Basta Boatlifts 2x2k50 User manual

866-GoBasta gobasta.com

COPYRIGHT 2022

BASTA INC.

8/22

L392-0121A

BASTA BOATLIFTS

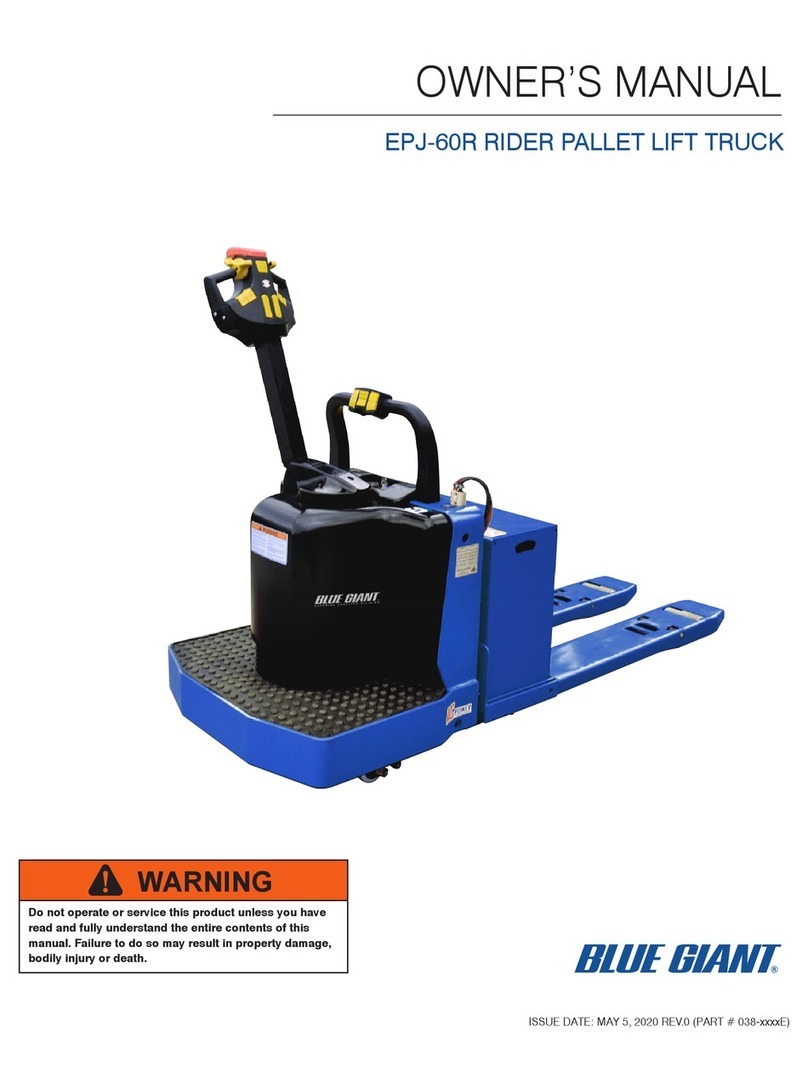

OVER-CENTER HYDRAULIC ALUMINUM LIFT

2,000 lb Capacity Per PWC Lift

Model 2x2k50 & 2x2k50W

PAGE 2

Basta Boatlifts are protected by one or more US Patents

www.gobasta.com/patents

DANGER

• Do not exceed the maximum weight capacity specified for the lift. Maximum weight

capacity can be found on the cover of this manual and on the H frame of the lift.

Improper use or failure to follow this instruction can cause property damage,

serious injury, or death.

• Never use for lifting humans or animals. Improper use or failure to follow this

instruction can cause property damage, serious injury, or death. The lift should only

be used for lifting boats & watercraft.

• Always avoid being under, and maintain adequate clearance from, the lift. Failure to

follow this instruction can cause serious injury or death.

• Always use AGM batteries and follow battery manufacturer’s warnings and instructions.

Improper use, or use of other batteries, have the potential to produce flammable hydrogen

gas which can result in serious injury or death.

• Visually inspect all parts and assemblies for damage or defects prior to assembling lift.

• Install the lift on firm and level ground.

• Verify the lower frame of the lift is level before each use.

• Do not play on or near the lift.

• Do not service the unit with the watercraft on the lift.

• High pressure hydraulics can penetrate skin. Oil injected into the skin from

high pressure systems can cause severe injury. In the case of injury, seek

medical attention immediately.

• Do not install the lift alone.

• The lift should only be used for lifting boats & watercraft.

• Passengers should stand clear of the lift when the lift is in operation.

