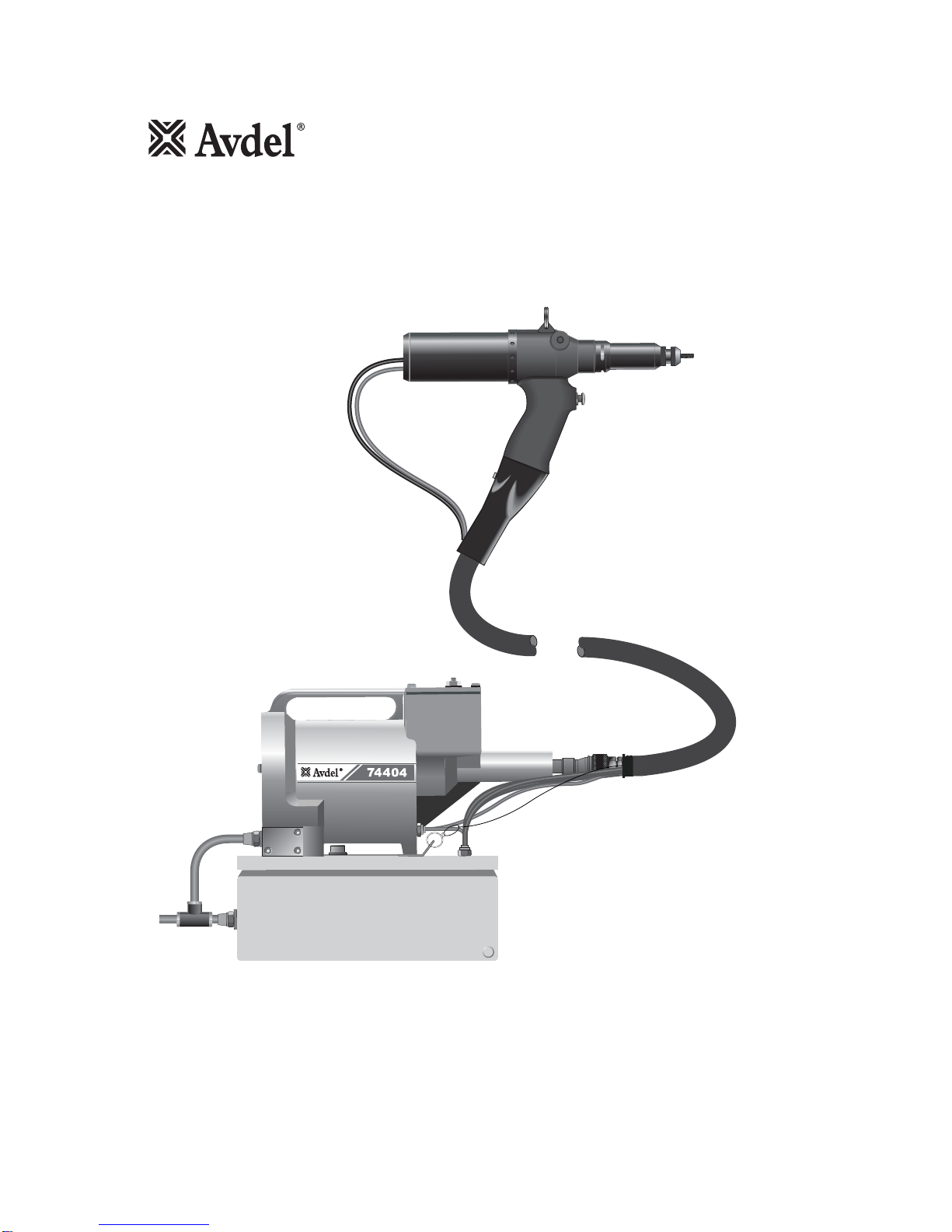

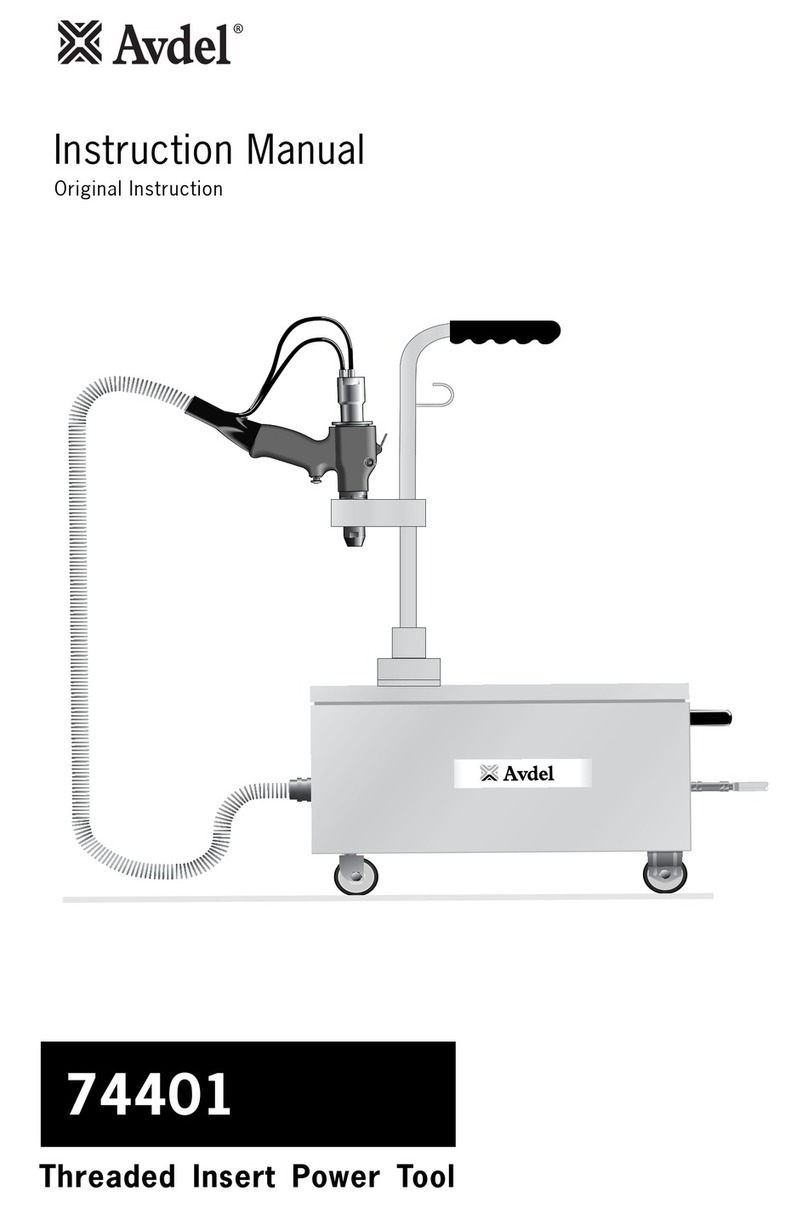

Avdel 74405 User manual

Hydro-Pneumatic Power Tool

74405

Instruction Manual

Original Instruction

3

Contents

Safety Instructions 4

Specifications

Tool Specification for 74405 5

Tool Specification for Intensifier 5

Tool Dimensions 5

Intent of Use 6

Putting into Service

Air Supply 7

Operating Procedure 7

Stroke Adjustment 8

Nose Assemblies

Fitting Instructions 9

Servicing Instructions 10

Nose Assembly Components 10

Servicing the Tool

Servicing 11

Daily / Weekly 11

Service Kit 11

Moly Lithium Grease EP 3753 Safety Data 12

Maintenance 13

Head Assembly 13

Air Motor Assembly 14

Handle and Trigger Assembly 14

Intensifier 15

General Assemblies and Parts Lists

Head Assembly General Assembly 16

Head Assembly Parts List 17

Intensifier General Assembly 18

Intensifier Parts List 19

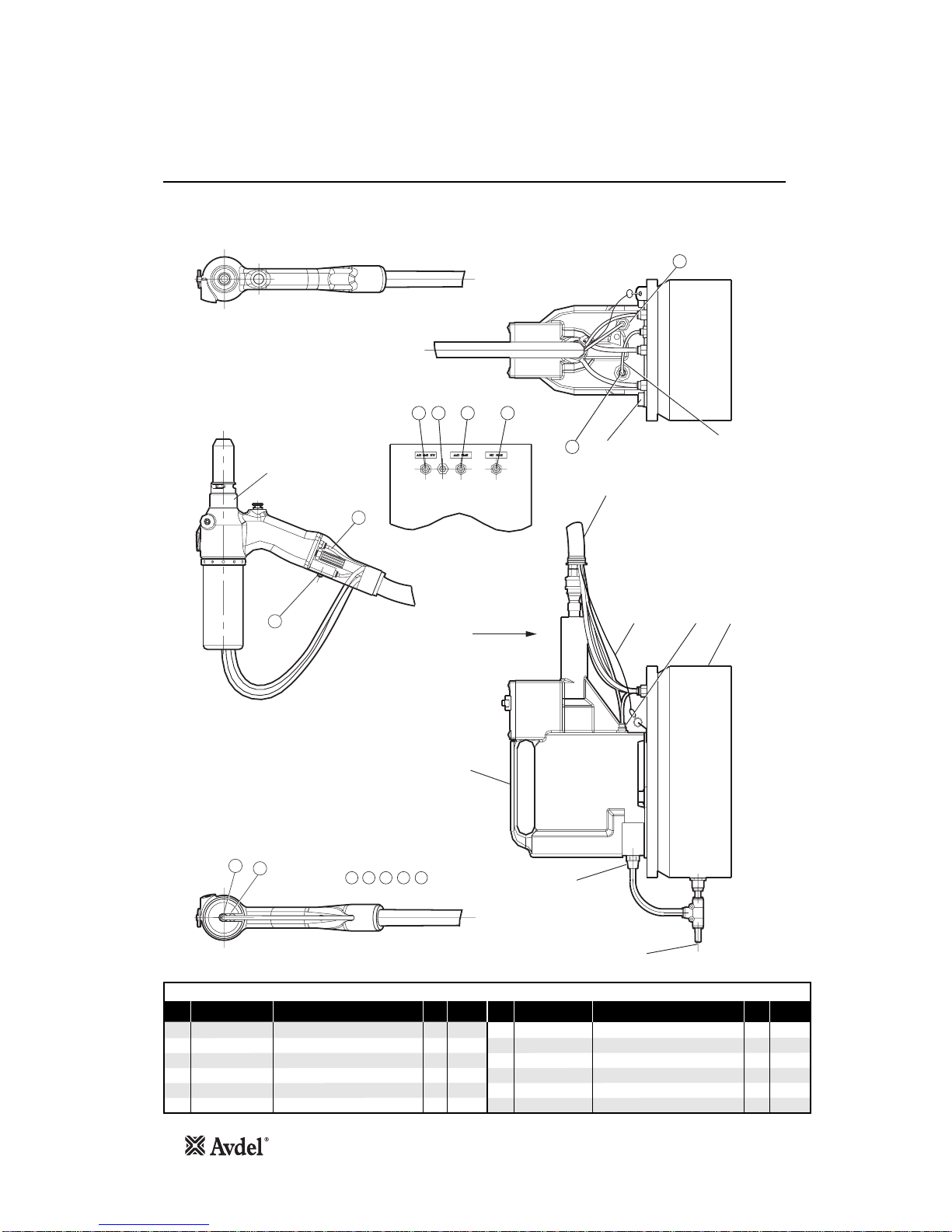

Hand Tool General Assembly and Parts List 20

Priming

Oil Details 21

Hyspin®VG 32 Oil Safety Data 21

Priming Procedure 22

Fault Diagnosis

Symptom, Possible Cause and Remedy 23-24

LIMITED WARRANTY

Avdel makes the limited warranty that it’s products will be free of defects in workmanship and materials

which occur under normal operating conditions. This Limited Warranty is contingent upon: (1) the product

being installed, maintained and operated in accordance with product literature and instructions, and (2)

confirmation by Avdel of such defect, upon inspection and testing. Avdel makes the foregoing limited

warranty for a period of twelve (12) months following Avdel’s delivery of the product to the direct purchaser

from Avdel. In the event of any breach of the foregoing warranty, the sole remedy shall be to return the

defective Goods for replacement or refund for the purchase price at Avdel’s option. THE FOREGOING

EXPRESS LIMITED WARRANTY AND REMEDY ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES

AND REMEDIES. ANY IMPLIED WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR MERCHANTABILITY

ARE HEREBY SPECIFICALLY DISCLAIMED AND EXCLUDED BY AVDEL.

