Introductory Information A-Series Dobby Loom Assembly Manual

Page | iv Introductory Information

Figure 40 - Dobby on the Loom ................................................................................................... 37

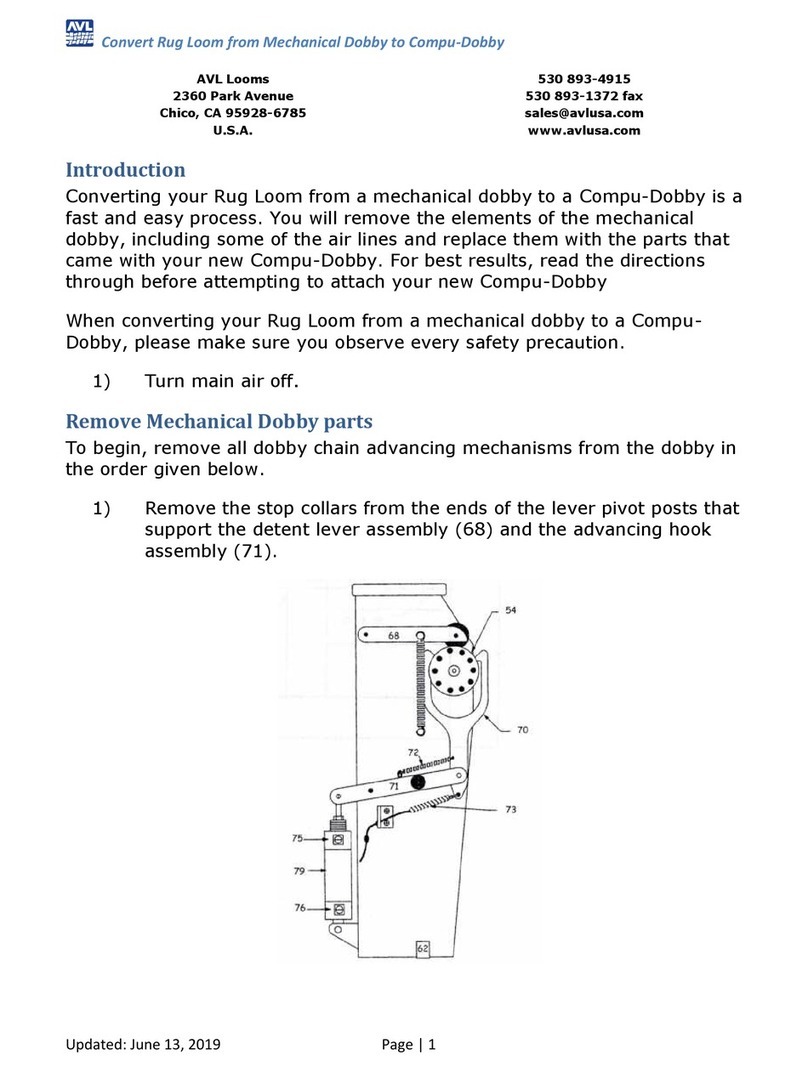

Figure 41 - Left side of the Mechanical Dobby with springs ....................................................... 39

Figure 42 - Dobby Cam and Pulley .............................................................................................. 40

Figure 43 - Treadle Pulleys ........................................................................................................... 41

Figure 44 - Bolt for the Treadle Cable .......................................................................................... 41

Figure 45 - Right Treadle Cables .................................................................................................. 42

Figure 46 - Dobby Cam with Turnbuckle ..................................................................................... 43

Figure 47 - Cam Cables ................................................................................................................ 45

Figure 48 - Slide Plate Eyebolt ..................................................................................................... 45

Figure 49 - Dobby Slide Plate to Spring Lever Cable .................................................................. 46

Figure 50 - Return Pulley Cable ................................................................................................... 46

Figure 51 - E-lift Spring Lever ..................................................................................................... 47

Figure 52 - Cable in Nautilus cam ................................................................................................ 48

Figure 53 - Secured Cable ............................................................................................................. 48

Figure 54 - Clip opened with pliers .............................................................................................. 49

Figure 55 - Berkeley Clips ............................................................................................................ 50

Figure 56 - Harness Cable Retainers ............................................................................................ 50

Figure 57 - Harness cables hanging on loom ................................................................................ 51

Figure 58 - Polyester Heddle Bundle ............................................................................................ 52

Figure 59 - Parallel Harness Sticks ............................................................................................... 54

Figure 60 - Harness Sticks with Heddles ...................................................................................... 54

Figure 61 - Harness wire ............................................................................................................... 55