CAUTION

WARNING

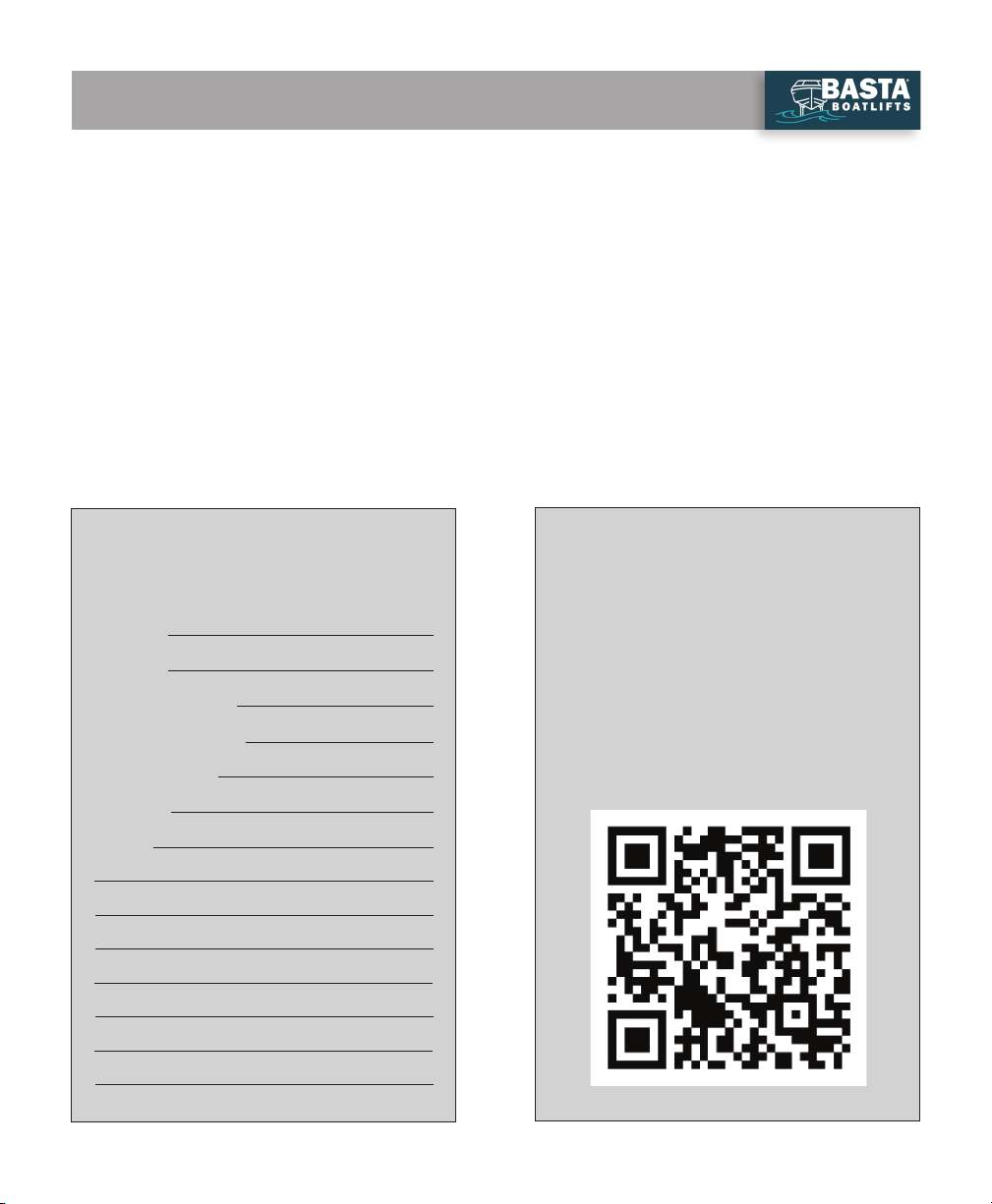

TABLE OF CONTENTS

PAGE 3

PRODUCT INFORMATION

Model #:

Serial #:

Purchased From:

Date of Purchase:

Contact Name:

Phone #:

Notes:

SAFETY ............................................................................................... P 2

PARTS LIST AND DIAGRAMS ................................................................. P 4-5

ASSEMBLY INSTRUCTIONS .................................................................... P 6-17

OPERATIONAL INSTRUCTIONS ............................................................... P 18

REMOTE CONTROL FOB INFORMATION ................................................... P 19

TROUBLESHOOTING / FAQ .................................................................... P 20

MAINTENANCE ..................................................................................... P 21

MAINTENANCE LOG .............................................................................. P 22

WARRANTY ......................................................................................... P 23

IMPORTANT!

WARRANTY MUST BE

REGISTERED WITHIN 30 DAYS

OF INSTALLATION.

