni originale Оригинална

(3+4 / 64-67)

Инструкция (3+4 / 68-71)

Originalne upute za rad (+4/72-75)

Izvirna navodila (3+4 / 76-80)

Originalno uputstvo za rad

(3+4 / 81-84)

návod na použitie Eredeti használati

(3+4 / 86-89)

PL

RU

UA

EE

LV

LT

C

CN

Instrukcją oryginalną (3+4 / 90-93)

Оригинальное руководст- по во

Эксплуатации (3+4 / 91-98)

Оригінальна інструкція з

Експлуатації (3+4 / 99-102)

Algupärane kasutusjuhend (3+4/103-106)

Originali instrukcija (3+4 / 107-110)

Instrukcijas oriģinālvalodā (3+4/ 111-114)

Původní návod k používání

Pôvodný (3+4 / 115-118)

安全性建

议

(3+4 / 119-122)

Avdel UK Limited

Pacific House

Tel.: +44 (0) 1707 292000

2 S iftfields Fax.: +44 (0) 1707 292199

Watchmead Industrial Estate Mail.: enquiries@infastech.com

Wel yn Garden City .avdel-global.com

Hertfordshire AL7 1LY .infastech.com

2

Avdel UK Limited

Pacific House

Tel.: +44 (0) 1707 292000

2 S iftfields Fax.: +44 (0) 1707 292199

Watchmead Industrial Estate Mail.: enquiries@infastech.com

Wel yn Garden City .avdel-global.com

Hertfordshire AL7 1LY .infastech.com

3

1 x

eRiv

TM

71603-01000

1 x

1 x

1 x

UK 07007-02124

EUROPE 07007-02125

US & JAPAN 07007-02126

AUSTRALIA 07007-02127

1 x

71603-02053 (3,0/3,2 mm)

1 x 71603-02054 (4,0 mm)

1 x 71603-02055 (4,8/5,0 mm)

STEM RETAINING NOSE TIPS

*** 3,0Ah

-

14,4V

07007

-

0212

3

***

1 x

1,5Ah

-

14,4V

07007

-

02122

BATTERY INDICATOR

Avdel UK Limited

Pacific House

Tel.: +44 (0) 1707 292000

2 S iftfields Fax.: +44 (0) 1707 292199

Watchmead Industrial Estate Mail.: enquiries@infastech.com

Wel yn Garden City .avdel-global.com

Hertfordshire AL7 1LY .infastech.com

4

I

I

I

I

I

II

I

V

V

V

I

1

3 2

4

1

5

D

Avdel UK Limited

Pacific House

Tel.: +44 (0) 1707 292000

2 S iftfields Fax.: +44 (0) 1707 292199

Watchmead Industrial Estate Mail.: enquiries@infastech.com

Wel yn Garden City .avdel-global.com

Hertfordshire AL7 1LY .infastech.com

11

Security advice

General security advice for electric riveting machines

Please read all security advices and instructions. Failure to comply ith the security advice and the instructions can lead to electric shock, fire and/or serious

injuries.

Please preserve all security advices and instructions for future reference

The term "electric riveting machine" used in the security advices refers to the line-po ered eRiv

TM

charger ( ith po er cord) and to the battery-po ered eRiv

TM

riveting machine ( ithout po er cord).

1. Workspace safety

a) Keep your workspace in a clean condition and provide sufficient lighting.

Messy or insufficiently illuminated ork areas can lead to accidents.

b) Do not operate the electric riveting machine in an environment with risk of explosions which contains flammable liquids, gases or dust.

Electric riveting machines create sparks hich can inflame the dust or the vapors.

c) Keep away children and other persons while operating the electric riveting machine.

In case of distraction you can lose control of the machine.

2. Electric safety

a) The connector plug of the electric riveting machine has to fit into the power socket.

The plug must not be modified in any ay. Do not use adapter plugs together ith protectively grounded electric riveting machines. Unchanged

plugs and fitting sockets reduce the risk of electric shocks.

b) Avoid body contact with grounded surfaces like pipes, heaters, cookers and refrigerators.

