20

MAINTENANCE

TM

DATE: WHAT WAS DONE:

21

TROUBLESHOOTING PROBLEMS AND FAQ

TROUBLESHOOTING PROBLEMS AND FAQ

Q: THE PUMP DOESN’T RUN

A: Check the battery charge and recharge if necessary.

A: Check the battery connections, clean and re-secure

if necessary.

Q: THE BATTERY WILL NOT HOLD A CHARGE

A: Verify that the loaded boat is not exceeding the weight

capacity of the lift. If the battery is a flooded-cell type,

check the electrolyte level.

A: Ensure the solar panel is properly connected.

A: Re-align the solar panel for proper exposure to the sun.

A: Recharge the battery with a 10 amp charger and

check the charge again.

A: Have the battery tested. It may be old and

require replacement.

A: If the lift is being used frequently during the day, it

may be necessary to use a 110-volt maintainer/charger.

Q: THE REMOTE CONTROL IS NOT FUNCTIONING

A:

A: Verify that the power unit battery is charged and connections are tight.

A: Reprogram the remote key fobs.

Q: HOW DOES THE REMOTE CONTROL WORK?

Q: DOES THE LIFT HAVE TO GO ALL THE WAY UP?

A: YES - in order for your lift to function as intended the lift

must ALWAYS be stored in the full upright position when

the boat is unattended.

Q: IS MY BOAT SECURE?

A: Yes, once you verify that the lift is Over-Center , switch

off the power and lock the power unit box, there is less

chance of theft.

™

Q: DO I NEED A MOORING LINE?

A: Under most circumstances one mooring line is sufficient

to prevent the boat from drifting away if the lift is

inadvertently lowered or the water level rises.

Q: HOW MUCH SUN DOES THE SOLAR PANEL NEED?

A: The panel should receive constant sun for at least 8 hours a day.

Q: WHAT IF I GET A NEW BOAT?

A: Re-leveling the boat lift may be necessary. A new lift

will be required if the boat exceeds the weight capacity

of your current lift.