Avdel UK Limited policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

4

Safety Rules

1Do not use outside the design intent.

2Do not use equipment with this tool/machine other than that recommended and supplied by Avdel UK Limited.

3Any modification undertaken by the customer to the tool/machine, nose assemblies, accessories or any equipment supplied by Avdel

UK Limited or their representatives, shall be the customer’s entire responsibility. Avdel UK Limited will be pleased to advise upon any

proposed modification.

4The tool/machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and

function by trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel UK

Limited procedures. Do not dismantle this tool/machine without prior reference to the maintenance instructions. Please contact Avdel

UK Limited. with your training requirements.

5The tool/machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the U.K. the “Health and

Safety at Work etc. Act 1974” applies. Any question regarding the correct operation of the tool/machine and operator safety should

be directed to Avdel UK Limited.

6The precautions to be observed when using this tool/machine must be explained by the customer to all operators.

7Always disconnect the airline from the tool/machine inlet before attempting to adjust, fit or remove a nose assembly.

8Do not operate a tool/machine that is directed towards any person(s) or the operator.

9Always adopt a firm footing or a stable position before operating the tool/machine.

10 Ensure that vent holes do not become blocked or covered.

11 The operating pressure shall not exceed 7 bar.

12 Do not operate the tool if it is not fitted with a complete nose assembly or swivel head unless specifically instructed otherwise.

13 Care shall be taken to ensure that spent stems are not allowed to create a hazard.

14 If the tool is fitted with a stem collector, it must be emptied when half full.

15 If the tool is fitted with a stem deflector, it should be rotated until the aperture is facing away from the operator and other person(s)

working in the vicinity.

