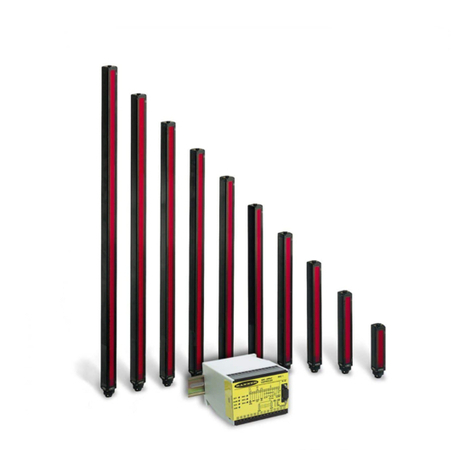

Compact, single-point devices for error-proofing of bin-picking operations

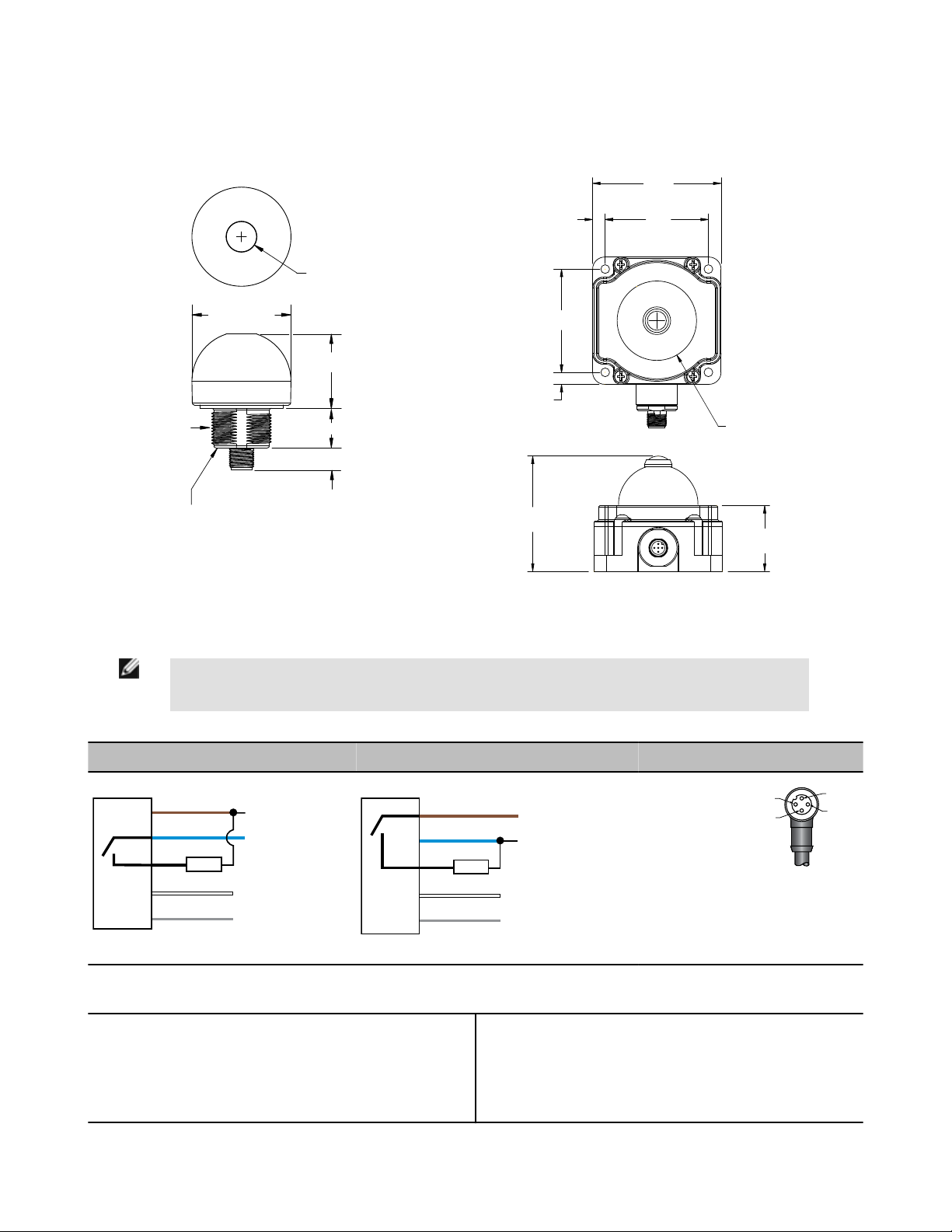

