Avery Dennison SNAP 500 User manual

Other manuals for SNAP 500

5

Other Avery Dennison Printer manuals

Avery Dennison

Avery Dennison Monarch Pathfinder Ultra Platinum 6039 User manual

Avery Dennison

Avery Dennison Monarch 9493 SNP Service manual

Avery Dennison

Avery Dennison Monarch 9460 Service manual

Avery Dennison

Avery Dennison Monarch 9906 User manual

Avery Dennison

Avery Dennison MonarchNet2 9855 User manual

Avery Dennison

Avery Dennison FRESHMARX 9415 Service manual

Avery Dennison

Avery Dennison MONARCH 9416 XL Installation and operating instructions

Avery Dennison

Avery Dennison Monarch 9864 User manual

Avery Dennison

Avery Dennison Monarch Tabletop Printer 1 Service manual

Avery Dennison

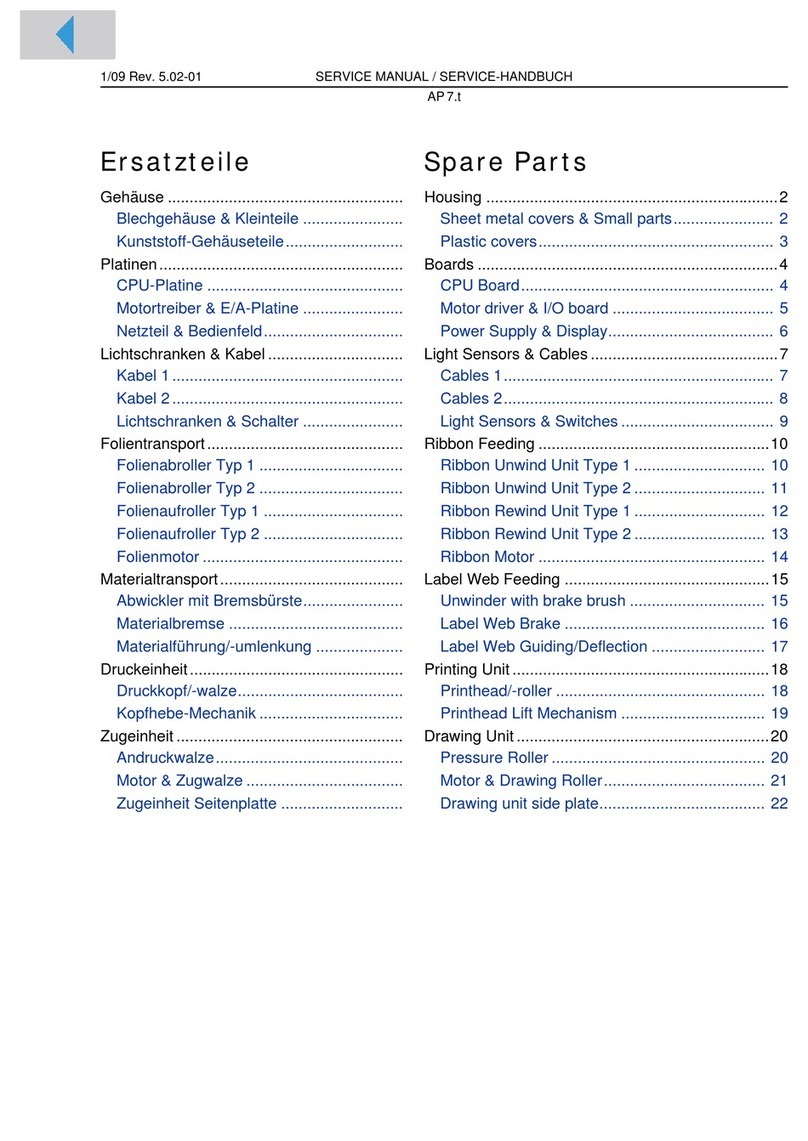

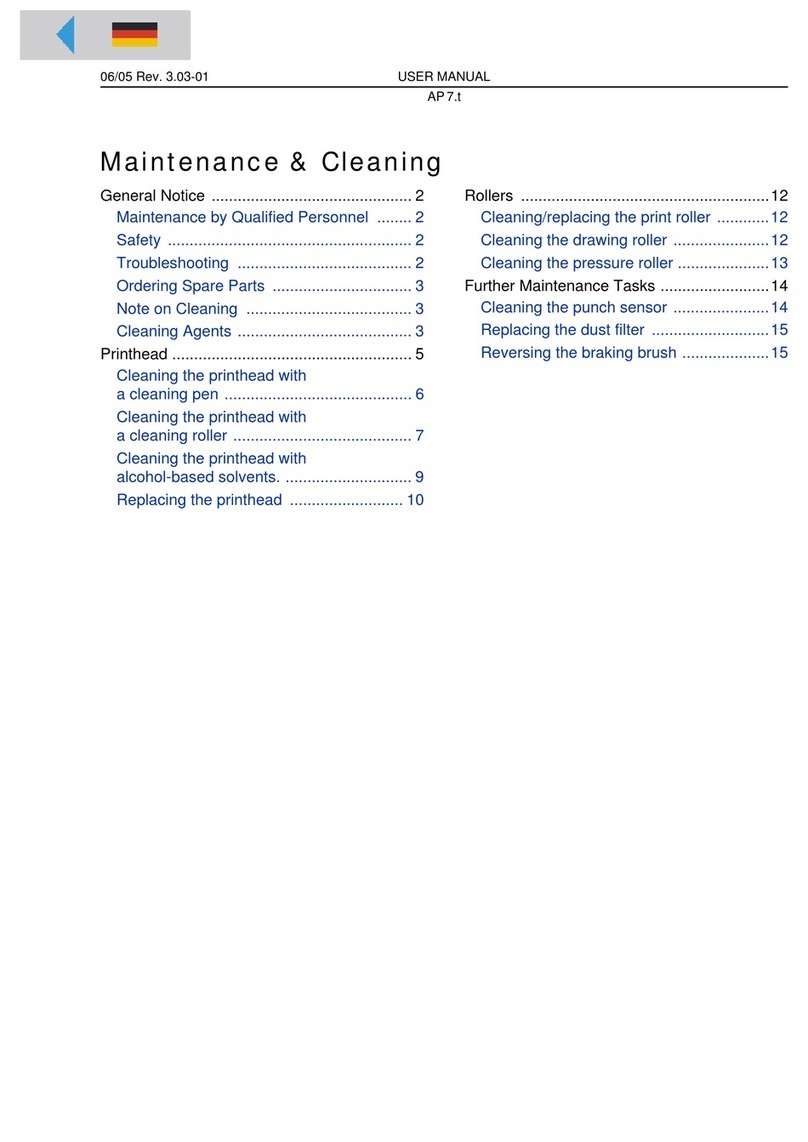

Avery Dennison AP7.t User manual

Avery Dennison

Avery Dennison SNAP 500 User manual

Avery Dennison

Avery Dennison Pathfinder6057 Operating and maintenance manual

Avery Dennison

