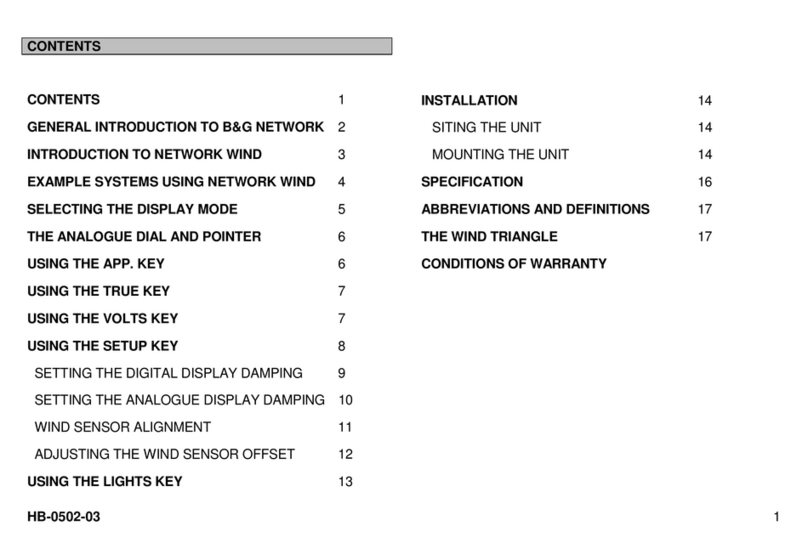

Wiring examples

Refer to the Quick Start Guide for more wiring examples.

1 Analog/pulse terminal 1 example: wiring for a 213 mast head unit

2 Analog/pulse terminal 2 example: wiring for a speed (paddlewheel) sensor, and three congurable analog sensors

3 Alarms terminal example: wiring for an overboard button input with audible alarm

¼Note: Wire colors depend on your sensor. Refer to the documentation for your sensors.

1 2 3

Screen (screen/gray or bare)

Pulse 1 (wind speed/violet)

Analog 1 (wind angle phase/red)

Analog 2 (wind angle phase/green)

Analog 3 (wind angle phase/blue)

5 V out (not connected)

12 V out (DC + /orange)

0 V (DC - /black)

Screen (screen/gray or bare)

Pulse 2 (speed/green)

Analog 4 (congurable 0–5 V input)

Analog 5 (congurable 0–5 V input)

Analog 6 (congurable 0–5 V input)