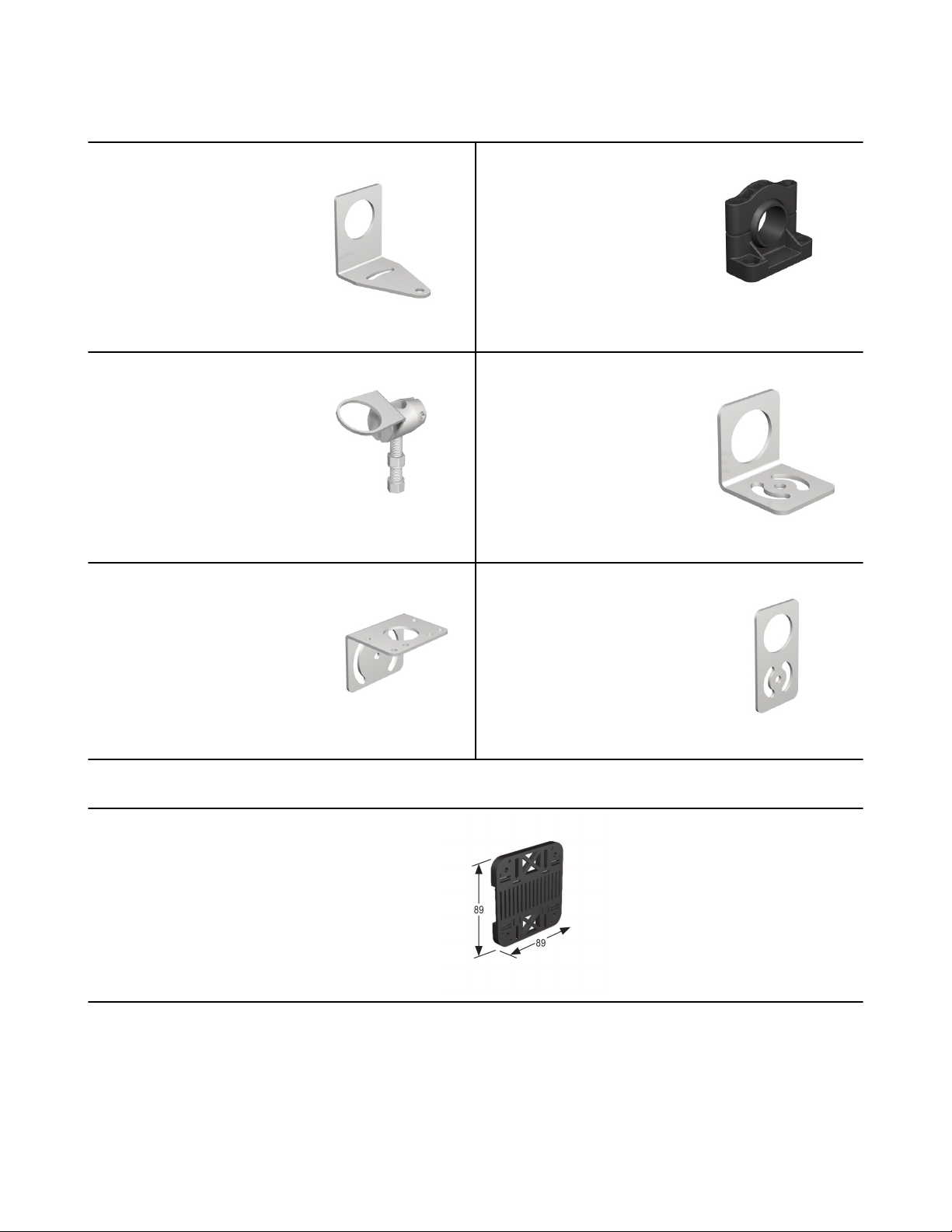

For the latest technical information about this product, including specifications, dimensions, and wiring, see www.BannerEngineering.com

