4

INTRODUCTION

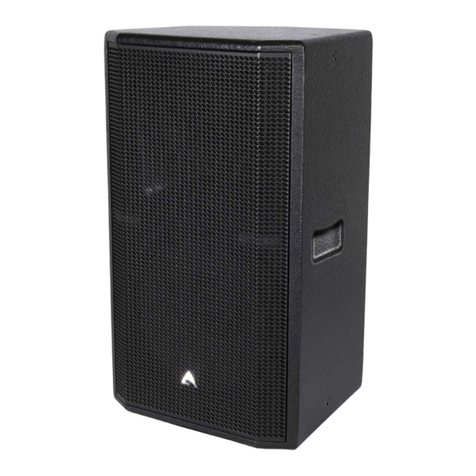

The AX2010V2 Vercal Line Array element is designed for a wide range of sound reinforcement applicaons where a exible and

easy to use vercal array systems is needed. The AX2010V2 has been designed both for rental live sound applicaons and for

xed installaons and has been engineered for the simplest use possible but without sacricing anything in sound quality and

performance.

The high frequency range is reproduced by two low-distoron compression drivers, equipped with very light-weight diaphragms.

Two transmission line waveforming waveguides have been used to load the HF drivers, in order to provide a detailed and natural

sound and to achieve a long-distance HF projecng capacity.

The two 10” woofers employed in the reproducon of the mid-bass range are equipped with very light-weight cones. The lightness

of the diaphragm is furthermore improved by the use of aluminium voice coil instead of convenonal copper. This ensure a fast

reproducon of the mid range and of mid-bass musical passages, improving also the thermal capacity of the voice coil and,

consequently, controlling the overall power compression. The two 10” woofers are back loaded by a short hybrid transmission

line that minimizes the eect of the box resonances and eliminates the “boxy” mid-bass sound commonly obtained from regular

bassreex enclosures. The crossover lter approach is based on a “Constant Power” technique. Thanks to a parcular phase

combinaon between the two ways around the crossover frequency, this approach is able to provide a very stable horizontal

coverage and a very stable o-axys sound image, also minimizing unwanted eects around the crossover frequency. The further

applicaon of phase linearizaon techniques, combined to constant power crossover, yield a linear phase response and a coherent

me response. This allows for a natural percepon of acousc instruments and voices and for an improved depth of the sound

image.

TECHNICAL SPECIFICATION

SYSTEM Remote Controls PRONET AX control soware

System’s Acousc Principle

Line Array Element

Short Transmission Line LF Back Loading

Acousc Transmission Line HF Waveguide

Network protocol CANBUS

Amplier Type Class D amplier with SMPS & PFC

Output Power 2x 1400 W

Frequency Response (±3dB) 75 Hz – 18 KHz (Processed) Mains Voltage Range (Vac) 100 - 240 V~ ±10% 50/60 Hz

Horizontal/Vertical Coverage

Angle 110° x 10° (-6dB) Consumpon* 700 W (nominal) 1700 W (max)

Maximum Peak SPL @ 1m 138 dB IN / OUT Connectors Neutrik XLR-M / XLR-F

TRANSDUCERS IN / OUT Network Connectors ETHERCON® (NE8FAV)

LF

Two 10” (260 mm), 2.5” (64 mm)

aluminium voice coil, 16Ω each,

paralleled

Mains Connector PowerCon® (NAC3MPXXA)

Mains Link Connector PowerCon® (NAC3MPXXB)

HF

Two 1.4” drivers, 2.5” (64 mm)

edgewound voice coil, tanium

diaphragm, 16Ω each, paralleled

Cooling Variable speed DC fan

ENCLOSURE & CONSTRUCTION

ELECTRICAL Dimensions (W x H x D) 746 mm (29.37”) x 341 mm (13.42”) x

530 mm (20.86”)

Input Impedance 20 kΩ balanced, 10 kΩ unbalanced Taper angle 5°

Input Sensivity +4 dBu / 1.25 V Construcon 15 mm, reinforced Phenolic Birch

Signal Processing

CORE2 processing, 40bit oang

point SHARC DSP, 24 bit AD/DA

converters

Paint High resistance, water based paint

Front Suspension Aluminium Fast Link structure

Direct access Controls

4 Presets (Standard/Long Throw/Down

Fill-Single Box, User), Network Terminaon,

GND Link.

Back Suspension High Strength Steel

Net Weight 41 Kg (90.4 lbs.)

* Nominal consumpon is measured with pink noise with a crest factor of 12 dB, this can be considered a standard music program.

INDEX

INTRODUCTION ...........................4

TECHNICAL SPECIFICATION ..................4

MECHANICAL DRAWING ....................5

OPTIONAL ACCESSORIES ....................5

SPARE PARTS ..............................5

I/O AND CONTROL OPERATIONS ..............6

MAINS IN .................................6

MAINS OUT ...............................6

FUSE HOLDER .............................6

INPUT ...................................6

LINK .....................................6

ON ......................................6

PROT ....................................6

SIGN/LIMIT ...............................6

GND LIFT .................................6

PRESET BUTTON ...........................7

PRESET USING EXAMPLE:

INSTALLATION IN A THEATRE WITH BALCONY ....8

NETWORK IN/OUT .........................9

TERMINATE ...............................9

PRONET AX - OPERATION ....................9

BASIC INSTALLING OPERATION ..............10

FLY BAR AND ACCESSORIES .................13

STACKED INSTALLATION ....................15