5 V out (DC + /red)

12 V out (not connected)

0 V (DC - /black)

Alarm 1, 0V

Alarm 1, out

Alarm 2, 0V

Alarm 2, out

MOB return

MOB send

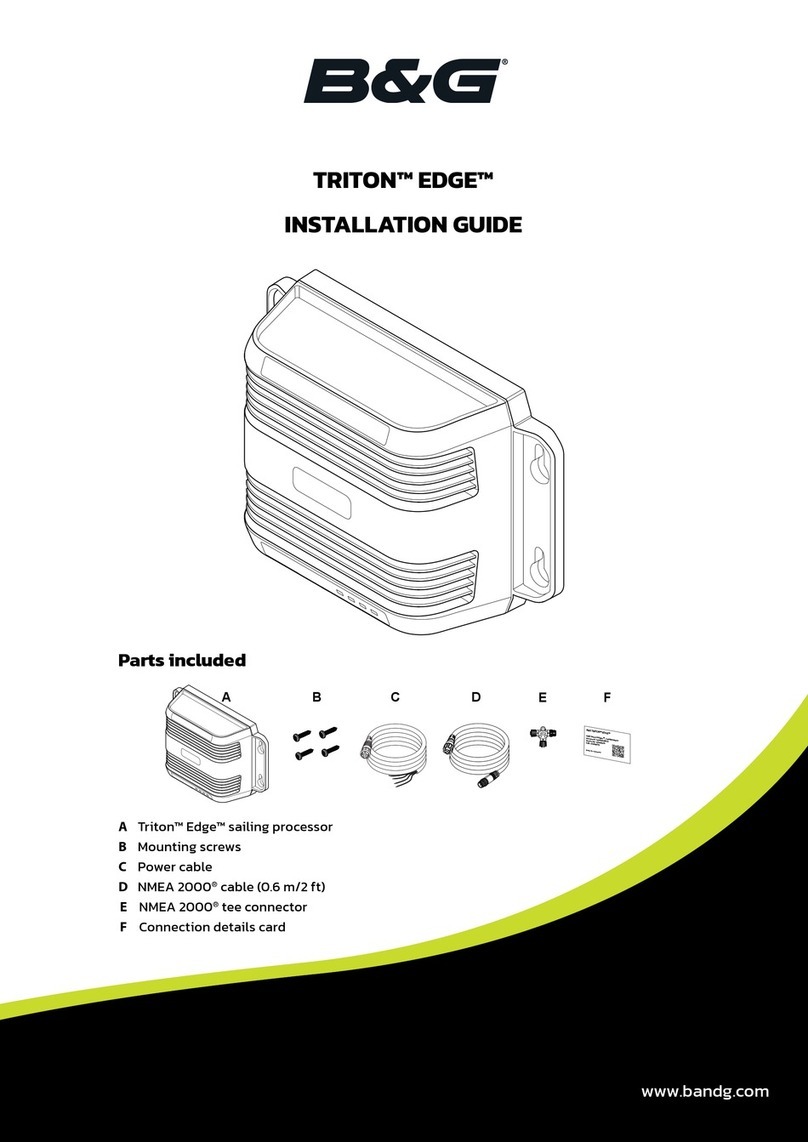

System examples

4

1 Hercules® or Hercules® WTP and a B&G® display connected via NMEA 2000® network

2 Hercules® or Hercules® WTP connected to laptop via Ethernet

3 Hercules® or Hercules® WTP connected to mobile devices via Wi-Fi® router

4 Hercules® or Hercules® WTP connected to Hercules® Expansion via Ethernet

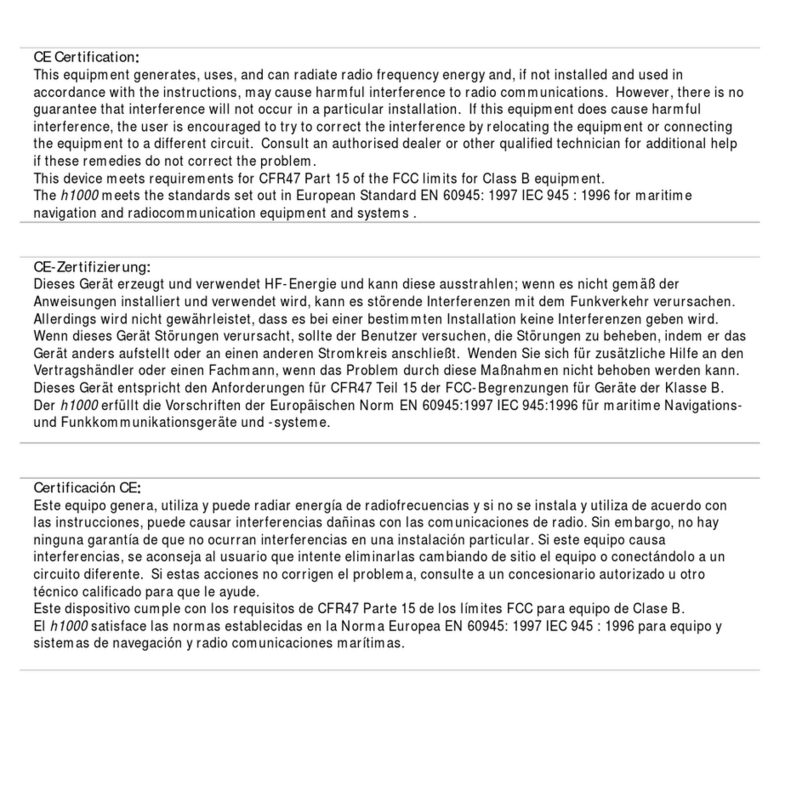

Connect the power cable

If required, strip the ends of the supplied power cable to expose three insulated wires,

and separate the drain wire from the cable shield at one end.