TO REGISTER, SCAN HERE OR VISIT

WWW.BASTABOATLIFTS.COM/SUPPORT

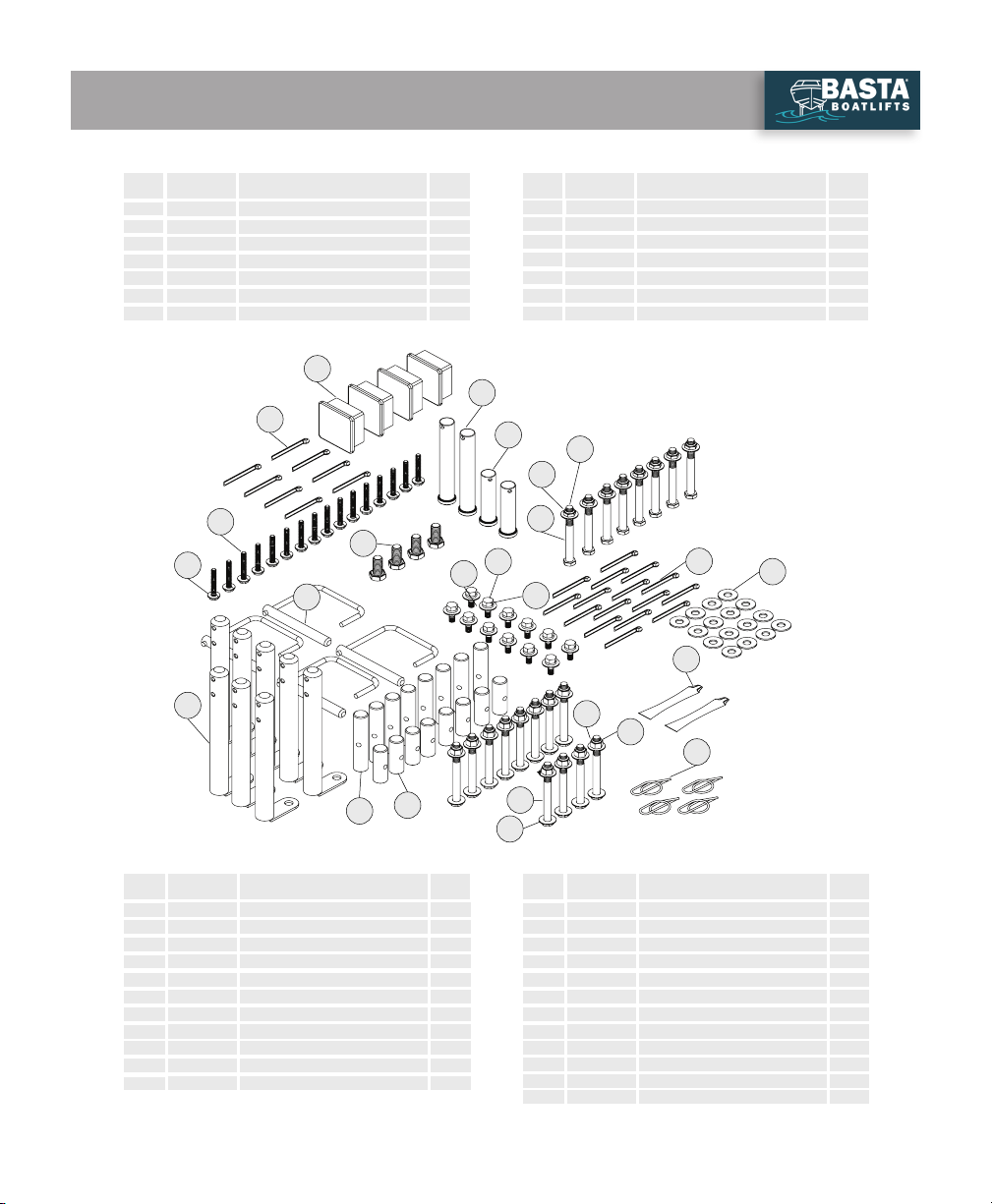

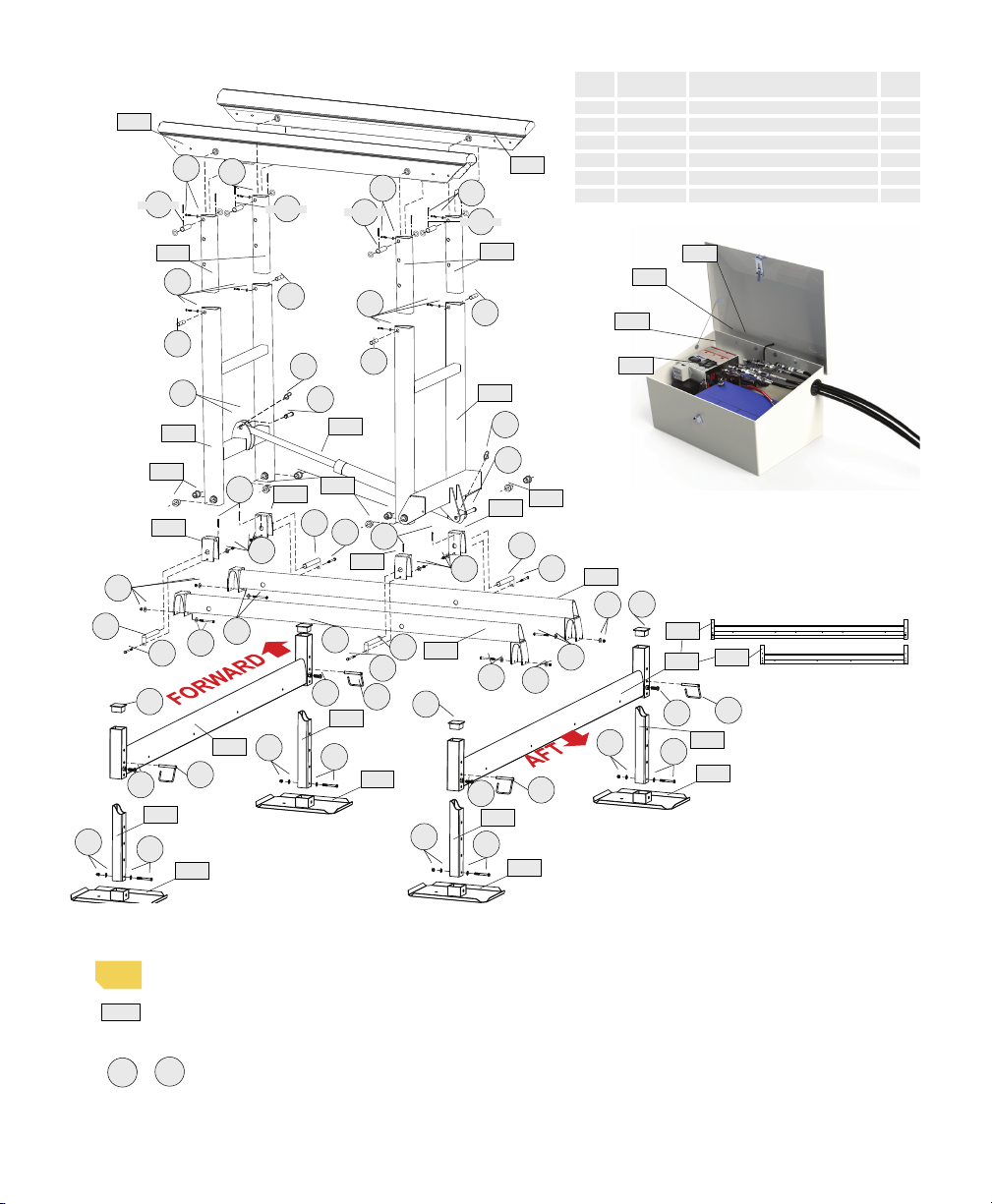

PART NO. DESCRIPTION QTY.ITEM ITEM PART NO. DESCRIPTION QTY.

ITEM ITEMPART NO. PART NO.DESCRIPTION DESCRIPTIONQTY. QT Y.

K200-0125 Leg

AA

BB

CC

DD1

DD2

EE

FF

GG

W117-0001

W105-0012

W111-0019

W111-0022

A431-0040

A431-0039

H310-0008

Foot Pad

Side Rail

118” Base Crossmember (2x2k50)

158” Base Crossmember (2x2k50W)

H-frame, Forward

H-Frame, Aft

Hydraulic Cylinder Assembly

H-Frame Arm, Inner

Bunk Rail Assembly, Left

Bunk Rail Assembly, Right

Base Pivot Bushing

Pivot Block

Bunk Board Assembly (part of JJ, KK)

HH

JJ

KK

LL

MM

NN

4

4

4

2

2

2

2

2

8

2

2

16

8

(4)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Nut, 3/8-16 Nylock SS

Bolt, Hex Head 3/8-16 x 3-1/2 SS

Bolt, Hex Head 5/16-18 x 1.0 SS

Washer, Flat 5/16 SS

Washer, Lock 5/16 SS

Clevis Pin 3/4 x 5.0 SS

Washer, Flat 3/8 SS

Base Pivot Pin SS

Bolt, Hex Head 3/8-16 x 3-3/4 SS

Ring Cotter Pin 3/4 x.091 SS

Anti-Seize Grease Packet

Cotter Pin 5/16

Cotter Pin 3/16 x 2.0 SS

P Pin SS

Bunk Pin SS

Nut, 3/8-16 Nylock Thin SS

Plastic Cap for 2” ID SQ Tube

Clevis Pin, 3/4 x 3.5 SS

Extension Pin SS

Bolt, Hex Head 1/2-13 x 1.0 SS

Bolt, Hex Head 1/4-20 x 1.75 full thread SS

Washer, Lock 1/4 SS

12

32

12

12

12

2

8

8

16

12

4

8

2

4

8

8

4

2

8

4

16

16

W102-0045

A427-0037

A427-0038

M621-1002

K200-0127

W410-0067

S362-0008

S313-0008

S313-0007

S322-0007

S342-0007

S503-0015

S103-0515

S503-0012

S520-1604

S103-0516

S522-0801

S520-1706

Y356-0003

S532-1801

S503-0020

S362-0108

F730-0021

S503-0013

S503-0011

S103-0705

S103-0338

S322-0006

17

12

21

22

14

20

6

18

8

15 19

11

2

10

2

1

13

35

4

9

7

2

16

23 S313-0013 Flat Washer, SAE 3/4 SS 16

23

PARTS LIST - BOAT LIFT

PAGE 4

1&2 2&10

BB

AA

17

20 14

DD 2&10

BB

1&2

1&2 2&10

BB

AA

AA

BB

1&2

14

20

17

DD

DD2

DD1

10&2

(2x2k50W)

(2x2k50)

2&1

2&1

20 14

CC

7

8

CC

7

16&2

12

16&2

MM

EE

LL

FF

6

GG

9

11

19

HH

HH

JJ

KK

A1

B1

C1

D1

20

10&2

2&10

2&10

2&10

7

7

8

8

8

12

19

19

19

17

17

11

14

18

1&2

21&22

21&22 21&22

21&22

21&22

21&22

MM

MM

MM LL

LL

AA

POWER PACKAGE DUAL

#H653-0015

R812-0016

PART NO.