Q: THE PUMP RUNS, BUT THE LIFT DOESN’T MOVE

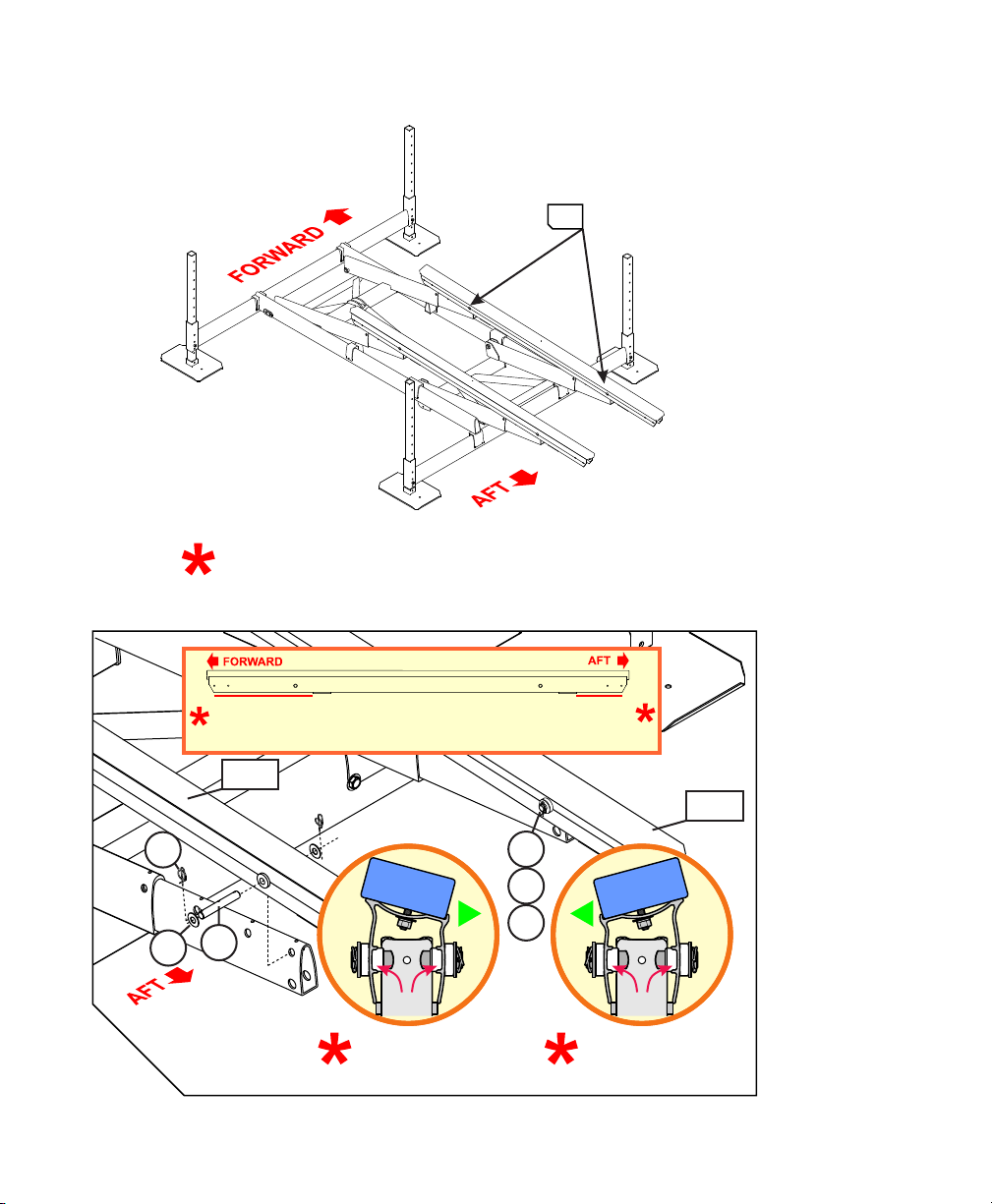

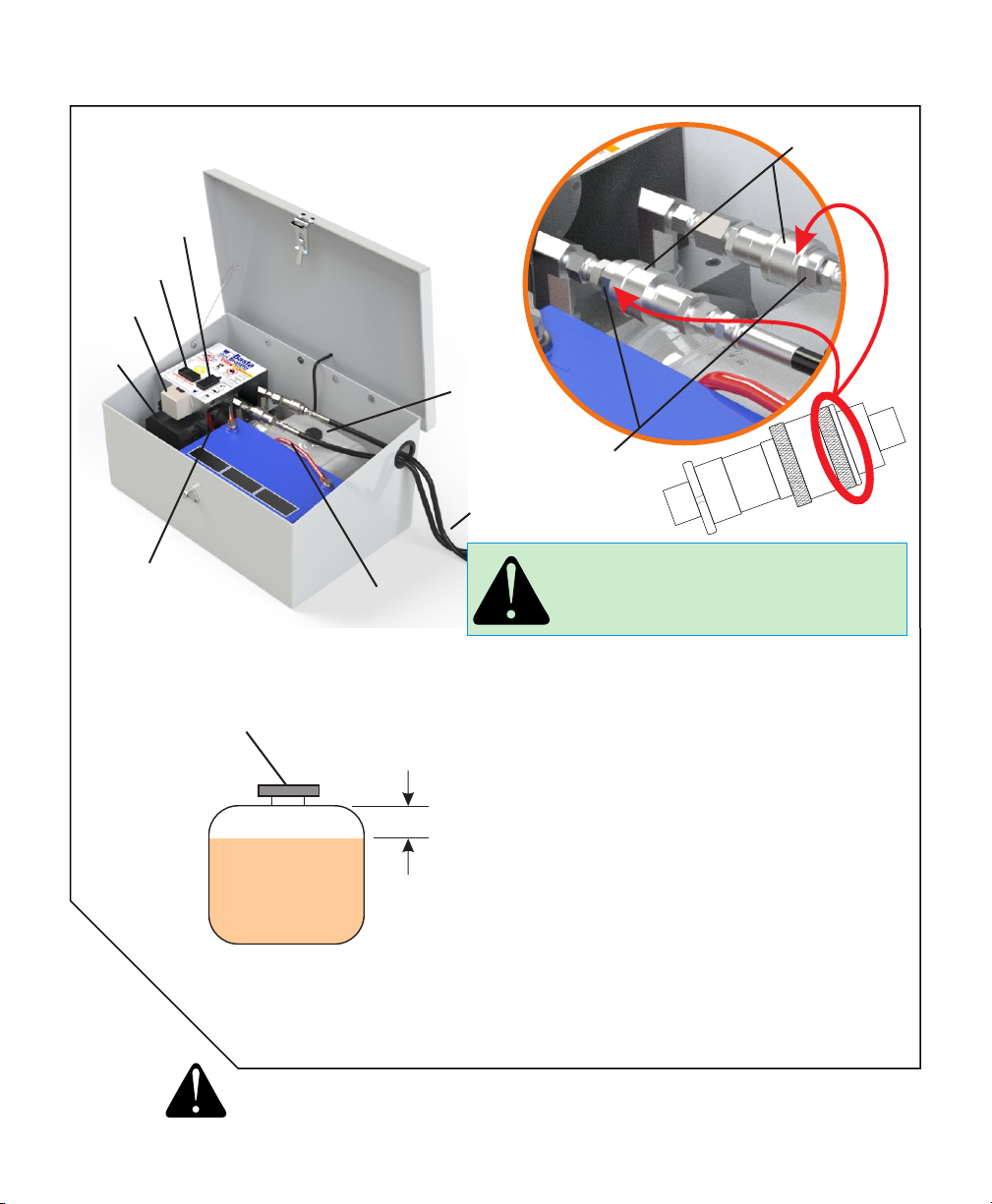

A: Check the 'quick couplers' in the Power Unit. If they are not

screwed together tight enough, built-in check valves will

not allow fluid to flow. See Page 13.

A: Check the fluid level. See Page 13.

Q: IS THE HYDRAULIC FLUID SAFE FOR THE FISH?

A:

We use a special low-toxicity hydraulic fluid that is safe

for the environment. This fluid is different than food-grade

oil. Only use Basta Boatlifts fluid in your hydraulic system.

Q: HOW DO I CHANGE THE HYDRAULIC FLUID?

A: Our fluid should not require replacement for a considerable

amount of time. If yours has been contaminated or the

hydraulic power unit has been replaced, visit our web site at

www.gobasta.com for detailed instructions.