At the power connector on the PCB, terminate the bare (drain) wire at the screen

pin (1). Terminate the black and red wires at the negative and positive pins (2 and 3

respectively).

Connect a 3 A fuse to the positive terminal of a 12 V or 24 V DC power supply.

Connect the red and black wires in the power cable to the positive and negative

terminals of the power supply, respectively. The bare (drain) wire is not used at the

power supply end of the cable, and should be cut.

Optional: Earth-ground wire (blue)

The blue wire in the power cable can be used to create a bleed path for excess

charge. Connect the blue wire to both the Earth-ground connection point (C) on the

PCB, and. a point on the hull in electrical contact with the water. If you don’t require

the blue wire, cut back both its ends.

1

2

3

1

2

3

C

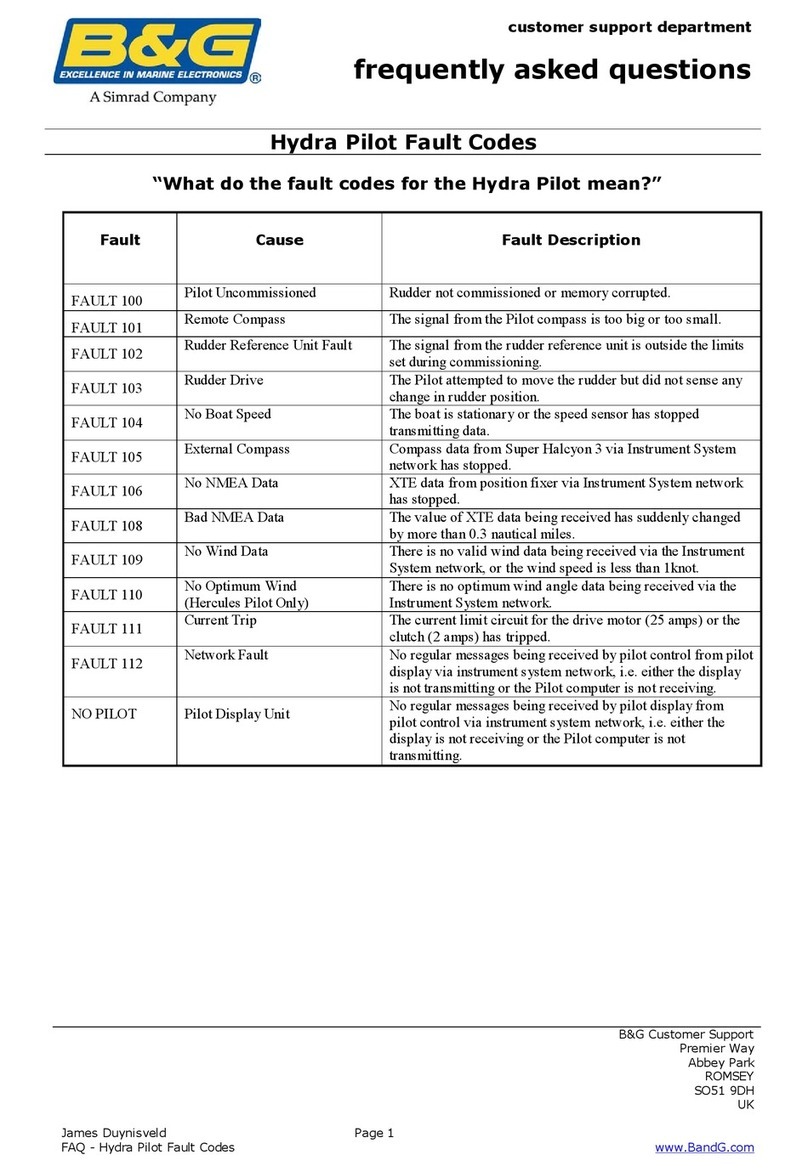

Connect the CAN (NMEA 2000®) cable

A NMEA 2000® network requires its own power supply protected by a 3 A fuse.

12 V (NET-S/red)

0 V (NET-C/black)

Data + (NET-H/white)

Data - (NET-L/blue)

Shield (bare)