R283-0002

R310-0001

R310-0002

Remote Control Master Unit

DESCRIPTION

Solar Controller

On/Off Switch

Up/Down Switch

1

QTY.

1

1

2

ITEM

A1

B1

C1

D1

E1

F1

R815-0011

C243-0003

Solar Panel Assembly

Enclosure

1

1

PAGE 5

Symbol Glossary for the following pages:

indicates an illustration for a procedure.

indicates a major part described in the parts list

on pages 4 and 5.

or indicate hardware items shown above and

described in the parts list on pages 4 and 5.

Tools needed for the job:

• Tape measure

• Level

• 9/16 ratchet

• 9/16 box-end wrench

• Large slip joint pliers

• Medium sized adjustable wrench

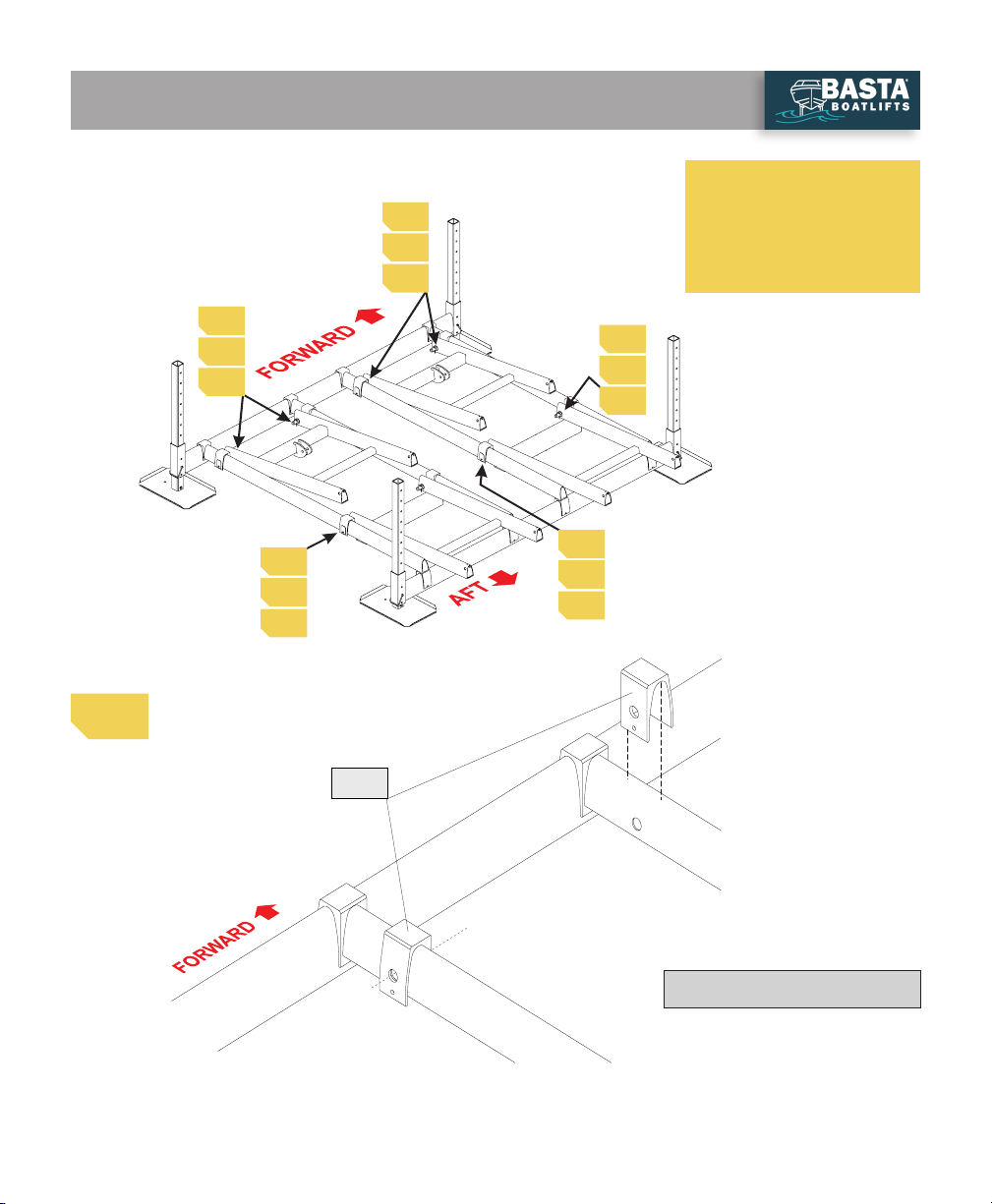

AA

a

1

c+d

9&15&23

9&23

9&15&23

9&23

NOTE: The 3 different holes

shown can be used for pin ‘14’

to allow fine height adjustment

during installation.

Pictured: Steps 1-3

QTY 4: 3/8 x 3.75” bolts (“10”)

QTY 4: 3/8 nylon insert lock nuts (“1”)

QTY 8: 3/8 flat washers (“2”)

QTY 4: leg P pins (“14”)

QTY 4: 1/2 x 1.0” bolts (“20”)

AA

DD

BB 20

2+1

14

10+2

Feet & Legs (4 Places)

Do not tighten bolt ‘20’

until step 17.

Do not tighten any

hardware until step 13.

Use a small amount of

‘moly’ lube on bolt

threads through the

assembly process.

ASSEMBLY INSTRUCTIONS

1

2

1

2

1

1

(2x2k50)

(2x2k50W)

3

3

1

PAGE 6

Forward Crossmember

3Aft Crossmember

QTY 4: 3/8 x 3.75” bolts (“10”)

QTY 8: 3/8 flat washers (“2”)

QTY 4: 3/8 nylon insert lock nuts (“1”)

QTY 4: 3/8 x 3.75” bolts (“10”)

QTY 8: 3/8 flat washers (“2”)

QTY 4: 3/8 nylon insert lock nuts (“1”)

DD

CC

10+2

1+2

1+2

DD

10+2

10+2

Assemble lift on level

ground and adjust legs

so that lift base frame

is level during lift

assembly.