16 When using the tool, the wearing of safety glasses is required both by the operator and others in the vicinity to protect against

fastener ejection, should a fastener be placed ‘in air’. We recommend wearing gloves if there are sharp edges or corners on the

application.

17 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool which should be

kept dry and clean for best possible grip.

18 When carrying the tool from place to place keep hands away from the trigger/lever to avoid inadvertent start up.

19 Excessive contact with hydraulic fluid oil should be avoided. To minimize the possibility of rashes, care should be taken to wash

thoroughly.

20 C.O.S.H.H. data for all hydraulic oils and lubricants is available on request from your tool supplier.

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

Tool Specification for 74405

Specifications

5

Air Pressure Minimum - Maximum 5-7 bar 60 - 100 lbf/in2

Free Air Volume Required @ 5.5 bar or 75 lbf/in215 litres .525 ft2

Stroke Maximum 16 mm .63 in

Motor Speed SPIN ON 2000 RPM

SPIN OFF 2000 RPM

Pull Force @ 5.5 bar or 75 lbf/in213.84 kN 3111 lbf

Cycle Time Approximately 3 seconds

Noise Level Less than 75 dB(A)

Weight Without equipment or hose 2 kg 4.4 lb

Vibration Less than 2.5 m/s2

Tool Specification for Intensifier

Air Pressure Minimum - Maximum 5-7 bar

Free Air Volume Required @ 5.5 bar or 75 lbf/in23.6 litres

Noise Level Less Than 75 dB(A)

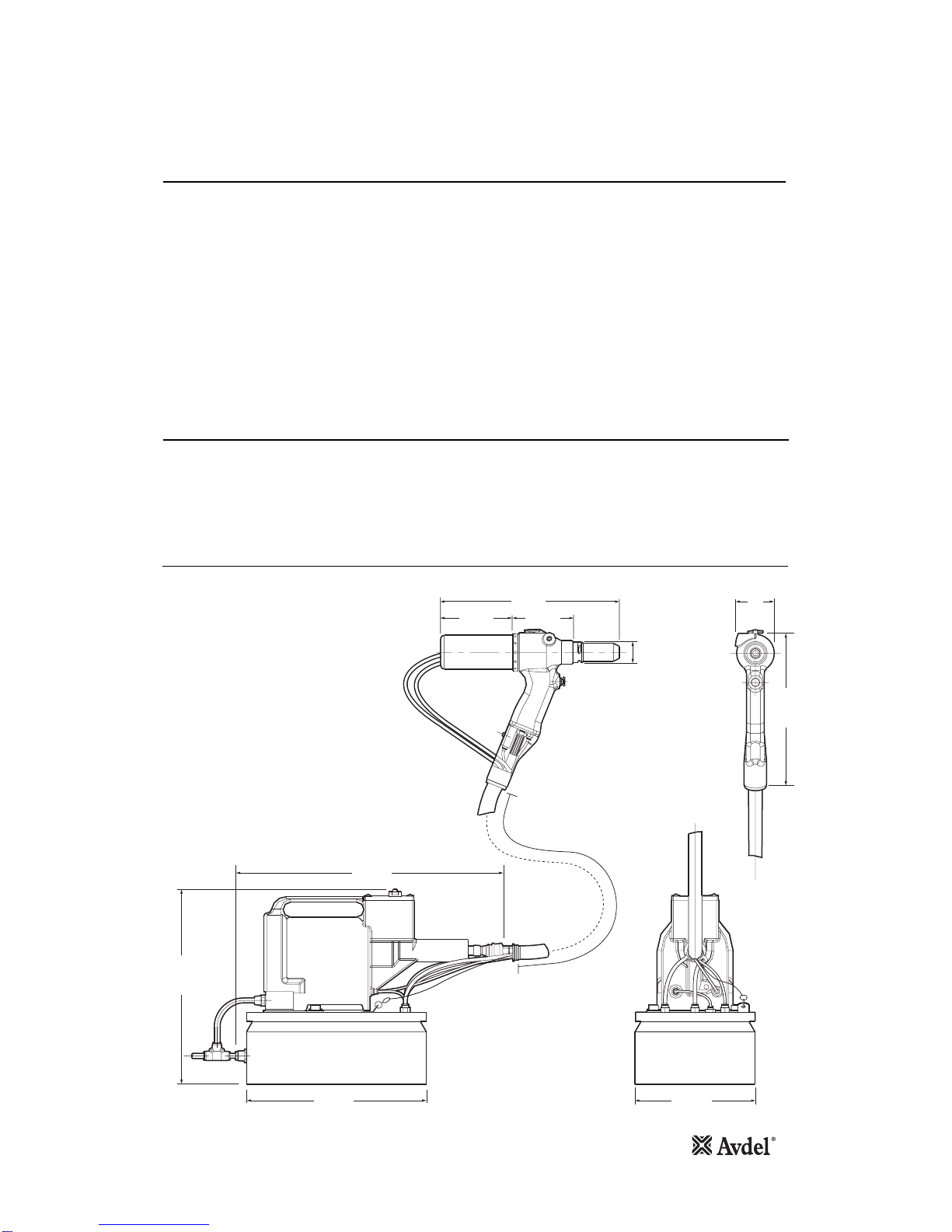

300

445

326

250

35

200

120 102

300 66

Tool Dimensions

Dimensions in millimetres

6

Intent of Use

The hydro-pneumatic 74405 tool is designed to place Avdel® Threaded Inserts at high speed making it ideal for batch or flow-line

assembly in a wide variety of applications throughout all industries.

A complete tool is made up of two seperate elements which will be supplied individually:

