B-K lighting PM4RM ROUND CAMLOCK Setup guide

Other B-K lighting Outdoor Light manuals

B-K lighting

B-K lighting Brick Star User manual

B-K lighting

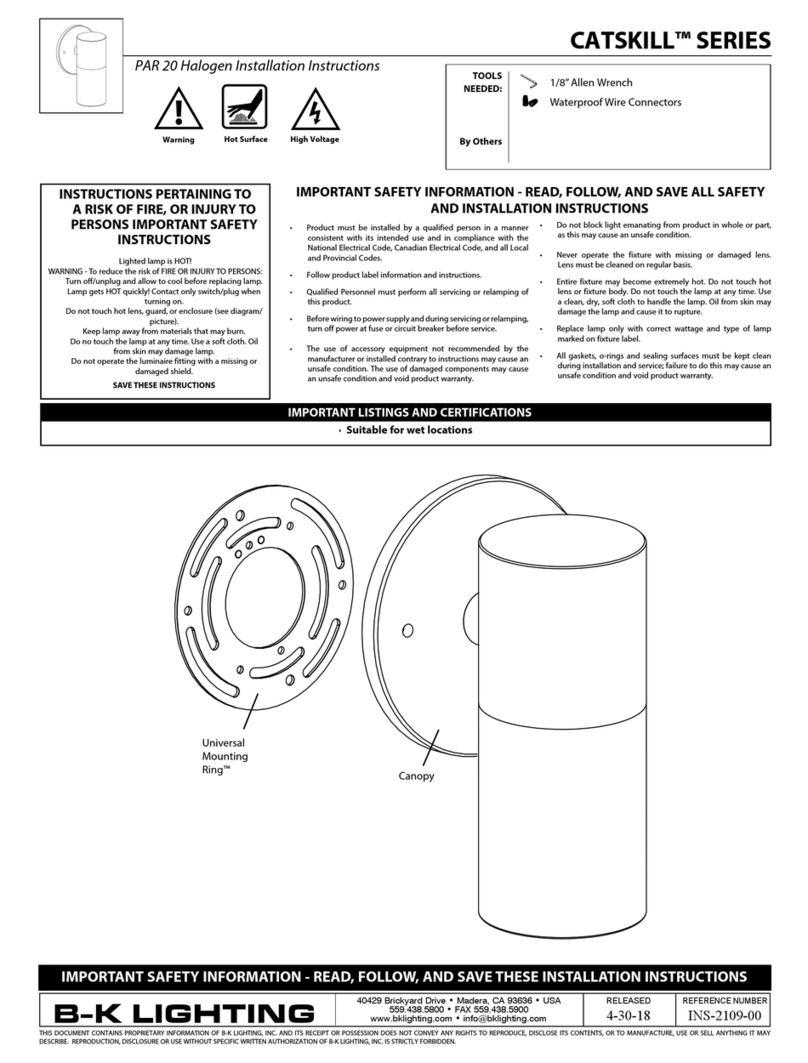

B-K lighting CATSKILL Series User manual

B-K lighting

B-K lighting BKSSL MINI-MICRO iLUME User manual

B-K lighting

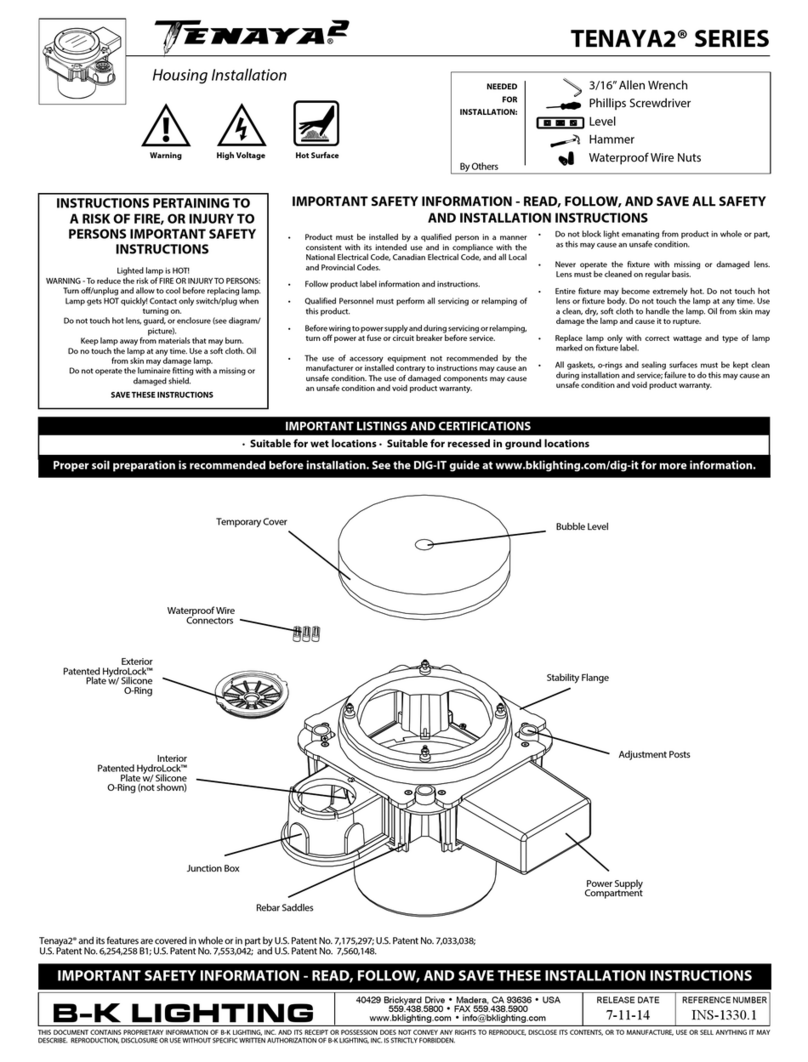

B-K lighting TENAYA2 Series User manual