2

3

PAGE 7

Pictured: Steps 4-6

QTY 8: pivot blocks (“MM”)

4

5

6

4

5

6

4

4

4

5

5

5

6

6

6

Pivot Blocks (8 places)

MM

Use a small amount of

‘moly’ lube on bolt

threads through the

assembly process.

ASSEMBLY INSTRUCTIONS

PAGE 8

4

H-frame Bushings (fwd & aft)

H-frames (4 places)

QTY 8: THIN 3/8 nylon insert lock nuts (“16”)

QTY 8: 3/8 flat washers (“2”)

QTY 8: 3/8 x 3.5 bolts (“7”)-Note shorter length!

QTY 8: cotter pins (“12”)

QTY 8: base pivot pins (“8”)

QTY 16: plastic bushings (“LL”)

Forward H-frame is

shown. Aft H-frame

installation is the same.

LL

LL

EE

78

12

16+2

5

6

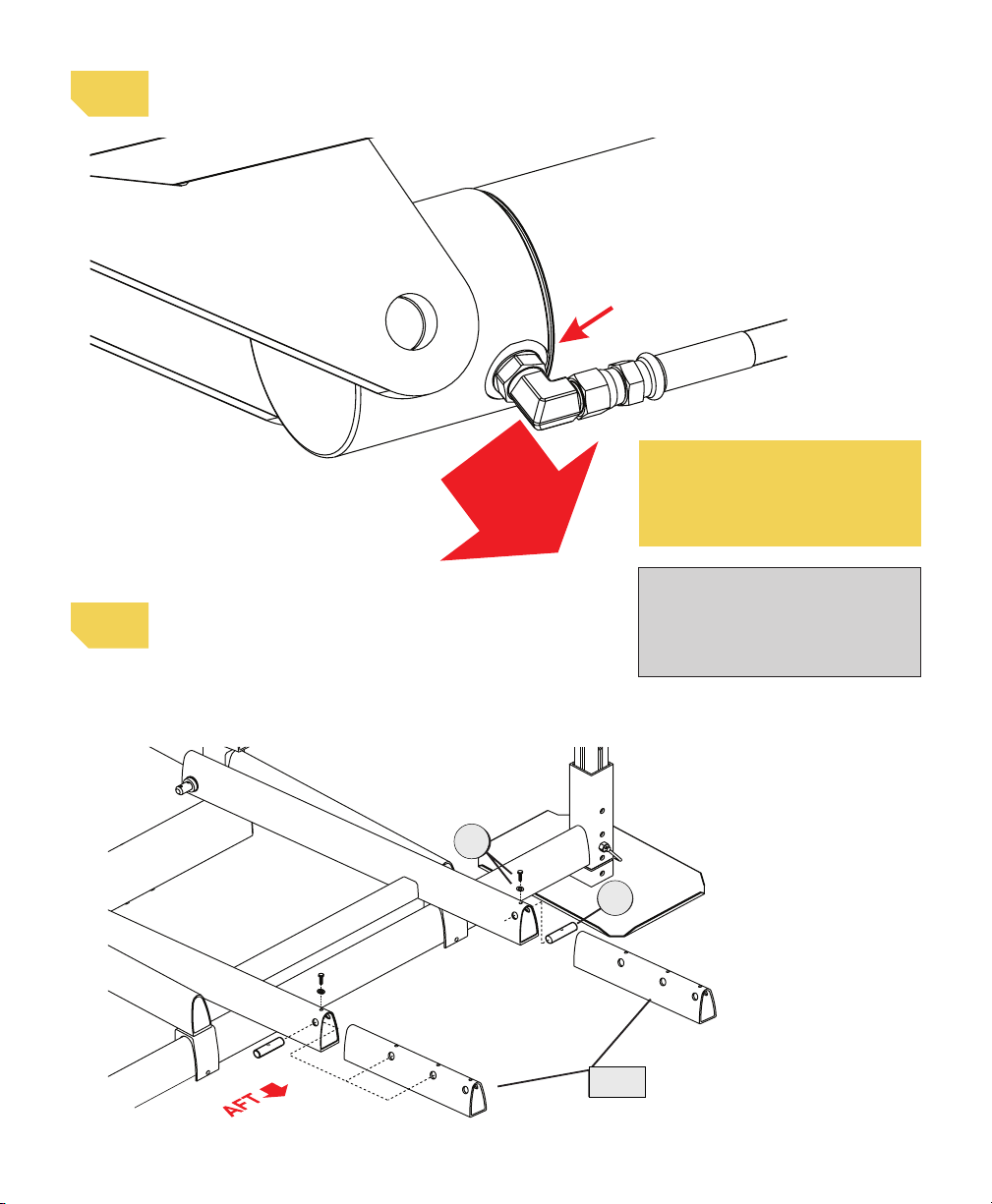

PAGE 9

Install cylinders with lift

in ‘down’ position.

Cylinders

QTY 2: 3/4 x 3.5” clevis pin (“18”)

QTY 2: 3/4 x 5” clevis pin (“6”)

QTY 4: ring type cotter pins (“11”)

18

Pictured: Steps 7-9

7

7

8

8

9

9

11+6

11+18

Use a small amount of

‘moly’ lube on bolt

threads through the

assembly process.

ASSEMBLY INSTRUCTIONS

PAGE 10

7

SRUW

SRLQWV

GRZQ

Inner Arms (8 places if used)

SRUW

SRLQWV

GRZQ

QTY 4: extension pins (“19”)

QTY 4: 1/4 x 1.75” bolt (“21”)

QTY 4: 1/4 lock washer (“22”)

IMPORTANT

Install cylinder with hose

fittings facing down!

HH

19

Cylinders

21+22

8

9

PAGE 11

LONG AT

FORWARD

END

SHORT

AT AFT

END

PLATES

Right Rail [KK] Left Rail [JJ]

bushing are

pre-installed

FROM FRONT

LOOKING AFT

FROM FRONT

LOOKING AFT

cotter pin

washer

cotter pin

washer

Pictured: Steps 10-12

Complete Step 11 to

raise lift to install

screws for pins. See

Step 12 for details.

10

Bunk Rail Assembly

12

10

12

10

12

15

QTY 8: bunk pivot pins (“15”)

QTY 16: cotter pin (“9”)

QTY 16: 3/4 flat washers (“23”)

KK

10

12

ASSEMBLY INSTRUCTIONS

10

PAGE 12

23

9 23

9

JJ

Step 1: Slide the Hydraulic Hose Assembly through the

access hole in the side of the fiberglass enclosure and

attach the ends to their corresponding Quick Couplers.

