Introductory Information Jacq3G Loom User’s Manual

Page | iv

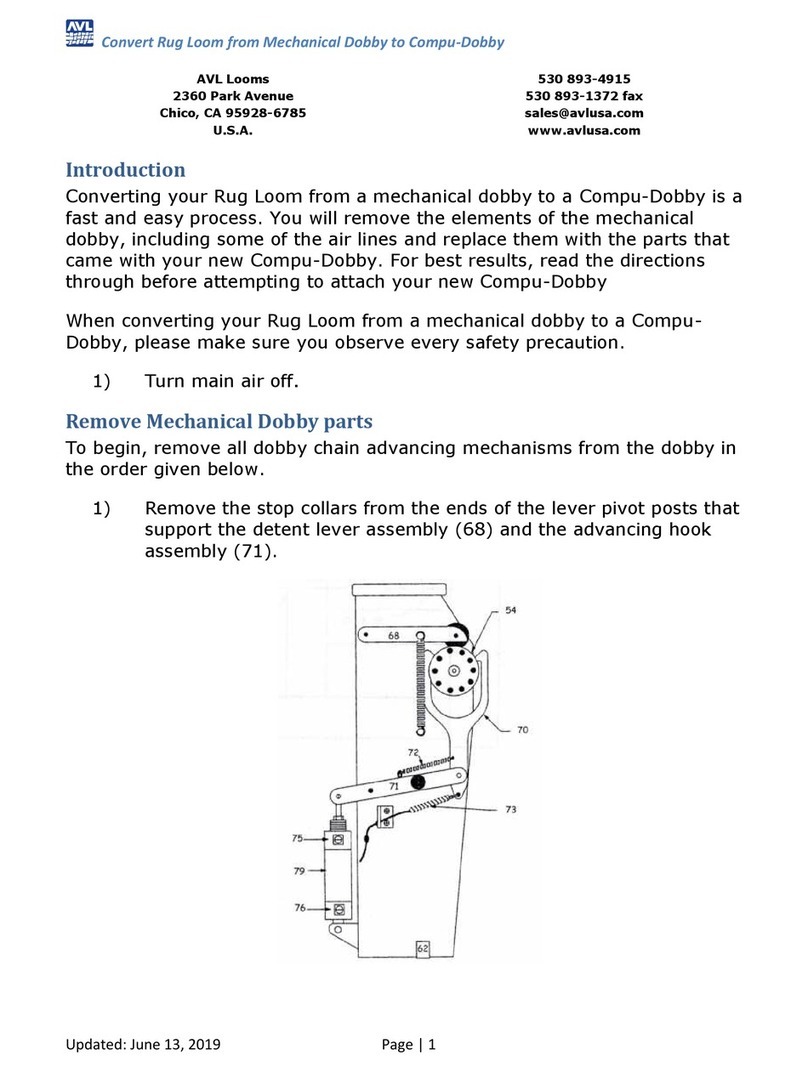

Figure 52 - Beater Leg .................................................................................................................. 67

Figure 53 – Beater Top and Reed ................................................................................................. 68

Figure 54 - Single-box Flyshuttle Beater ...................................................................................... 69

Figure 55 - Beater Reed Support .................................................................................................. 70

Figure 56 - String tie-up and handle ............................................................................................. 71

Figure 57 - Axle Block on loom ................................................................................................... 73

Figure 58 - Beater Retainer ........................................................................................................... 73

Figure 59 - Beater Retainer ........................................................................................................... 74

Figure 60 - Beater Pivot Base ....................................................................................................... 74

Figure 61 - Overhead Beater ......................................................................................................... 75

Figure 62 - Overhead Beater Uprights .......................................................................................... 76

Figure 63 - Mount hanging arms .................................................................................................. 77

Figure 64 - Place Hanging Arms on Loom ................................................................................... 78

Figure 65 - Beater Axle................................................................................................................. 79

Figure 66 - Push Arms and Tilt Arms ........................................................................................... 79

Figure 67 - Racking the Overhead Beater..................................................................................... 81

Figure 68 - Beater Return Spring Assembly ................................................................................. 82

Figure 69 - Beater Reed Support .................................................................................................. 83

Figure 70 - String tie-up and handle ............................................................................................. 85

Figure 71 - Vertical Pull Upper Pulley Assembly ........................................................................ 86

Figure 72 - Drop Box Assembly from Rear.................................................................................. 86

Figure 73 - Flyshuttle Box from back ........................................................................................... 87

Figure 74 - Flyshuttle on cord ....................................................................................................... 88

Figure 75 - knot on flyshuttle cord ............................................................................................... 89

Figure 76 - Routing Flyshuttle Cord ............................................................................................. 90

Figure 77 - Spring and washer on Flyshuttle cord ........................................................................ 90

Figure 78 - Flyshuttle adjustment screw ....................................................................................... 92

Figure 79 - Flyshuttle Turnbuckle ................................................................................................ 93

Figure 80 - 4-box Shift Handle Cable to Drop Box ...................................................................... 94

Figure 81 - 4-box Flyshuttle Beater Shift Handle ......................................................................... 95

Figure 82 - Bench (shown with Tool Bag - optional) ................................................................... 98

Figure 83 - E-Lift parts installed (Main Drive Sprocket not visible) ......................................... 103

Figure 84 - Chain with Connecting Parts .................................................................................... 104

Figure 85 - Chain with Connecting Link partially inserted ........................................................ 105

Figure 86 - Chain with Link End and Link Clip in place ........................................................... 105

Figure 87 - Closing the Connecting Link Clip with Pliers ......................................................... 106

Figure 88 - Main Drive Sprocket with motor and chain (Interior View) .................................... 107

Figure 89 - Interior of Control Box, connection for E-Lift Motor .............................................. 108

Figure 90 - Air Lift cylinders on loom........................................................................................ 112

Figure 91 - A-Lift Foot Pedal ..................................................................................................... 113

Figure 92 - FRL Detail (may vary) ............................................................................................. 114

Figure 96 - Control Box, Side 1 (Showing Vents, Power Switch and Power Source) ............... 117

Figure 97 - Control Box, Side 2 (Showing Module Data Cable Plugs –CAT5) ......................... 118

Figure 98 - Control Box Side 3 (Showing Driver Board Power Cable Plugs) ........................... 118

Figure 99 - Control Box, Side 4 (Showing E-Lift and Computer Connections) ........................ 119

Figure 100 - Control Box, Top (Showing Cautionary Note) ...................................................... 119