Installation and General Maintenance Recommendations

Page 2

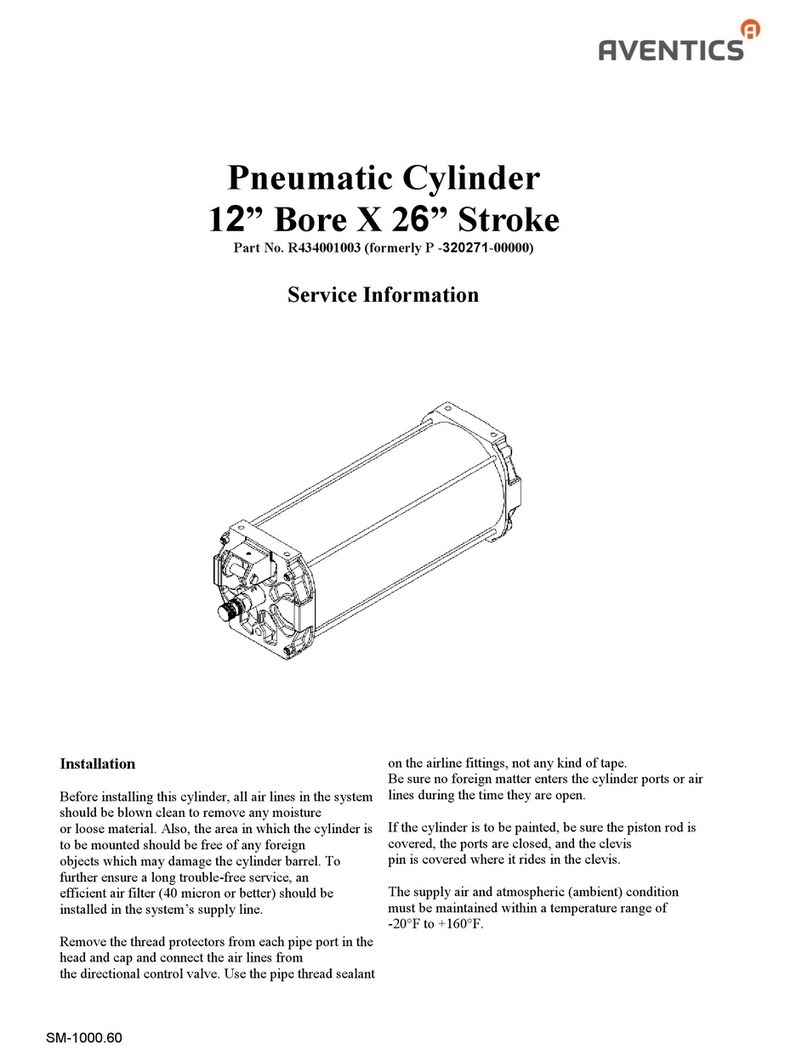

Installation

Before installing the Controlair®Valve, all air lines in the

system should be blown clean to remove any moisture, dirt,

or harmful contamination. Strainers are furnished in the Inlet

and Outlet ports to protect the valve from large particles of

forgoing matter in the line. To further ensure long, trouble-

free service, a 10 Micron or better filter should be installed

in the supply line to the valve.

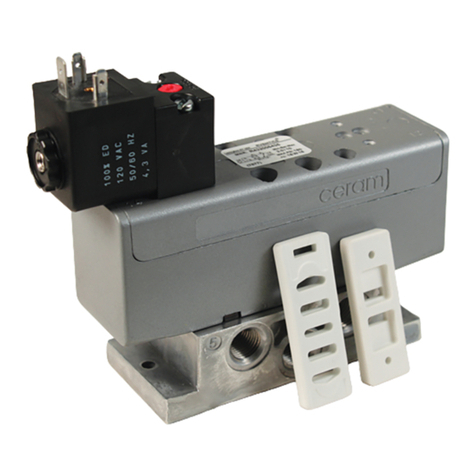

All Controlair Valves utilize a pipe bracket. Piping

connections made to the pipe bracket need not be disturbed

when removing the operator portion for maintenance.

The H-1 Controlair Valves are designed for floor mounting;

the complete assembly is installed and removed from the

top of the floor. The valve extends beneath the floor. Refer

to page 3 & 4 for panel opening dimensions. Allow suitable

clearance for pipe bracket cap screws which are 1 ¾” long.

H-1-A Controlair Valve is mounted directly to a floor

platform by two bolts through the lugs in the pipe bracket.

The floor, or platform normally serves as a stop for the

pedal. Refer to installation view on page 5 for panel opening

dimensions. Allow suitable clearance for pipe bracket

screws which are 1 ¾” long.

General Maintenance

Maintenance periods should be scheduled in accordance

with frequency of use and working environment of the

Controlair Valve.

All valves must be visually inspected for wear and given an

“in system” operating performance and leakage test at least

once a year. If these visual observations indicate valve

repair is required, the valve must be removed, repaired and

tested.

A major overhaul is recommended at one million cycles.

However, where frequency of use is such that it would

require more than two years to obtain one million cycles, the

valve must be overhauled at the two-year period.

When it is determined that the Controlair Valve requires a

major repair as a result of the one million cycles, one year

routine inspection, or the two year service period has

elapsed, the device must be disassembled, cleaned,

inspected, parts replaced as required, rebuilt and tested for

leakage, and proper operation prior to installation. Refer to

Major Repair and Maintenance Instruction, pages 12 & 13,

and Test Procedures, page 14.

One complete Controlair Valve should be kept in stock for

each four valves in service. During the maintenance period,

replace the complete valve with the “stand-by” unit. This will

reduce production time loss and afford inspection and

replacement of worn parts at a more appropriate or

opportune time and favorable location.

Notice that the operating portion of a valve can be removed

without disturbing the pipe connections. Remove the valve

from the pipe bracket by loosening four (4) screws and lift

the unit free.

No special tools are required to maintain the Controlair

Valve.

Technical Data

Maximum Operating Pressure........................200 psi (13.8 Bar)

Admissible Medium ........................................Air, clean and dry

Operating Temperature..................................-40° F to +160° F (-40° C to 71° C)

Hysteresis ......................................................1 ½ psi

Control Pressure Range.................................(Reference Identity Chart, Pg 7)

Pressure Change ...........................................½ psi Increment

Mounting ........................................................Flange Plate

Port Size ........................................................¼ - 18 NPTF

Materials

Controlair Valve Housing and Body............Die Cast Aluminum

Internal Parts ..............................................Brass, Rubber (buna-N), Aluminum,

Steel, Plastic and Hytrel Inlet Valve

Assemblies

Weight............................................................9 lbs. (4.1 Kg.) approximately