Figure 62 - Metal Heddle Frame ................................................................................................... 56

Figure 63 - Beam Retainer ............................................................................................................ 61

Figure 64 - Warp Beam Handle .................................................................................................... 62

Figure 65 - Lower Warp Beam Tension ....................................................................................... 64

Figure 66 - Tension Arm Bolt ....................................................................................................... 65

Figure 67 - Lower Beam Tension Cord ........................................................................................ 66

Figure 68 - Upper Position Tension .............................................................................................. 67

Figure 69 - Tension Cable around Brake Drum ............................................................................ 68

Figure 70 - Upper Tension Tie-up ................................................................................................ 69

Figure 71 - Weight with wooden bracket removed ...................................................................... 70

Figure 72 - Tension Arm with Weight .......................................................................................... 70

Figure 73 - Cloth Beam Assembly................................................................................................ 71

Figure 74 - Right Side Cloth Beam Support ................................................................................. 72

Figure 75 - Pressure Roller Bracket .............................................................................................. 73

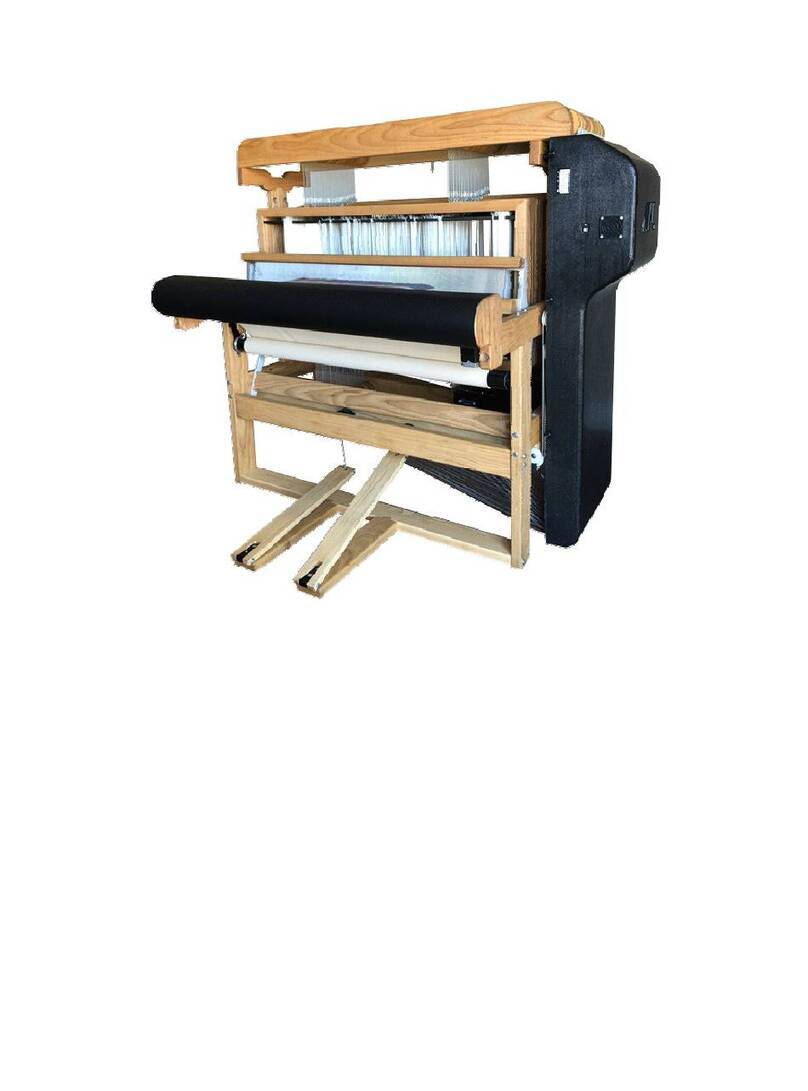

Figure 76 - Pressure Roller and Cloth Beam on Loom ................................................................. 74

Figure 77 - Cloth Storage System Rollers .................................................................................... 75

Figure 78 - Cloth Take-up Drum .................................................................................................. 75

Figure 79 - Cloth Storage Drum ................................................................................................... 76

Figure 80 - Routing the Cloth Take-up Cord ................................................................................ 77

Figure 81 - Knot on Cloth Take-up Drum .................................................................................... 78

Figure 82 - Cloth Storage Apron .................................................................................................. 79

Figure 83 - Pre-installed Hex Nuts ............................................................................................... 80

Figure 84 - Button Head Cap Screws ........................................................................................... 81

Figure 85 - Loosen Nut ................................................................................................................. 81