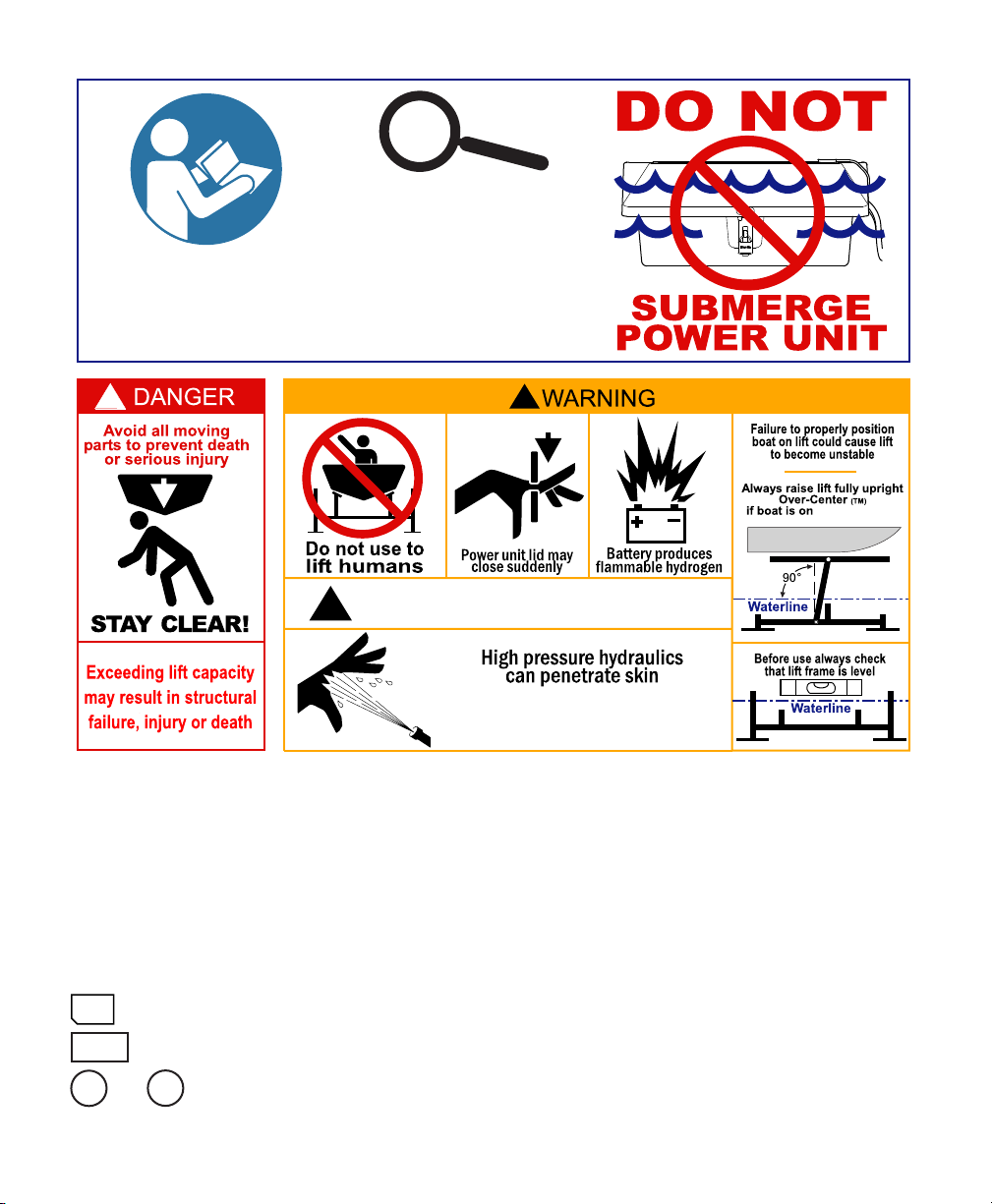

POWER-UP

At power-up the remote fob function has a ten second delay.

Failure to wait for this ten seconds can make the wait time much

longer.

LIFT OPERATION

The remote fob is non-functional until it is enabled by

depressing the lower right unlock button momentarily. After

the initial ten second delay, depressing the unlock button enables

operation using the remote fob. The lockout is re-enabled after

60 seconds without a button press.

Lift operation using the fob is limited to 120 seconds of

continuous operation. If a longer cycle is needed it is necessary

to release and then re-depress the button.

LOW BATTERY LOCKOUT

This control incorporates a low voltage lockout which is

intended to protect the battery from abuse and over-discharge.

When the battery drops below the low battery threshold during

pump operation, further activation using the Fob is not allowed.

The battery needs to be checked prior to further operation. The

manual switches will allow the lift to operate if sufficient battery

power is present.

FOB PROGRAMMING

At initial power up there is a five second window when it is

possible to reprogram the receiver to enroll a remote fob. Up to

four fobs may be enrolled. If a fifth fob is enrolled, the first

enrolled fob will fall off the list.

To enroll a fob, turn off the power to the lift for fifteen or more

seconds. When power is turned back on press both the UP and

DOWN buttons on the fob simultaneously. This must be done

within the first five seconds after power is applied.

LIGHTING CIRCUIT

The lighting circuit is activated whenever the lift is operated. The

lights stay on for 2 minutes after the lift is operated

The lights may be manually turned on or off by depressing the

lower left button on the remote Fob. When manually enabled the

lights will automatically turn off after 4 minutes. This is prevents

accidental battery discharge.

STORAGE

Always leave the boat in the fully raised, Over-Center™

position with the power off.

