B. Braun Vista basic User manual

Other manuals for Vista basic

2

This manual suits for next models

2

Other B. Braun Medical Equipment manuals

B. Braun

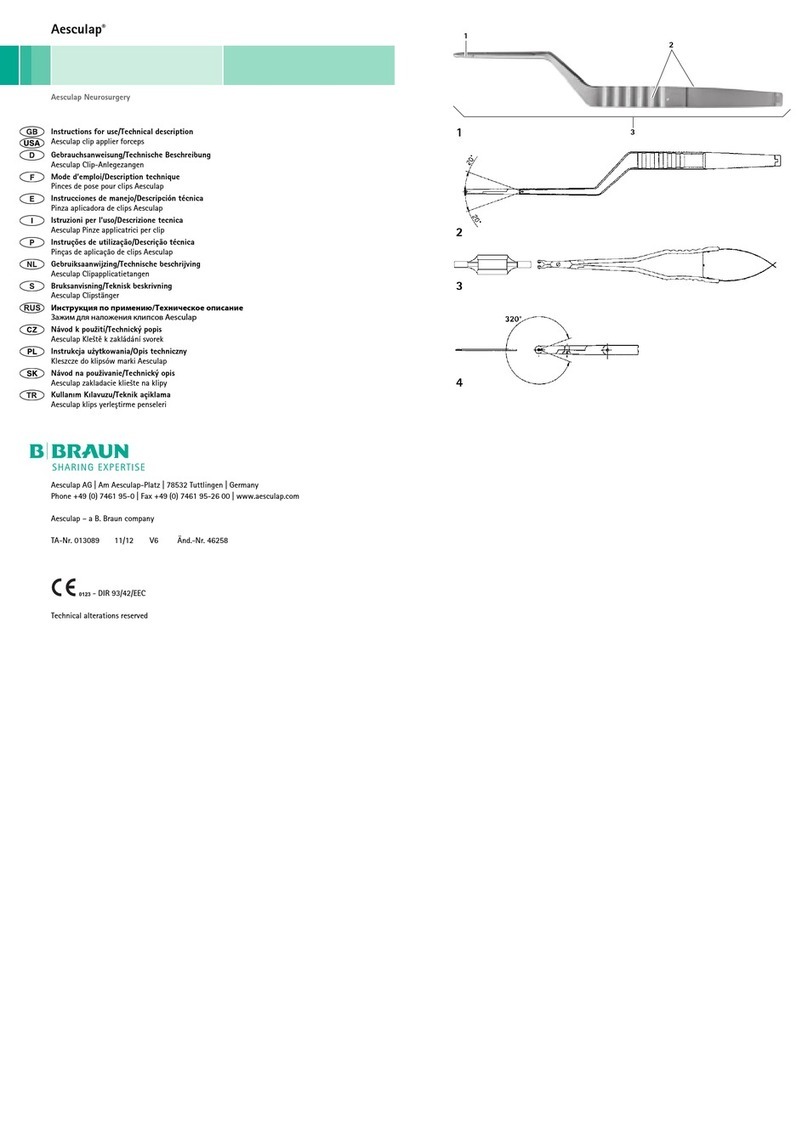

B. Braun Aesculap Acculan 3Ti User manual

B. Braun

B. Braun Aesculap MACS T 011148 Manual

B. Braun

B. Braun H.E.L.P. Plasmat Futura User manual

B. Braun

B. Braun Aesculap Lektrafuse GN200 User manual

B. Braun

B. Braun Aesculap Spine S4 User manual

B. Braun

B. Braun Aesculap S4 Manual

B. Braun

B. Braun Perfusor compact User manual

B. Braun

B. Braun Infusomat Space User manual

B. Braun

B. Braun Aesculap Endoscopic Technology Manual

B. Braun

B. Braun PERFUSOR-secura FT User manual

B. Braun

B. Braun Proxima 2 User manual

B. Braun

B. Braun Aesculap S4 Manual

B. Braun

B. Braun AESCULAP AVM User manual

B. Braun

B. Braun Actreen Glys Set Tiemann Series User manual

B. Braun

B. Braun Actreen Lite Series User manual

B. Braun

B. Braun Perfusor Space User manual

B. Braun

B. Braun Aesculap MINOP InVent trocar Manual

B. Braun

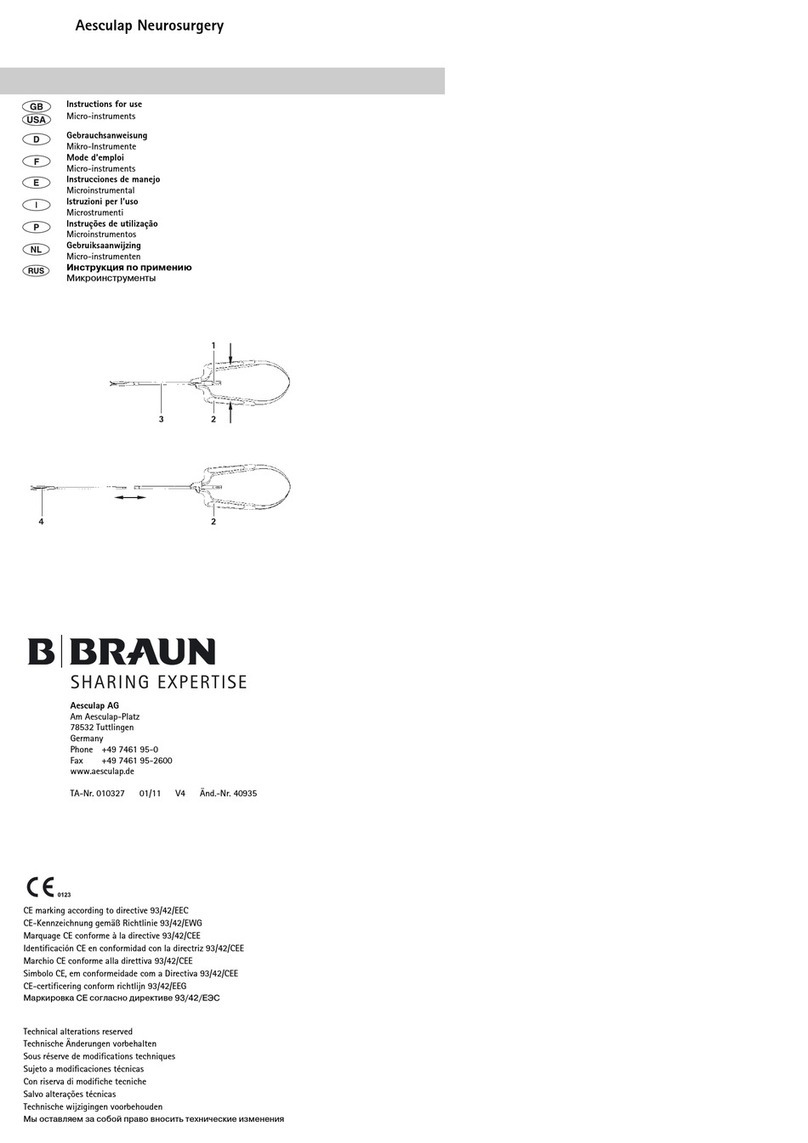

B. Braun AESCULAP 010327 User manual

B. Braun

B. Braun Infusomat compact plus P User manual

B. Braun

B. Braun HORIZON Nxt User manual