•Base Tool - 74405-01000

•Nose Assembly - see datasheet 07900-00857

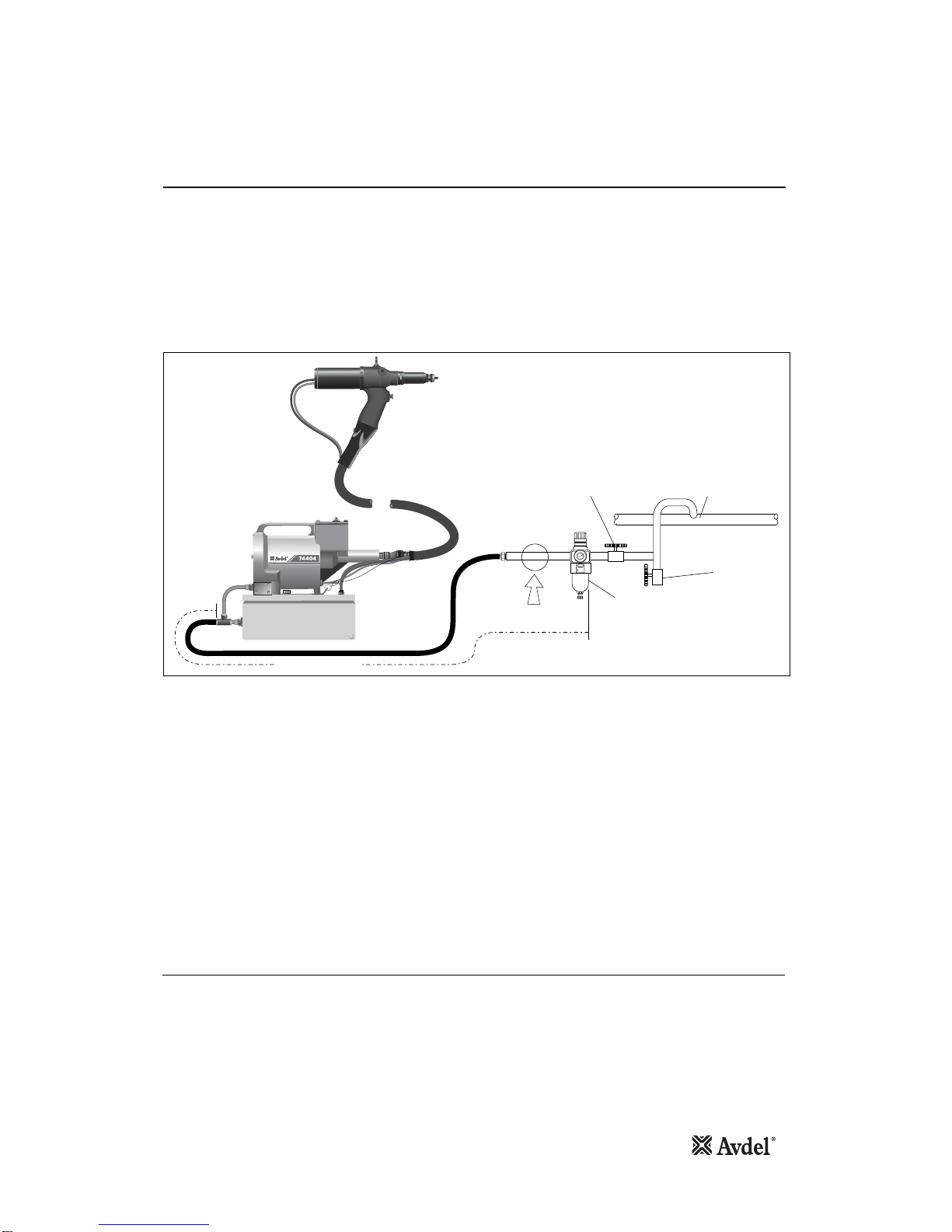

Air Supply

Putting into Service

7

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and

filtering systems on the main air supply. These should be fitted within 3 metres of the tool (see diagram below) to ensure

maximum tool life and minimum tool maintenance.

Air supply hoses should have a minimum effective working pressure rating of 150% of the maximum pressure produced in the system

or 10 bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured where

operating conditions may result in hoses being damaged. All air hoses MUST have a minimum bore diameter of 6.4 millimetres or 1/4

inch.

Read servicing daily details page 11.

Follow the steps below when connecting the tool to the intensifier and main air supply:

•Push the end of the large hydraulic hose from the tool into the quick release connector on the end of the intensifier.

•On the front face of the intensifier (Refer to page 18):

•Push the black pneumatic (4mm OD) line into the reducer fitting which is located in the left hand bulkhead connector.

•Push the blue pneumatic (4mm OD) line into the plastic collet of the right hand bulkhead connector.

•On the top face of the control box (Refer to page 20):

•Push the blue pneumatic (6mm OD) line into the reducer labelled ‘Air Motor Spin On’ on the top face of the control box - LH side.

•Push the black pneumatic (6mm OD) line into the reducer labelled ‘Air Motor Spin Off’ on the top face of the control box - middle.

•Push the black pneumatic (4mm OD) line from the flexible hose assembly into the reducer labelled ‘Aux Spin Off’ on the top face

of the control box - RH side.

•Push the black pneumatic (4mm OD) line from the reducer fitting on the intensifier into the reducer labelled ‘Intensifier Timer’ on

the top face of the control box.

•Fit a pneumatic hose between the male connector at the rear of the intensifier and main air supply.

8

6

4

2

0

10

12

14

16

TAKE OFF POINT

FROM

MAIN SUPPLY

STOP COCK

(USED DURING MAINTENANCE

OF FILTER/REGULATOR OR LUBRICATION UNITS)

MAIN SUPPLY

DRAIN POINT

AIR LUBRICATION PRESSURE REGULATOR

AND FILTER (DRAIN DAILY)

3 METRES MAXIMUM

Operating Procedure

•Before you use the tool, remove the Screw 3* on top of the oil reservoir of the intensifier to allow venting. Replace screw when

transporting the intensifier.

•Ensure that a nose assembly suitable for the fastener is fitted (see separate nose assembly data sheet 07900-00857).

•Connect the tool to the intensifier and the intensifier to the air supply.

•Offer up insert, lip first to the drive screw. A light pressure will start the motor and automatically thread the insert up against the

nose and stop.

•Insert the fastener into the application squarely.

•Fully depress the trigger. This will both place the insert into the application and reverse it off the drive screw.

* Item number refers to Intensifier general assembly and parts list on pages 18 and 19.