If your body is grounded, an increased risk of electric shock persists.

c) Do not expose electric riveting machines to rain or humidity. Water entering an electric riveting machine increases the risk of electric shock.

d) Do not misuse the cable to carry or hang up the electric riveting machine or to pull the plug from the socket.

Do not expose the cable to heat, oil, sharp edges and moving device parts. Damaged or ent ined cables increase the risk of an electric shock.

e) If you are using the electric riveting machine outside, only use extension cords suitable for outside use.

The use of an extension cord suitable for outside use reduces the risk of electric shock.

f) If the use of the electric riveting device in a wet environment is unavoidable, use a fault-current circuit breaker.

The use of a fault-current circuit breaker reduces the risk of electric shock.

3. People safety

a) Stay alert, be careful with your actions and use the electric riveting machine in a reasonable way.

Do not use the electric riveting machine if you are tired or under the influence of alcohol, drugs or medication. A momentary inattentiveness hile

using the electric riveting machine can lead to serious injuries.

b) Wear protective clothing and always wear protective goggles. Wearing protective clothing like a dust mask, skid-proof safety shoes, a

protective helmet or ear protectors (depending on the conditions and aims you use the electric riveting machine for) reduces the risk of injuries.

c) Avoid inadvertent start ups of the machine. Make sure that the electric riveting machine is turned off before you connect it to the electric supply

and/or to the battery, hile picking it up or carrying it. Holding your fingers close to the po er s itch hen carrying the electric riveting machine or

connecting it to the po er supply hile it is turned on may lead to injuries.

d) Remove adjusting tools and screwdrivers before switching on the electric riveting machine.

A tool or scre driver placed into a rotating part of the device can lead to injuries.

e) Avoid unnatural body positions. Ensure you are standing firmly and al ays preserve your balance.

This ay you can better control the electric riveting machine, should an unexpected situation occur.

f) Wear appropriate clothes. Do not wear large clothes or jewelry. Avoid putting your hair, clothes and gloves close to the moving parts of the

device. Wide clothing, long hair and je elry can be caught up in the moving parts.

g) If the mandrel collection devices can be mounted, make sure that they are connected and used correctly.

4. Operation and handling of the electric riveting machine

a) Do not overload the machine.

Use the electric riveting machine that is suitable for your ork.

The suitable electric riveting machine allo s you to ork better and safer in the specified range of performance.

b) Do not use an electric riveting machine that has a defect power switch.

An electric riveting machine hich cannot be turned on and off any more is dangerous and has to be repaired.

c) Remove the plug from the power socket and/or remove the battery before making adjustments to the device, changing accessories or

putting the device away.

This safety precaution prevents the inadvertent start of the electric riveting machine.

d) Store unused electric riveting machines out of the reach of children.

Do not allo persons not familiar ith the device or persons ho haven't read these instructions to operate the device. Electric riveting machines

are dangerous hen in the hands of inexperienced persons.

GB

Avdel UK Limited

Pacific House

Tel.: +44 (0) 1707 292000

2 S iftfields Fax.: +44 (0) 1707 292199

Watchmead Industrial Estate Mail.: enquiries@infastech.com

Wel yn Garden City .avdel-global.com

Hertfordshire AL7 1LY .infastech.com

12

e) Pay attention to the maintenance of electric riveting machines.

Check if the moving parts are functioning fla lessly and do not jam. Check for broken and damaged parts that could influence the operation of the

electric riveting machine.

Repair the damaged parts before using the device. Many accidents ith electric riveting machines stem from maintenance failures.

f) Use the electric riveting machine, accessories, tools etc. according to these instructions.

Take into consideration the orking conditions and the type of ork. The use of electric riveting machines for tasks other than the intended ones

can lead to dangerous situations.

5. Use and handling of the battery tools

a) Only recharge the batteries in charging devices approved by the manufacturer.

There is a risk of fire hen using a charging device designed for a specific battery type hen it is used ith other batteries.

b) In electric riveting machines, only use batteries that have been designed for this type of use.

Using other battery types may lead to fire and injuries.

c) When not using the battery, keep it away from paper clips, coins, keys, nails, screws and other small metallic object which may cause

the contacts to connect. If the battery contacts short-circuit, it may lead to burns or fire.

d) Fluid may emerge from the battery if it is used incorrectly.