Ensure each Quick Coupler is fully seated, tight and

with no gap at the connection joint. Complete for each

set of hoses.

Step 2: Remove shipping plug in hydraulic reservoir and

replace with breather plug before first use.

Step 3: Install Battery as shown. Connect the Red Battery

Cable to the positive terminal (+) and the Black

Battery Cable to the negative terminal (-).

Step 4: Before moving into the water, test the lift on dry

ground using the Up/Down Switch and the Key Fob

Transmitters. Inspect the system for leaks.

NEGATIVE BATTERY CABLE

(BLACK)

BREATHER CAP

POSITIVE BATTERY CABLE

(RED)

HOSE ASSEMBLY

FEMALE

QUICK COUPLER

MALE

QUICK COUPLER

Complete Power Unit Package

NO GAP!

IMPORTANT

ONLY ADD FLUID WITH LIFT IN

DOWN POSITION

Hydraulic fluid shown with lift in the

DOWN position

one

inch

1”

The control unit contains two

separate lift control com-

puters. Up to 4 fobs may be

enrolled for each lift.

1

1

2

2

LIFT 1

SWITCH

LIFT 2

SWITCH

CONNECT POWER UNIT

11

PAGE 13

Raise lift to install 1/4

x 1.75” bolts (“21”).

Bunk Rail Assembly

raise lifttoinstall 1/4x1.75” bolts( )"15"

QTY 4: 1/4 x 1.75” bolts (“21”)

QTY 4: 1/4 lock washers (“22”)

12

12

12

12

21+22

21+22

21+22

21+22

Pictured: Step 12

JJ

KK

Use a small amount of

‘moly’ lube on bolt

threads through the

assembly process.

Placement may need

to be modified based

on watercraft draft and

weather conditions.

ASSEMBLY INSTRUCTIONS

12

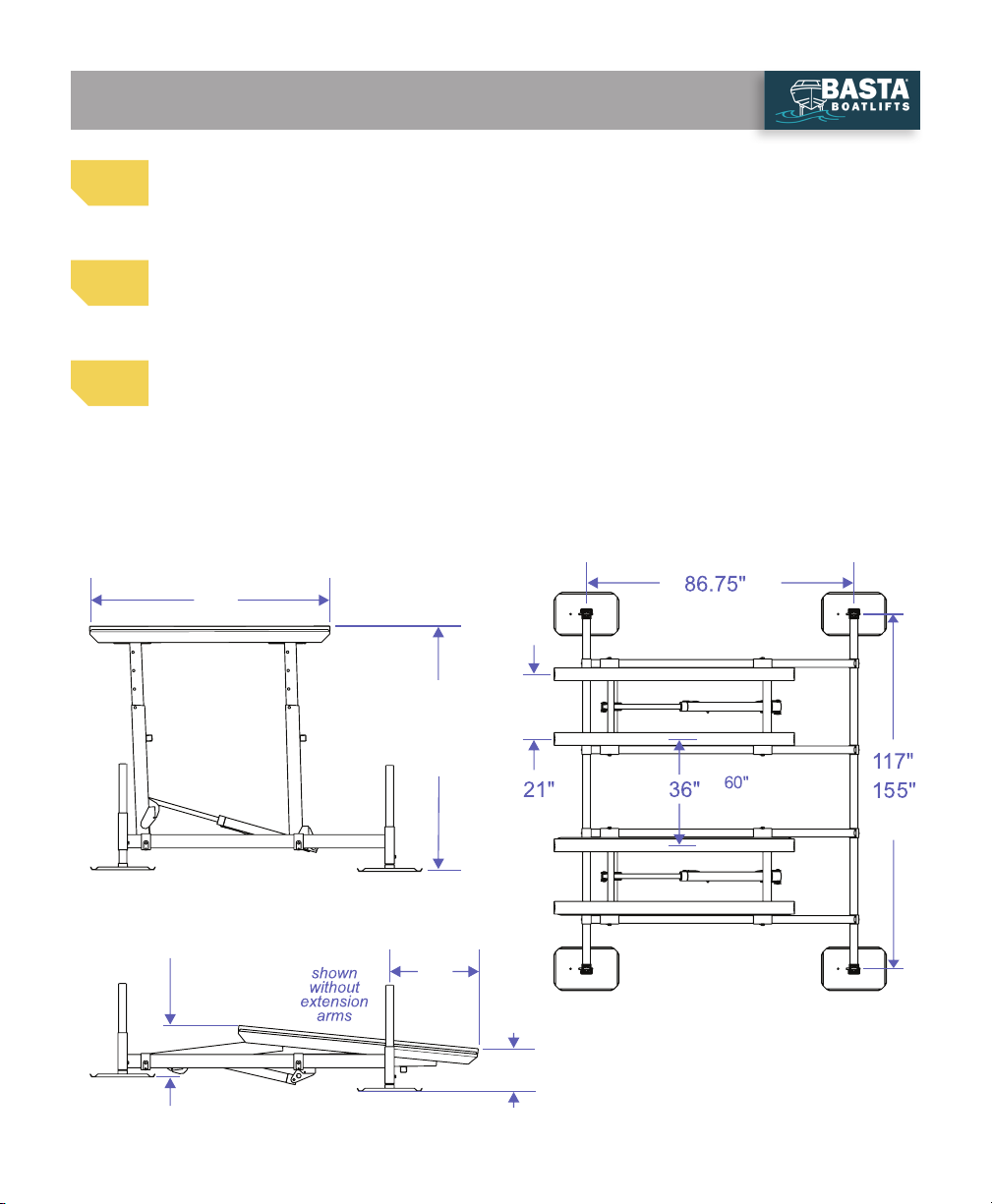

PAGE 14

for

2x2kW

[ ]

for

2x2kW

[ ]

without extensions: 59”

with extensions: 65” - 82”

80”

24”

19”

29”

for

2x2kW

[ ]

23”

for

2x2kW

[ ]

30”

without extensions: 62”

with extensions: 68” - 85”

[ ]

for

2x2kW

USE DIAGRAM TO HELP PLACE THE LIFT

Test lift on dry ground for leaks, remote control function and correct operation before moving into

water. Tighten all hardware.

Lower the lift completely, then raise it slightly. Disconnect the Hydraulic Hose Quick Couplers in the

Power Unit box to separate it from the lift.

Move the lift to nal destination. Use this diagram to help place the lift. Lift placement should be so

that the top of the aft end of the bunks are one foot above the high-water mark when the lift is in the

full up position, and one foot below the low water mark, when the lift is in the down position.