• Rugged, cost-effective and easy-to-install solutions for error-proofing and

parts-verification applications

• Compact devices are completely self-contained — no controller needed

• Illuminated dome provides a big, easy-to-see green, red or yellow job light

• Push-button and passive-actuation models available

• Choose NPN or PNP output, depending on model

• Fully encapsulated IP67 construction — ideal for use in abusive environ-

ments; rated to IP69K, depending on installation; see specifications

• Immune to ambient light, EMI and RFI interference

• 12 to 30V dc operation

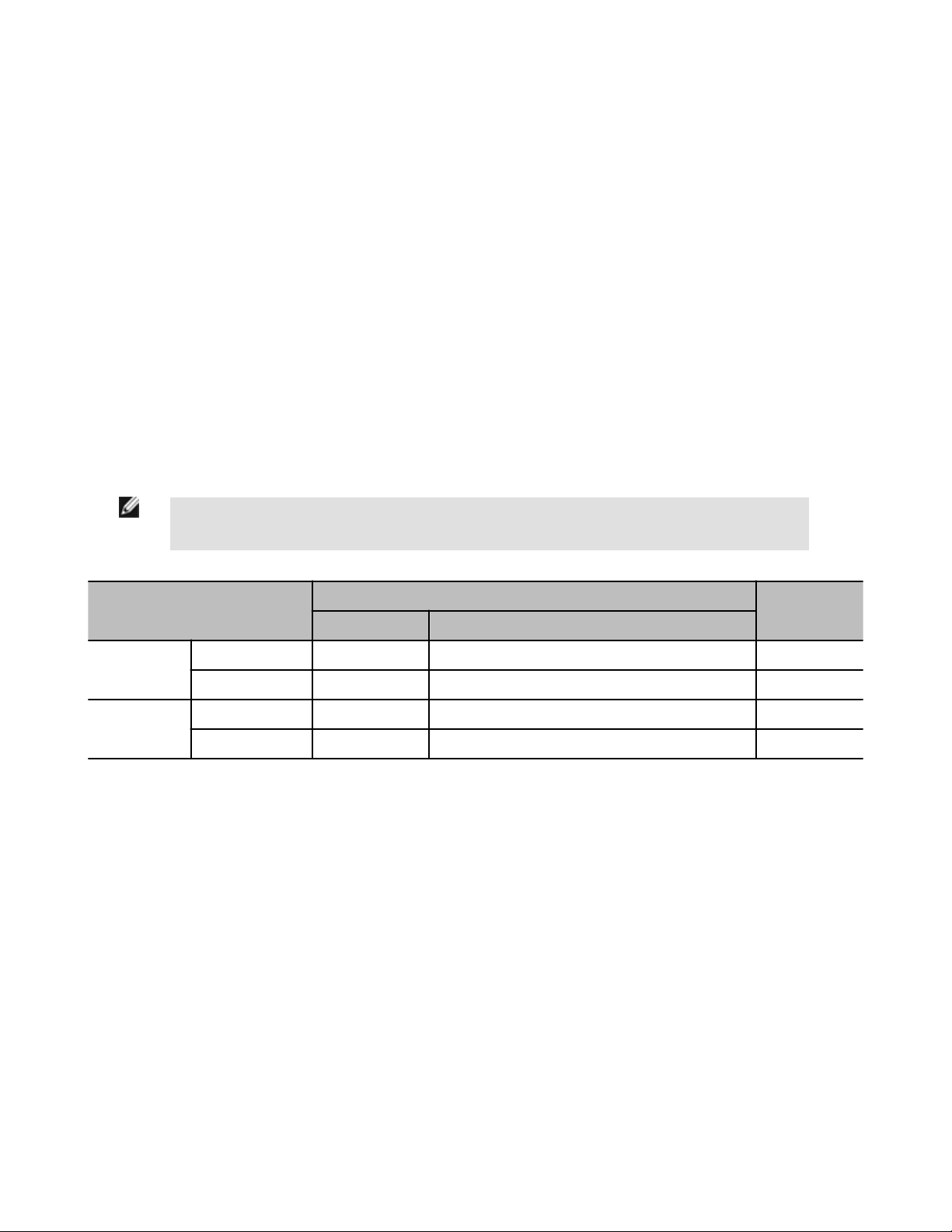

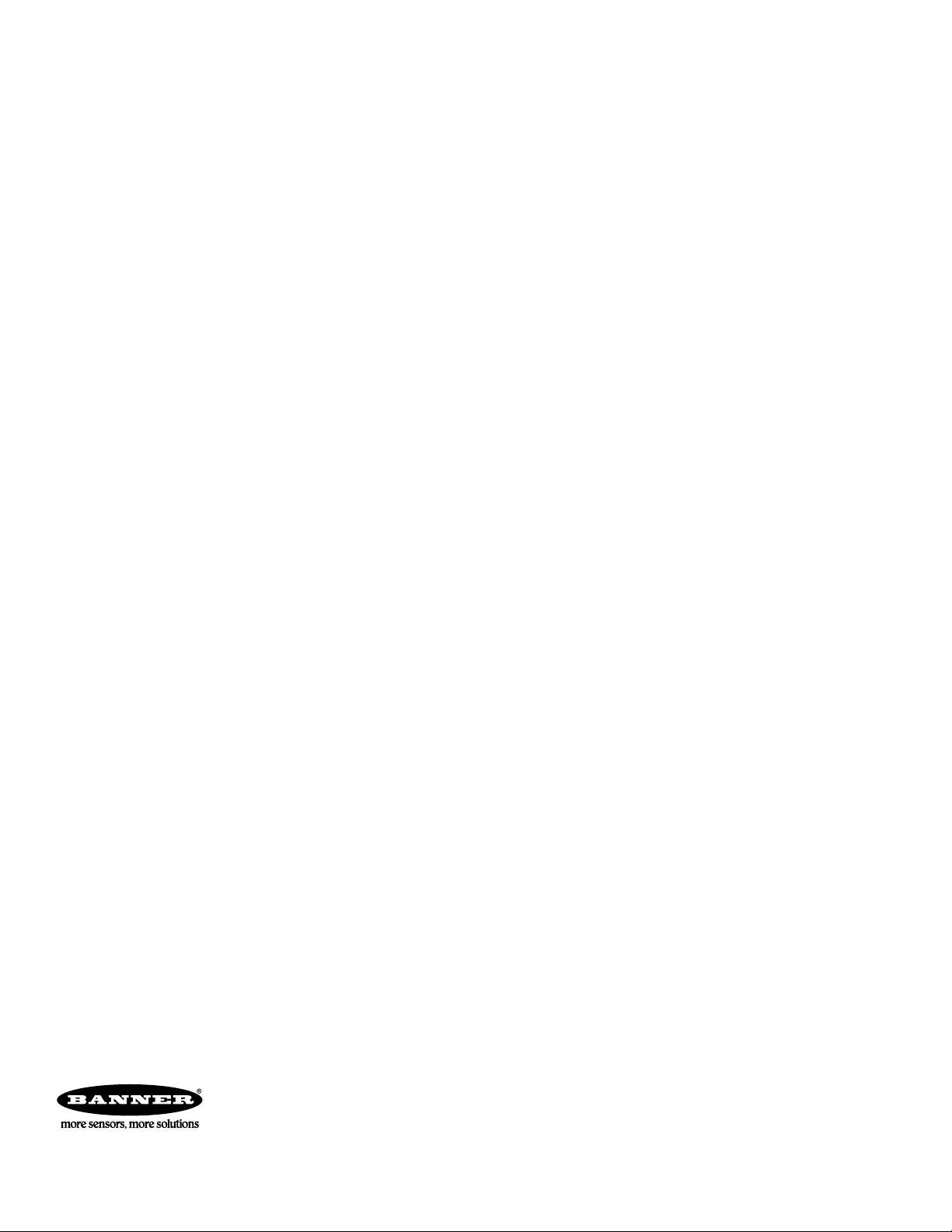

Models

Model Sensing Mode /

LED Housing Range Cable* Output*** Job Light

K50RPLPGRYC3QPMA Polarized retrore-

flective, visible red,

680 nm

50 mm dome

30 mm mount

polycarbonate

2 m

5-pin Euro

PUR pigtail

QD

PNP,

normally

closed

Green/

yellow/

red

K50RPLPGRYC4QPMA

K50APFF50GRYC3QPMA

Fixed field, infra-

red, 880 nm

50 mm cutoff

PNP,

normally

open

K50APFF50GRYC4QPMA

K50APFF100GRYC3QPMA 100 mm cut-

off

K50APFF100GRYC4QPMA