B-K lighting

B-K lighting SARATOGA Series User manual

B-K lighting

B-K lighting Precision 2 CO2 Series User manual

B-K lighting

B-K lighting PS User manual

B-K lighting

B-K lighting HP2RM User manual

B-K lighting

B-K lighting DENALI User manual

B-K lighting

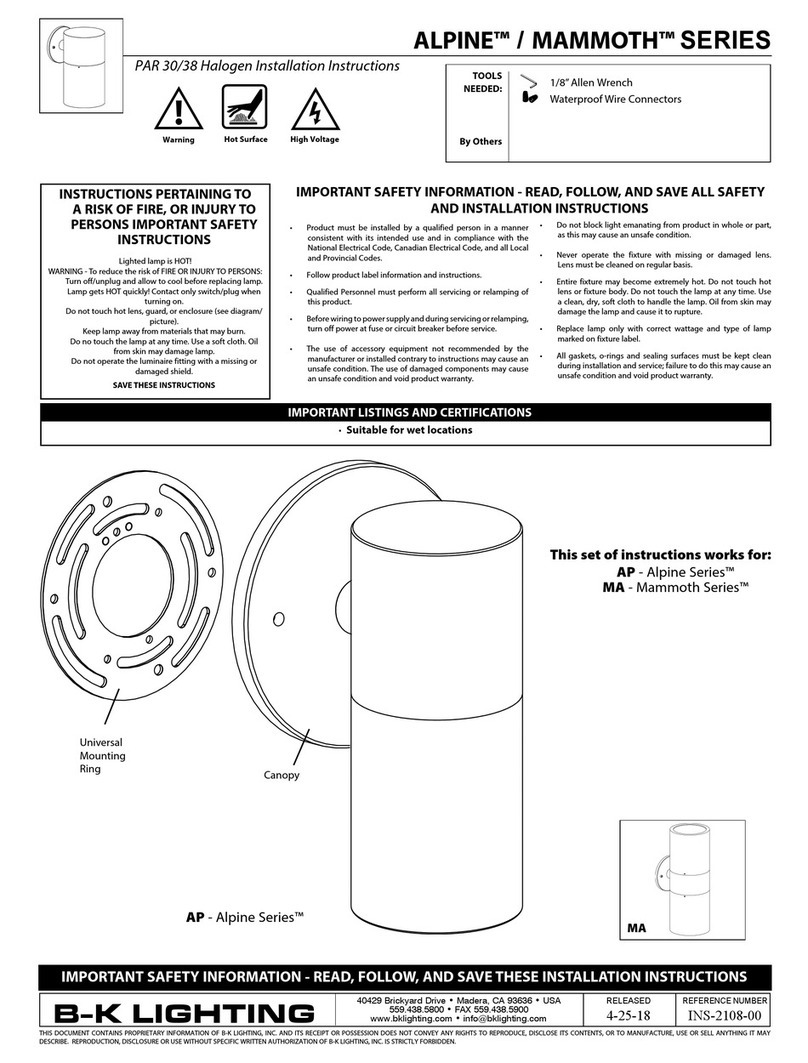

B-K lighting ALPINE Series User manual

B-K lighting