13

14

15

PLACEMENT INSTRUCTIONS

PAGE 15

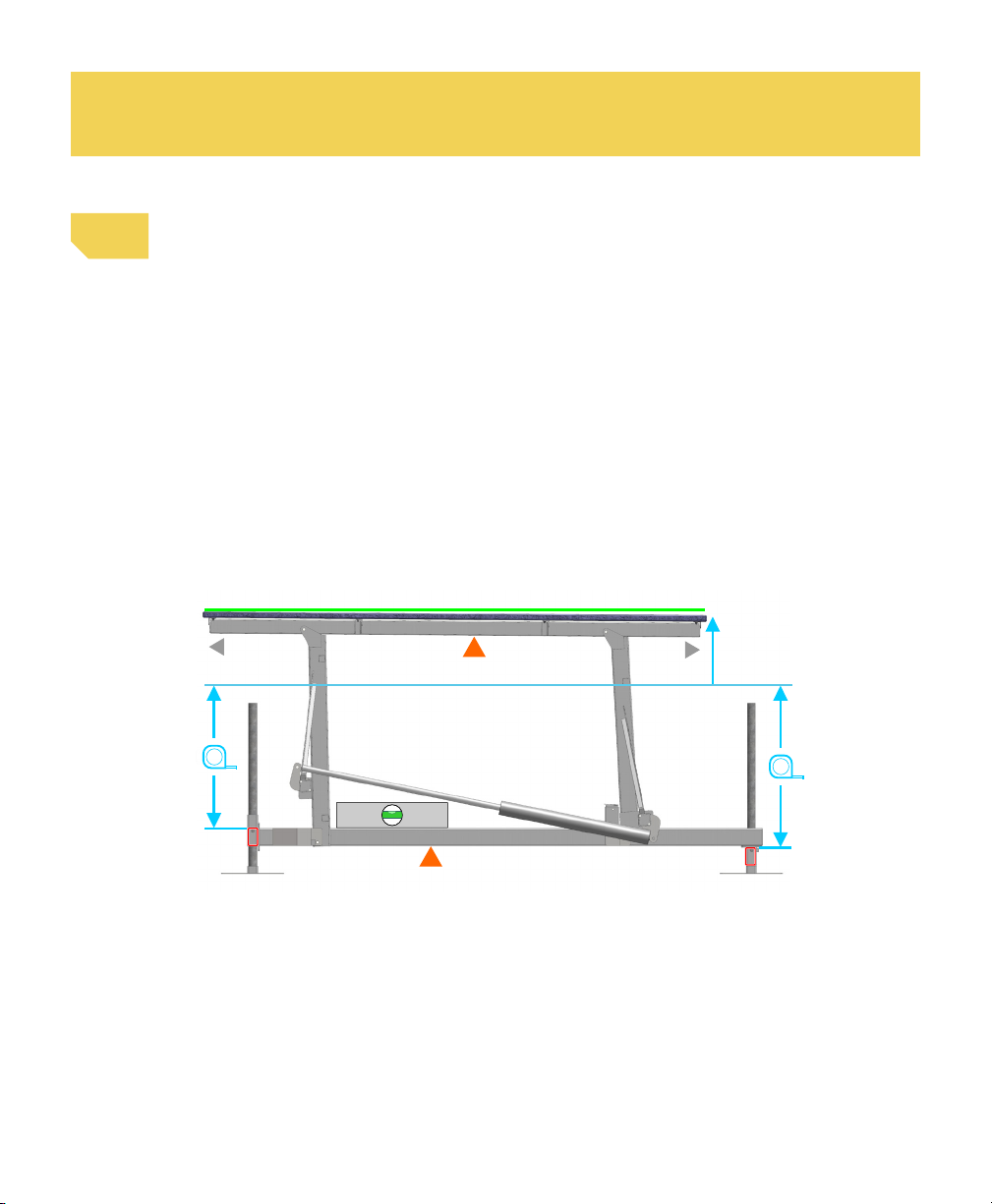

IMPORTANT: The leveling process must be completed to ensure stability of the lift frame

and Over-Center safety lock.

Level the lift following these instructions while referencing image below:

Step 1: Use a tape measure (reference image on right) to determine that the lower

frame is level.

Step 2: If the lower frame needs to be raised start with the lowest corner first then

work your way around the lift in a circle, corner to corner. Adjust the lift legs as needed.

Step 3: To make adjustments, first make sure the lift is properly supported.

Then, loosen the anti-sway bolts, remove the P-pin and raise or lower

the lift crossmember on the leg. Level the lift one corner at a time,

while making sure not to have more than 5” of difference in height

between the corners to prevent binding.

LEVEL

NOT LEVEL

MUST BE LEVEL

FORWARD AFT

FWD

CROSS-

MEMBER AFT

CROSS-

MEMBER

+

4.5”

12”

Surface of Water

Leveling requires a second person to support the crossmember while making adjustments.

If the lift is too heavy for two people, a ratchet strap or winch system will be required to

raise/lower the frame corners.

Contact Basta at 866-GO-BASTA for additional help.

16

PAGE 16

Re-connect the Hydraulic Hose Quick Couplers inside the Power Unit box.

Fully raise lift and finish adjusting the legs so that the base frame is level side-to-side

and forward-to-aft. After the lift is assembled and installed, all fasteners should be

checked for proper tightness and reinspected periodically.

Load the watercraft onto the lift using the following operational

instructions:

1. Align the watercraft so it is centered between the bunks

side-to side.

2. Move the craft forward to position its center of gravity near

the bunks’ centers.

Perform the following adjustments to finalize the lift installation:

1. Disembark and raise the watercraft. If more than two inches of settling occurs,

STOP, carefully lower the lift to remove the watercraft and re-level the lift.

Continue repeating this step until the lift can be raised into the full Over-

Center™ position without settling.

2. Remove the watercraft. Verify that the lift frame is level. Re-level the framework

if necessary.

3. Check all bolts for proper tightness.

Shown: a properly

centered watercraft.

Typically, where your

knee rests will align

with the center of the

bunk.

The lift legs can be cut off above

the leg sockets after installation

for a cleaner look. First, make

sure that the lift has fully settled

and has been re-leveled.

If you plan to add a canopy, relocate the

lift into deeper water, or load a heavier

watercraft in the future, you must keep

the existing leg length.

17

18

19

OPTIONAL

PAGE 17

PAGE 18

IMPORTANT:

• If you purchase a new vessel, make sure does not exceed the weight capacity limits of the lift.

Maximum weight capacity can be found on the cover of this manual and on the H frame of the lift.

• Always turn power unit OFF when not in use.

• Keep inside of power unit box dry.

• To prevent unauthorized use lock box using padlock through the latch hasp.

• Securing your mooring line to the dock may provide additional security should the lift be lowered

inadvertently.