Avoid contact ith that fluid. In case of accidental contact ith the body, rinse the area ith ater. If the battery fluid comes in contact ith the

eyes, additionally call for medical help. Emerging battery fluid can lead to burns and irritation of the skin.

6. Service

AOnly let qualified personnel repair your electric riveting machine and use only original spare parts for that.

This ensures the continuous safety of the electric riveting machine.

7. Security advices for electric riveting machines

•Hold the electric riveting machine firmly ith both hands hen orking and keep standing steadily. The electric riveting machine can be operated

safer hen using both hands.

•Immediately turn off the electric riveting machine if the electric riveting tool jams.

•Be prepared for a high reacting torque hich causes strong recoil. The tool jams hen the electric riveting machine is overloaded.

•Hold the electric riveting machine tightly.

•Secure the ork-piece that is to be riveted. A ork-piece is held more securely by a clamping device or a bench vise than by hand.

•Make sure that the po er s itch is turned to the "Off" position before inserting a battery. Holding your fingers close to the po er s itch hen

carrying the electric riveting machine or inserting a battery hile is “On” may lead to accidents.

•Do not open the battery, as this leads to the risk of a short-circuit. Keep the battery a ay from heat (e.g. permanent sun radiation) and from fire

due to risk of explosion.

•If the battery is damaged or used in an inappropriate manner, vapors may emerge from it. Get some fresh air and call for medical help in case of

complaints. The vapors can lead to irritation of the respiratory tracts.

•If the battery is defective, fluid may emerge from it and coat adjacent objects. Check the parts affected, clean them or replace them, if necessary.

•Use the battery only ith your eRiv

TM

electric riveting machine. This is the only ay to prevent dangerous overload of the battery.

Technical specifications

Battery-powered eRiv

TM

electric riveting machine

For processing blind rivets ith pole cross-sections of 2.4-5.0 mm, all materials

•Weight: 1.59 kg ( ithout battery)

•Stroke: 21 mm

•Engine: 14.4 V DC motor

•Installation force: 9000 N

•CE according to EU regulation No. 2006/42/EG

11

GB

Avdel UK Limited

Pacific House

Tel.: +44 (0) 1707 292000

2 S iftfields Fax.: +44 (0) 1707 292199

Watchmead Industrial Estate Mail.: enquiries@infastech.com

Wel yn Garden City .avdel-global.com

Hertfordshire AL7 1LY .infastech.com

13

C

A

B

E

F

G

H

Quick-replacement of the rechargeable battery

•Nominal voltage: 14.4 V

•Capacity:

oLi-Ion 1.5 Ah (4 cells)

o***Li-Ion 3.0 Ah (8 cells)

•Weight:

o1.5 Ah: 0.33 kg

o3.0 Ah: 0.55 kg

Charging device

•Input voltage: 100-240 V / 50-60 Hz

•Output voltage: 14,4 V

•Output current: max. 1.5 A

•Recharging time:

o1.5 Ah: <60 minutes

o3.0 Ah: <120 minutes

•Weight: 0.41 kg

Operational description

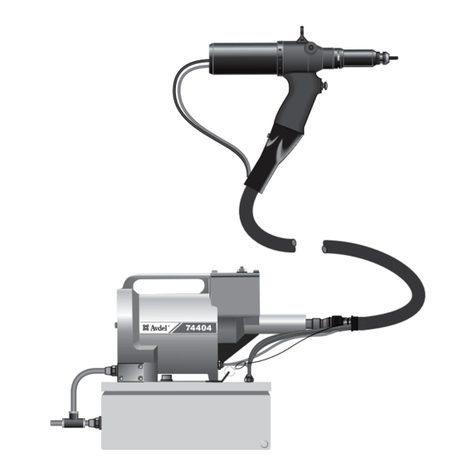

Depicted components

The numbering of the components in the picture refers to the

picture of the electric riveting machine

A) Nosepiece

B) Front sleeve

C) Failure indication

D) Mandrel collector

E) Trigger

F) Riveting area illumination

G) Battery

H) Battery locking s itch

*** The components depicted or described are not part of the

default scope of delivery. You can find all accessories in our

accessory program.