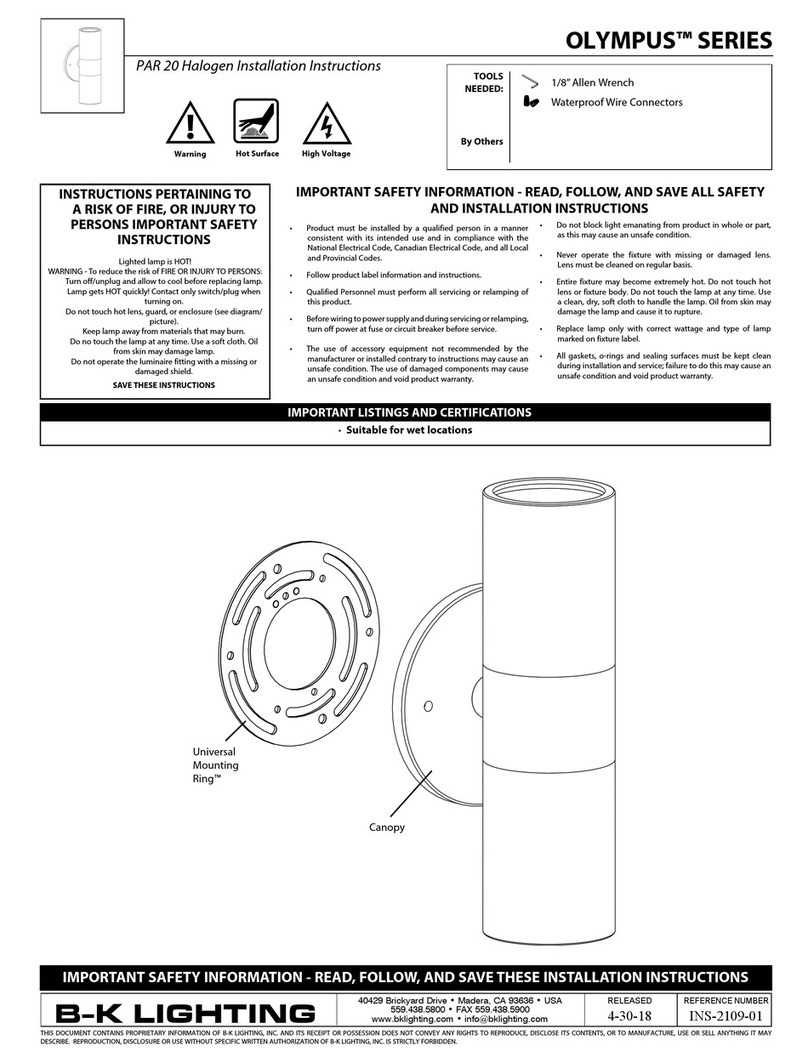

B-K lighting OLYMPUS Series User manual

B-K lighting

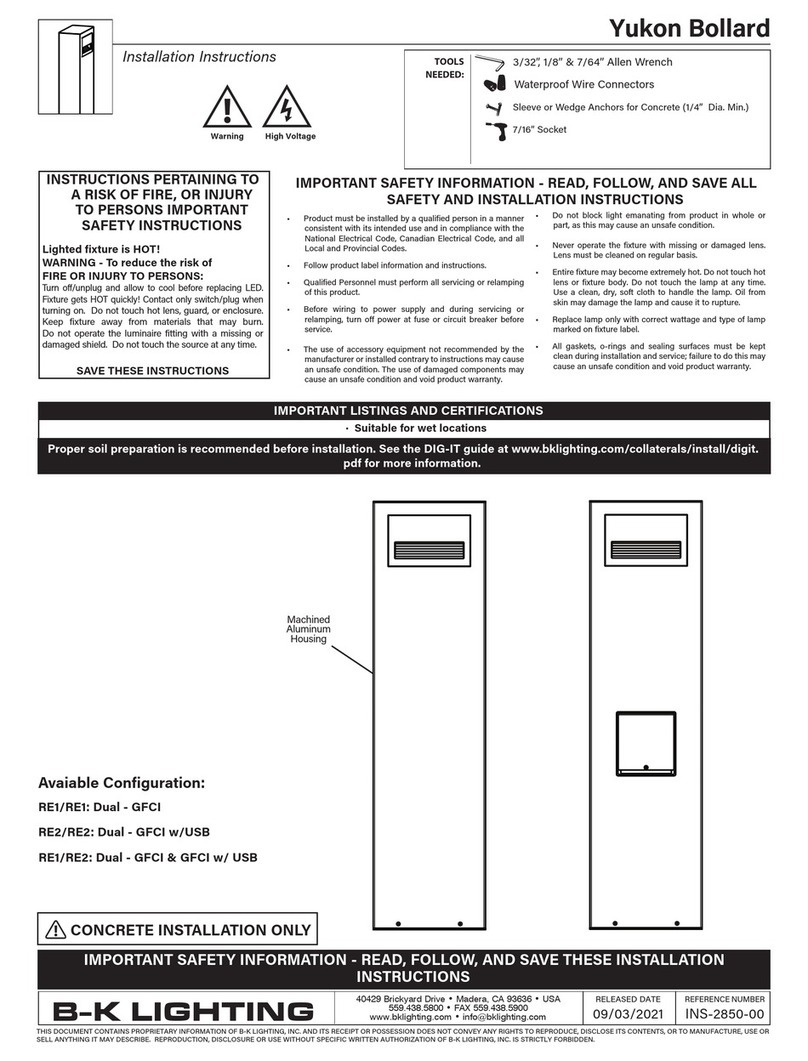

B-K lighting Yukon Bollard User manual

B-K lighting

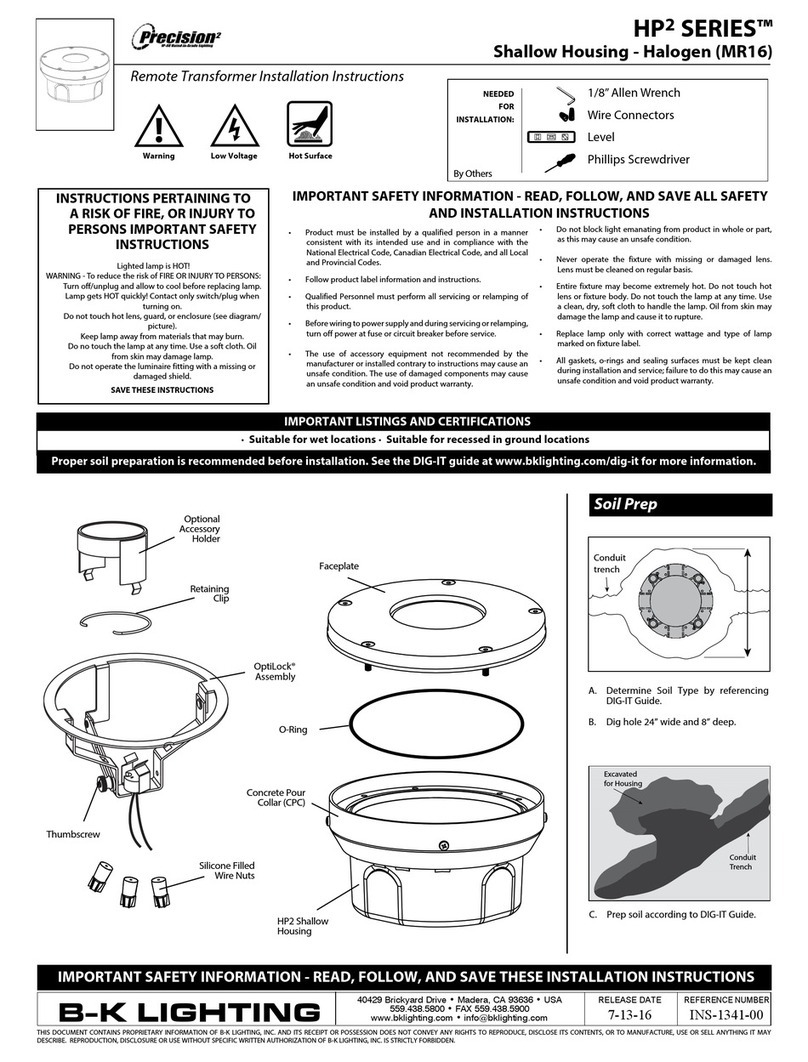

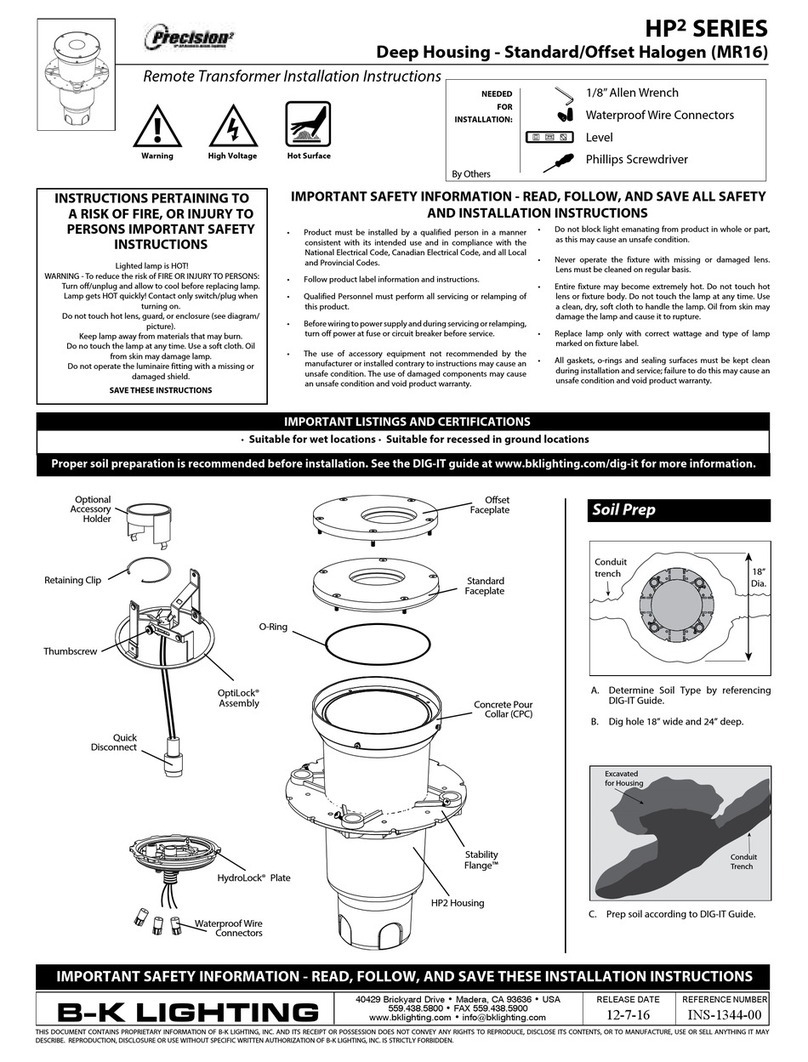

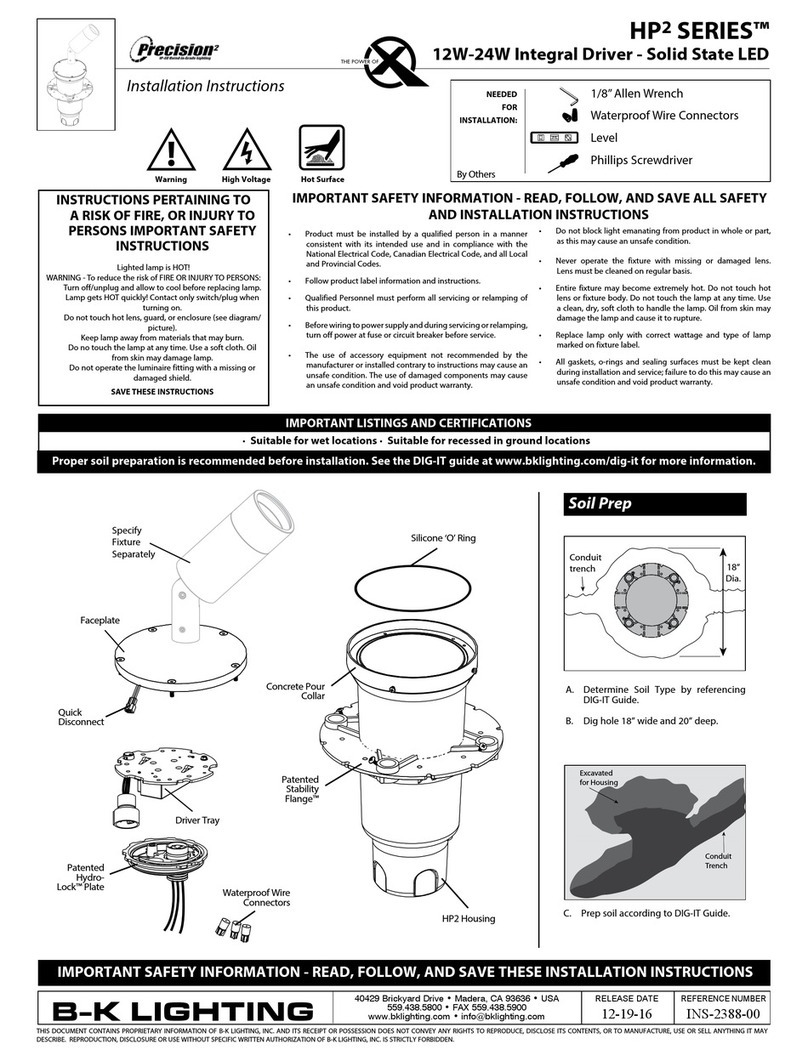

B-K lighting Precision2 HP2 Series User manual

B-K lighting

