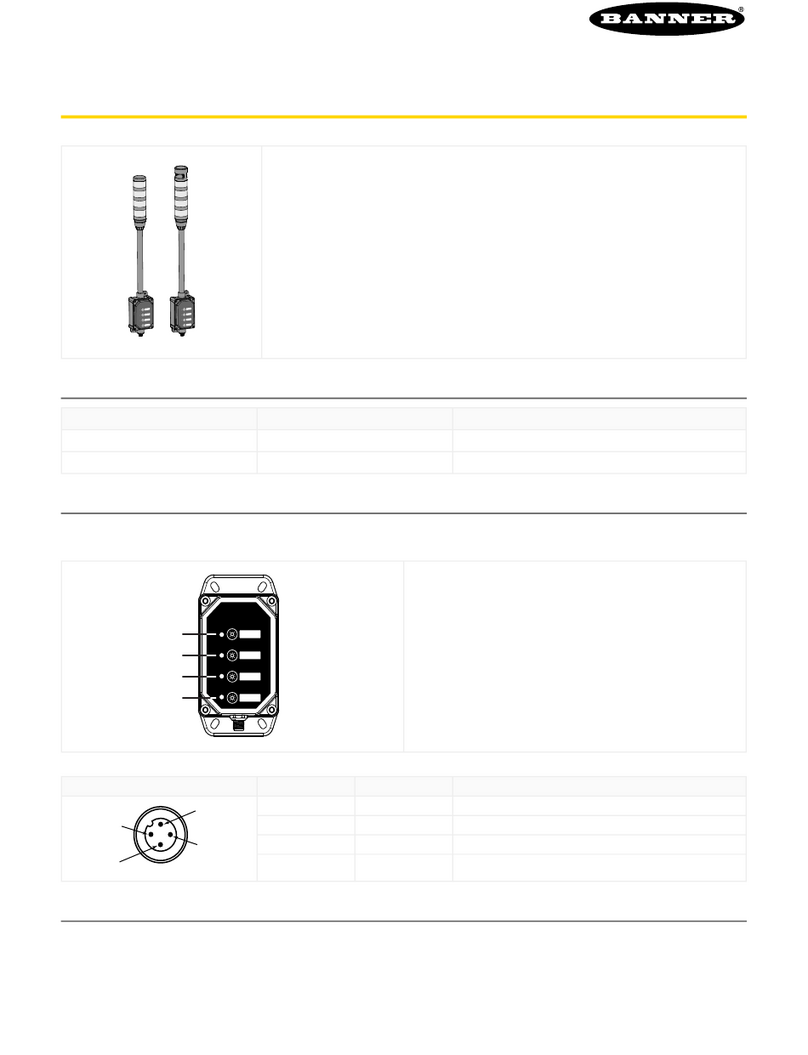

LED Condition ON Solid OFF Flashing (2 Hz)

Red Light curtain is obstructed Light curtain is unobstructed Non-functioning emitter

Amber

Dirty lens (whether the light curtain is blocked

or clear); remains ON until the receiver detects

proper light signal strength

n/a Light signal of one of more beam(s)

is degraded

2.3 Two Solid-State Outputs

The receiver has two discrete outputs (Output #1 and Output #2). Each output is independent and can be configured for

either NPN or PNP operation. The sensor is factory-configured for PNP outputs. These outputs are rated to 150 mA and are

short circuit protected.

2.4 EIA-485 Interface

The receiver has a serial EIA-485 interface to provide sensor measurements. By default, the MINI-ARRAY Basic will auto

stream FBB (First Beam Blocked) and TBB (Total Beams Blocked). This can be modified using the Banner Sensor

Configuration Software.

2.5 Sensing Scan Time

Scan time is a function of the sensor length (total number of beams considered) and the scan mode (interlaced or straight

scan). See Models on p. 3.

2.6 Supplied System Software

The device’s configuration can be modified by connecting to the Banner Sensor Configuration Software via an appropriate

EIA-485 interface (consult a Banner Engineering representative for more information). Settings include measurement mode,

discrete output configuration, scan type, blanking and more. The software also enables the user to check sensor alignment,

obtain sensor readings, and verify sensor status.

After the desired configuration has been written to the receiver, the receiver stores the settings in non-volatile memory.

Note: Connect the sensor to the Sensor Configuration Software within 5 seconds after making a proper

connection to an active power supply. If the sensor is not connected to the configuration software within 5

seconds after applying power, the sensor goes into auto stream mode.

2.7 System Self-Diagnostics

Output #2 can be configured for Alarm/Health Status using Banner's Sensor Configuration Software. This enables advanced

electronic and signal processing to allow the receiver to continually monitor and evaluate light signal quality and alert the user

to light signal degradation or sensor faults. The sensor can detect marginal alignment, permanently blocked channels, a

faulty emitter element, or a non-functioning emitter.

The receiver was designed to detect system failures and remain operational. Potential problems include a dirty lens that

completely blocks the optical light signal or a light signal failure (caused by either the emitter or receiver). Although sensor

failures are rare, the Two-Piece MINI-ARRAY Basic is designed to continue to function while warning the user of fault

conditions. This minimizes system down time and provides advanced notice that system maintenance or repairs are required.

Whenever the receiver detects proper operation, Output #2 is active (ON, a healthy condition). When the sensor detects a

system problem (either a sensor fault or a degraded signal), Output #2 is inactive (turns OFF, an alarm condition).

A system problem is acknowledged in two ways:

1. The condition of the diagnostic LEDs.

2. Output #2 is inactive (OFF), when Output #2 is configured for Alarm/Health Status.

MINI-ARRAY® BASIC Two-Piece Measuring Light Curtain

6 www.bannerengineering.com - Tel: + 1 888 373 6767