Avery Dennison AP4.4 User manual

Avery Dennison

Avery Dennison Monarch 9485 User guide

Avery Dennison

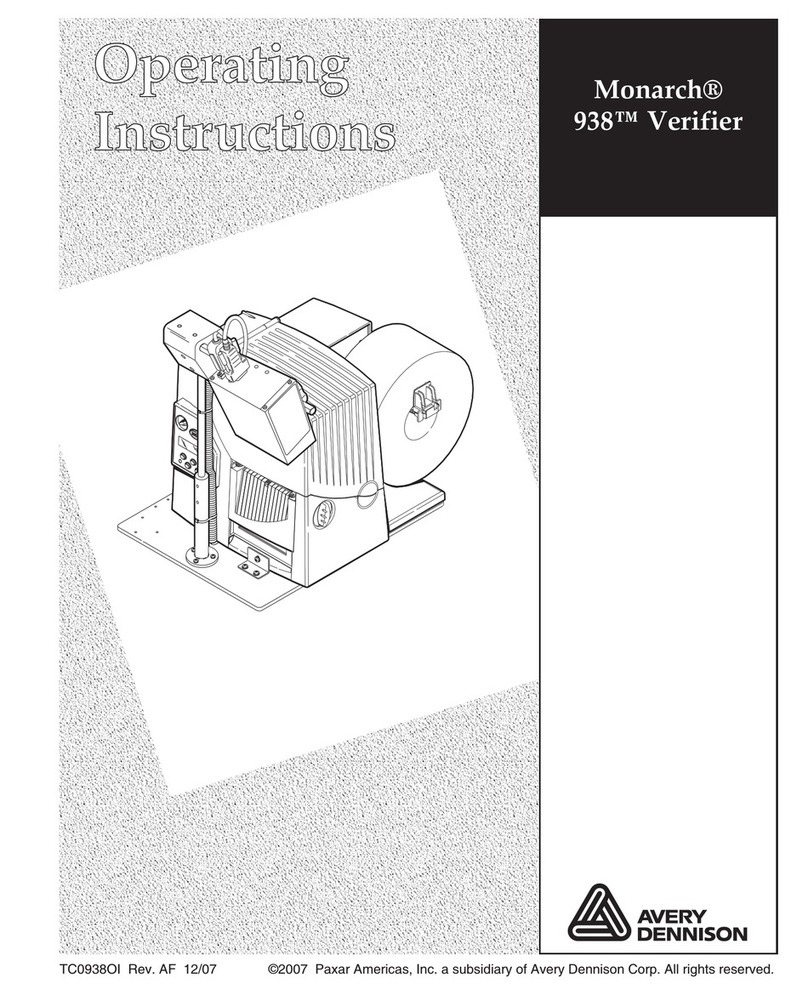

Avery Dennison Monarch 938 User manual

Avery Dennison

Avery Dennison AP5.4 User manual

Avery Dennison

Avery Dennison SNAP 500 User manual

Avery Dennison

Avery Dennison AP7.t User manual

Avery Dennison

Avery Dennison 9417 User manual

Avery Dennison

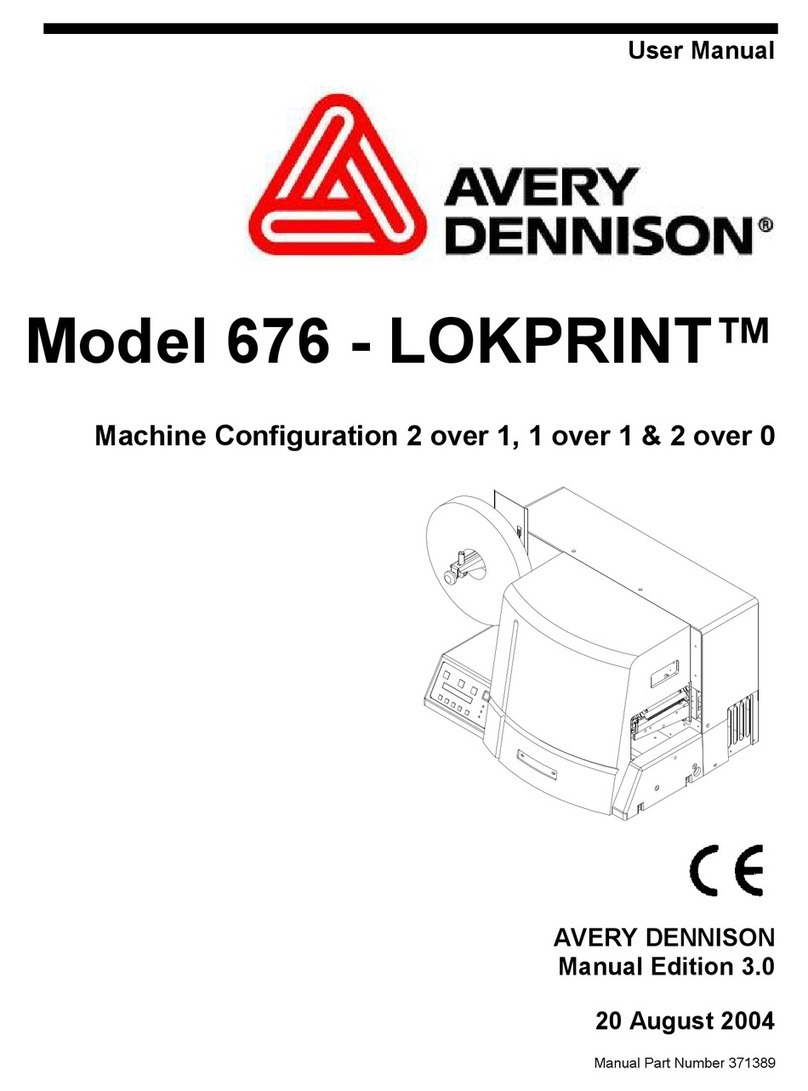

Avery Dennison LOKPRINT 676 User manual