Charging the battery

Note: The battery is partially charged on delivery.

To guarantee full po er of the battery, charge it completely in the charger before first use. Pay attention to the charge indicator on the charging device. The Li-Ion

battery can be recharged at any time ithout affecting its fatigue life. Interrupting the charging process doesn't damage the battery.

Note: The optimum operating temperature range lies bet een 0°C (32 °F) and 45°C (113°F).

Please consider the notices for disposal.

Removing the battery

The battery (G) is equipped ith a locking mechanism (H). As long as the battery remains inside the electric riveting machine it is held in position by a spring. To

remove the battery (G), press the unlocking button (H) and pull the battery from the electric riveting device.

Don't use force.

Putting the device into operation

Insert the battery. Only use original eRiv

TM

Li-Ion batteries ith the voltage depicted on the type label of your electric riveting machine.

The use of other batteries may lead to injuries and risk of fire.

Push the battery (G) from under into the stand of the electric riveting machine, holding the locking button (H) pressed. Push the battery into the stand completely

until it is securely locked.

12

Data on no

ise and vibrations

•Noise emission: L

PA

= 78,8 dB

•Uncertainty: K = 3 dB

•The noise level during operation can

exceed 80 dB(A)

•Use ear protectors!

•Vibrations: <2.5 m/s2

GB

To

tal eight (including 1x

1.5 Ah battery,

charging device and packaging): 4.5 kg

Configurations ith po er plugs for orld ide

use are available (CE/ECM/UL/ETL/CB/SAA)

Avdel UK Limited

Pacific House

Tel.: +44 (0) 1707 292000

2 S iftfields Fax.: +44 (0) 1707 292199

Watchmead Industrial Estate Mail.: enquiries@infastech.com

Wel yn Garden City .avdel-global.com

Hertfordshire AL7 1LY .infastech.com

14

Switching the device into stand-by mode

Press the trigger (E) for a short time. The hite LED for the illumination of the riveting area lights up. The device is thereby s itched to stand-by for three minutes.

Pressing the po er s itch again ill reset the stand-by counter to three minutes.

Changing nozzles

The nozzles (A) are marked ith numbers corresponding to the rivet cross-section. Hold the po er s itch (E) pressed, that ill lead to the clamping mechanism

moving into the rear position. Use the included rench SW 11 to s itch to the required nozzle and release the po er s itch.

Riveting

Insert the rivet into the nozzle (A) and the other end of the rivet into the ork-pieces to be riveted. Press the po er s itch until the rivet is removed, then release

the po er s itch. Tilt the riveting device back ards so that the removed rivet pin falls into the mandrel collection device (D). If the rivet doesn't come off in a

single orking stroke, repeat the procedure.

Failure

If rivets hich exceed the indicated po er of the device are used or if the battery is empty or overloaded, the device ill stop operating and the red LED (C) ill

light up. Wait until the red LED (C) goes out and press the po er s itch (E) for a short time. The device ill revert to the original position.

If the battery is empty, the device is po ered do n by a protective circuit and the orking tool doesn't move any more.

Don't press the po er s itch again after the electric riveting machine has been po ered do n automatically, this may lead to battery damage.

Changing the clamping jaw (>> page 3)

The clamping ja s are earing parts. If you are unable to rivet in a single orking stroke you should change the clamping ja s:

I. (1) Front sleeve

II. (2) Clamping sleeve

(3) Riveting machine

(4) Clamping ja s (3 parts)

Remove the front sleeve (1) and the clamping sleeve (2) from the device (3) and remove the clamping ja s (4)

from the clamping sleeve (2).

III. Oil the clamping sleeve (2) ith Molykote® D grease (5).

IV. Hold the clamping sleeve (2) so that its for ard part is faced do n.

V. Place the clamping ja s (4) in the clamping sleeve (2) ith their smooth sides facing out ards.

VI. Mount the clamping sleeve (2) ith the ne clamping ja s (4) and finally replace the for ard sleeve (1).

Notices on optimal handling of the battery

Keep the battery a ay from etness and ater. Only store the battery at temperatures from 0° to 45°C. Do not leave the battery in the car, e.g. in summer. If the

battery is orking for significantly shorter periods of time after a recharge, it is used up and needs to be replaced.