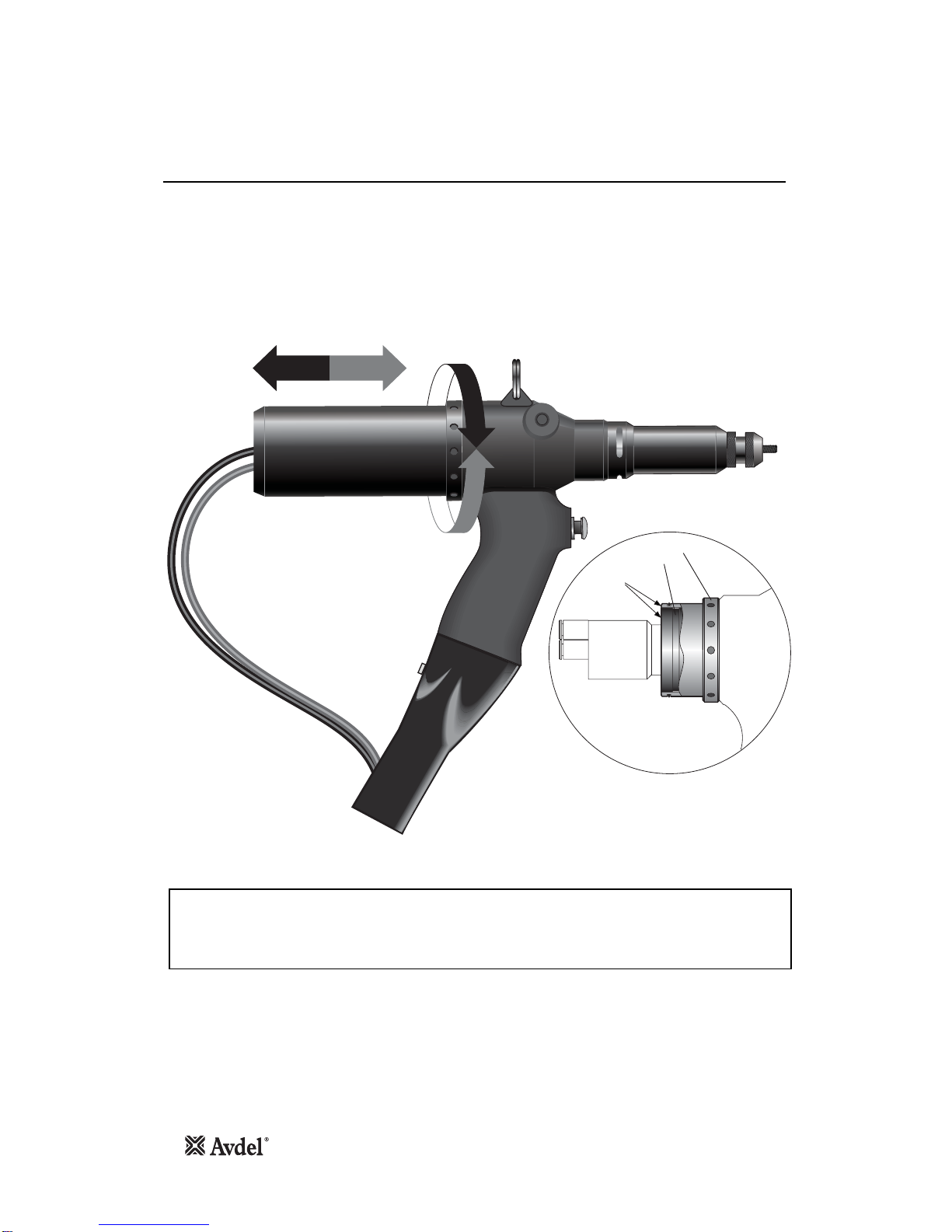

Stroke Adjustment

Putting into Service

8

This adjustment is necessary to insure optimum insert deformation. It is suggested, therefore, that a test plate with the same thickness

and hole size as the workpiece is used.

If deformation is insufficient, the insert willl rotate inside the application.

If deformation is excessive, thread distortion will occur and possibly drive screw fracture.

The stroke is adjusted by the amount the Stroke Adjustment Lock Nut 12, (parts list page 17), is screwed in or out. To shorten the

stroke, screw in; to lengthen the stroke, unscrew the rear casing. Adjust until optimum deformation is obtained.

Item numbers in bold refer to the illustrations on pages 16 and 17.

IMPORTANT

At the correct stroke the rear faces of the Adjustment Ring 47 and the Stroke Adjustment Lock Nut 12 will be

flush.

The Adjustment Ring 47 must not be wound out beyond this point.

Note

47 12

Rear Casing (48)

Removed

Faces Flush

See

Note

Fitting Instructions

IMPORTANT

The Nose Assembly must be fitted before operating the tool.

It is essential that the correct nose assembly is fitted prior to operating the tool. By knowing your original complete tool part number

or the details of the fastener to be placed, you will be able to order a new complete nose assembly using the datasheet 07900-

00857 for nose assembly components.

* Item included in the 74405 Service Kit. For complete list see page 11.

9

IMPORTANT

The air supply must be disconnected when fitting or removing nose assemblies unless specifically instructed

otherwise.

•If still fitted remove the nose casing and adaptor nut.

•Insert Drive Shaft 4into spindle.

•Fit Drive Screw 3onto Drive Shaft 4.

•Insert Reducing Sleeve 5(if required) into the adaptor nut.

•Position Friction Ring 51* onto the spindle.

•Screw the adaptor nut onto the spindle.

•Hold the spindle with a spanner*, tighten the lock nut anti-clockwise, ensuring the friction ring is not caught between the faces of the

spindle and the adapter nut.

•Screw on the nose casing together with Nose Tip 1and nose tip Lock Nut 2.

•The reverse operation is carried out for equipment removal.

•With tool still disconnected from air supply, screw one insert onto the drive screw manually making sure the insert is flush with the end of

the drive screw.

•Set nose tip in exact position and lock nose tip nut clockwise with a spanner*.

•Remove the insert from the drive screw.

(Item numbers in bold refer to illustration below, 51* refers to illustration on page 16).

1

2

3

5

SPINDLE FRICTION RING

LOCK NUT

ADAPTOR NUT NOSE CASING

4

51*

*

Items in grey are included in the base tool.

Nose Assembly Components

10

•Remove the nose equipment using the reverse procedure to the ‘Fitting Instructions’ (see page 9).

•Any worn or damaged part should be replaced.

•Particularly check wear on Drive Screw 3and Drive Shaft 4.

•Assemble according to fitting instructions.

(Item numbers in bold refer to illustration on page 9)

Servicing Instructions

See separate data sheet 07900-00857 for nose assembly components.

Servicing

Daily

Weekly

Servicing the Tool

IMPORTANT

Read safety instructions on page 4.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

The tool shall be examined regularly for damage and malfunction.

•Daily, before use or when first putting the tool into service, pour a few drops of clean, light lubricating oil into the air inlet of the tool. If the

tool is in continuous use, the air hose should be disconnected from the main air supply and the tool lubricated every two to three hours.

•Check for air leaks. If damaged, hoses and couplings should be replaced by new items.

•If there is no filter on the pressure regulator, bleed the air line to clear it of accumulated dirt or water before connecting the air hose to the

tool.

•Check that the nose assembly is correct.

•Check the stroke of the tool is adequate to place selected insert (see Stroke Adjustment page 8).

•Inspect the drive screw in the nose assembly for wear or damage. Renew, if necessary.

•Check for oil leaks and air leaks on air supply hose and fittings.

For all servicing we recommend the use of the Service Kit, part number 74405-99990, detailed below.

Regular servicing should be carried out and a comprehensive inspection performed annually or every 500,000 cycles, whichever is

sooner.

Grease used during tool maintenance can be ordered as a single item, the part number is shown in the Service Kit above.

PART Nº DESCRIPTIONPART Nº DESCRIPTION Nº OFF Nº OFF

SERVICE KIT : 74405-99990

07900-00618 PUSHER 1

07900-00409 12mm/13mm SPANNER 1

07900-00632 17mm/19mm SPANNER 2

74200-12196 17mm THIN SPANNER 1

07900-00642 27mm/30mm SPANNER 1

07900-00859 42mm SPANNER 1

07900-00158 Ø2mm PIN PUNCH 1

07900-00624 Ø4mm PIN PUNCH 1

07900-00469 2.5mm ALLEN KEY 1

07900-00351 3mm ALLEN KEY 1

07900-00224 4mm ALLEN KEY 1

07900-00225 5mm ALLEN KEY 1

07900-00226 6mm ALLEN KEY 1

07900-00521 Ø1/4" ROD 1

07900-00639 NYLON BUSH 1

07900-00640 METAL BUSH 1

07900-00161 EXTERNAL CIRCLIP PLIERS 1

07900-00157 INTERNAL CIRCLIP PLIERS 1

07900-00625 SOFT MALLET 1

07900-00426 COMBINATION SPANNER 1

07900-00860 BULLET 1

07900-00717 SPANNER FOR INTENSIFIER 1

07900-00692 TRIGGER VALVE EXTRACTOR 1

07992-00020 GREASE - MOLY LITHIUM EP3753 1

07992-00075 GREASE - MOLYKOTE®55M 1

07900-00775 GREASE - MOLYKOTE®111 1

11

12

Servicing the Tool

Moly Lithium Grease EP 3753 Safety Data

Grease can be ordered as a single item, the part number is shown in the Service Kit page 11.