• Leaving your bilge pump on the automatic setting may prevent the accumulation of rainwater in

your vessel and overloading of the lift.

• Service your lift according to recommended Maintenance (page 19).

• Only use Basta Boatlifts approved fluid in lift. Contact Basta Boatlifts or authorized dealer for

approved biodegradable hydraulic fluid.

• When not in use, store the lift in the upright position to prevent it from being an unknown hazard

underwater.

• Store with the power off.

Step 1: Power on. Using the manual switch on the control panel, switch the On/Off switch to the

“On” position.

Step 2: Lower the Lift. Using the Key Fob, unlock the Fob by pressing and releasing the lock button.

Next, press the down button to lower the lift.

Step 3: Carefully guide the watercraft off the lift. Repeat in reverse order upon return.

For more questions or troubleshooting, consult your Authorized Dealer, the FAQs page on

Bastaboatlifts.com or give us a call at 425-641-8911.

OPERATIONAL INSTRUCTIONS

PAGE 19

FOB POWER-UP

After turning on the ON/OFF switch in the dock box, the fob

receiver requires a 5 second delay before the fob is enabled.

FOB OPERATION

Depress the unlock button (lower right), this will allow normal

operation of the fob. The lockout is re-enabled after 60

seconds without a button press. Lift operation using the fob

is limited to 120 seconds of continuous operation. If a longer

cycle is needed it is necessary to release button and then

re-depress.

FOB PROGRAMMING

1. Turn off the ON/OFF switch.

2. Wait 20 seconds.

3. Turn power back on, and within 5 seconds of

power on, press both the UP and DOWN buttons

on the fob simultaneously for 1 second then

release.

4. Repeat steps 1-3 for additional Fobs. Up

to four fobs may be enrolled. If a fifth fob

is enrolled, the first enrolled fob will fall off the list.

BATTERY REPLACEMENT

Fob uses CR2032, 3 volt battery, commonly found online or at

drug / hardware stores. Part numbers vary by manufacturer.

LOW BATTERY LOCKOUT

The remote control contains a low voltage lockout which

is intended to protect the lift’s battery from over-discharge.

When the battery drops below the low battery threshold

during operation, further use of the fob is not allowed. The

manual UP/DOWN switches will allow the lift to operate

when sufficient battery power is present. The lift should

be checked and charged prior to further operation.

TROUBLESHOOTING

If fob worked previously, but

does not currently, replace fob

battery or verify fob battery

has greater than 3v. If fob does

not work after replacement

of fob battery, load test lift

battery ensuring voltage does not drop below 11v while

in use. If you have questions, contact your local dealer or

Basta Boatlifts.

UNDERWATER LIGHTS

The underwater lights are activated whenever the

lift is operated. The lights stay on for 2 minutes

after the lift is operated. The lights may be

manually turned on or off by depressing the lower

left button on the remote fob. When manually enabled the

lights will automatically turn off after

4 minutes. This prevents accidental battery discharge.

REMOTE CONTROL FOB INFORMATION

For more answers to frequently asked questions, visit:

bastaboatlifts.com/support/

frequently-asked-questions/

Q: THE BATTERY WILL NOT HOLD A CHARGE

A: Verify that the loaded watercraft is not exceeding the

weight capacity of the lift. If the battery is a

flooded-cell type, check the electrolyte level.

A: Ensure the solar panel is properly connected.

A: Re-align the solar panel for proper exposure to

the sun.

A: Recharge the battery with a 10 amp charger and

check the charge again.

A: Have the battery tested. It may be old and require

replacement.

A: If the lift is being used frequently during the day, it

may be necessary to use a 110-volt maintainer/charger.

Q: THE REMOTE CONTROL IS NOT

FUNCTIONING

A: The battery in the key fob transmitter may be

low. Replace it with a new lithium CR2032. These

are widely available at variety, hardware and even

grocery stores. Polarity is marked on the battery

holder.

A: Verify that the power unit battery is charged

and connections are tight.

A: Reprogram the remote key fobs.

Q: THE PUMP DOESN’T RUN

A: Check the battery charge and recharge if

necessary.

A: Check the battery connections, clean and

re-secure if necessary.

Q: THE PUMP RUNS, BUT THE LIFT

DOESN’T MOVE

A: Check the ‘Quick Couplers’ in the Power Unit.

If they are not screwed together tight enough,

built-in check valves will not allow fluid to flow.

See Page 12.

A: Check the fluid level. See Page 19.

Q: DOES THE LIFT HAVE TO GO ALL THE

WAY UP?

A: YES - in order for your lift to function as

intended the lift must ALWAYS be stored in the full

upright position when the watercraft is unattended.

Q: IS MY VESSEL SECURE?

A: Yes, once you verify that the lift is Over-Center™,

switch off the power and lock the power

unit box, there is less chance of theft.

Q: DO I NEED A MOORING LINE?

A: Under most circumstances one mooring line is

sufficient to prevent the watercraft from drifting away

if the lift is inadvertently lowered or the water level

rises.

Q: HOW MUCH SUN DOES THE SOLAR

PANEL NEED?

A: The panel should receive constant sun for at

least 8 hours a day.

Q: HOW DO I CHANGE THE HYDRAULIC

FLUID?

A: Our fluid should not require replacement for

a considerable amount of time. If yours has been

contaminated or the hydraulic power unit has

been replaced, visit our web site at

www.gobasta.com for detailed instructions.

Q: HOW DO I KNOW WHEN IT IS TIME TO

CHANGE THE FLUID?

A: Basta Boatlifts’ hydraulic fluid lasts between 3-6 years

depending on usage. If you begin to hear an increased pitch

in the sound of your pump motor, it is likely time to flush your

hydraulic fluid. You can also tell by the clarity of the fluid.

Fluid that is ready to be changed will be dark in color or cloudy.

New fluid is clear.

Q: WHAT IF I GET A NEW VESSEL?

A: Re-leveling the lift may be necessary.

A new lift will be required if the watercraft exceeds the

weight capacity of your current lift.

PAGE 20

TROUBLESHOOTING AND FAQ

This manual suits for next models

1

Table of contents

Other Basta Boatlifts Lifting System manuals

Basta Boatlifts

Basta Boatlifts Over-Center 12k64 User manual

Basta Boatlifts

Basta Boatlifts 1.4k60 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 18k59 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 7k51 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 36k60 User manual

Basta Boatlifts

Basta Boatlifts 8k53 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 4.5k37 User manual

Basta Boatlifts

Basta Boatlifts Over-Center BM4050SP User manual

Basta Boatlifts

Basta Boatlifts Over-Center 10k53 User manual

Basta Boatlifts

Basta Boatlifts Over-Center 4.5k37 User manual