K50APPBGRYC3QPMA

Push button

—

K50APPBGRYC4QPMA

K80APPBGRYC3QPMA 50 mm dome

Flat or DIN- mount

polycarbonate

K80APPBGRYC4QPMA

* 5-pin 150 mm Euro-style PUR pigtail QD models are listed. For 2 m (6') PVC cable model, omit suffix “QPMA” from model number (e.g.,

“K50RPLPGRYC3”). For 9 m (30') PVC cable model, replace suffix “QPMA” with “W/30” (e.g., “K50RPLPGRYC3 W/30”). For 150 mm

(6") PVC pigtail with 5-pin Euro-style fitting, replace suffix “QPMA” with “QP” (e.g., “K50RPLPGRYC3QP”).

A model with a QD requires a mating cable (see 5-Pin Euro-Style Cordsets on page 4).

** PNP models only are listed. For other output types, contact the Factory.

WARNING: Not To Be Used for Personnel Protection

Never use this product as a sensing device for personnel protection. Doing so could lead to serious injury

or death. This product does NOT include the self-checking redundant circuitry necessary to allow its use in

personnel safety applications. A sensor failure or malfunction can cause either an energized or de-ener-

gized sensor output condition.

EZ-LIGHT K50 and K80 Specialty — 3-Color

P/N 137551 rev. A 7/7/2011