FOR ASSISTANCE OR SERVICE:

Contact your local dealer or call 1 - 866 - GO BASTA

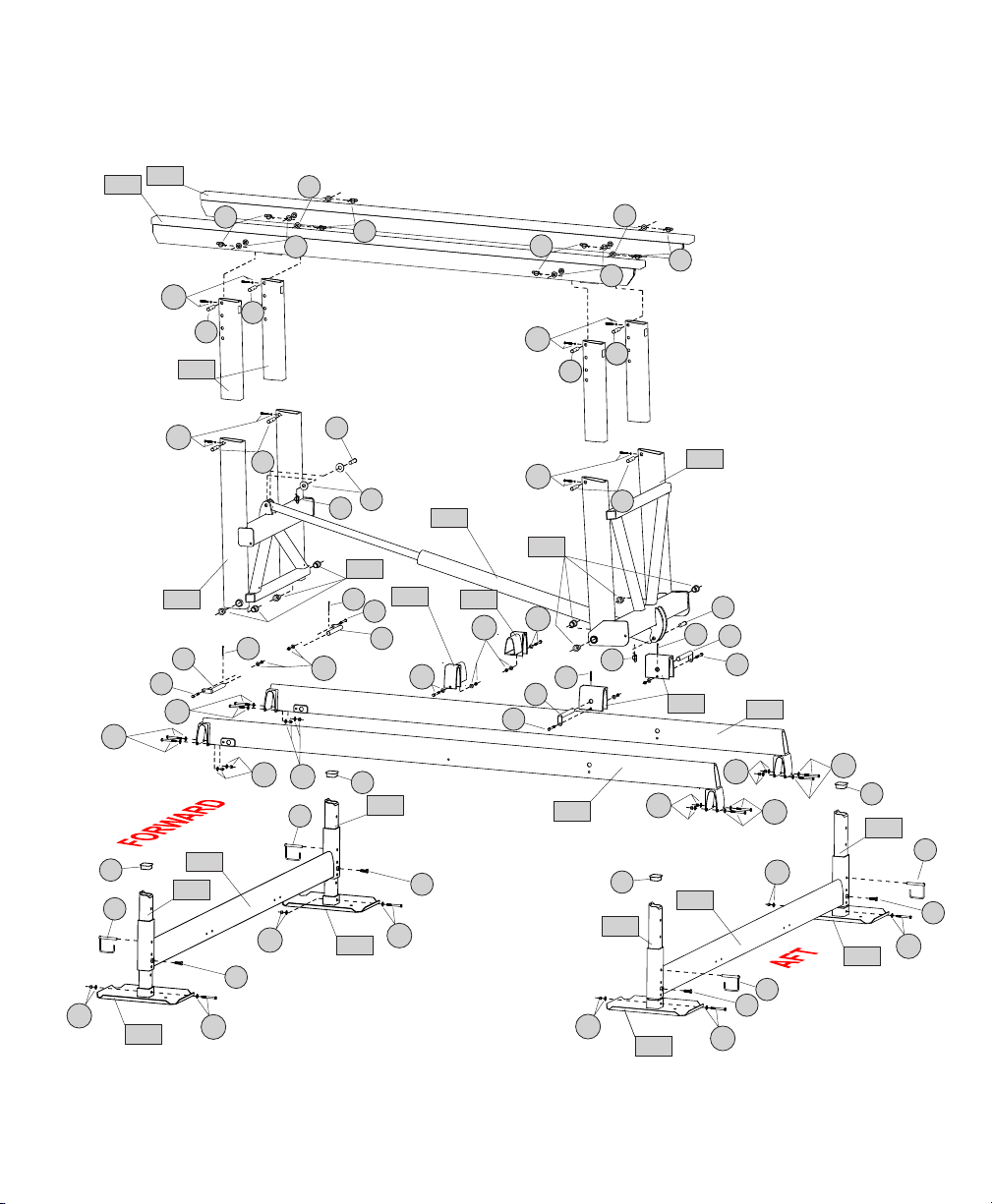

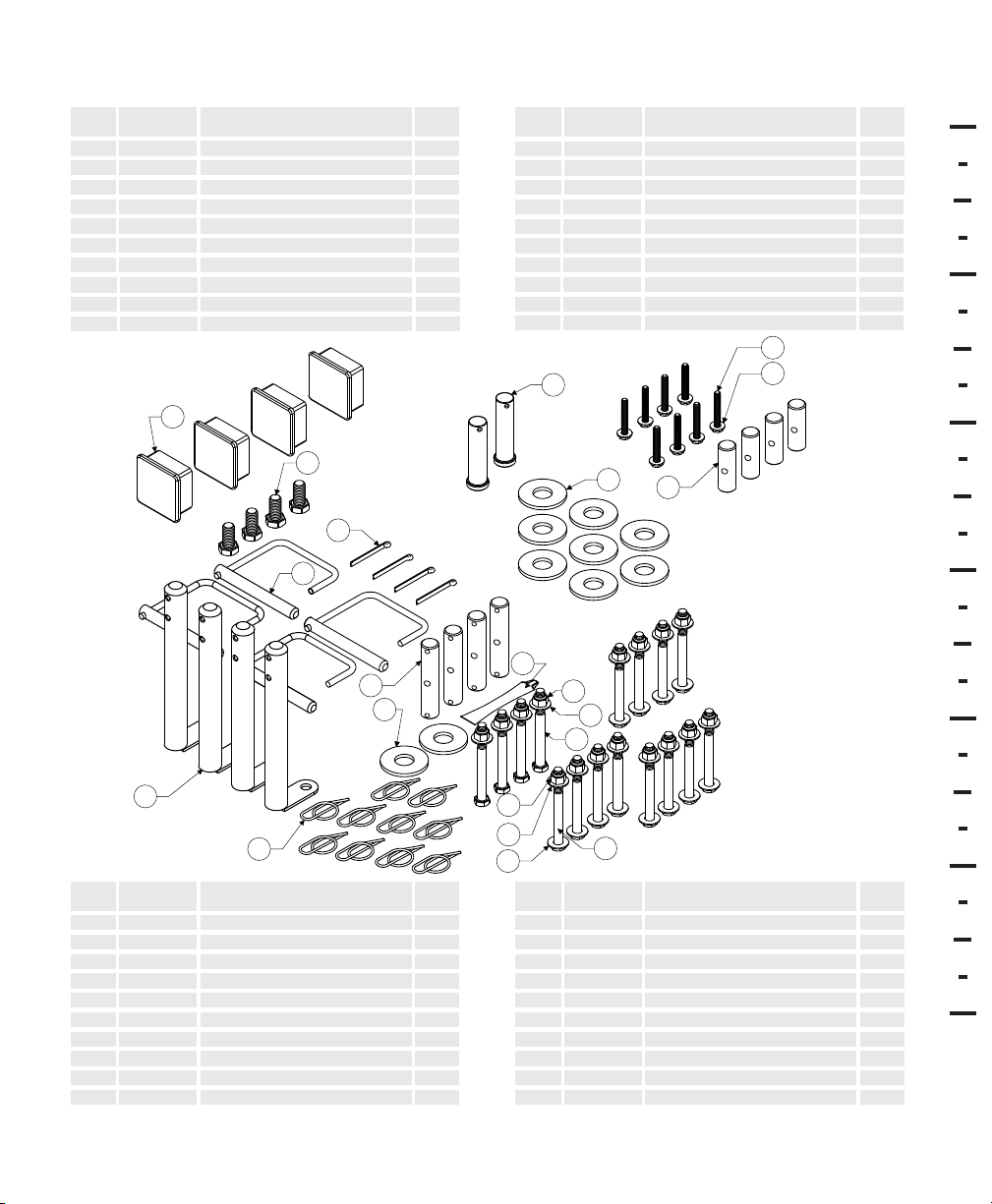

Your Basta Boatlift requires very little maintenance once installed.

Occasionally wipe the solar panel with a clean, damp cloth to preserve its charging performance.