First Aid

SKIN:

As the grease is completely water resistant it is best removed with an approved emulsifying skin cleaner.

INGESTION:

Ensure the individual drinks 30ml Milk of Magnesia, preferably in a cup of milk.

EYES:

Irritant but not harmful. Irrigate with water and seek medical attention.

Fire

FLASH POINT: Above 220°C.

Not classified as flammable.

Suitable extinguishing media: CO2, Halon or water spray if applied by an experienced operator.

Environment

Scrape up for incineration or disposal on approved site.

Handling

Use barrier cream or oil resistant gloves

Storage

Away from heat and oxidising agent.

C.O.S.H.H. data for all hydraulic oils and lubricants is available on request from your local tool supplier.

13

Maintenance

IMPORTANT

Read Safety Instructions on page 4.

The employer is responsible for ensuring that tool maintenance instructions are given to the appropriate personnel.

The operator should not be involved in maintenance or repair of the tool unless properly trained.

The tool shall be examined regularly for damage and malfunction.

Every 500,000 cycles the tool should be completely dismantled and new components should be used where worn, damaged or

recommended. All ‘O’ rings and seals should be renewed and lubricated with Moly Lithium grease EP 3753 before assembling.

The air line must be disconnected before any servicing or dismantling is attempted unless specifically instructed otherwise.

It is recommended that any dismantling operation be carried out in clean conditions.

Prior to dismantling the tool it is necessary to remove the nose assembly. For simple removal instructions see the nose assemblies

section, page 9.

Remove Bleed Screw 32 and Washer 31 and drain oil from tool.

For total tool servicing we advise that you proceed with dismantling of sub-assemblies in the order shown below.

To disconnect the Oil Hose 46* and Air Delivery and Return Hose 45* from the tool, disengage Spiral Protection Sleeve 47* from

Sleeve 39 and lower Sleeve 39 to gain access to the hoses.

Disconnect Air Hoses by pushing and releasing the quick release connectors. Using two spanners, undo Oil Hose 46* at Air Connector

38 leaving the connector attached to the handle of the tool. Remove the tool.

Remove the nose equipment from the tool by loosening the nose tip lock nut and unscrewing the nose tip. Unscrew Nose Casing 33,

and with the aid of spanners* remove the components of the nose assembly. Remove the two Air Tubes 48* from the Centre

Connectors 1.

*refers to items included in the 74405 Service Kit. For a complete list see page 11.

Item numbers in bold refer to the Base Tool General Assembly drawings and Parts Lists pages 16-17.

Item numbers bold* refer to the Intensifier General Assembly drawings and Parts List pages 18-19.

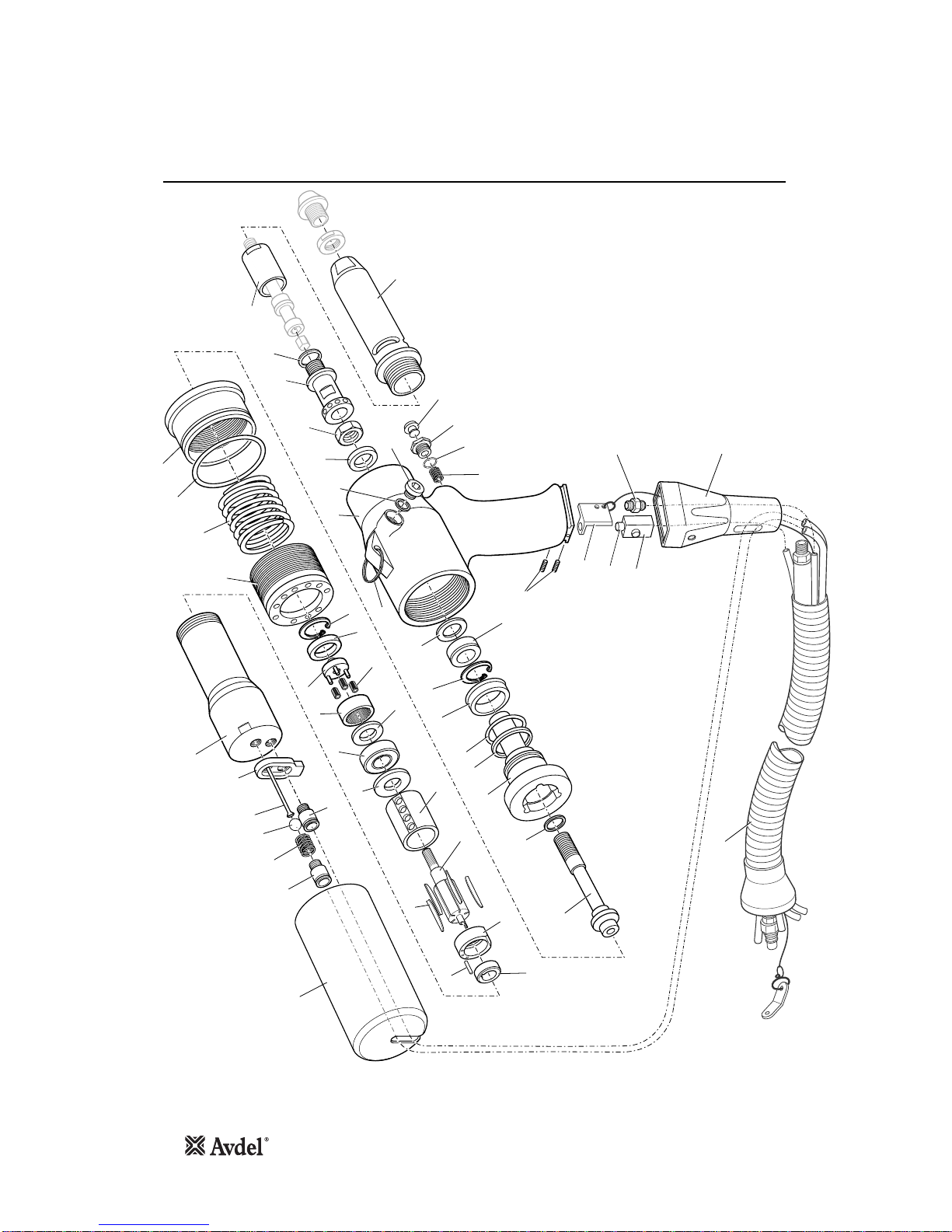

Head Assembly

•Using the pins of the combination spanner*, unscrew Stroke Adjustment Lock Nut 12.

•Withdraw Stroke Adjustment Lock Nut 12, Air Motor Assembly 49, Spring 13, Movement Pivot 22, Shim Adjustment Ring 23,

Piston 24 and Lip Seal 25.

•Grip the flats on the Air Motor Casing 3in a vice fitted with soft jaws and with a spanner* separate the air motor assembly from the

Piston 24. Spring 13 and Stroke Adjustment Lock Nut 12 can now be removed from Air Motor Casing 3.