Please consider the notices for disposal.

Maintenance and service

Take the battery out of the electric riveting machine for transportation and storage.

Risk of injury occurs if you inadvertently press the po er s itch.

[?] Keep the electric riveting machine and the ventilation slots clean to ensure good and safe operation.

If the electric riveting machine should fail despite the meticulous manufacturing and quality control procedures, the repairs should be done by an authorized service

center for AVDEL electric riveting devices.

Please, quote the serial number indicated on the type label of the electric riveting machine henever turning to our customer service or ordering spare parts.

Disposal

Electric riveting machines, accessories and packaging should be disposed in a ay hich makes them available for environment-friendly recycling.

Only valid for European Union countries:

Do not dispose of electric riveting machines in household aste.

According to European regulation 2002/96/EG concerning electric and electronic appliances and its implementation in national la s, the electric riveting machines

that are not functional need to be collected separately to make them available for environment-friendly recycling.

Batteries:

Li-Ion: Do not dispose of batteries in household aste, do not thro them into fire or ater. Batteries should be collected and recycled or disposed of in an

environment-friendly ay. Only valid for European Union countries: According to European regulation 91/157/EWG, defective and used up batteries need to be

recycled. Batteries that are not functional can be handed over at your store or directly disposed of in an environment-friendly ay.

13

GB

Avdel UK Limited

Pacific House

Tel.: +44 (0) 1707 292000

2 S iftfields Fax.: +44 (0) 1707 292199

Watchmead Industrial Estate Mail.: enquiries@infastech.com

Wel yn Garden City .avdel-global.com

Hertfordshire AL7 1LY .infastech.com

123

KONFORMITÄTSERKLÄRUNG

Wir erklären hiermit, dass folgendes Produkt:

Produktbezeichnung: eRiv

TM

b10 Akku-Blindniet-Werkzeug

Artikelnummer: 71603

allen einschlägigen Bestimmungen der Richtlinien Maschinen (2006/42/EG) und Elektromagnetische Verträglichkeit

(2004/108/EG) entspricht.

DECLARATION OF CONFORMITY

We hereby declare at our o n responsibilty, that the follo ing product

Product name : eRiv

TM

b10 Battery po ered blind riveting tool

Item number: 71603

conform to the follo ing standards or standartization documents :

Machine Guideline (2006/42/EG) and electromagnetic compatibility (2004/108/EG)

Date of issue: 18-4-2012

______________________________________

A. See raj (Technology Manager)

Avdel UK Limited

Watchmead Industrial Estate.

Wel yn Garden city

Herts.

AL7 1LY

Avdel UK Limited

Pacific House

Tel.: +44 (0) 1707 292000

2 S iftfields Fax.: +44 (0) 1707 292199

Watchmead Industrial Estate Mail.: enquiries@infastech.com

Wel yn Garden City .avdel-global.com

Hertfordshire AL7 1LY .infastech.com

124

Table of contents

Other Avdel Power Tools manuals

Avdel

Avdel 7536 Operation instructions

Avdel

Avdel 07572 User manual

Avdel

Avdel Genesis 71210-20310 User manual

Avdel

Avdel Genesis G1 71204 User manual

Avdel

Avdel Genesis G3 User manual

Avdel

Avdel Genesis nG3 User manual

Avdel

Avdel 71404 User manual

Avdel

Avdel 07900-09080 User manual

Avdel

Avdel 74200 User manual

Avdel

Avdel 0727 User manual

Avdel

Avdel Genesis G1 User manual

Avdel

Avdel nG2S 71401 User manual

Avdel

Avdel genesis g2 User manual

Avdel

Avdel 7536 User manual

Avdel

Avdel Genesis G3 HD User manual

Avdel

Avdel T51 User manual

Avdel

Avdel Genesis G2LB User manual

Avdel

Avdel 7432 User manual

Avdel

Avdel 74101 User manual

Avdel

Avdel 74405 User manual