Every 6 months, we recommend:

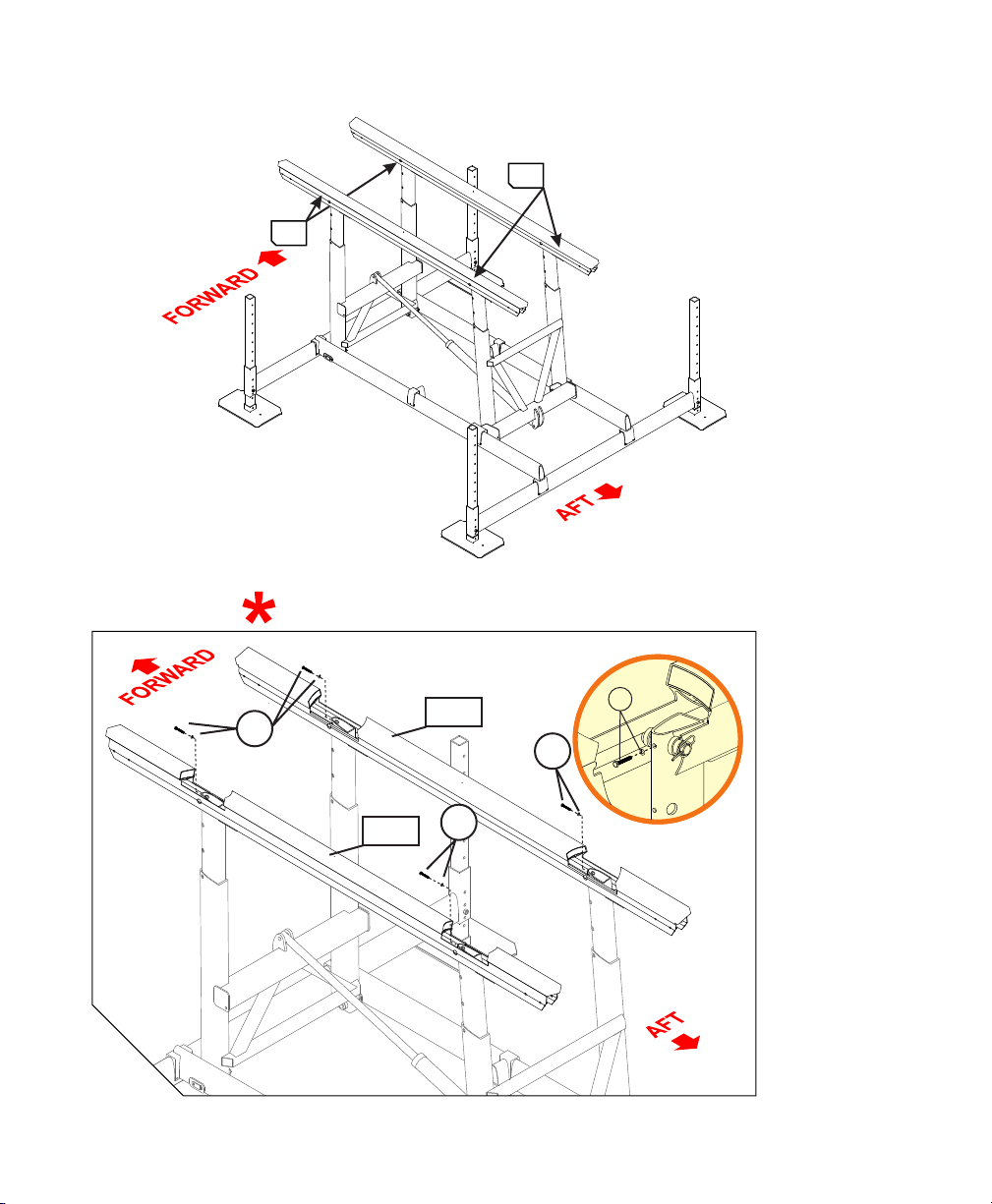

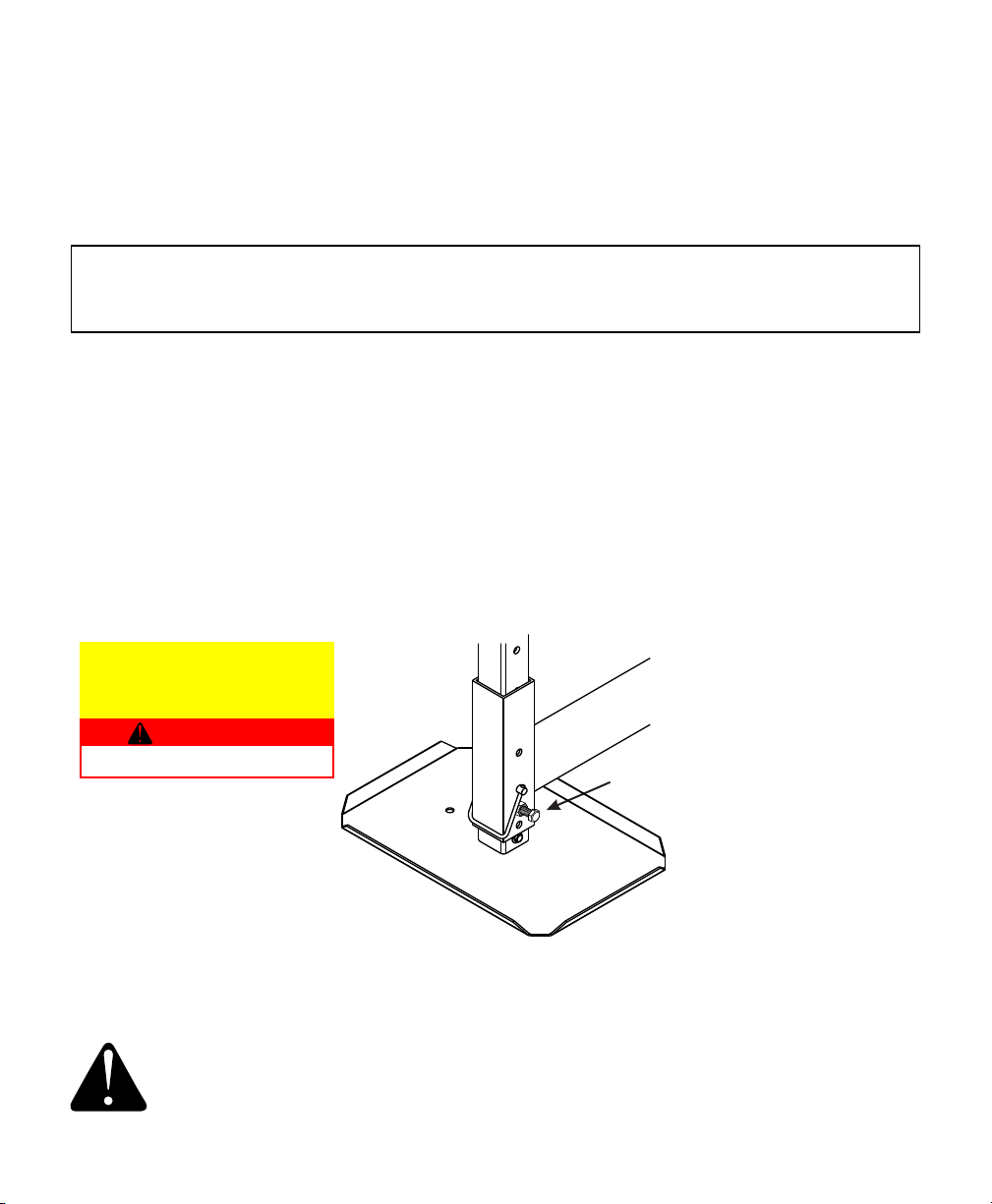

Inspect the lift frame for level and adjust the legs as necessary

Inspect the hoses, cylinders and fittings for leaks and wear - tighten as necessary.

Check the wire terminals for snugness and corrosion.

Check the hydraulic fluid and battery electrolyte levels (AGM batteries excluded):

The battery electrolyte in a flooded-cell battery should be slightly above the indicator ring in each cell.

Carefully add DISTILLED water if necessary. (Does not apply to AGM batteries.) Do not over-fill.

The hydraulic fluid level should be about one inch below the top of the reservoir with the lift DOWN.

DO NOT add fluid with the lift in the raised position!

Use only Basta Boatlifts biodegradable hydraulic fluid.

The battery in the key fob transmitter may be low. Replace it with a

new lithium CR2032. These are widely available at variety, hardware

and even grocery stores. Polarity is marked on the battery holder.