•Using circlip pliers* remove Circlip 26 and extract Lip Seal 42.

•From the Air Motor Casing 3remove Centre Connector 1using an Allen key* and extract Spring 2, Ball 4and Pushrod 5.

•Reassemble in reverse order of dismantling, observing the following:

•Use nylon bush* and pusher* to fit Lip Seal 42 into it’s housing.

•Use circlip pliers* to fit Circlip 26.

•Insert metal bush* into Handle 28.

•Fit Lip Seal 25 onto Piston 24.

•Screw bullet* onto Piston 24 to ease insertion of Lip Seal 25 into the handle.

•Insert Piston 24 into the handle through the metal bush*, then remove the bush* and bullet* from the piston.

Reassembly of Head Assembly

•Assemble in reverse order of dismantling

•When reassembling, clean threads of air motor and piston and assemble using Loctite®243.

14

Air Motor Assembly

Handle and Trigger Assembly

Maintenance

•Tap the Air Motor Casing 3gently on the bench to remove the air motor assembly from the casing.

•Using circlip pliers*, remove Circlip 14.

•Remove Bearing 15 and Planet Gear Spindle 11, together with three Planets 16 from Planet Gear 10.

•Remove Planet Gear 10 and Spacer 17.

•Using a soft mallet, tap on splined head of Rotor 19 and remove Bearing 9and Front End Plate 8.

•Tap out Rotor 19 and Rotor Blades 7, five off.

•Place Rear End Plate 20 in the vice and using a pin punch*, tap on centre of Rotor 19 to remove Bearing 21.

Take care not to lose Pin 6.

•Remove Bearing 21.

•Assemble in reverse order of dismantling, observing the following:

•Rear side of Rotor 19 must touch Rear End Plate 20 without any axial gap. Any existing gap will disappear when Bearing 21 is fully

located.

•When inserting the air motor assembly into Air Motor Casing 3, align components so that Pin 6locates the centre hole between the

spin-on and spin-off ports of the air motor casing.

•Using a spanner, undo Lock Nut 35 and remove Trigger 34, ‘O’ Ring 36 and Spring 2from Handle 28.

•Remove Screw 41 to release Emergency Spin-Off Button 40.

•Assemble in reverse order to dismantling.

*refers to items included in the 74405 Service Kit. For a complete list see page 11.

Item numbers in bold refer to the Base Tool General Assembly drawing and Parts List pages 16-17.

15

Intensifier

Maintenance

* Refers to items included in the 74405 Service Kit. For complete list see page 11.

Items in bold refer to the Intensifier General Assembly drawing and Parts List on pages 18-19.

•When dismantling the intensifier assembly, first disconnect the air supply hose to Inlet Connector 22.

•Using an Allen Key* undo four Screws 27 and remove Protection Plate 24.

•Disconnect the trigger hose from the Connector/Reducing Valve 48 by depressing the outlet collet and withdrawing the hose.

•Remove Cover Plate 4and Gasket 35 by removing Screws 37 and Washers 36 using Allen Key*.

•Ensure that gasket is not damaged to ensure a proper seal on assembly.

•Invert intensifier assembly and drain oil from reservoir into a suitable container.

•Remove Quick Release Connector 32 together with Connector 31 and Seals 33 with suitable spanner*.

•Remove Screw 19 using a suitable Allen Key* and remove Silencer Cover 16, Foam Silencer 15, Spacer 18 and Retaining Plate

20.

•Using a screwdriver, carefully remove internal Retaining Ring 14. Clean and inspect groove for sign of damage.

•Using Extractor*, insert male threaded end into End Cover 12 and withdraw it along with ‘O’ Ring 13.

•Insert Rod* through the connector orifice at the front of the Body Assembly 8and tap out Piston Rod 9together with Air Piston

Spacer 26, ‘O’ Ring 28, Air Piston 11, ‘O’ Ring 10 and Nut 17.

•Remove Seal Plug 7with spanner*.

•Insert Rod* through connector orifice at the front of the Body Assembly 8and push out Seal Housing 5and associated ‘O’ rings

and lip seals.

•Remove Valve Housing Assembly 34 from the main body with a suitable spanner*. Clean by blowing through with a low-pressure

air jet.

•Remove Piston Rod 9from Air Piston 11 by gripping the first 20 mm (3/4”) of the rod in a vice fitted with soft jaws, taking care not

to damage or mark the working surface.

•Unscrew locking Nut 17 with a suitable spanner*.

•Assemble in the reverse order of dismantling, observing the following:

•Clean all parts and renew all ‘O’ rings.

•Lubricate all seals using Moly Lithium grease.

•Valve Housing Assembly 34 must be refitted using a thread sealing adhesive.

•Assemble the Piston Assembly using a new Nut 17.

•End Cover 12 must be fitted correctly inside Retaining Ring 14. The tool must not be operated if the end cover has been omitted.

IMPORTANT

Priming is ALWAYS necessary after the tool has been dismantled and prior to operating.

16

Head Assembly 74405-12000

12

1

3

49 ASSEMBLY

48

5

52

4

6

7

8

9

10 11

37

13

14

15

16

17

18

19

20

21

22

53Flexible HoseAssembly

Reference Only

23

24 46 45

25 26 50

27

28

34

31

32

35

36

41

40

53Ref

38

39

33

2

42

30

43 51

44

29

12

47

54

General Assembly

Parts List

Head Assembly 74405-12000

17

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

07655-09220

07555-09219

74401-12046

07555-09218

74401-12047

07555-09216

07555-09213

07555-09210

07555-09206

74200-12065

74200-12063

74405-12003

74401-12025

74200-12061

74200-12062

07555-09208

74200-12066

07555-09211

74200-12070

07555-09214

07555-09215

74405-12021

74200-12055

74405-12020

07003-00341

07265-02005

07265-03021

CENTRE CONNECTOR

SPRING

AIR MOTOR CASING

BALL

PUSHROD

PIN

ROTOR BLADE

FRONT END PLATE

BEARING

PLANET GEAR

PLANET GEAR SPINDLE

STROKE ADJUSTMENT LOCK NUT

SPRING

CIRCLIP

BEARING

PLANET

SPACER

STATOR

ROTOR

REAR END PLATE

BEARING

MOVEMENT PIVOT

SHIM ADJUSTMENT RING

PISTON

LIP SEAL

CIRCLIP

SUSPENSION RING

2

2

1

1

1

1

5

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

----

1

-

5

------

1

--------

1

----

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

HANDLE - MACHINED

SPACER

LOCKNUT

OIL SEAL WASHER

BLEED SCREW

NOSE CASING

TRIGGER

LOCK NUT

'O' RING

'O' RING

AIR CONNECTOR 4mm

SLEEVE

AUXILIARY SPIN OFF BUTTON

SCREW

LIP SEAL

SPINDLE

ADAPTOR NUT

'O' RING

BEARING TAPE

ADJUSTMENT RING

PROTECTIVE COVER

AIR MOTOR ASSEMBLY

BEARING TAPE

FRICTION RING

AIR MOTOR GUIDE

FLEXIBLE HOSE ASSEMBLY (REFERENCE ONLY)