B-K lighting EC Setup guide

B-K lighting

B-K lighting DENALI ST-DE-TR-A User manual

B-K lighting

B-K lighting HP2 SERIES User manual

B-K lighting

B-K lighting GARDEN STAR GR-K User manual

B-K lighting

B-K lighting HP2 SERIES User manual

B-K lighting

B-K lighting ARTISTAR UPLIGHT User manual

B-K lighting

B-K lighting Litestick User manual

Popular Outdoor Light manuals by other brands

HEPER

HEPER DOGO Side LW6048.585-US Installation & maintenance instructions

Maretti

Maretti VIBE S 14.6080.04.A quick start guide

BEGA

BEGA 84 253 Installation and technical information

HEPER

HEPER LW8034.003-US Installation & maintenance instructions

HEPER

HEPER MINIMO Installation & maintenance instructions

LIGMAN

LIGMAN BAMBOO 3 installation manual

Maretti

Maretti TUBE CUBE WALL 14.4998.04 quick start guide

Maxim Lighting

Maxim Lighting Carriage House VX 40428WGOB installation instructions

urban ambiance

urban ambiance UQL1273 installation instructions

TotalPond

TotalPond 52238 instruction manual

Donner & Blitzen

Donner & Blitzen 0-02661479-2 owner's manual

LIGMAN

LIGMAN DE-20023 installation manual