BUTTON LOCATOR

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

----

1

---------

1

------------

74405-12001

74405-12054

07655-00803

07265-02011

07265-02010

74405-12027

07265-03023

07265-03022

07555-00502

07003-00391

07005-01951

74401-12008

74405-12057

74401-12002

07003-00273

74200-12044

74200-12092

07003-00342

71213-02022

74405-12002

74405-12004

74405-12030

71213-02021

07003-00028

74405-12061

07008-00444

74405-12056

ITEM PART Nº DESCRIPTION QTY SPARES* ITEM PART Nº DESCRIPTION QTY SPARES*

74405-12000 PARTS LIST *These are minimum recommended levels of spares based on regular servicing

General Assembly

18

Intensifier 74404-02000

31

33

34

6

30

35

36

1234578911 12 1314 15 16

17

19

18

20

37

39

22

23

2427

32

29

10

38

2628

25

VIEW ON ARROW 'A'

VIEW ON ARROW 'B'

'B'

'A'

6

21

46

45

51 48 4541

42

43

47

49

50

44

40

Parts List

19

Intensifier 74404-02000

74404-02000 PARTS LIST

ITEM PART Nº DESCRIPTION QTY ITEM PART Nº DESCRIPTION QTY SPARES

1 07003-00037 1/4" BSP DOWTY SEAL 1 1

2 07240-00211 FILLER SCREW 1 -

3 07001-00418 M4 BLEED SCREW SOCKET HD 1 1

4 07240-00210 COVER PLATE 1 -

5 71420-02006 SEAL HOUSING 1 -

6 07003-00153 'O' RING 2 -

7 71420-02007 SEAL PLUG 1 -

8 71420-02300 BODY ASSEMBLY 1 -

9 71420-02008 PISTON ROD 1 -

10 07003-00182 'O' RING 1 1

11 07240-00206 AIR PISTON 1 -

12 07240-00207 END COVER 1 -

13 07003-00183 'O' RING 1 1

14 07004-00069 RETAINING RING 1 1

15 07240-00213 FOAM SILENCER 1 1

16 07240-00214 SILENCER COVER 1 -

17 07002-00017 NUT 1 1

18 07240-00215 SPACER 1 -

19 07001-00417 M6 SCREW BUTTON HEAD 1 1

20 07240-00216 RETAINING PLATE 1 -

21 07005-01524 VALVE 1 -

22 07005-00041 INLET CONNECTOR 1 -

23 07003-00065 SEALING WASHER 1 -

24 07240-00220 PROTECTION PLATE 1 -

25 07007-01503 BOOK MARK LABEL 1 -

26 74404-02001 AIR PISTON SPACER 1 -

27 07001-00396 M4 SCREW COUNTERSUNK 4 -

28 07008-00181 'O' RING 1 -

29 07003-00337 LIP SEAL 1 1

30 07003-00336 LIP SEAL 2 2

31 07005-00406 CONNECTOR 1 -

32 07005-00759 QUICK RELEASE CONNECTOR 1 -

33 07003-00142 BONDED SEAL 2 1

34 07240-00400 VALVE HOUSING ASSEMBLY 1 -

35 07240-00209 GASKET 1 1

36 07002-00073 WASHER 4 1

37 07001-00554 10-24 UNC SCREW BUTTON HD 4 1

38 07007-01504 CE LABEL 1 -

39 07240-00217 LABEL 1 -

40 74404-02010 LABEL 2 -

41 07005-01976 TIMING VALVE 1 -

42 07001-00248 M4 SCREW COUNTERSUNK 2 -

43 07002-00123 M4 NUT 2 1

44 07005-01431 BULKHEAD CONNECTOR 1 1

45 07005-00456 MALE HOSE CONNECTOR 2 -

46 07005-00591 3mm BLACK TUBE A/R - -

47 07005-01084 4mm BLACK TUBE (110mm) - -

48 07005-01977 CONNECTOR/REDUCING VALVE 1 -

49 07001-00176 M6 SCREW CAP HEAD 3 -

50 07007-00292 1/4" BSP REDCAP 1 -

51 07005-00855 BULKHEAD UNION 1

SPARES

20

Hand Tool 74405-01000

1

3

4

LANYARD*

2*

8

9

10

11 11

5

6

7

3

2

1

5

2

1

6MM BLUE PIPE TO SPIN ON FITTINGS

SPIN ON

SPIN OFF

1

6MM BLACK PIPE TO SPIN OFF FITTINGS

2

4MM BLACK PIPE TO AUXILIARY SPIN OFF FITTINGS

AUXILIARY SPIN OFF

3

4MM BLUE PIPE TO HAND TOOL TRIGGER

4

CONNECTIONS TO TIMER OUTLET ON INTENSIFIER

5

VIEW ON ARROW A

A

3

4TRIGGER LINK

SLEEVE and LANYARD TOOL

BRACKET REMOVED FOR CLARITY

NOTES

3 POSITIONS

5

4

ITEMS 10 & 11, UTILISED TO

LINK INTENSIFIER TIMER OUTLET

TO CONTROL CABINET INTENSIFIER

OUTLET

TO TOOL

TRIGGER

9

74405-01000 PARTS LIST

ITEM PART Nº DESCRIPTION QTYSPARESITEM PART Nº DESCRIPTION QTY SPARES

1 74405-12000 THREADED INSERT HAND TOOL 1 -

2 07008-00444 FLEXIBLE HOSE ASSEMBLY 1 -

3 74404-02000 INTENSIFIER 1 -

4 07007-02065 CONTROL SYSTEM 1 -

5 74405-12080 MODIFIED M8 NUTSERT®9-

6 07001-00469 M8x15 SOCKET CAP HD SCREW 3 -

7 07002-00105 M8 WASHER 3 -

8 07005-10072 8MM TUBING x 2.5M 2 -

9 07005-01573 MALE CONNECTOR 8MM TUBE 2 -

10 07005-01977 6MM TO 4MM REDUCER 1 -

11 07005-01084 BLACK PLASTIC PIPE 4MM 1 -

12 07007-01424 TIE WRAP 1 -

General Assembly and Parts List

Table of contents

Other Avdel Power Tools manuals

Avdel

Avdel Avbolt 07220 User manual

Avdel

Avdel Genesis G2LB User manual

Avdel

Avdel 73435-02000 User manual

Avdel

Avdel 07900-09080 User manual

Avdel

Avdel Genesis G2LB User manual

Avdel

Avdel 71234 User manual

Avdel

Avdel Avbolt 07220 User manual

Avdel

Avdel 74110 User manual

Avdel

Avdel 74401 User manual

Avdel

Avdel Genesis G1 71204 User manual

Avdel

Avdel 07572 User manual

Avdel

Avdel Genesis G3 User manual

Avdel

Avdel Genesis G1 User manual

Avdel

Avdel 0727 User manual

Avdel

Avdel TX2000 User manual

Avdel

Avdel G3LB Tool User manual

Avdel

Avdel GenesisG2-s User manual

Avdel

Avdel Genesis 7537 User manual

Avdel

Avdel 74100 User manual

Avdel

Avdel 71404 User manual